-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 31. 2025, 16:34:29

In the wave of electronic industry innovation, flexible circuit has emerged as a transformative foundational component, reshaping the design paradigm and application boundaries of electronic products. Unlike rigid printed circuit boards that restrict form and adaptability, flexible circuit features inherent flexibility, lightweight properties, and reliable electrical performance, enabling electronic devices to break free from traditional structural constraints. From daily consumer electronics to industrial automation and precision medical equipment, flexible circuit serves as the "vascular system" that connects components and transmits signals, laying a solid foundation for the development of flexible, portable, and intelligent electronic products. As global demand for high-performance and adaptive electronics continues to rise, the strategic value of flexible circuit in driving industry upgrading has become increasingly prominent.

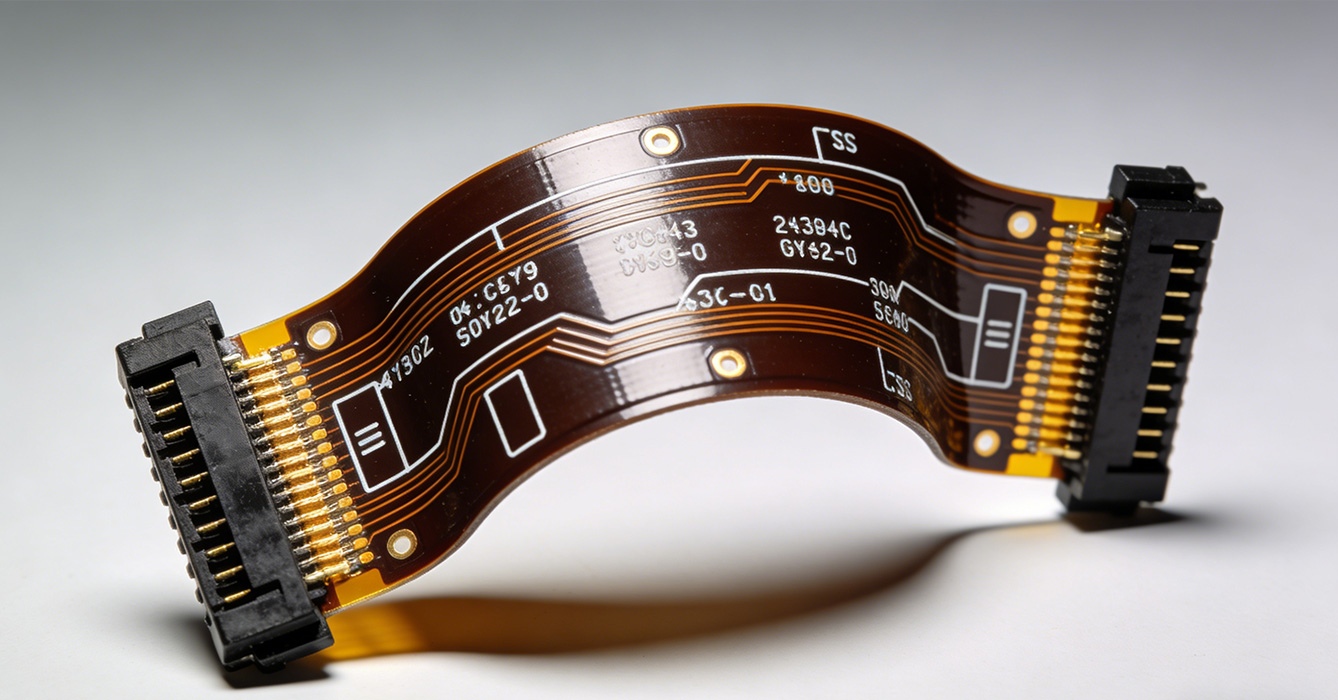

The widespread application of flexible circuit stems from its three core characteristics that perfectly match the needs of modern electronic development. Firstly, its exceptional flexibility and conformability allow it to adapt to diverse form factors. Flexible circuit can be bent, folded, or curved to fit irregular spaces—whether it is the narrow internal structure of a wireless earbud, the foldable hinge of a smart phone, or the contoured surface of a wearable device. This characteristic maximizes space utilization, enabling the design of more compact and ergonomic electronic products.

Secondly, flexible circuit boasts superior integration efficiency. It can integrate multiple circuit functions, such as signal transmission, power supply, and sensor connection, into a single flexible substrate, reducing the need for bulky connectors and wiring harnesses. This integration not only simplifies the internal structure of electronic products but also reduces connection failure points, improving overall product reliability. For battery-powered devices, the lightweight and integrated design of flexible circuit also helps extend battery life, enhancing user experience.

Thirdly, flexible circuit exhibits excellent environmental adaptability. Manufactured with high-performance materials such as polyimide, it can withstand extreme temperatures, humidity, and vibrations, maintaining stable electrical performance in harsh environments. This adaptability expands its application scope from indoor consumer electronics to outdoor industrial equipment, aerospace components, and other high-demand scenarios, making it a versatile component across industries.

Flexible circuit has become an indispensable core component in multiple industries, driving innovation and upgrading in diverse fields. In the consumer electronics sector, it is the key to realizing the lightweight and miniaturization of products. For example, in smart watches, flexible circuit connects display screens, sensors, and batteries in a limited space, enabling functions such as health monitoring and wireless communication. In foldable smart phones, high-performance flexible circuit ensures stable signal transmission during repeated folding, supporting the core user experience of such products.

In the industrial automation field, flexible circuit plays a vital role in intelligent sensors and control systems. Industrial sensors equipped with flexible circuit can be embedded into machinery and equipment surfaces, adapting to complex industrial environments while collecting real-time data on temperature, pressure, and operation status. This supports the construction of smart factories and realizes predictive maintenance, improving production efficiency and reducing downtime.

In the medical device industry, flexible circuit contributes to the development of precision medical equipment. For instance, in minimally invasive surgical instruments and portable diagnostic devices, flexible circuit's miniaturization and biocompatibility ensure safe and reliable operation in the human body or complex medical environments. It enables accurate signal transmission for diagnostic data, advancing the development of personalized medical care.

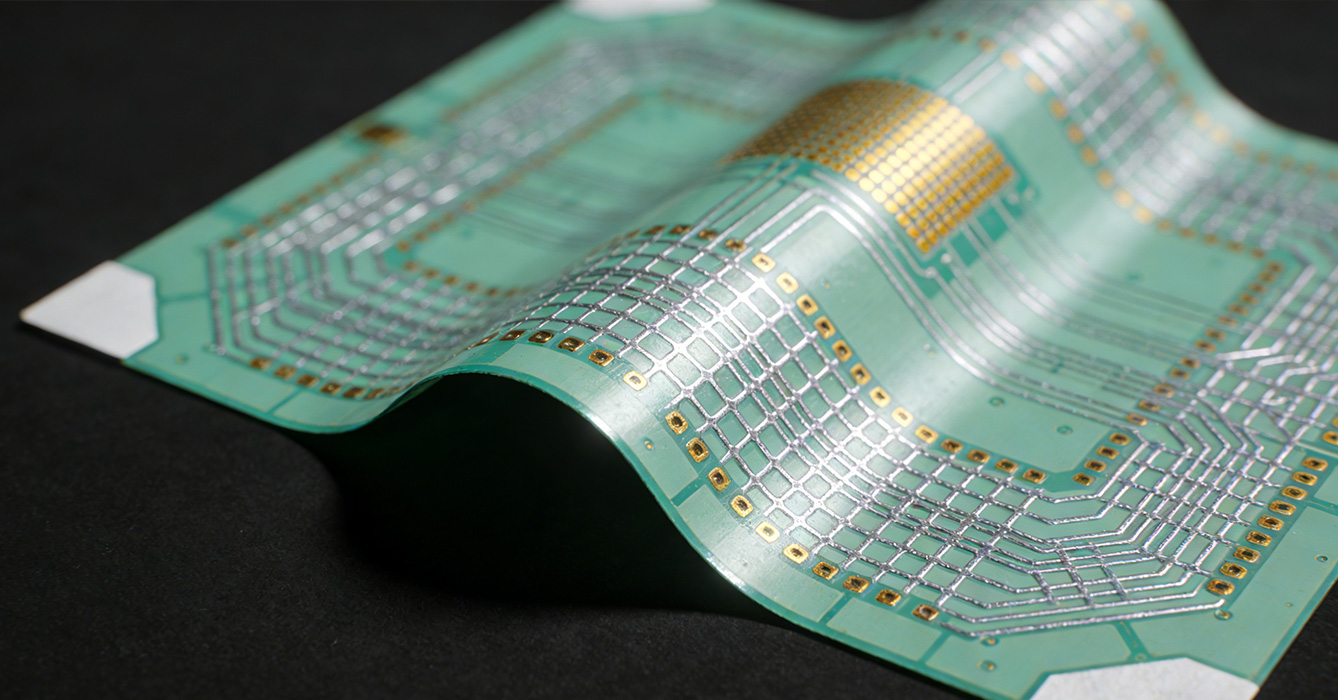

The development of flexible circuit has undergone continuous technological iteration, driven by the growing demand for high-performance electronics. In terms of material technology, traditional polyester substrates have gradually been supplemented by high-performance polyimide and liquid crystal polymer (LCP) materials. These advanced materials offer better thermal stability, signal integrity, and chemical resistance, meeting the high-frequency and high-temperature requirements of emerging technologies such as 5G and automotive electronics.

In manufacturing processes, the adoption of precision technologies such as laser drilling, automated optical inspection (AOI), and additive manufacturing has improved the production accuracy and efficiency of flexible circuit. Laser drilling enables the fabrication of ultra-fine vias, supporting higher component density, while AOI technology ensures strict quality control, reducing production defects. These technological advancements have promoted the upgrading of flexible circuit from basic signal transmission to high-performance, multi-functional integration.

As the electronic industry evolves toward intelligence and sustainability, flexible circuit is moving in two key directions. One trend is the integration of intelligent functions. Flexible circuit will gradually integrate with flexible sensors, energy-harvesting modules, and wireless communication technologies, enabling it to not only transmit signals but also collect environmental data and generate power independently. This will support the development of self-sufficient smart devices in the Internet of Things (IoT) ecosystem.

Another trend is the pursuit of sustainability. Manufacturers are increasingly adopting eco-friendly materials such as recyclable substrates and lead-free conductive materials in flexible circuit production. Meanwhile, energy-efficient manufacturing processes are being promoted to reduce carbon emissions, aligning with global carbon neutrality goals. Additionally, the development of stretchable flexible circuit will further expand its application boundaries, enabling innovative products such as smart clothing and skin-like sensors.

In conclusion, flexible circuit has become the foundation of modern flexible electronics, driving the innovation and development of electronic products through its flexibility, integration efficiency, and environmental adaptability. Its cross-industry application has reshaped the competitive landscape of consumer electronics, industrial automation, and medical devices. With continuous technological evolution and the embrace of intelligence and sustainability trends, flexible circuit will continue to play a core role in shaping the future of the electronic industry. For enterprises pursuing technological innovation, grasping the development trend of flexible circuit and leveraging its core value is an important strategy to gain a competitive edge in the market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB