-

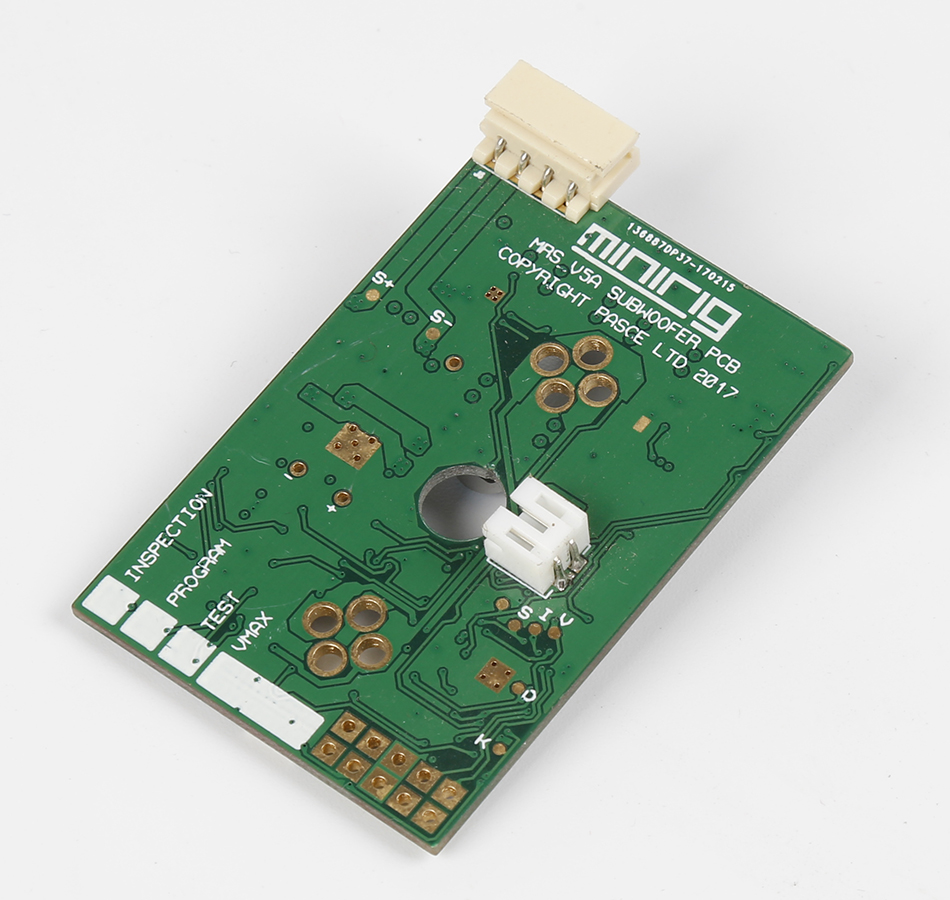

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 15. 2025, 14:23:29

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, from smartphones to kitchen appliances. Their assembly process is a crucial component in electronics manufacturing, ensuring that each device functions correctly and efficiently. In this article, we will demystify the PCB assembly process, explore its stages, and discuss why it’s essential for manufacturers to pay attention to each step.

PCB assembly is the process of connecting electronic components to a printed circuit board. This involves several steps that include placing components, soldering, and testing to ensure the board operates as intended.

The purpose of this process is to create a functional board that can control and power a device. It's a complex procedure that requires precision and attention to detail, making it essential for companies to utilize professional PCB assembly services.

Before a PCB can be assembled, it must first be designed. Engineers use specialized software to create a schematic of the board, outlining where each component will be placed. This design phase is critical because any errors can lead to malfunctioning boards.

Once the design is finalized, a prototype is created. This initial version is tested to identify any design flaws. Prototyping helps save time and resources by catching potential issues early in the process.

After the design and prototyping phase, the necessary components are sourced. This step involves acquiring all the electronic parts needed to assemble the PCB, such as resistors, capacitors, and integrated circuits.

Sourcing quality components is vital, as substandard parts can lead to failures and reliability issues in the final product.

Once all components are ready, the assembly process begins with applying solder paste to the PCB. Solder paste is a mixture of tiny solder balls and flux, which helps the solder flow and bond to the board.

A stencil is used to apply the solder paste precisely where components will be placed. This ensures that when the board is heated, the solder will melt and create a strong electrical connection.

The next step is the pick and place process, where machines automatically position components onto the PCB. These machines are highly accurate and can place thousands of components per hour.

Pick and place machines use vacuum nozzles to pick components from reels or trays and place them onto the board, aligning them with the solder paste. This automation is crucial for efficiency and accuracy, especially in high-volume manufacturing.

Once all components are in place, the board goes through reflow soldering. This involves passing the board through a specialized oven that heats it to melt the solder paste.

As the solder cools, it forms solid connections between the components and the board. Reflow soldering is a critical step, as poor solder joints can cause the board to fail.

After soldering, the PCB undergoes rigorous inspection to ensure quality. Automated optical inspection (AOI) systems are commonly used to check for misplaced components, soldering defects, and other issues.

For more complex boards, X-ray inspection might be employed to examine hidden solder joints under components. Quality control is essential to prevent faulty boards from reaching the final product.

The final stage of PCB assembly is testing. This step ensures that the board functions correctly and meets the design specifications.

Testing can involve functional tests, in-circuit tests, or a combination of both. Any boards that fail testing are either repaired or discarded, ensuring only high-quality products are shipped to customers.

Hiring professional PCB assembly services can significantly enhance the quality and reliability of electronic products. Experts in PCB assembly have the tools, experience, and knowledge to handle the complexities of the process.

Professional services also offer several advantages:

Efficiency: With advanced equipment and skilled technicians, professional assembly services can produce PCBs quickly and accurately.

Cost-Effectiveness: While it might seem cheaper to handle assembly in-house, the costs of equipment, labor, and potential errors can add up. Outsourcing can be more economical in the long run.

Quality Assurance: Reputable PCB assembly services prioritize quality control, ensuring that each board meets high standards.

Scalability: As demand increases, professional services can scale production to meet needs without compromising quality.

Understanding the PCB assembly process is crucial for anyone involved in electronics manufacturing. Each step, from design and prototyping to testing, plays a vital role in ensuring the quality and functionality of the final product.

By utilizing professional PCB assembly services, manufacturers can benefit from increased efficiency, reduced costs, and improved product quality. As technology continues to advance, the demand for reliable and efficient PCB assembly processes will only grow.

Whether you're a small startup or an established manufacturer, investing in quality PCB assembly can make a significant difference in your product's success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB