-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 20. 2025, 17:47:11

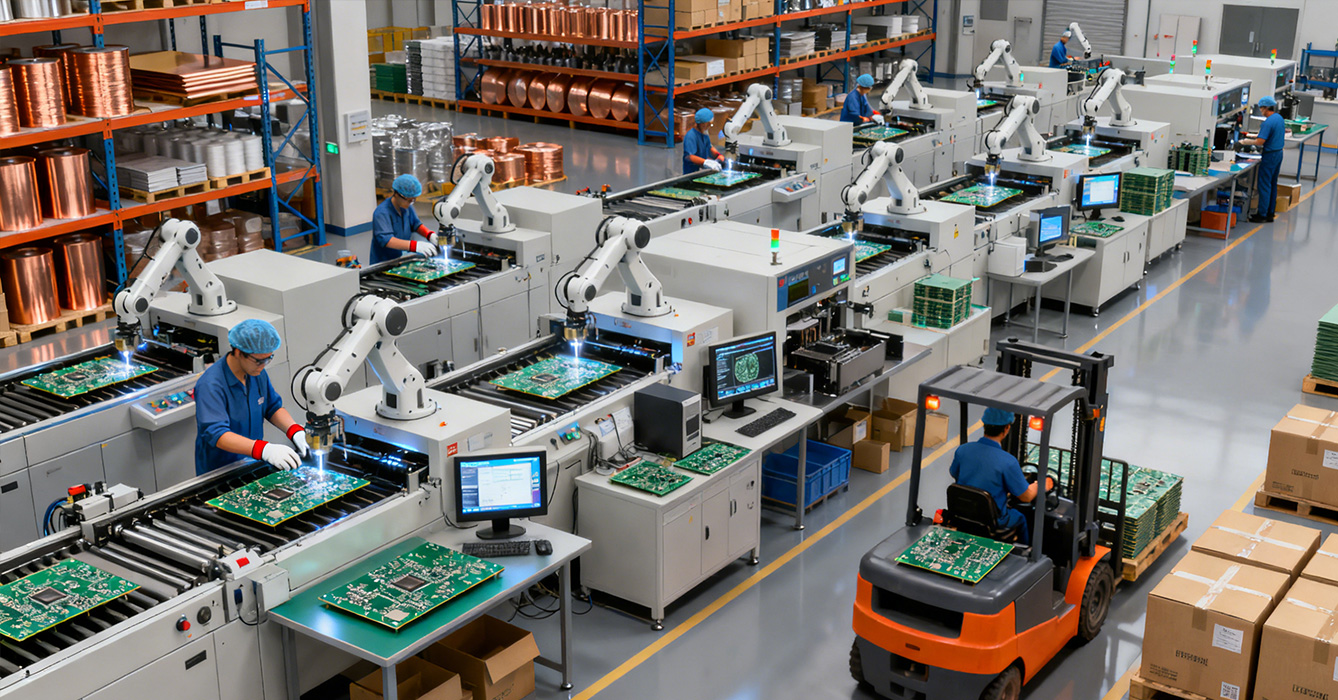

A qualified Sinkpad PCB manufacturer serves as the cornerstone of high-power electronic systems, as the performance stability of sinkpad structures—critical for thermal management and current-carrying capacity—directly depends on the manufacturer’s technical expertise, quality control systems, and industrialization capabilities. With the booming demand for high-power electronics in EVs, AI servers, and 5G infrastructure, sinkpad PCB manufacturers are evolving from simple processing providers to total solution partners. This article systematically analyzes the core competencies of leading manufacturers, showcases benchmark enterprise practices, reveals industry distribution characteristics, and provides actionable selection guidelines—all anchored in ISO 9001 quality standards and industry-specific certifications—to help customers identify reliable partners in a fragmented market (CR10=52.1% ).

Thermal Management Expertise: Leading manufacturers specialize in sinkpad-specific processes such as thick copper (3-10oz) lamination, thermal via array drilling (≥10 vias/cm²), and composite core (diamond/copper, copper-aluminum) sintering. For example, Plexus has developed proprietary low-temperature lamination technology (<200°C) to prevent composite material degradation, ensuring thermal conductivity ≥401 W/(m・K) .

Customization Flexibility: Ability to adapt to diverse application scenarios—from miniaturized sinkpads for wearable devices to large-format designs for industrial inverters. This includes flexible layer stack optimization (1-40 layers), non-standard sinkpad profiling, and compatibility with special materials (e.g., low-loss dielectrics for RF applications).

R&D Innovation: Sustained investment in core technologies, with annual R&D intensity averaging 5% of revenue. Key R&D focuses include heat dissipation enhancement, material compatibility improvement, and process automation—such as AI-driven thermal via positioning optimization for AI server sinkpads.

ISO 9001 Core Implementation: Strict adherence to process control (CPK ≥1.33 for key parameters), traceability systems (unique batch QR codes linking raw materials to test results), and continuous improvement mechanisms (internal audits + 8D corrective actions).

Extended Industry Certifications: For vertical markets, leading manufacturers hold supplementary certifications: IATF 16949 for automotive-grade sinkpads (complying with AEC-Q200), UL 94V-0 for flame retardancy, and RoHS/REACH for environmental compliance. Seco , a supplier to Nvidia and North American EV leaders, integrates IATF 16949 into ISO 9001 processes to meet zero-defect requirements .

Advanced Testing Capabilities: Equipped with specialized equipment for sinkpad validation: LFA (Laser Flash Analysis) for thermal conductivity, X-ray CT for internal void detection, and thermal cycling chambers (-40°C to 125°C, 1000 cycles) to simulate real-world conditions.

Scalable Manufacturing: Balancing low-volume customization and high-volume production. Top manufacturers operate multiple production bases , enabling rapid capacity expansion and regional supply.

Robust Supply Chain: Tiered supplier management for critical materials (99.85%+ high-purity copper, composite cores) with PPAP validation and quarterly audits. Leading manufacturers achieve incoming material defect rates ≤0.5% , far below the industry average of 2.1%.

Delivery Reliability: On-time delivery rate ≥98% through MES (Manufacturing Execution System) integration and lean production. For urgent custom orders, flexible production lines can reduce lead times by 30% compared to standard workflows.

Market Position: Global largest PCB manufacturer (12.4% market share ) with 6 consecutive years of top ranking (2017-2022).

Sinkpad Strengths:

One-stop supply of sinkpad PCBs (rigid, flexible, HDI integrated), ideal for complex systems like EV domain controllers and AI servers.

Leading thermal management technology: Specializes in high-power sinkpads for automotive electronics (intelligent cockpit, ADAS) and AI server HDI thick boards (mass-produced for top clients) .

R&D focus: Investing in humanoid robot sinkpad solutions (flexible sinkpads as "nervous system") and next-gen automotive radar boards.

Quality System: ISO 9001 + IATF 16949 + UL certification, with traceability records retained for 5 years (automotive applications).

Market Focus: AI servers, NEV, and industrial automation.

Key Achievements:

Mass-produces sinkpad PCBs for Nvidia’s AI servers and develops next-gen products .

10+ years of cooperation with North American NEV leaders, supplying sinkpads for powertrains and battery management systems.

Competitive Edge: Strong customization capability for high-current sinkpads (up to 400A) and strict compliance with automotive-grade vibration and humidity requirements (85°C/85% RH, 2000h).

China’s Dominance: As the global PCB manufacturing hub, China hosts 18,373 PCB-related enterprises , with 48.14% concentrated in Guangdong Province (8,844 companies)—forming a complete industrial chain from raw materials to finished products.

Key Clusters:

Shenzhen: Home to global leaders like Plexus),with strong R&D and proximity to downstream electronics clients (EV makers, 5G equipment providers).

Jiangsu/Zhejiang: Focus on mid-to-high-end sinkpad PCBs, with advantages in precision drilling and material innovation.

Global Layout: Leading manufacturers (e.g., Plexus)) have overseas production bases (Taiwan, Kaohsiung) to meet regional supply demands and reduce logistics risks .

Supply Chain Efficiency: Proximity to material suppliers (copper core, dielectric) reduces lead times by 15-20%.

Technical Synergy: Industry clusters foster knowledge sharing, enabling manufacturers to quickly adopt advanced processes (e.g., AI inspection) from peers.

Cost Competitiveness: Economies of scale in clusters lower production costs without compromising quality—critical for high-volume applications like EVs.

To ensure optimal performance and reliability, customers should evaluate manufacturers against 6 core dimensions, each with clear key indicators and benchmark standards:

Key Indicators: ISO 9001 certification status + industry-specific supplementary certifications

Benchmark Standard: Must hold ISO 9001 as the foundational quality certification; supplementary certifications required based on application: IATF 16949 for automotive-grade sinkpads, UL 94V-0 for flame retardancy compliance, and full RoHS/REACH alignment for environmental safety.

Key Indicators: Thick copper processing range, thermal conductivity performance, customization flexibility (layer stack, material compatibility)

Benchmark Standard: Capable of processing thick copper from 3oz to 10oz; sinkpad thermal conductivity ≥401 W/(m·K); supports 1-40 layer stack designs; compatible with special materials (diamond/copper composites, low-loss dielectrics) and non-standard sinkpad profiling.

Key Indicators: Batch defect rate, process capability (CPK value), in-house testing equipment availability

Benchmark Standard: Batch defect rate ≤0.05%; CPK ≥1.33 for critical manufacturing parameters; in-house testing facilities including LFA (Laser Flash Analysis) for thermal conductivity, X-ray CT for internal void detection, and thermal cycling chambers.

Key Indicators: Monthly output volume, custom order lead time, number of production bases

Benchmark Standard: Annual production capacity ≥100k units; lead time for custom orders ≤15 days; multiple production bases to support regional supply and capacity scalability.

Key Indicators: Industry-specific experience, cooperation with leading clients

Benchmark Standard: At least 3 years of focused experience in the target application sector (e.g., EV, AI servers, 5G); documented cooperation with top 50 global electronics companies or leading industry players.

Key Indicators: Traceability period, technical response time, complaint resolution rate

Benchmark Standard: Traceability records retained for ≥3 years; 24-hour technical response for urgent issues; customer complaint resolution rate ≥95%.

On-Site Audit: Verify ISO 9001 implementation (process documentation completeness, MES system integration, testing lab qualification) and production line environmental control (ESD Class 1000 required for electrostatic protection).

Sample Validation: Conduct performance testing on prototype sinkpads, including thermal resistance (<0.5°C/W), current-carrying capacity verification, and thermal cycling stability (1000 cycles of -40°C to 125°C).

Supplier Background Check: Review market share data, industry rankings, and third-party supplier audit reports (e.g., tier-1 supplier qualification certificates for global EV manufacturers or Fortune 500 electronics clients).

Intelligent Manufacturing: AI-driven process optimization (e.g., predictive maintenance for lamination equipment) and digital twin simulation to reduce new product development cycles by 30% .

Advanced Materials: Wider adoption of diamond-copper composites and recycled copper cores to balance thermal performance and sustainability goals.

Emerging Applications: Growth in AI servers (high-layer sinkpads), humanoid robots (flexible sinkpads), and 6G infrastructure (low-loss sinkpads) will drive demand for specialized manufacturers .

Regionalization: Manufacturers will expand production bases in Europe/North America to meet local content requirements (e.g., EV battery regulations) and reduce cross-border logistics risks.

Eco-Friendly Processes: Adoption of water-based etching technologies and energy-efficient production lines to reduce carbon footprint—aligned with ISO 14001 (environmental management system) and global customer sustainability requirements.

A high-quality Sinkpad PCB manufacturer is defined by its technical mastery of thermal management, strict adherence to ISO 9001 quality standards, and ability to adapt to diverse industry needs. Benchmark enterprises like 鹏鼎控股 and 世运电路 demonstrate that success lies in integrating R&D innovation, scalable production, and customer-centricity. With China’s Guangdong-led clusters offering robust supply chains and cost advantages, customers can leverage the selection criteria outlined to identify partners that deliver both performance and reliability. As high-power electronics continue to evolve, manufacturers that embrace intelligent manufacturing, sustainable practices, and vertical market specialization will remain at the forefront—empowering customers to achieve their technological and business objectives.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB