-

- PCB TYPE

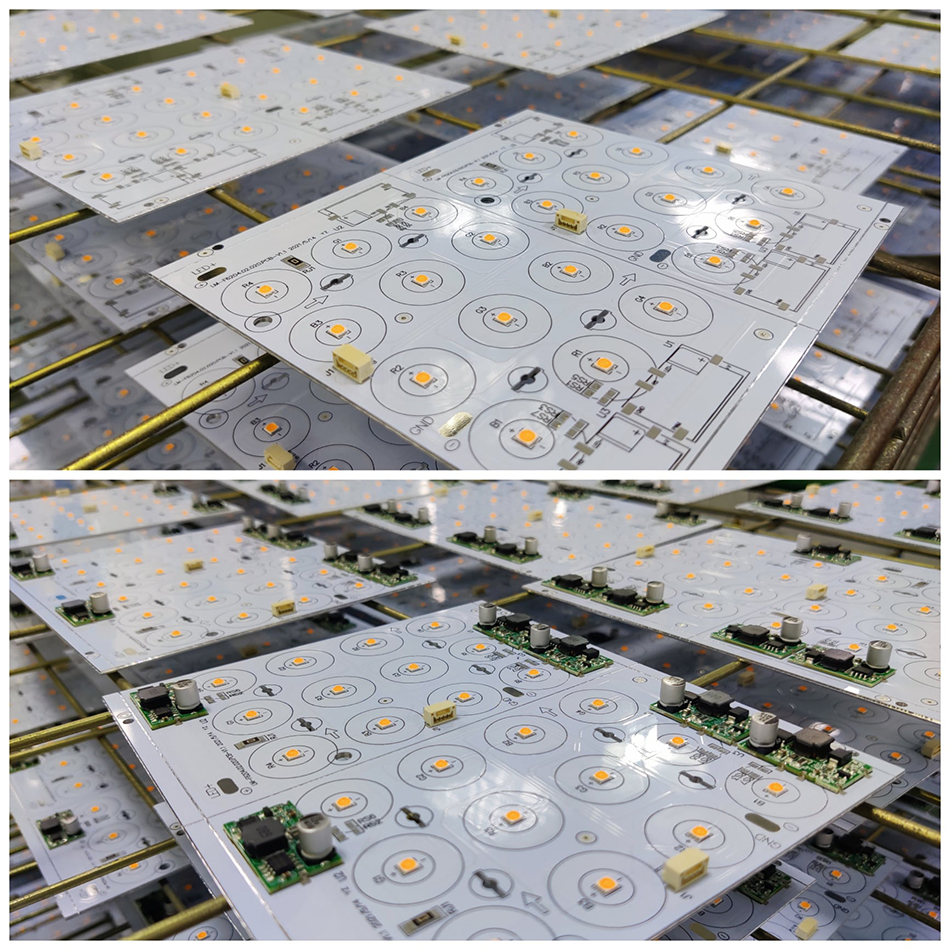

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 06. 2025, 09:40:05

Electromechanical Assembly is the foundational process of merging mechanical components (gears, motors, enclosures) with electrical systems (PCBs, wiring harnesses, sensors) to create functional, integrated devices. Unlike specialized subsets like precision or industrial electromechanical assembly, this core discipline focuses on systematic synergy—ensuring mechanical motion and electronic control work in harmony across diverse applications, from everyday consumer gadgets to mid-scale industrial equipment. It acts as the backbone of modern manufacturing, transforming disjointed parts into cohesive products that balance performance, cost, and usability. As electronics grow more intertwined with mechanical systems (driven by IoT and automation), electromechanical assembly has evolved from a technical step to a strategic enabler of product innovation. This article explores its core value, cross-industry applications, key technical pillars, and evolving role in smart manufacturing.

Electromechanical assembly delivers three irreplaceable benefits to product development:

- Mechanical-Electronic Fusion: It resolves compatibility challenges between mechanical and electrical components. For example, aligning a small DC motor with a PCB’s driver circuit requires precise mounting to avoid vibration-induced signal interference—a task central to electromechanical assembly.

- Complexity Simplification: By integrating sub-systems (e.g., a printer’s paper feed mechanism with its control board), it reduces the complexity of final product assembly, cutting production time and error rates.

- Reliability Enhancement: Properly executed assembly ensures robust connections (e.g., strain-relieved wiring, corrosion-resistant terminals) that prevent premature failures, extending product lifespan and reducing warranty costs.

Electromechanical assembly is ubiquitous across sectors, adapting to diverse functional needs:

Devices like laptops, printers, and gaming consoles rely on it to integrate mechanical parts (keyboards, cooling fans) with electronics (motherboards, power supplies). For instance, a laptop’s hinge assembly must be calibrated to work with its lid-sensor circuit, ensuring the screen turns on/off smoothly when opened or closed.

Smart refrigerators, robotic vacuums, and HVAC systems use electromechanical assembly to link mechanical actuators (e.g., fridge door motors, vacuum brushes) with IoT-enabled control modules. This integration lets users remotely monitor and adjust device functions via smartphone apps.

Conveyor belts, automated sorting systems, and warehouse robots depend on it to synchronize motor-driven mechanical components with proximity sensors and control PCBs. For example, a sorting machine’s mechanical arms are aligned with optical sensors to direct packages to the correct bins.

Successful electromechanical assembly relies on three technical foundations:

Using industry-standard connectors (e.g., USB-C, terminal blocks) and mounting protocols ensures components from different suppliers work seamlessly together, reducing customization costs and simplifying repairs.

Assembling pre-tested modular sub-systems (e.g., pre-wired motor units) speeds up production. For example, a manufacturer can produce multiple appliance models using the same electromechanical motor module,Just adjust the exterior housing.

Post-assembly testing uses automated tools to verify mechanical motion (e.g., motor speed, actuator travel) and electrical performance (e.g., signal continuity, sensor accuracy) simultaneously. This ensures every unit meets specifications before shipping.

Electromechanical assembly is evolving with smart manufacturing:

- Digital Twin Simulation: Virtual replicas of assemblies let engineers test mechanical-electronic interactions before physical production, reducing rework and optimizing designs.

- Sustainable Materials: Use of recycled plastics for enclosures and lead-free solder for connections aligns assembly with global eco-friendly manufacturing goals.

- Cobotic Assembly: Collaborative robots assist human technicians with repetitive tasks (e.g., wiring harness installation), improving efficiency while maintaining precision for complex alignments.

Electromechanical Assembly is the unsung connector of modern product development, merging mechanical and electronic worlds to create the devices and systems we rely on daily. Its ability to simplify complexity, enhance reliability, and adapt across industries makes it indispensable for manufacturers. As smart technology and sustainability become central to product design, electromechanical assembly will continue to innovate—blending traditional craftsmanship with digital tools to deliver cost-effective, high-performance solutions. For businesses, mastering this core discipline is key to staying competitive in a market where seamless integration and user-centric design drive success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB