-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 20. 2025, 17:47:11

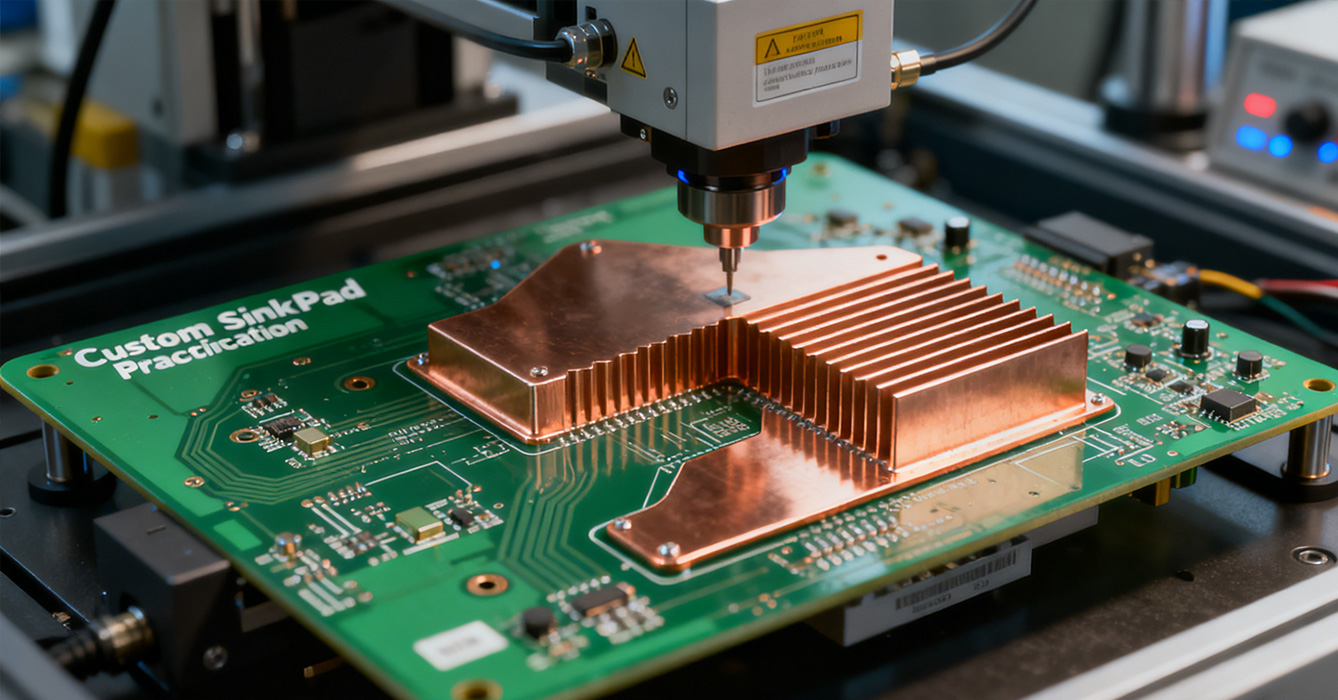

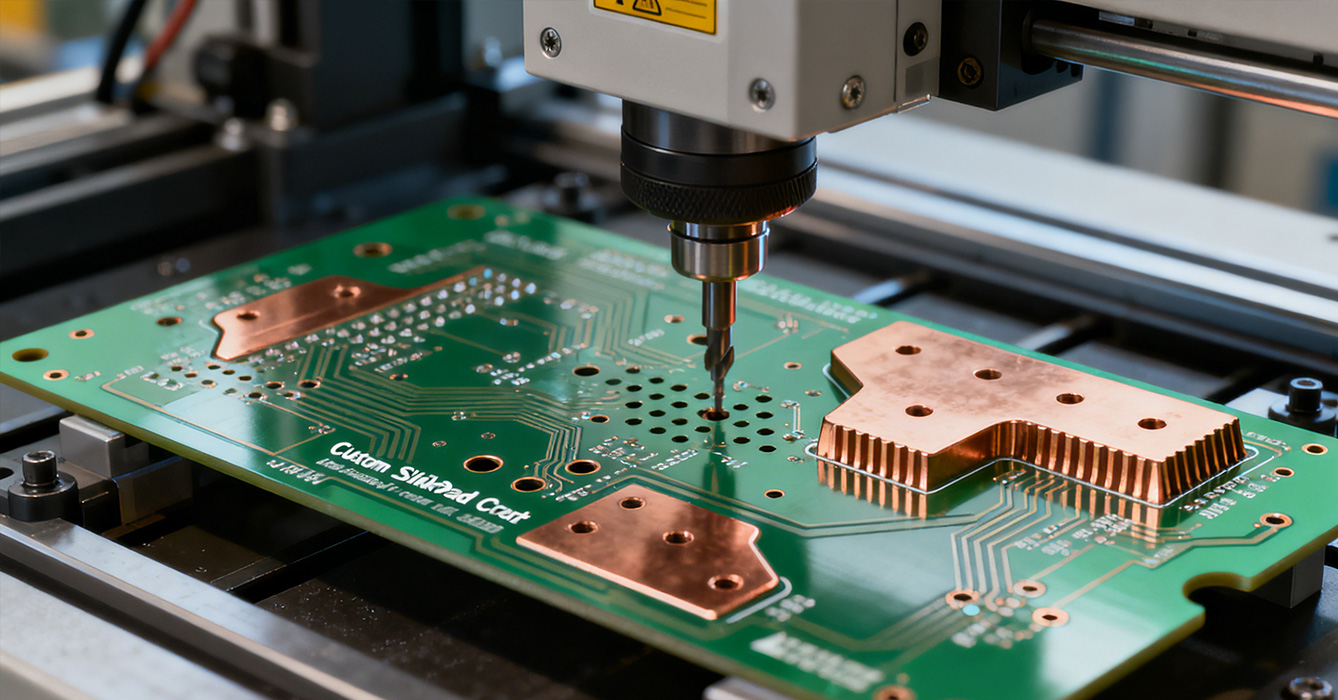

Custom Sinkpad PCB Fabrication has become a cornerstone for industries demanding tailored thermal and electrical performance, as off-the-shelf solutions often fail to address unique form factors, power densities, or environmental constraints. When paired with ISO 9001 certification, custom fabrication ensures that personalized designs—from compact wearable electronics to rugged industrial power modules—maintain uncompromised quality, reliability, and compliance. ISO 9001’s process-centric framework provides the structure to navigate the complexities of custom manufacturing, balancing flexibility with strict quality control. This article explores how ISO 9001-certified manufacturers deliver custom Sinkpad PCB solutions, covering key fabrication stages, quality integration, industry-specific adaptations, and customer collaboration workflows.

Custom fabrication requires a structured approach to translate customer needs into functional, high-quality PCBs, with ISO 9001 guiding every step to mitigate risks and ensure consistency.

The foundation of successful custom fabrication lies in deep needs understanding and ISO 9001-mandated risk assessment. Manufacturers collaborate closely with customers to map critical parameters: thermal load thresholds, mechanical form factors (e.g., conformal, compact), environmental operating conditions (temperature, vibration), and signal integrity requirements. ISO 9001’s risk-based thinking drives cross-functional reviews (engineering, quality, production) to identify potential challenges—such as thermal expansion mismatches in custom layer stacks or material compatibility for extreme environments. For example, a custom Sinkpad PCB for a wearable medical device requires miniaturized dimensions paired with high thermal conductivity; the team would assess risks of copper core thinning and validate via simulation to ensure performance without compromising structural integrity.

Custom Sinkpad PCB design leverages ISO 9001’s focus on evidence-based decision-making, integrating customer specifications with thermal-electrical synergy. Engineers optimize layer stacks for unique form factors—such as flexible Sinkpad PCBs for curved automotive components or high-layer-count designs for dense 5G modules. Material customization is central here: selecting copper-aluminum hybrids for weight-sensitive aerospace applications, diamond-copper composites for ultra-high thermal density, or low-loss dielectrics for RF-focused custom designs. ISO 9001 requires documented design controls, including version tracking and customer approval milestones, to ensure alignment throughout the iteration process. This stage also includes prototype validation, where small-batch samples undergo thermal cycling, mechanical stress testing, and signal integrity analysis to confirm compliance with custom requirements.

Custom Sinkpad PCB fabrication demands flexible manufacturing workflows, all governed by ISO 9001’s process control standards. For low-volume custom orders (e.g., industrial prototypes), manufacturers adapt thick copper lamination, thermal via drilling, and sinkpad profiling processes without sacrificing precision. ISO 9001 mandates real-time monitoring of key parameters—such as lamination temperature for custom composite cores or drilling speed for unique via layouts—using MES systems to maintain consistency. For example, a custom Sinkpad PCB for a solar inverter may require non-standard sinkpad spacing to fit existing enclosure constraints; the fabrication team adjusts tooling paths and inspects each unit via AOI and X-ray to ensure dimensional accuracy. Even with process adaptations, ISO 9001’s CPK process capability requirements (≥1.33) are maintained to avoid defects in tailored designs.

ISO 9001’s quality assurance framework is customized to match the unique requirements of each Sinkpad PCB project. Testing protocols are tailored to address customer-specific risks: thermal resistance testing for high-power custom designs, vibration analysis for ruggedized industrial applications, or EMI shielding validation for RF-focused solutions. Non-destructive inspection techniques—such as ultrasonic testing for custom adhesive bonds or laser profilometry for sinkpad flatness—ensure internal and external quality without damaging the product. ISO 9001-required traceability is maintained via unique batch codes, linking each custom PCB to raw materials, process data, and test results, enabling full accountability for personalized solutions.

Custom Sinkpad PCB fabrication inherently carries more variability than standard production, making ISO 9001’s structured framework indispensable for mitigating risks and delivering consistent quality.

Custom designs often involve unique combinations of materials, layer stacks, and processes, increasing the potential for errors. ISO 9001’s documented procedures—from design reviews to process work instructions—provide a roadmap for navigating this complexity. For example, a custom Sinkpad PCB integrating both thick copper cores and flexible substrates requires a specialized lamination process; ISO 9001 mandates that this process is documented, tested, and validated before full production, reducing the risk of delamination or performance failure.

In custom fabrication, design iterations are common as customer needs evolve or prototype testing reveals adjustments. ISO 9001’s formal change management process ensures that any modifications—whether to sinkpad dimensions, material selection, or via placement—undergo cross-departmental review and customer approval. This prevents miscommunication and ensures that changes do not compromise thermal performance, mechanical stability, or compliance with industry standards.

ISO 9001’s focus on customer satisfaction aligns perfectly with custom fabrication, where success is defined by meeting unique customer needs. Manufacturers conduct regular customer feedback loops throughout the fabrication process—from prototype approval to post-delivery support—to address concerns and refine solutions. For example, if a customer’s custom Sinkpad PCB requires adjustments to fit a revised enclosure design, ISO 9001’s corrective action procedures ensure that the change is implemented efficiently while maintaining quality standards.

ISO 9001-certified manufacturers tailor fabrication processes to address the unique demands of key industries, ensuring custom solutions meet sector-specific requirements:

Custom Sinkpad PCBs for EV powertrains and ADAS systems require conformal designs to fit tight under-hood spaces, paired with vibration-resistant structures. ISO 9001-aligned fabrication includes AEC-Q200 compliance testing, with custom thermal via layouts to cool high-current components (e.g., SiC modules) without increasing footprint. Manufacturers often customize copper core thickness to balance thermal conductivity and weight, supporting EV range optimization.

RF-focused custom Sinkpad PCBs demand low-loss dielectric materials and precise impedance control for high-frequency signals. Fabrication includes custom ground plane designs to minimize EMI, with sinkpad structures tailored to cool RF power amplifiers in dense base station modules. ISO 9001’s process validation ensures that custom signal routing and via placement maintain signal integrity across operating frequencies.

Custom Sinkpad PCBs for industrial motor drives and edge computing require ruggedized designs to withstand dust, humidity, and temperature cycling. Fabrication includes custom grid copper pour patterns for enhanced heat dissipation and reinforced mounting holes for vibration resistance. ISO 9001’s supply chain controls ensure that custom materials—such as corrosion-resistant copper cores—meet industrial durability standards.

ISO 9001-certified manufacturers follow a customer-centric workflow to deliver tailored solutions efficiently:

Needs Discovery: Detailed consultation to define thermal, mechanical, and electrical requirements, supported by ISO 9001’s requirement documentation.

Design & Simulation: Custom layout design with thermal-electrical simulation, including customer reviews at key milestones.

Prototype Fabrication: Small-batch prototyping with comprehensive testing (thermal, mechanical, electrical) to validate performance.

Process Optimization: Refinement of fabrication processes based on prototype results, aligned with ISO 9001’s continuous improvement principle.

Batch Production: Scaled manufacturing with real-time process monitoring and quality checks.

Delivery & Support: Timely delivery with traceability documentation, plus post-delivery technical support to address any issues.

Custom Sinkpad PCB Fabrication, when guided by ISO 9001’s quality management system, delivers tailored high-power solutions that balance flexibility, performance, and reliability. By integrating ISO 9001’s process control, risk management, and customer-centricity into every stage—from need alignment to post-delivery support—manufacturers address the unique challenges of custom designs while ensuring consistent quality. Whether for automotive, 5G, or industrial applications, ISO 9001-driven custom fabrication empowers customers to achieve their specific performance goals without compromising on compliance or durability. As high-power electronics continue to demand personalized solutions, this synergy of customization and quality management will remain a key driver of market competitiveness.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB