-

- PCB TYPE

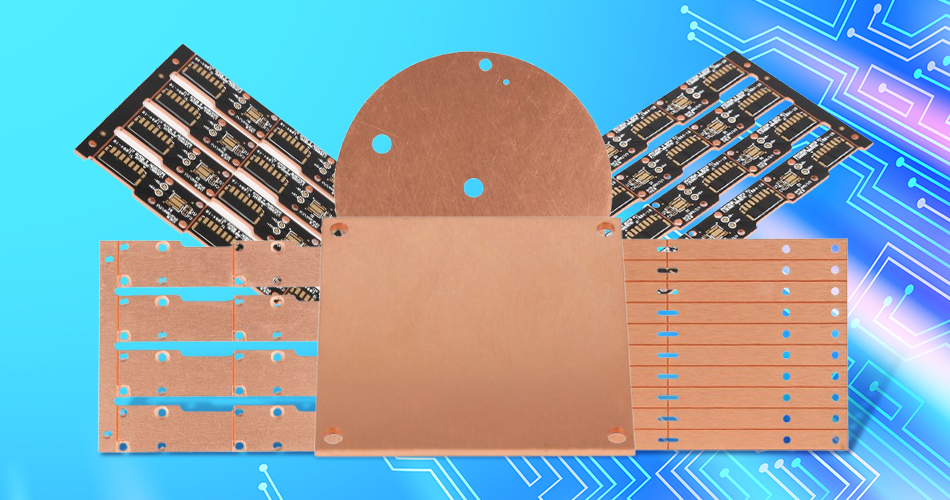

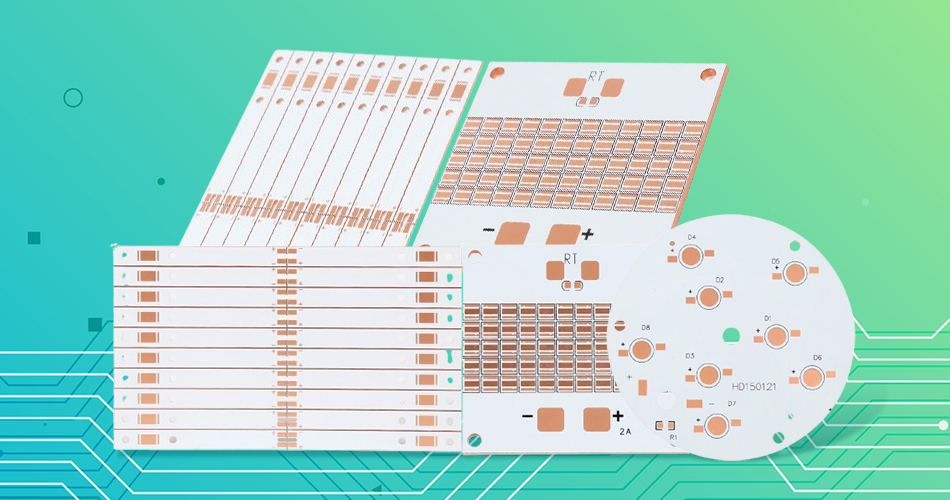

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 11. 2025, 13:31:52

High Efficiency Direct Thermal Solution represents a paradigm shift in thermal management, addressing the limitations of traditional cooling methods for today’s power-dense electronics. As devices from EV powertrains to data center servers push toward higher performance in smaller footprints, conventional thermal approaches—such as passive heatsinks or indirect heat pipes—struggle to keep up, leading to thermal throttling, reduced reliability, and increased energy waste. Unlike basic direct thermal designs, this solution emphasizes system-level efficiency: integrating advanced materials, precision heat transfer pathways, and intelligent control to minimize thermal resistance while maximizing energy efficiency. By delivering targeted, low-loss heat dissipation, it enables electronics to operate at peak performance without compromising lifespan or sustainability. This article explores the core characteristics, technical components, industry applications, and transformative impact of High Efficiency Direct Thermal Solutions.

What sets these solutions apart is their focus on holistic efficiency, defined by three key traits:

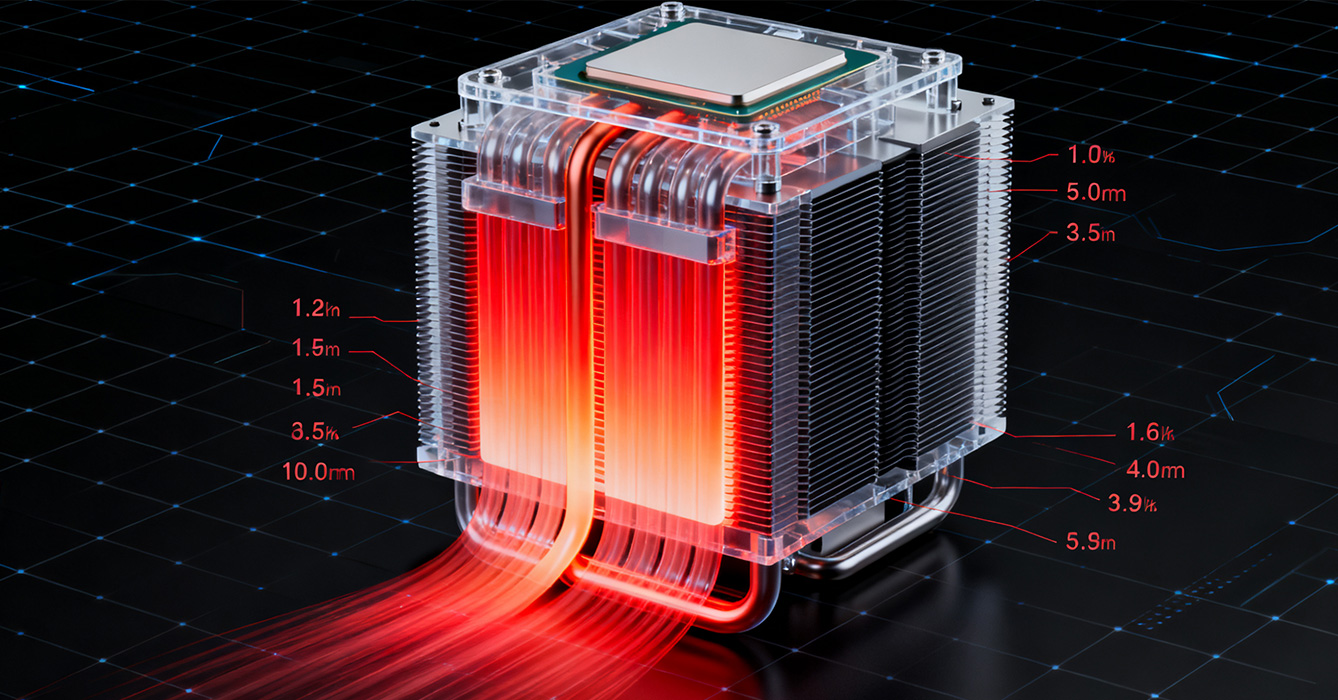

- Ultra-Low Thermal Resistance: They achieve thermal resistance as low as 0.1°C/W by eliminating intermediate heat transfer layers. For example, bonding a high-power component directly to a copper-integrated cooling base skips thermal interface materials (TIMs) that degrade over time, ensuring consistent heat flow even in long-term operation.

- Energy-Efficient Cooling: Unlike energy-intensive active cooling (e.g., high-speed fans), these solutions optimize passive cooling with augmented designs—such as finned thermal cores with enhanced surface area—or use low-power active elements (e.g., piezoelectric fans) only when necessary, cutting cooling-related energy consumption by 20–25%.

- Form-Factor Adaptability: They are engineered to fit constrained spaces, with flexible or modular designs that conform to irregular PCB shapes or component layouts. This adaptability is critical for compact devices like wearable medical monitors or EV battery packs where space is at a premium.

High Efficiency Direct Thermal Solutions rely on four integrated components to deliver superior performance:

Nanostructured TIMs—such as graphene-reinforced thermal greases or phase-change materials (PCMs)—fill microscopic gaps between components and cooling surfaces, reducing contact resistance by 35% compared to traditional TIMs. PCMs also act as thermal buffers, absorbing peak heat loads to prevent sudden temperature spikes.

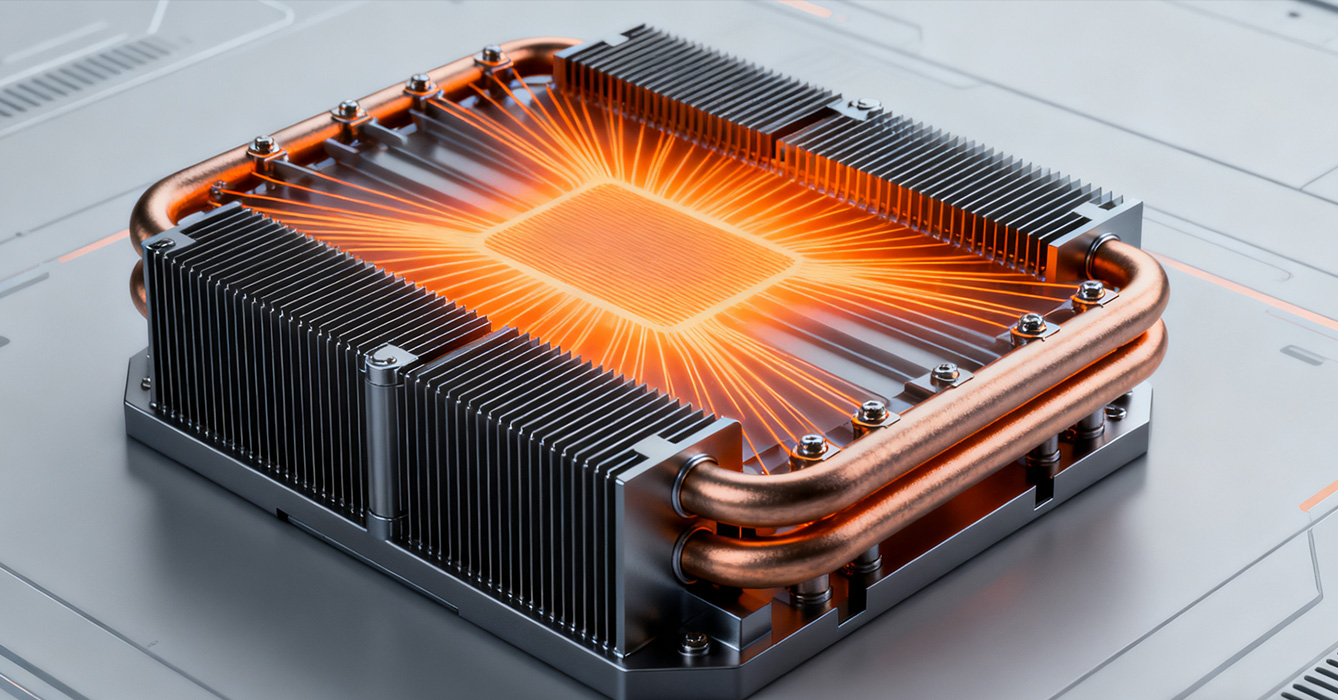

Cores made from copper-tungsten alloys or aluminum nitride (AlN) combine high thermal conductivity with mechanical stability. They are precision-machined to create micro-channels that distribute heat evenly, avoiding hotspots that degrade component performance. For example, a server CPU’s direct thermal core uses micro-channels to spread heat across a 10x larger area than the CPU die itself.

Integrated temperature sensors and microcontrollers adjust cooling output in real time. If a power transistor’s temperature rises above a threshold, the system activates auxiliary cooling (e.g., a low-power fan) or adjusts component power draw—maintaining optimal thermal conditions without wasting energy on constant maximum cooling.

For industrial or automotive applications, solutions include hermetically sealed enclosures filled with dielectric coolants. These enclosures protect the thermal path from dust, moisture, and vibration while enabling direct heat transfer from components to the coolant—critical for EV traction inverters operating in underhood environments.

HPC clusters and AI servers use these solutions to cool GPUs and CPUs operating at 300W+ power levels. Direct thermal cores bonded to processors eliminate thermal throttling, boosting computing performance by 15% while reducing cooling energy use by 22% compared to traditional air cooling.

Grid-scale battery energy storage systems (BESS) rely on them to cool lithium-ion battery modules. Direct thermal paths transfer heat from battery cells to liquid cooling loops, maintaining cell temperatures within ±2°C—extending battery lifespan by 30% and preventing thermal runaway risks.

Satellite payloads and aircraft radar systems use lightweight, high-efficiency direct thermal solutions. Aluminum-lithium heat spreaders with embedded heat pipes dissipate heat in vacuum environments, ensuring critical electronics operate reliably in extreme temperature swings (-50°C to 85°C).

The evolution of these solutions is driven by sustainability and miniaturization:

- Bionic Thermal Designs: Inspired by natural heat-dissipating structures (e.g., leaf veins), 3D-printed thermal cores with fractal micro-channels will increase surface area by 50% without increasing volume.

- Carbon-Neutral Cooling Materials: Manufacturers are developing bio-based TIMs and recycled metal heat cores to reduce the carbon footprint of thermal solutions by up to 40%.

High Efficiency Direct Thermal Solution is not just an incremental improvement but a critical enabler for next-generation power-dense electronics. By focusing on low thermal resistance, energy efficiency, and adaptability, it solves the thermal challenges that limit performance and reliability. As industries from data centers to aerospace push for higher power in smaller packages, these solutions will remain at the forefront—proving that effective thermal management is as important as component innovation for driving technological progress. For engineers and manufacturers, adopting High Efficiency Direct Thermal Solutions is key to delivering products that are both high-performing and sustainable.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB