-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 11. 2025, 13:33:27

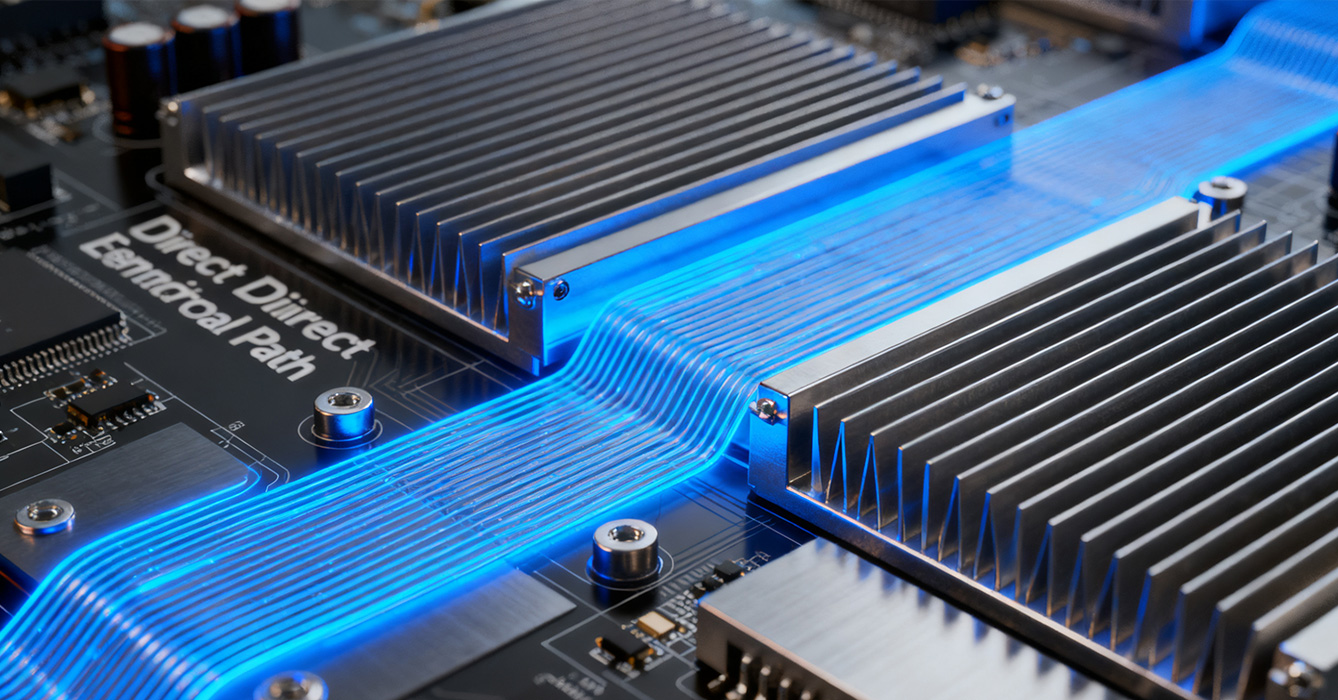

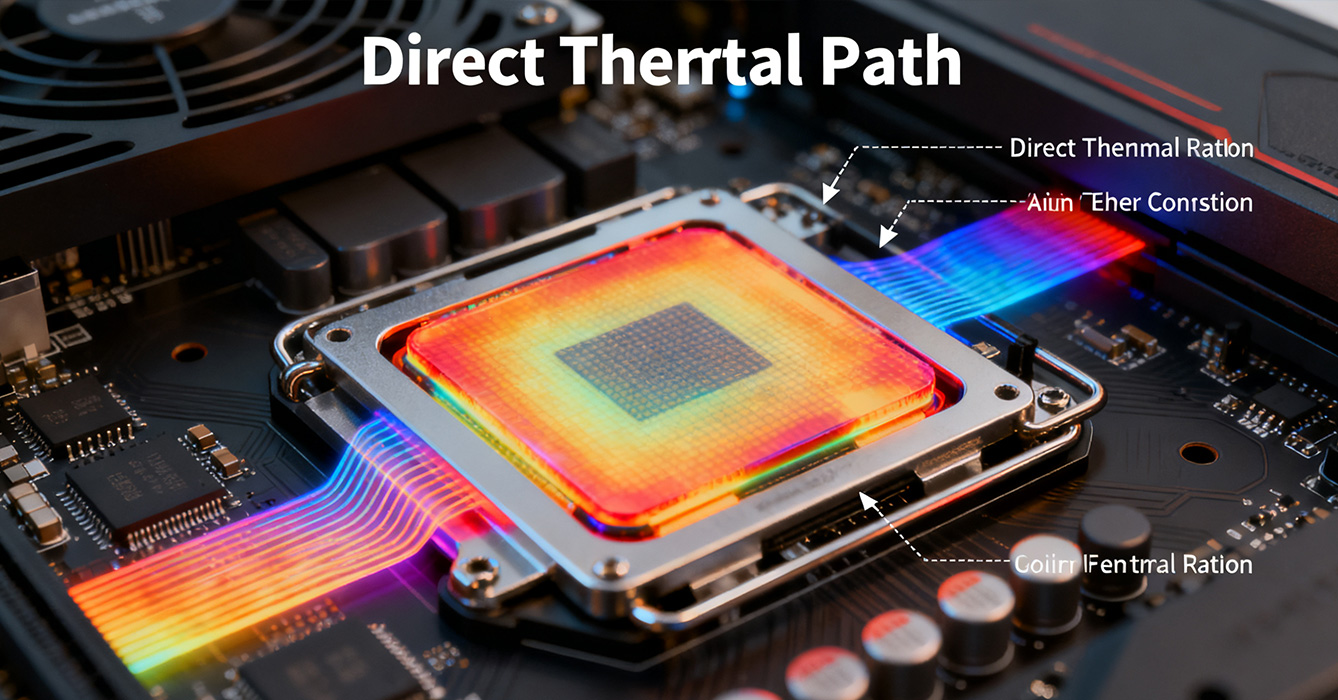

Direct Thermal Path is the backbone of effective thermal management in modern electronics, referring to the intentional design of low-resistance pathways that channel heat from high-power components directly to cooling mechanisms. Unlike generic heat dissipation approaches that rely on passive spreading alone, this engineered pathway prioritizes targeted heat migration—eliminating bottlenecks and ensuring heat reaches cooling solutions before it degrades performance or reliability. As electronics span from tiny wearables to large-scale industrial systems, Direct Thermal Path design must adapt to varying form factors, power densities, and operating environments. This article explores the tailored engineering methodologies for different heat sources, cross-domain adaptation strategies, validation techniques, and how it enables reliable operation across industries.

Direct Thermal Path design varies based on the type and distribution of heat sources, with three key methodologies:

- Point Source Path Optimization: For concentrated heat sources (e.g., power transistors, laser diodes), paths are designed as "heat funnels." Dense arrays of thermal vias are placed directly beneath the component, connecting to a dedicated thermal plane that acts as a conduit to heatsinks. This funnels heat from the small component footprint to a larger cooling surface, reducing resistance by 30–40% compared to broad-area spreading.

- Area Source Path Partitioning: For components with distributed heat (e.g., LED arrays, CPU packages), paths use partitioned thermal planes. Each section of the plane is linked to the component’s hot zones via dedicated copper traces, ensuring uniform heat migration. For example, an LED panel’s Direct Thermal Path uses separate copper strips for each LED, preventing heat from one LED affecting neighboring ones.

- Dynamic Path Routing: For systems with variable heat loads (e.g., automotive ECUs that switch between idle and high-power modes), paths include thermally conductive switches. These switches—made from shape-memory alloys or phase-change materials—redirect heat to alternate cooling paths when primary routes reach capacity, maintaining optimal flow under changing conditions.

Direct Thermal Path must overcome unique challenges in different industries, with specialized solutions:

Challenge: Extreme space constraints and skin-contact temperature limits.

Solution: Thin, flexible Direct Thermal Paths using copper-polyimide composites. These paths snake around other components (e.g., batteries, sensors) to connect heat sources to the device’s metal chassis—using the chassis as a passive heatsink without exceeding 40°C at the skin interface.

Challenge: Vibration, dust, and wide temperature swings.

Solution: Rigid Direct Thermal Paths with vibration-dampening mounts. Copper bus bars act as paths between power modules and liquid cooling jackets, while conformal coatings protect vias and planes from dust and moisture. The paths are designed to maintain integrity even as temperatures fluctuate from -20°C to 105°C.

Challenge: High power density and outdoor exposure.

Solution: Modular Direct Thermal Path networks. Multiple parallel paths connect groups of IGBTs to a central liquid cooling manifold, ensuring even heat distribution. The paths use corrosion-resistant nickel-plated copper to withstand rain, humidity, and UV exposure over decades of operation.

Ensuring Direct Thermal Path effectiveness requires rigorous validation:

- Infrared (IR) Thermal Mapping: IR cameras capture heat distribution across the PCB, revealing if paths are channeling heat as intended. Hotspots indicate bottlenecks that require path redesign (e.g., adding more thermal vias).

- Thermal Resistance Testing: Engineers measure the resistance of the entire path using heat flux sensors, comparing results to simulation models. Discrepancies highlight areas where real-world conditions (e.g., assembly tolerances) affect path performance.

- Long-Term Aging Tests: Paths are subjected to thousands of thermal cycles to simulate years of operation. This validates that materials (e.g., solder joints, TIMs) don’t degrade and disrupt heat flow over time.

Two trends are shaping the next generation of Direct Thermal Path:

- AI-Driven Path Optimization: Machine learning algorithms analyze heat simulation data to generate optimal path layouts automatically. For a new PCB design, the AI can propose thermal via positions, plane sizes, and trace routes in minutes—reducing engineering time by 50%.

- Multi-Material Path Integration: Combining materials like graphene (high conductivity) and ceramic (electrical insulation) creates hybrid paths. These paths conduct heat efficiently while isolating sensitive circuitry, enabling Direct Thermal Paths in mixed-signal systems where electrical interference is a concern.

Direct Thermal Path is not a one-size-fits-all solution but an engineered system tailored to each application’s unique heat characteristics. By optimizing paths for point, area, or dynamic heat sources, adapting to industry-specific challenges, and validating performance rigorously, it ensures electronics operate reliably across diverse environments. As power densities continue to rise, Direct Thermal Path design will remain a critical discipline—bridging the gap between component heat generation and effective cooling. For engineers, mastering its tailored methodologies is key to delivering products that balance performance, size, and longevity.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB