-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 30. 2025, 18:58:03

In the rapidly evolving electronics industry, the demand for personalized, application-specific components has driven the rise of customize FPCB as a core enabler of product innovation. Unlike standard off-the-shelf FPCBs that impose design limitations, customize FPCB offers tailored solutions that align with the unique spatial constraints, performance requirements, and functional goals of diverse electronic products. From compact wearable devices to complex industrial control systems, customize FPCB empowers engineers and designers to translate creative concepts into practical, high-performance products. Its ability to adapt to varied industry needs has made it a cornerstone of modern electronic development, helping brands gain a competitive edge in crowded markets.

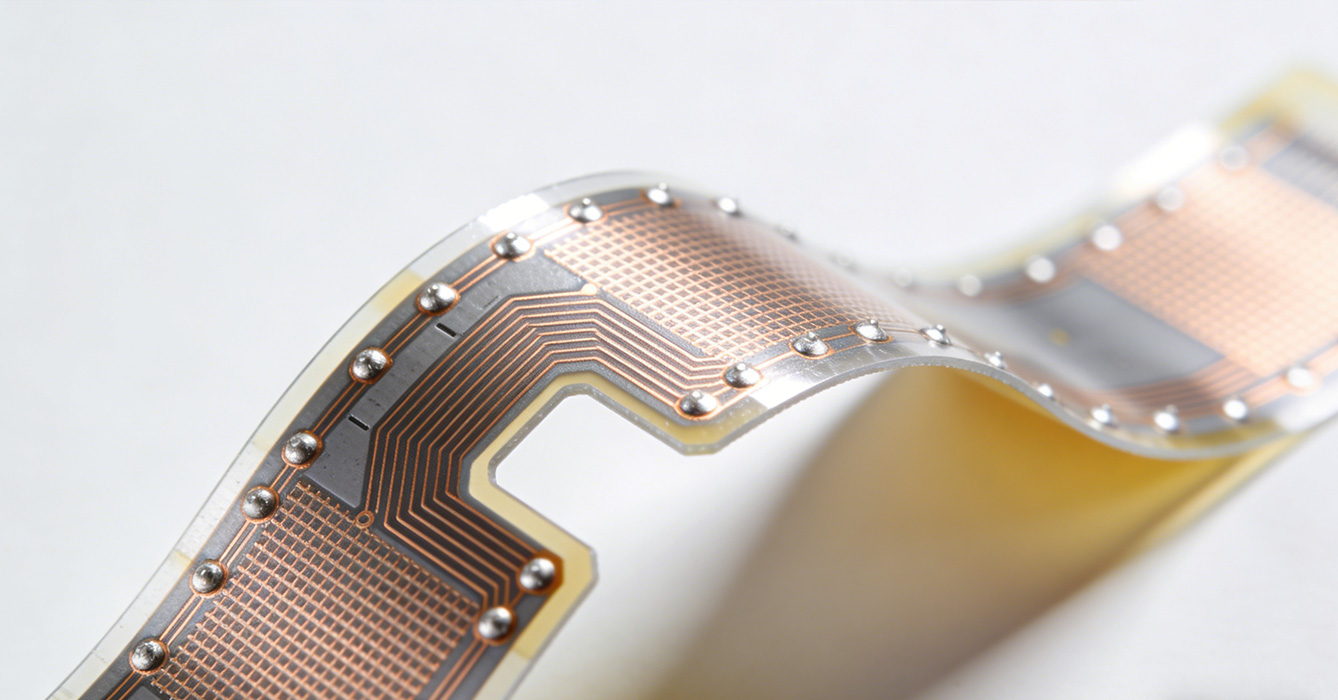

The primary advantage of customize FPCB lies in its ability to break free from the one-size-fits-all limitations of standard FPCBs. Firstly, it delivers design flexibility that matches product-specific form factors. Whether a product requires ultra-thin circuits for a slim smartwatch, curved layouts for a wearable fitness band, or multi-layer configurations for a compact industrial sensor, customize FPCB can be tailored to fit exact spatial requirements. This flexibility eliminates the need for compromise in product design, allowing for more ergonomic, compact, and aesthetically pleasing electronic devices.

Secondly, customize FPCB enables performance optimization for targeted applications. Different electronic products operate in varying environments and have distinct performance needs—for example, a medical device may require biocompatible materials, while an automotive component needs resistance to high temperatures and vibration. Customize FPCB solutions address these specifics by selecting appropriate substrates, optimizing circuit traces, and integrating specialized features, ensuring the final product meets the exact performance and reliability standards of its intended use case.

Thirdly, it supports agile product development and iteration. Custom FPCB providers often offer collaborative design support, working closely with clients to refine designs and resolve potential issues early in the development process. This collaborative approach reduces rework, shortens development cycles, and enables faster prototyping, allowing brands to bring innovative products to market more quickly.

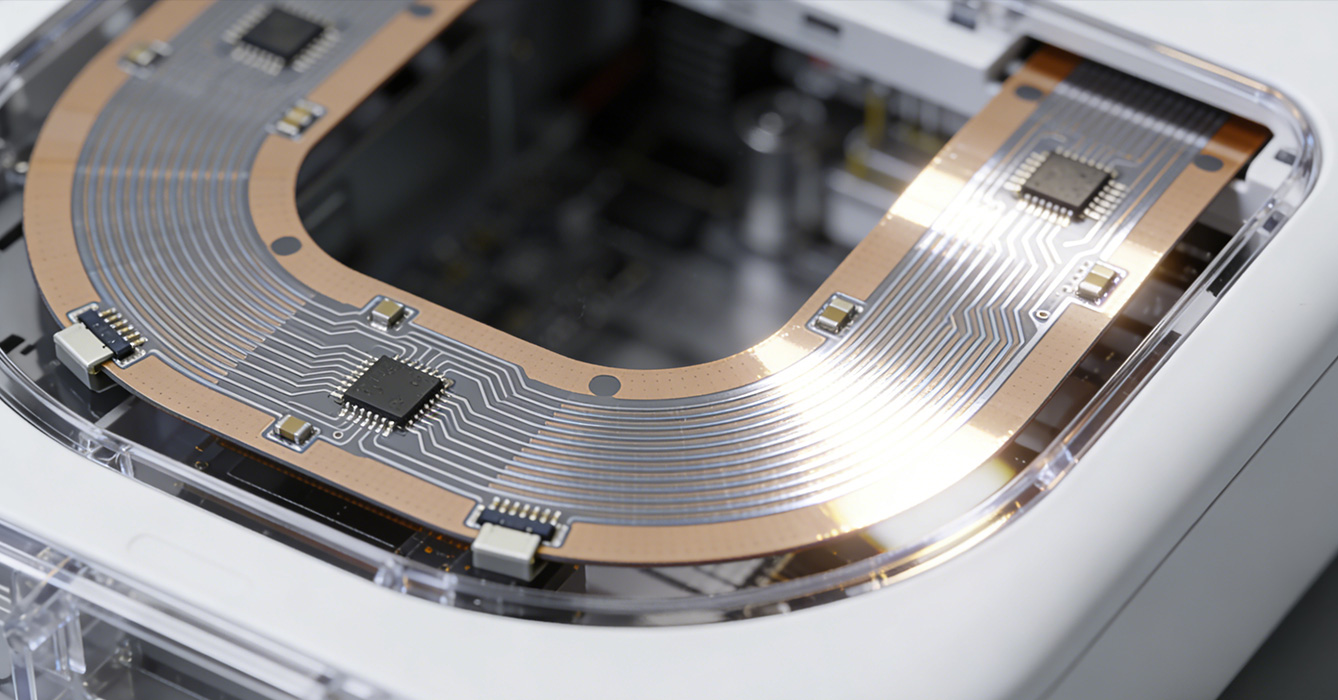

Customize FPCB has found widespread application across a broad spectrum of industries, each leveraging its tailored capabilities to drive innovation. In the consumer electronics sector, it is a key component of smart wearables, foldable smartphones, and wireless audio devices. For example, customize FPCB enables the slim, flexible design of wireless earbud circuits, ensuring they fit within the compact form factor while delivering stable audio signal transmission.

In the industrial sector, customize FPCB supports the development of smart factory equipment, such as sensors for predictive maintenance and automated control modules. These applications require FPCBs that can withstand harsh industrial environments—including dust, humidity, and temperature fluctuations—and customize FPCB solutions are tailored to meet these durability and performance needs, ensuring reliable operation in critical industrial processes.

The medical device industry also relies heavily on customize FPCB for products like portable diagnostic tools, wearable health monitors, and minimally invasive surgical instruments. Custom solutions here prioritize biocompatibility, miniaturization, and stable signal transmission, enabling the development of devices that are both safe for patient use and effective in delivering accurate medical data.

Additionally, the automotive industry uses customize FPCB for in-vehicle electronics, such as infotainment systems, advanced driver-assistance systems (ADAS), and interior ambient lighting. Custom designs ensure these components fit within the complex contours of modern vehicles while withstanding the rigors of automotive environments.

Selecting the right provider for customize FPCB is critical to ensuring project success. Firstly, evaluate the provider’s design and engineering capabilities. A reliable partner should have an experienced team that can collaborate closely with clients, understand their specific needs, and offer expert advice on design optimization, material selection, and manufacturability.

Secondly, assess their manufacturing flexibility and scalability. The provider should be able to accommodate both small-batch prototyping and large-scale production, adapting to the different stages of product development. This scalability ensures that customize FPCB solutions can support product growth from concept to mass market.

Thirdly, verify their quality control systems. High-quality customize FPCB requires rigorous testing and inspection throughout the manufacturing process to ensure performance and reliability. Look for providers with established quality certifications and comprehensive testing protocols, including electrical performance testing, mechanical durability testing, and environmental resistance testing.

Finally, consider their communication and project management capabilities. Timely communication is essential for custom projects, and a good provider should offer transparent progress updates and responsive support to address any issues that arise during development and production.

As the electronics industry moves toward digitalization and sustainability, customize FPCB is evolving to meet new demands. One key trend is the integration of digital design tools and automation. Advanced CAD software and AI-driven design optimization enable faster, more accurate customization, reducing development time and improving design precision. Automated manufacturing processes also enhance consistency and efficiency in producing customize FPCB solutions.

Sustainability is another growing focus, with more providers offering customize FPCB solutions made from eco-friendly materials, such as recyclable substrates and lead-free components. Additionally, energy-efficient manufacturing processes are being adopted to reduce the environmental impact of custom FPCB production. These trends align with global efforts to promote sustainable electronics and meet the increasing demand for eco-conscious products from consumers and regulators.

In conclusion, customize FPCB has become an indispensable tool for driving innovation in the electronics industry, offering tailored solutions that meet the unique needs of diverse products and industries. Its design flexibility, performance optimization, and support for agile development make it a key partner for brands looking to differentiate their products in competitive markets. By selecting a reliable customize FPCB provider with strong design capabilities, manufacturing flexibility, and quality control, businesses can unlock the full potential of their electronic innovations. As digitalization and sustainability trends continue to shape the industry, customize FPCB will remain at the forefront of electronic component innovation, enabling the development of smarter, more efficient, and more sustainable products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB