-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 31. 2025, 16:32:19

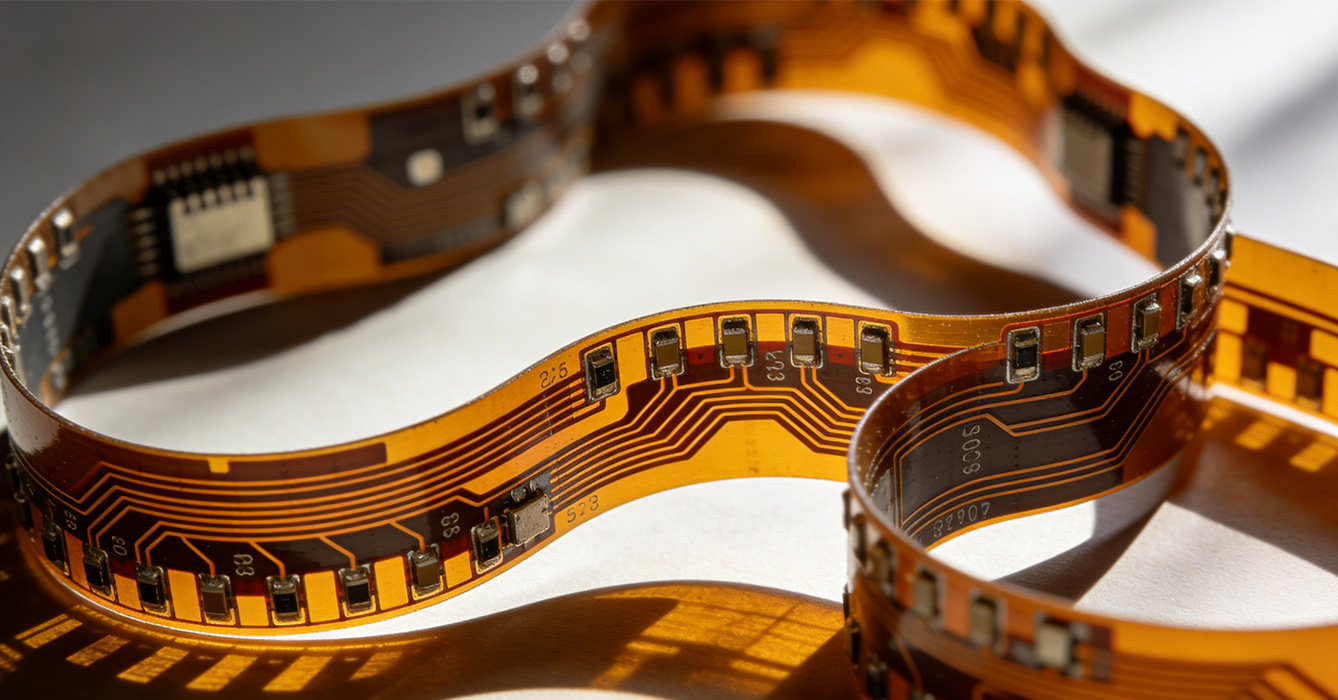

In the dynamic landscape of electronic product development, the demand for personalized, high-performance components has made customize flexible circuit a cornerstone of innovation. Unlike standard flexible circuits that offer limited adaptability, a customize flexible circuit is engineered to meet the unique spatial, functional, and environmental requirements of specific applications. From compact wearable devices to rugged industrial equipment, customize flexible circuit breaks through the design constraints of traditional electronic components, enabling engineers to translate creative concepts into practical, efficient products. As industries ranging from consumer electronics to smart manufacturing pursue greater product differentiation, the role of customize flexible circuit in delivering tailored solutions has become increasingly indispensable.

The value of customize flexible circuit lies in its ability to address the diverse pain points of electronic product development that standard components cannot resolve. Firstly, it offers unparalleled design flexibility. Customize flexible circuit can be tailored to fit irregular shapes, ultra-compact spaces, or curved surfaces—whether it’s the slim profile of a smart earbud, the foldable structure of a portable display, or the contoured fit of a wearable health monitor. This adaptability eliminates design compromises, allowing products to be more ergonomic, aesthetically pleasing, and space-efficient.

Secondly, it enables performance customization for targeted scenarios. Different applications have distinct performance demands: a medical device may require biocompatible materials and low-power consumption, while an industrial sensor needs high-temperature resistance and anti-interference capabilities. Customize flexible circuit solutions optimize material selection, circuit layout, and shielding design to match these specific requirements, ensuring stable operation in the intended environment. This performance tailoring directly enhances product reliability and extends service life.

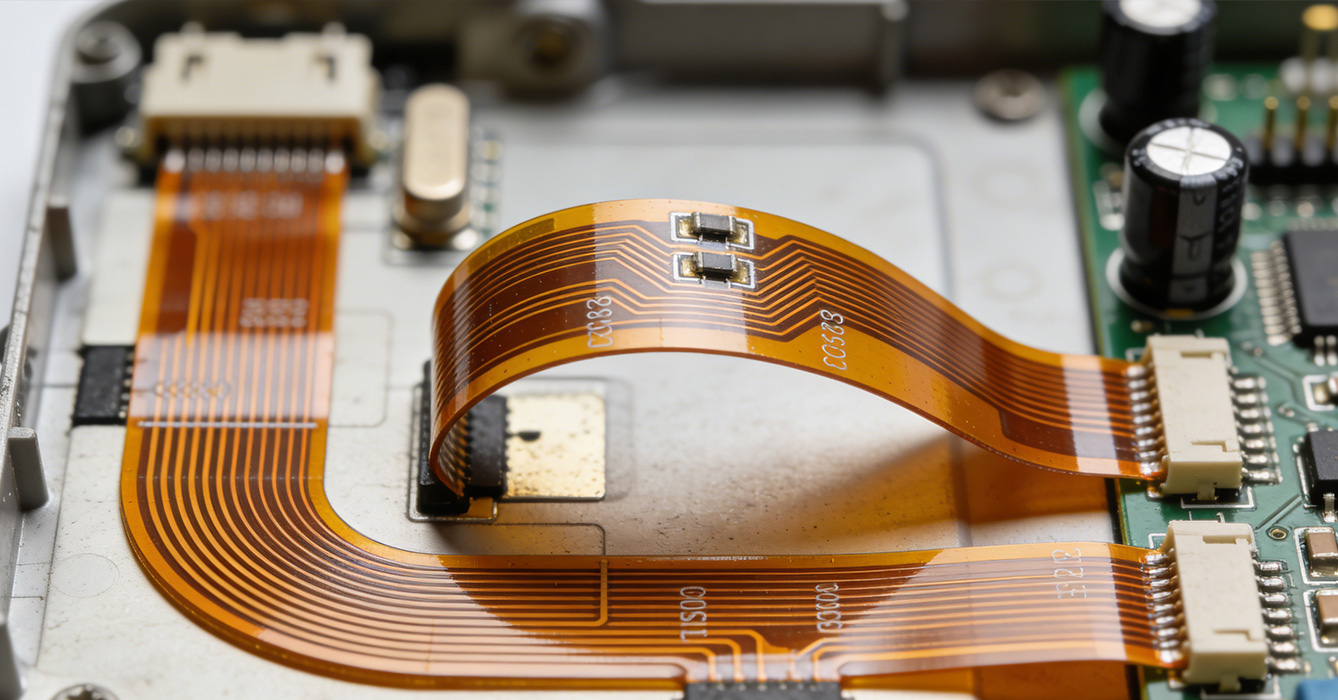

Thirdly, it supports integrated functionality to simplify product design. A customize flexible circuit can integrate multiple functions—such as signal transmission, power supply, and sensor connection—into a single component, reducing the need for additional wiring and connectors. This integration not only simplifies the internal structure of electronic products but also reduces the risk of connection failures, improving overall product stability while lowering production costs.

Customize flexible circuit has expanded beyond traditional electronic sectors, driving innovation in a range of emerging fields. In the smart building industry, it is used in intelligent lighting systems and environmental monitoring sensors. Customized flexible circuits fit seamlessly into building materials such as ceiling panels and wall surfaces, enabling hidden installation and smart control—supporting the development of energy-efficient, connected smart buildings.

In the new energy sector, customize flexible circuit plays a key role in electric vehicle (EV) battery management systems (BMS) and solar energy equipment. For EVs, customized flexible circuits are tailored to the complex spatial layout of battery packs, ensuring accurate data collection on battery temperature and voltage while withstanding high-temperature operating conditions. In solar panels, they enable flexible, lightweight design, facilitating the installation of solar energy systems on irregular surfaces such as building facades and curved roofs.

The entertainment and wearable tech industries also rely heavily on customize flexible circuit. For example, in virtual reality (VR) headsets, customized flexible circuits connect display modules, motion sensors, and audio components in a limited space, ensuring seamless signal transmission and a lightweight user experience. In fitness wearables, they conform to the body’s contours, enabling continuous monitoring of vital signs without compromising comfort.

To maximize the value of customize flexible circuit, careful attention must be paid to the design and implementation process. Firstly, in-depth demand analysis is critical. Engineers need to fully understand the application’s spatial constraints, operating environment, performance requirements, and production scale to develop a customized solution that balances functionality and practicality.

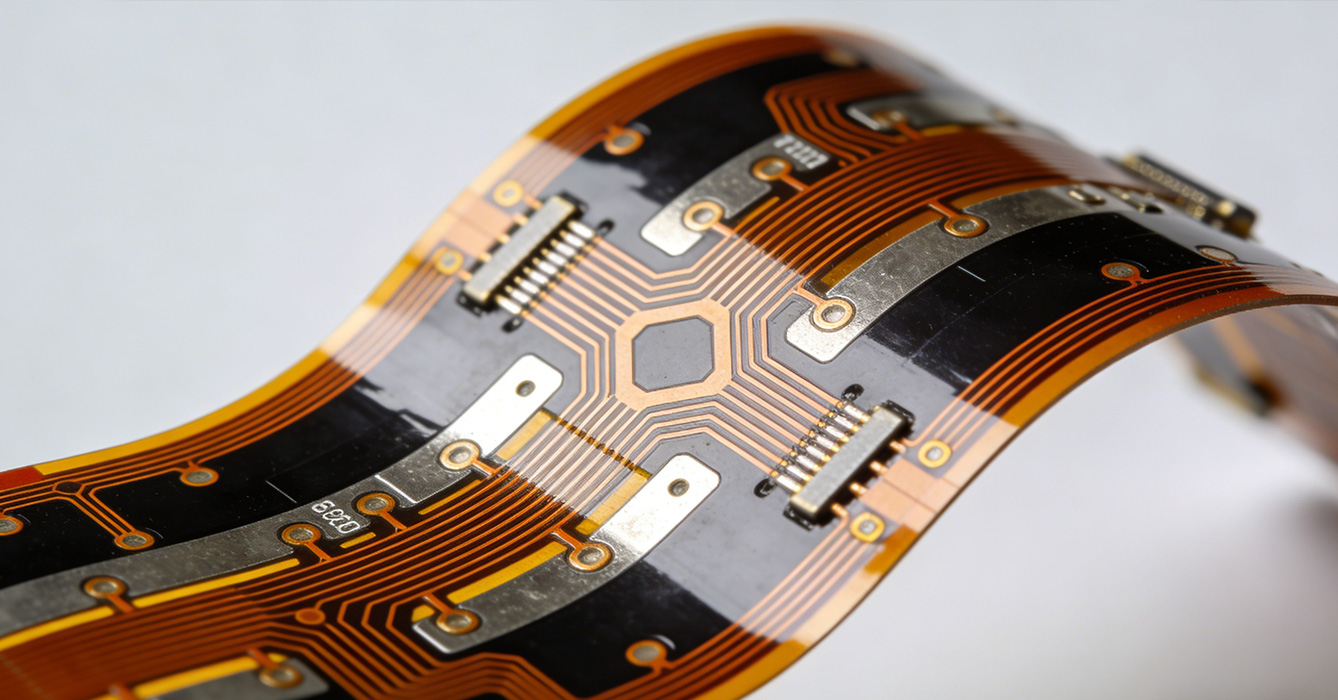

Secondly, material selection is a key decision point. The choice of substrate (such as polyimide or polyester) and conductive materials depends on the application’s needs: high-temperature scenarios require heat-resistant polyimide, while cost-sensitive consumer products may use polyester. Additionally, protective materials such as coverlay must be selected to enhance durability and environmental resistance.

Thirdly, rigorous testing and validation are essential. Customize flexible circuit should undergo comprehensive testing—including electrical performance testing, mechanical durability testing (such as bending and vibration tests), and environmental resistance testing—to ensure it meets the application’s requirements. Prototyping and iterative testing early in the design process help identify and resolve potential issues, reducing the risk of production delays.

As the electronics industry evolves, customize flexible circuit is moving toward intelligence and sustainability. One key trend is the integration of smart components such as flexible sensors and wireless communication modules. This enables customize flexible circuit to not only transmit signals but also collect and process data, supporting the development of self-aware, connected devices for the Internet of Things (IoT) ecosystem.

Sustainability is another growing focus. Manufacturers are increasingly using eco-friendly materials—such as recyclable substrates and lead-free conductive materials—in customize flexible circuit production. Additionally, energy-efficient design optimization and low-carbon manufacturing processes are being adopted to reduce environmental impact, aligning with global efforts to promote sustainable electronics.

In conclusion, customize flexible circuit has become a driving force for innovation in the electronics industry, offering tailored solutions that meet the unique needs of diverse applications. Its design flexibility, performance customization, and integrated functionality make it indispensable across smart buildings, new energy, wearable tech, and beyond. By prioritizing in-depth demand analysis, careful material selection, and rigorous testing, businesses can fully leverage the value of customize flexible circuit to create differentiated, high-performance products. As intelligence and sustainability trends deepen, customize flexible circuit will continue to evolve, playing an even more critical role in shaping the future of electronic innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB