-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 16. 2025, 19:24:22

In today’s fast-paced world of electronics, the need for quick and efficient PCB assembly services is more crucial than ever. Whether you are a small startup testing a new product or an established company looking to bring a new device to market, quick-turn rigid PCB assembly services can make a significant difference in your production timeline and overall success.

Quick-turn rigid PCB assembly refers to the rapid manufacturing and assembly of rigid printed circuit boards (PCBs). This process is designed to accelerate the time it takes from designing a PCB to having a finished product ready for testing or deployment. Quick-turn services are particularly beneficial for companies that need to quickly prototype designs or those facing tight deadlines.

There are numerous benefits to using quick-turn PCB assembly services, especially when working with rigid PCBs:

Speed: The most obvious advantage is speed. Quick-turn services can reduce the typical lead times from weeks to just a few days.

Flexibility: This service provides flexibility for design changes, allowing you to iterate and improve products rapidly.

Cost-Effective Prototyping: By reducing the turnaround time, quick-turn services help lower the cost of prototyping and testing new designs.

Market Competitiveness: Faster product development cycles can give you an edge over competitors by getting your product to market sooner.

Before diving into quick-turn assembly, it’s essential to understand the role of PCB prototyping services in the design and development process. Prototyping involves creating a working model of your circuit design to test its functionality and performance. Here’s why prototyping is a critical step:

Prototyping allows engineers to:

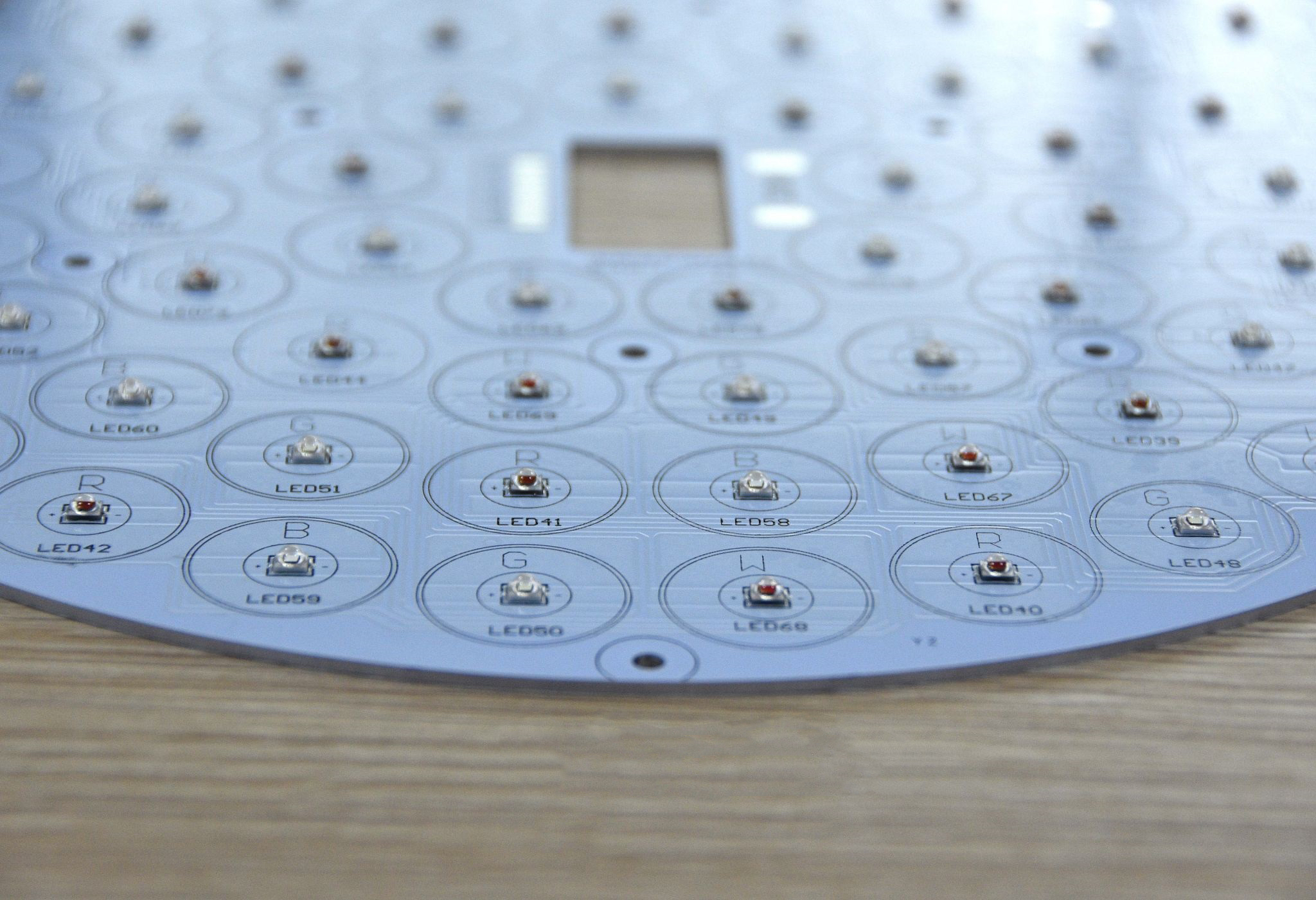

Validate Designs: Ensure the design works as intended and meets all specifications.

Identify and Fix Issues: Detect design flaws or errors before full-scale production.

Optimize Performance: Make necessary adjustments to enhance the efficiency and functionality of the PCB.

Reduce Costs: Catching and fixing issues early can save significant costs compared to post-production changes.

Design Creation: Develop a detailed design using PCB design software.

Material Selection: Choose the right materials for your PCB based on the application requirements.

Fabrication: Manufacture the bare board using the chosen materials.

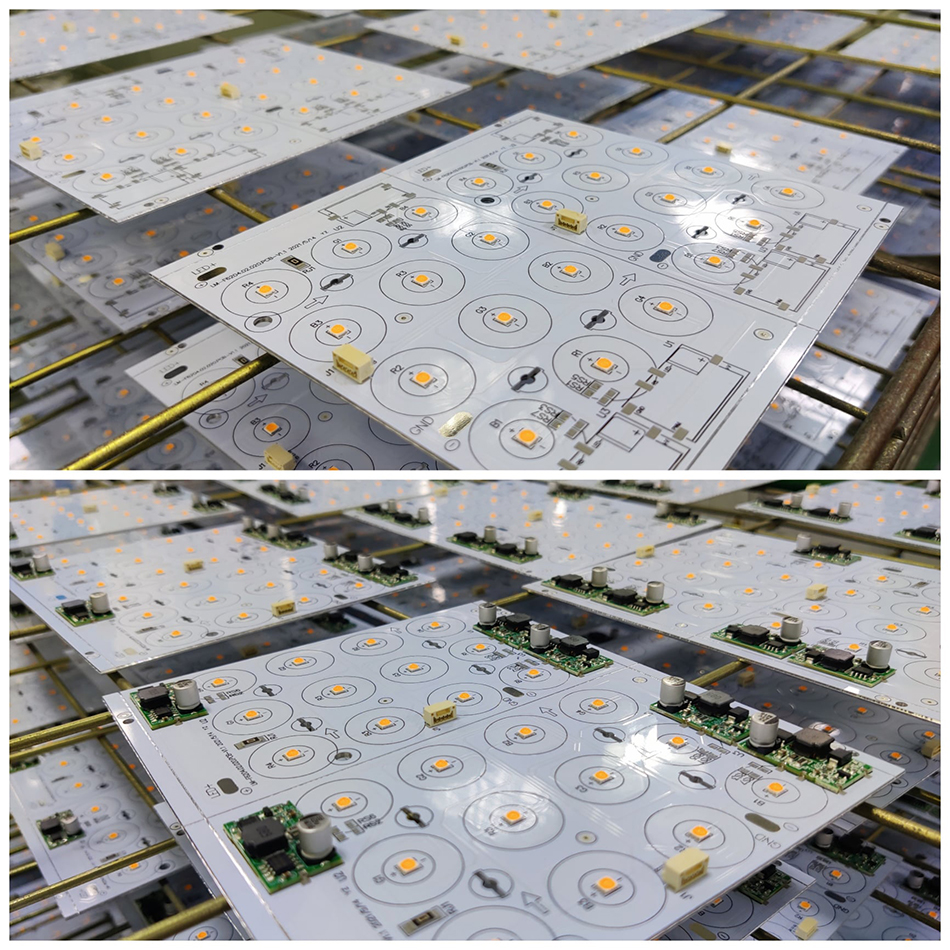

Assembly: Populate the board with components and solder them in place.

Testing: Conduct thorough testing to ensure the board operates as expected.

When you opt for a quick PCB assembly service, here’s what you can typically expect from your provider:

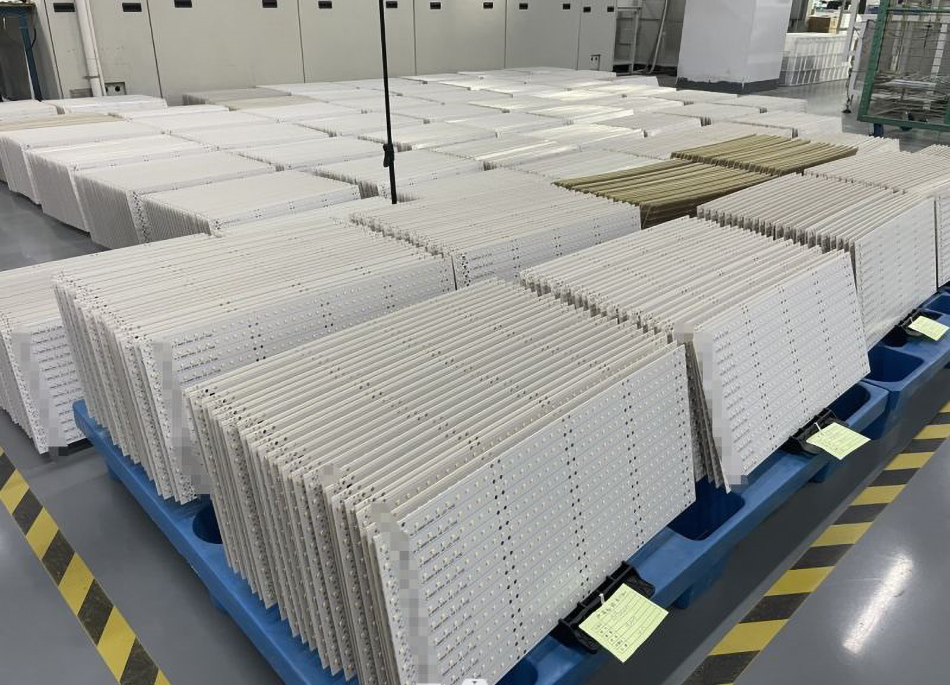

Providers of quick PCB assembly services use streamlined processes to ensure fast turnaround times. This includes automated assembly lines, advanced soldering technology, and precision testing equipment.

Despite the rapid pace, quality is never compromised. Reliable service providers adhere to stringent quality control measures to ensure each PCB meets industry standards and customer specifications.

Quick-turn services are adaptable to your project’s specific needs. Whether you need a small batch for prototyping or a larger production run, these services can scale to meet your demands.

Selecting the right service provider is crucial to the success of your project. Here are some factors to consider:

Choose a provider with a proven track record and expertise in PCB assembly. Experienced providers are more likely to deliver high-quality results and offer valuable insights throughout the process.

Good customer support is essential, especially when working under tight deadlines. Ensure that your provider offers responsive support to address any concerns or issues promptly.

Evaluate the provider’s technology and capabilities to ensure they can handle your specific requirements. Advanced machinery and skilled technicians are crucial for a successful quick-turn assembly.

While cost is always a consideration, focus on the overall value. A slightly higher price may be justified by faster turnaround times, better quality, and superior support.

Quick-turn rigid PCB assembly services play a vital role in today’s electronics industry. By reducing lead times and offering flexibility, these services enable companies to innovate faster and bring products to market more efficiently. Whether you’re prototyping a new design or preparing for a production run, choosing the right quick PCB assembly service can make all the difference in achieving your project goals.

By understanding the benefits and selecting a reputable provider, you can ensure that your PCBs are assembled quickly, accurately, and to the highest standards. Embrace the advantages of quick-turn services and stay ahead in the ever-evolving world of electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB