-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 26. 2025, 10:03:38

In the world of electronics, the demand for smaller, more efficient, and versatile components is constantly rising. One technology that has emerged to meet these needs is the polyimide flexible circuit board. Known for its exceptional flexibility and reliability, it has become a cornerstone in modern electronic design and manufacturing. This article will delve into what polyimide flexible circuit boards are, their benefits, applications, and how they compare to traditional rigid circuit boards.

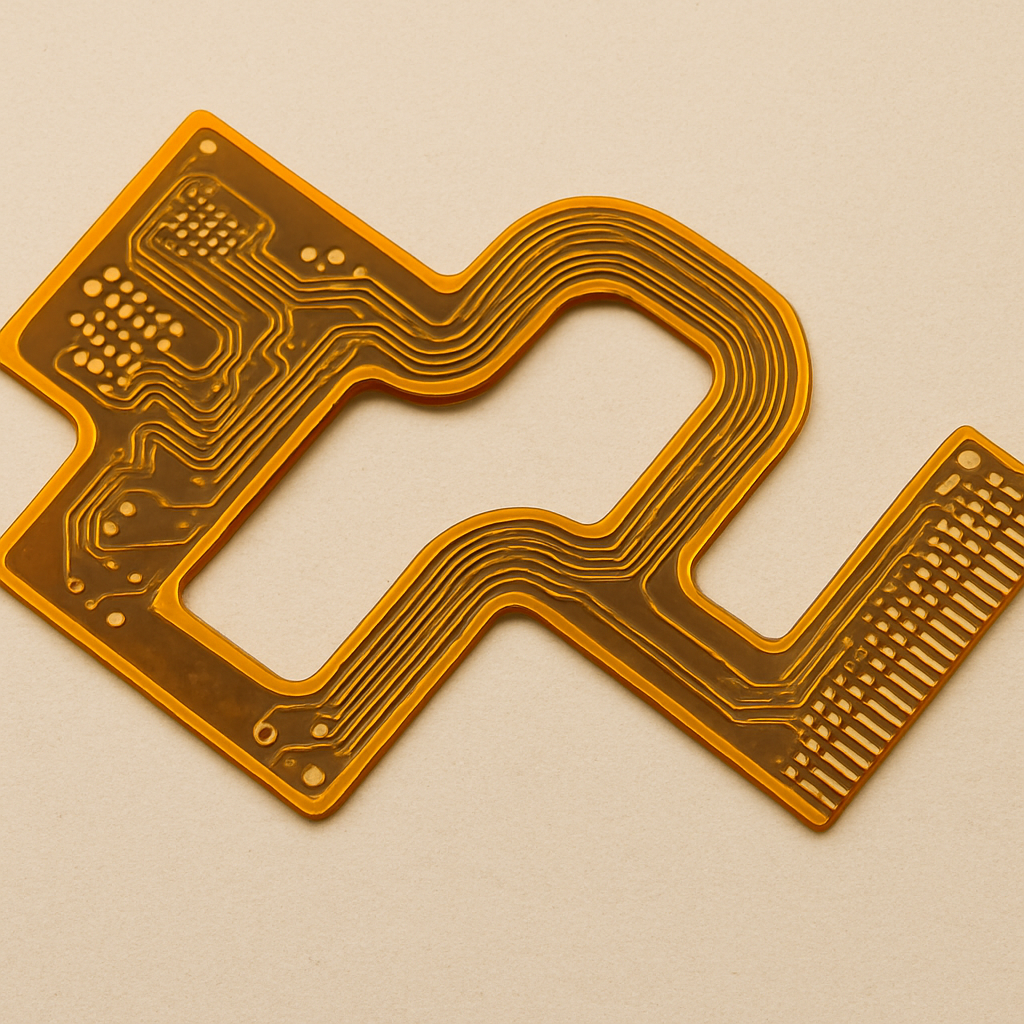

Polyimide flexible circuit boards, often referred to as flex PCBs, are a type of printed circuit board that can bend and flex. Unlike traditional rigid PCBs, these are built on a flexible polyimide film. Polyimide is a type of polymer known for its excellent thermal stability, mechanical strength, and chemical resistance, making it an ideal material for flexible PCBs.

These circuit boards are composed of a conductive layer, usually made from copper, laminated between insulating layers of polyimide. The flexible nature of these boards allows them to be bent, folded, and twisted to fit into complex and compact spaces that rigid circuit boards cannot.

One of the most significant advantages of polyimide flexible circuit boards is their ability to bend and adapt to different shapes and spaces. This flexibility allows for more innovative and compact designs in electronic devices. Devices like smartphones, cameras, and wearable technology all benefit from the space-saving properties of flex PCBs.

Polyimide is known for its strength and durability. Flexible circuit boards made from this material can withstand harsh environmental conditions, such as extreme temperatures and exposure to chemicals. This durability makes them suitable for applications in industries like aerospace and medical devices, where reliability is paramount.

Flexible PCBs are generally lighter than their rigid counterparts, which can be a critical factor in industries like automotive and aerospace, where reducing weight is essential. Additionally, the ability to reduce the number of connectors and solder joints by integrating multiple layers into a single flexible board can lead to cost savings in manufacturing and assembly.

The design of flexible circuit boards often results in improved signal integrity. The reduced number of interconnects and shorter signal paths minimize potential points of failure and electromagnetic interference, which is crucial for maintaining the performance of high-speed electronic devices.

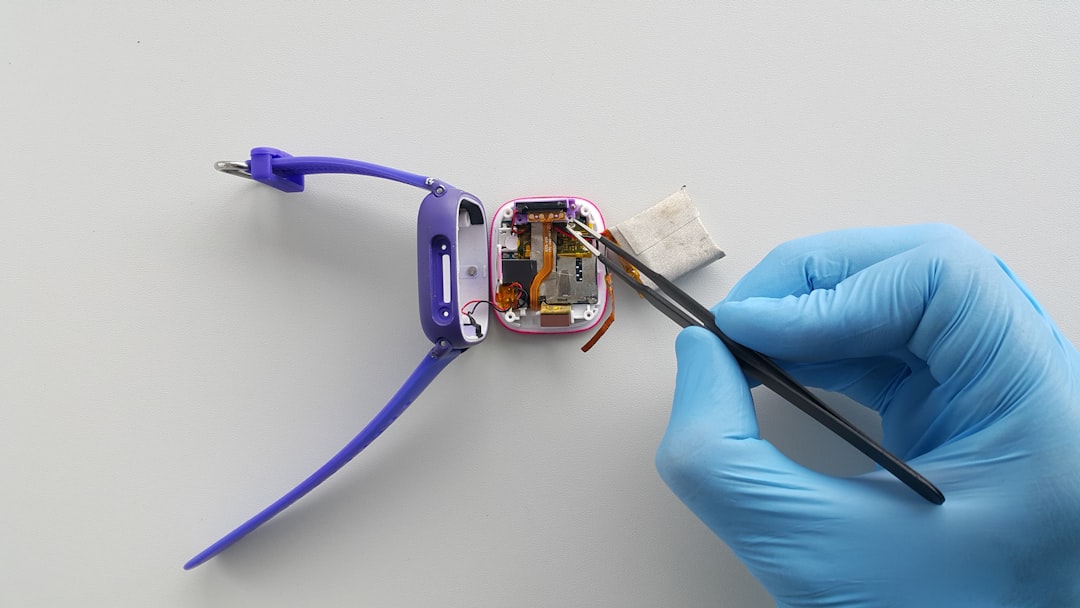

In consumer electronics, space is often at a premium. Flexible circuit boards allow manufacturers to design thinner and more compact devices. Smartphones, tablets, and laptops often use flex PCBs to connect components like cameras and displays, enabling sleek, lightweight designs without compromising functionality.

Medical devices often require flexible and reliable circuit boards that can operate in challenging environments. Flexible PCBs are used in a variety of medical applications, including wearable health monitors, implantable devices, and diagnostic equipment. Their flexibility and durability make them ideal for medical technology that requires consistent performance under demanding conditions.

The automotive and aerospace industries demand high performance and reliability from their components. Flexible circuit boards are used in these sectors for applications such as engine controls, sensors, and lighting systems. Their ability to withstand extreme temperatures and vibrations makes them particularly well-suited for these environments.

In industrial settings, flexible PCBs are used in machines and equipment that require robust, reliable connections. They are often found in control systems, sensors, and robotic arms, where their durability and flexibility offer significant advantages over traditional rigid boards.

While both flexible and rigid circuit boards serve to connect electronic components, they offer different benefits and limitations.

Flexible circuit boards can be bent and shaped to fit into spaces that rigid boards cannot, providing greater design flexibility. This makes them ideal for applications where space is limited or where the board needs to conform to a specific shape.

Rigid circuit boards require more connectors and solder joints, which can increase the risk of failure points and signal interference. Flexible PCBs can integrate multiple layers into a single board, reducing the need for additional connections and enhancing reliability.

The initial cost of producing flexible circuit boards can be higher due to the complexity of their design and manufacturing process. However, the potential cost savings in assembly and the reduced need for connectors can offset these initial expenses.

Rigid circuit boards can be more susceptible to damage from vibrations and environmental factors. In contrast, flexible PCBs, especially those made with polyimide, offer superior durability and resistance to harsh conditions, making them suitable for more demanding applications.

When designing with polyimide flexible circuit boards, engineers must consider several factors to optimize performance and reliability.

Choosing the right materials for the conductive and insulating layers is crucial. Copper is commonly used for the conductive layer due to its excellent electrical properties, while polyimide remains the preferred choice for the insulating layers because of its flexibility and thermal stability.

Designers must carefully plan the configuration of layers within the flexible PCB to ensure optimal performance. This includes determining the number of layers, the thickness of each layer, and the arrangement of conductive traces to minimize interference and maximize signal integrity.

Thorough testing and validation are essential to ensure that the flexible circuit board meets the required specifications and performance criteria. This includes testing for electrical performance, mechanical durability, and environmental resistance.

Polyimide flexible circuit boards represent a significant advancement in electronic design and manufacturing, offering unparalleled flexibility, durability, and efficiency. As technology continues to evolve, the demand for these versatile components will only increase, paving the way for more innovative and compact electronic devices. Whether in consumer electronics, medical devices, or industrial equipment, the benefits of polyimide flexible circuit boards are undeniable, making them an essential component in the future of electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB