-

- PCB TYPE

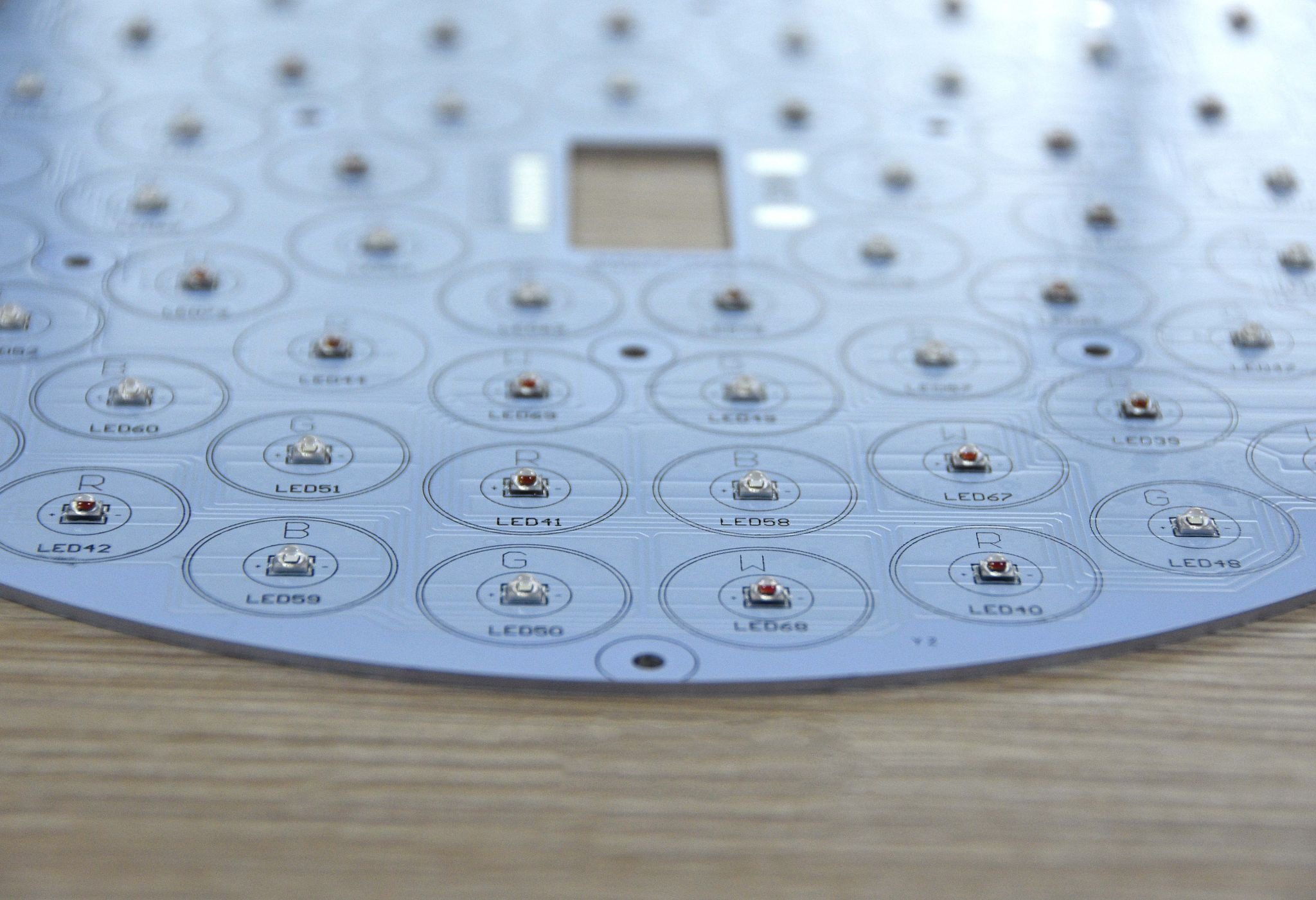

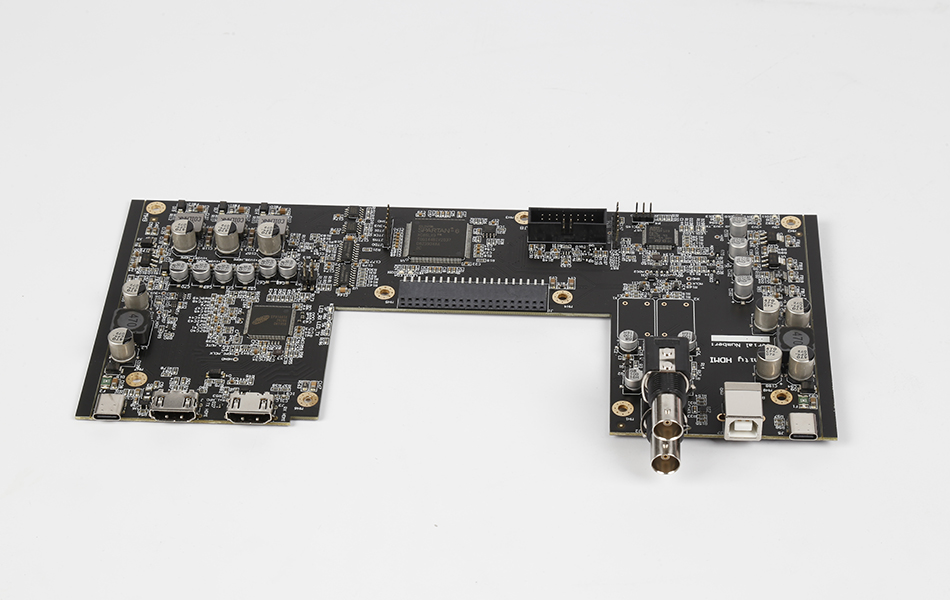

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 06. 2025, 09:41:52

PCB Assembly has transcended traditional manufacturing boundaries to become a nexus of digital collaboration and supply chain resilience—critical traits in today’s volatile electronics landscape. As global disruptions (component shortages, geopolitical shifts) and technical demands (higher density, faster prototyping) intensify, PCB assembly no longer hinges solely on precision soldering but on seamless integration of cross-functional teams, agile supply networks, and innovative technologies. This evolution empowers manufacturers to navigate uncertainties while delivering high-quality, on-time assemblies for applications ranging from automotive infotainment to industrial IoT gateways. This article explores how digital collaboration redefines workflow efficiency, strategies for building supply chain resilience, and emerging technologies shaping the next era of PCB assembly.

The traditional linear PCB assembly workflow—design → sourcing → production → testing—is being replaced by iterative, cross-team collaboration powered by cloud and data tools:

- Cloud-Based Design Ecosystems: Engineers, procurement teams, and assembly partners access shared CAD platforms (e.g., Altium 365) to review designs in real time. This allows procurement to flag long-lead components during the DFM phase, while assembly teams suggest tweaks for better solderability—reducing design iterations by 30–40%.

- Real-Time Production Dashboards: Stakeholders across locations monitor assembly progress via cloud dashboards that display KPIs like solder defect rates, component stock levels, and reflow oven efficiency. For example, a design team in California can track the production of their PCB in a Vietnam facility, addressing issues (e.g., unexpected component substitutions) as they arise.

- Collaborative Quality Control: AI-powered inspection tools (AOI/X-ray) share defect data with design and assembly teams simultaneously. Engineers can trace recurring issues (e.g., tombstoning of 0402 components) back to design choices, while assembly technicians adjust placement parameters—creating a closed-loop improvement cycle.

Resilient supply chains are no longer optional but essential for consistent PCB assembly, with three key strategies emerging:

Manufacturers maintain approved vendor lists (AVLs) with 2–3 suppliers per critical component, including regional alternatives to mitigate geopolitical risks. Pre-qualification of substitute components (e.g., equivalent resistors from different brands) ensures production can continue if primary sources are unavailable, cutting downtime by up to 50% during shortages.

Data-driven inventory tools use demand forecasting and historical usage to stock “buffer” components for high-volume or hard-to-source parts. Just-in-time (JIT) principles are balanced with safety stocks—for example, a medical device manufacturer might keep 3 months of supply for a custom PCB connector to avoid production halts.

Nearshoring or regional assembly hubs reduce reliance on single global facilities. A European automotive supplier, for instance, might partner with PCB assemblers in Poland and Romania to serve local car plants, minimizing shipping delays and customs complexities.

- 3D-Printed Solder Masks: Additive manufacturing is being used to print custom solder masks directly onto PCBs, enabling faster prototyping of complex designs (e.g., curved or irregularly shaped boards) without the need for traditional stencils.

- Digital Thread Integration: A continuous data thread connects every stage of PCB assembly—from design files to test reports—ensuring full traceability. This is critical for industries like aerospace, where regulators require detailed documentation of every component’s origin and assembly steps.

- Autonomous Guided Vehicles (AGVs): AGVs transport PCBs between assembly stations (printing → placement → reflow) in high-volume facilities, reducing human error and increasing throughput by optimizing material flow.

Car manufacturers use digital collaboration to align PCB assembly with vehicle production schedules. For example, a Tesla supplier shares real-time component stock data with Tesla’s design team, enabling proactive adjustments to infotainment PCB designs if a chip is delayed.

IIoT device makers rely on regional assembly hubs to deliver PCBs to factories in remote locations. A mining equipment manufacturer, for instance, uses a South African assembly partner to supply sensor PCBs, avoiding long shipping times from Asia and ensuring timely maintenance of mining machinery.

PCB Assembly has evolved into a resilient, collaborative discipline that leverages digital tools and agile strategies to thrive in uncertain times. By breaking down silos through cloud-based collaboration, building flexible supply chains, and adopting emerging technologies, manufacturers can deliver consistent, high-quality assemblies while adapting to disruptions. As electronics become more integral to every industry, this focus on resilience and collaboration will remain the cornerstone of successful PCB assembly—ensuring it continues to power innovation in a dynamic world.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB