-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 30. 2025, 18:59:09

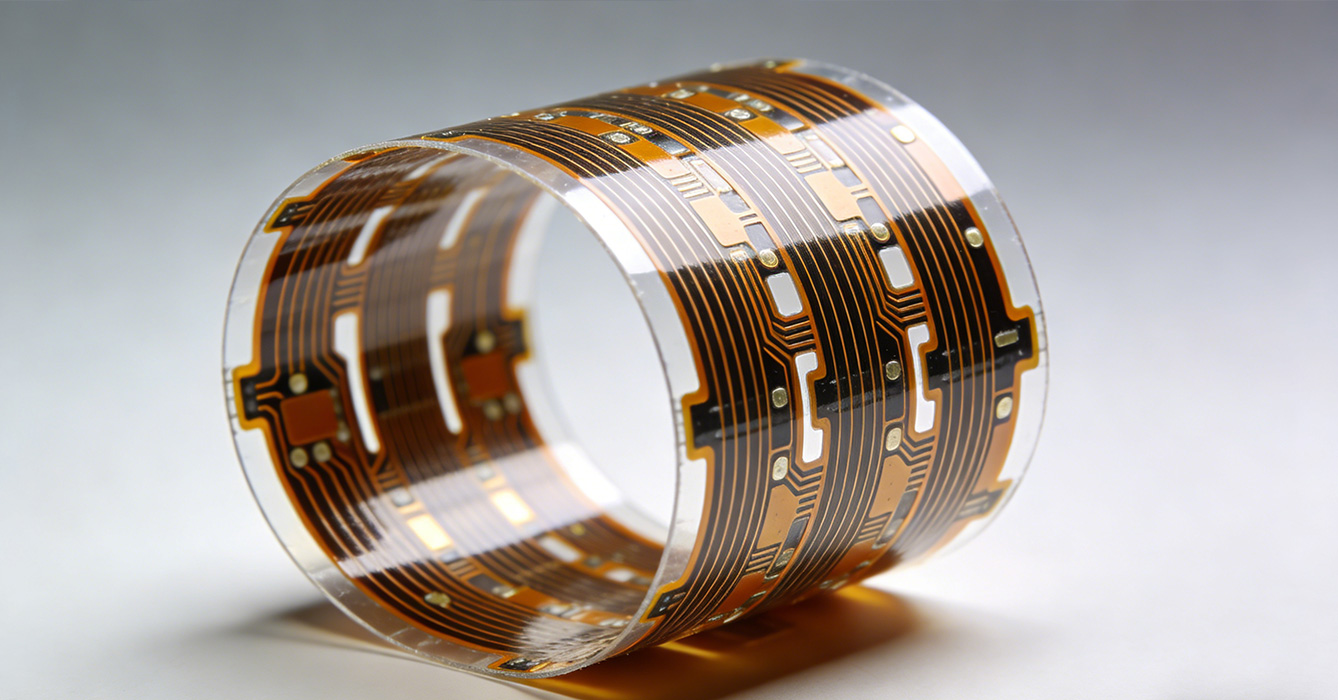

In the era of electronic innovation dominated by miniaturization, intelligence, and adaptability, FPCB (Flexible Printed Circuit Board) has evolved from a supporting component to a core connector that underpins the entire flexible electronics ecosystem. Unlike rigid PCBs that limit product form and application scenarios, FPCB’s unique flexibility, lightweight nature, and reliable electrical performance have broken through traditional design boundaries. It serves as a critical bridge between electronic components, enabling seamless integration of diverse technologies in fields such as consumer electronics, industrial IoT, and smart healthcare. As global demand for flexible, portable, and intelligent electronic products surges, FPCB’s role in driving industry upgrading and technological innovation becomes increasingly irreplaceable.

FPCB’s dominant position in the flexible electronics ecosystem stems from its three core characteristics that complement modern electronic product needs. Firstly, its exceptional flexibility and conformability allow it to adapt to complex form factors—whether it is the curved contour of a smart watch, the foldable structure of a foldable phone, or the irregular shape of a medical implant. This characteristic enables product designers to fully release their creativity, developing devices that are more ergonomic and space-efficient.

Secondly, FPCB boasts superior integration efficiency. By integrating multiple circuit functions into a single flexible board, it reduces the need for bulky connectors and wiring harnesses, significantly simplifying product internal structures. This not only reduces product weight and volume but also improves overall reliability by minimizing connection failure points. For battery-powered devices such as wireless earbuds and portable sensors, this integration efficiency directly extends battery life and enhances user experience.

Thirdly, FPCB exhibits excellent environmental adaptability. Manufactured with high-performance substrates like polyimide, it can withstand extreme temperatures, vibrations, and humidity, making it suitable for both indoor precision equipment and outdoor harsh environment applications. This adaptability expands FPCB’s application boundaries, allowing it to play a role in aerospace, automotive, and industrial control sectors that have strict environmental requirements.

As a core connector, FPCB is closely integrated with emerging technologies, empowering innovation across multiple industries. In the consumer electronics sector, FPCB is the cornerstone of smart wearable devices and foldable electronics. For example, in smart glasses, FPCB connects microprocessors, sensors, and display modules in a limited space, enabling functions such as real-time data transmission and augmented reality (AR) display. In foldable smartphones, FPCB with high bending resistance ensures stable signal transmission during repeated folding, supporting the core user experience of such devices.

In the industrial IoT (IIoT) field, FPCB enables the miniaturization and flexibility of smart sensors. These sensors, integrated with FPCB, can be embedded into machinery, pipelines, and equipment surfaces, collecting real-time data on temperature, pressure, and operation status. FPCB’s durability ensures long-term stable operation of sensors in dusty, high-temperature industrial environments, laying the foundation for smart factory construction and predictive maintenance.

In smart healthcare, FPCB plays a vital role in portable diagnostic devices and wearable health monitors. For instance, in a skin-worn glucose monitor, FPCB connects biosensors, microcontrollers, and wireless communication modules, enabling continuous, non-invasive glucose level monitoring. Its biocompatibility and flexibility ensure comfortable wear and reliable data transmission, advancing the development of personalized healthcare.

To fully leverage FPCB’s ecosystem value, effective synergy between design and manufacturing is essential. In terms of design, engineers must prioritize material selection based on application scenarios—choosing high-temperature resistant polyimide substrates for automotive and industrial applications, and lightweight polyester substrates for cost-sensitive consumer electronics. Meanwhile, thermal management design is critical: optimizing circuit trace layout and integrating heat-dissipating structures to prevent performance degradation caused by heat accumulation.

In manufacturing, precision processes are the guarantee of FPCB quality. Advanced technologies such as laser drilling and automated optical inspection (AOI) ensure the accuracy of circuit patterns and the reliability of connections. Additionally, strict quality control systems—from raw material inspection to final product testing—ensure that FPCB meets the performance requirements of different application scenarios. Collaboration between design and manufacturing teams in the early stages of product development can avoid design flaws and improve production efficiency.

The future development of FPCB is closely aligned with the trends of intelligence and sustainability in the electronics industry. One key trend is the integration of smart functions into FPCB, such as embedding flexible sensors and energy-harvesting modules. This enables FPCB to not only transmit signals but also collect environmental data and generate power independently, supporting the development of self-sufficient smart devices.

Sustainability is another important direction. Manufacturers are actively exploring eco-friendly substrates and lead-free manufacturing processes to reduce FPCB’s environmental impact. The development of recyclable FPCB materials and energy-efficient production technologies also aligns with global carbon neutrality goals. Furthermore, as 6G and quantum computing technologies evolve, FPCB will need to adapt to higher-frequency signal transmission requirements, driving the development of more advanced substrate materials and manufacturing processes.

In conclusion, FPCB, as the core connector of the flexible electronics ecosystem, has reshaped the design and application of electronic products through its unique flexibility, integration efficiency, and environmental adaptability. Its integration with emerging technologies has driven innovation in consumer electronics, industrial IoT, and smart healthcare. By emphasizing design-manufacturing synergy and embracing intelligence and sustainability trends, FPCB will continue to expand its application boundaries and solidify its position as a cornerstone of the modern electronics industry. For enterprises pursuing technological innovation, leveraging FPCB’s core value is a key strategy to gain a competitive edge in the evolving electronic market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB