-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 26. 2025, 10:08:22

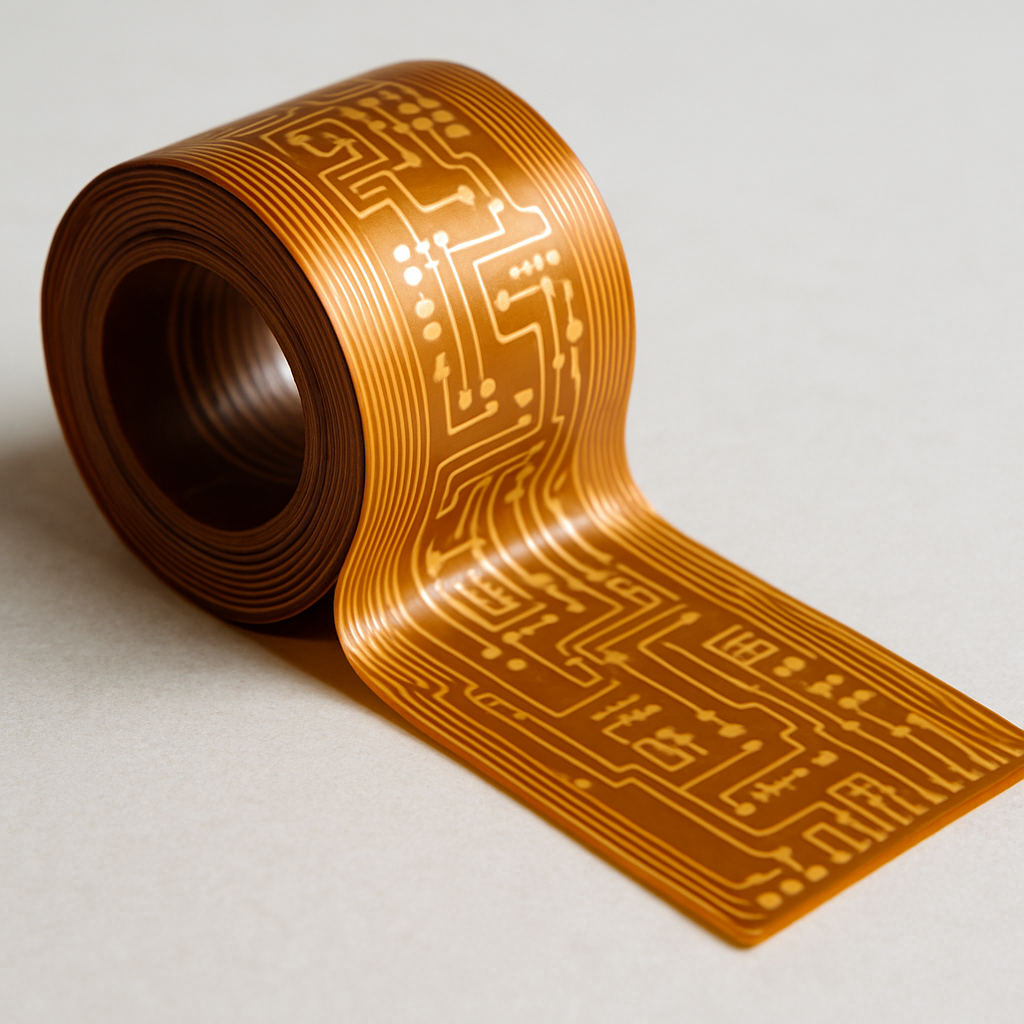

In today's fast-paced electronic world, the demand for smaller, lighter, and more flexible devices is ever-increasing. This demand has paved the way for innovative manufacturing processes like roll-to-roll flexible PCB manufacturing. But what exactly is this process, and why is it gaining so much attention in the electronics industry? Let's dive into the world of flexible circuit boards and explore the intricacies of their manufacturing process.

Flexible circuit boards, often referred to as flex PCBs, are printed circuit boards designed to be flexible, as opposed to the rigid PCBs used in many traditional electronic devices. This flexibility allows them to be bent, twisted, or folded into virtually any shape, making them ideal for a wide range of applications, from wearable electronics to medical devices.

One of the main benefits of flexible PCBs is their ability to fit into compact and irregularly shaped spaces, which is crucial for modern electronics. Additionally, they are lightweight, reducing the overall weight of devices. Their flexibility also enhances durability, as they can absorb stresses and vibrations without breaking.

Flexible PCBs are used in a variety of applications. They are commonly found in consumer electronics like smartphones and tablets, where space is at a premium. They are also used in the automotive industry for dashboard displays and in medical devices where they need to conform to the human body.

Roll-to-roll (R2R) manufacturing is a process used to produce flexible PCBs in a continuous roll format, rather than as individual pieces. This method is particularly suited for large-scale production and offers several advantages over traditional methods.

In roll-to-roll manufacturing, a flexible substrate, often made of polyimide or polyester, is fed through a series of rollers. As it moves, various processes such as coating, printing, and etching are applied to create the desired circuit pattern. The continuous nature of this process allows for high-speed production, significantly reducing manufacturing time and costs.

Roll-to-roll manufacturing offers several benefits. It is highly efficient, as the continuous process minimizes downtime between production stages. It is also cost-effective, as it reduces material waste and labor costs. Additionally, R2R manufacturing allows for consistent quality, as the automated process minimizes human error.

While roll-to-roll manufacturing streamlines the production of flexible PCBs, it still involves several key steps that ensure the quality and functionality of the final product.

The first step in the process is preparing the substrate. This involves cleaning and treating the flexible material to ensure it adheres properly to subsequent layers. A clean substrate is crucial for preventing defects in the final product.

The next step is creating the circuit pattern on the substrate. This is typically done using a photolithographic process, where light-sensitive chemicals are used to imprint the circuit design onto the substrate. This step is critical, as it determines the functionality of the PCB.

Once the circuit pattern is applied, the substrate undergoes etching to remove unwanted material, leaving behind the desired circuit paths. Plating is then used to add a thin layer of metal, such as copper, to improve electrical conductivity.

After the circuit paths are established, components are added to the PCB through a process called assembly. This involves placing and soldering electronic components onto the board. Finally, the finished PCB undergoes testing to ensure it meets all performance and quality standards.

While roll-to-roll manufacturing offers many advantages, it also presents certain challenges that manufacturers must address to maintain quality and efficiency.

Handling flexible materials can be challenging, as they are prone to stretching and tearing during processing. Manufacturers must carefully control tension and alignment to prevent defects.

Ensuring precise alignment of the circuit patterns is crucial to the functionality of the PCB. Any misalignment can lead to faulty connections or short circuits, impacting the performance of the final product.

Maintaining consistent quality throughout the roll-to-roll process requires rigorous quality control measures. Automated inspection systems are often used to detect defects early in the production process, allowing for corrective actions to be taken.

As technology continues to advance, the demand for flexible PCBs is expected to grow. Roll-to-roll manufacturing is poised to become a key player in meeting this demand, offering a scalable and cost-effective solution for producing high-quality flexible circuit boards.

Future innovations in roll-to-roll manufacturing may include the integration of more advanced materials and processes, such as the use of conductive inks and 3D printing techniques. These advancements could further enhance the capabilities and applications of flexible PCBs.

As with all manufacturing processes, sustainability is a growing concern. Efforts are being made to develop more eco-friendly materials and processes in roll-to-roll PCB manufacturing, reducing waste and minimizing environmental impact.

Roll-to-roll flexible PCB manufacturing is transforming the electronics industry by offering a versatile and efficient method for producing flexible circuit boards. With its many advantages, this process is set to play a pivotal role in the future of electronics manufacturing, supporting the development of innovative and compact devices that meet the needs of tomorrow's consumers.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB