-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 31. 2025, 15:03:18

In recent years, energy efficiency has become a crucial consideration in electronic design and manufacturing. LED technology, particularly energy-efficient LED PCB (Printed Circuit Board) assembly, has gained prominence for its potential to reduce power consumption and enhance performance. This article delves into the significance of LED PCB assembly, exploring how it contributes to energy efficiency and discussing the components and processes involved.

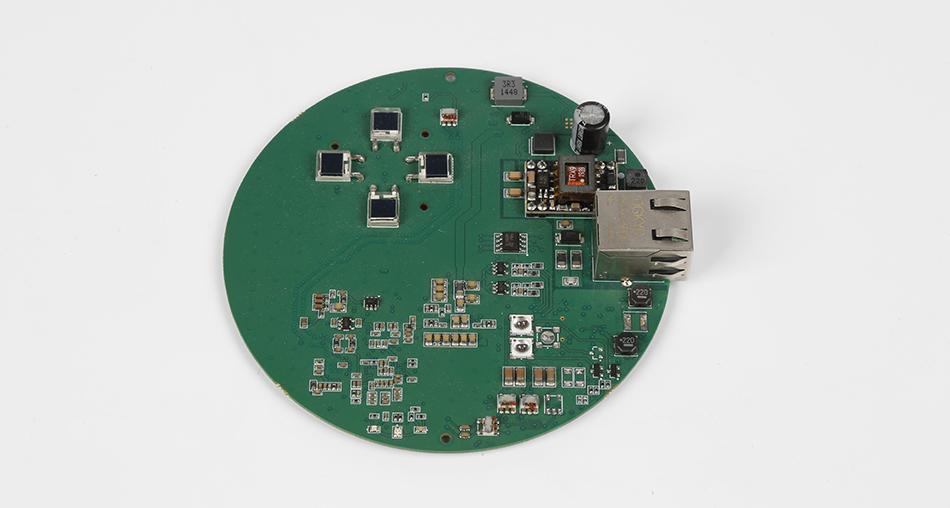

An LED circuit board is a printed circuit board specifically designed to connect and power light-emitting diodes (LEDs). These boards play a vital role in providing a stable and efficient platform for LEDs to operate. The primary function of LED circuit boards is to connect the LEDs to a power source while ensuring optimal thermal management to prevent overheating.

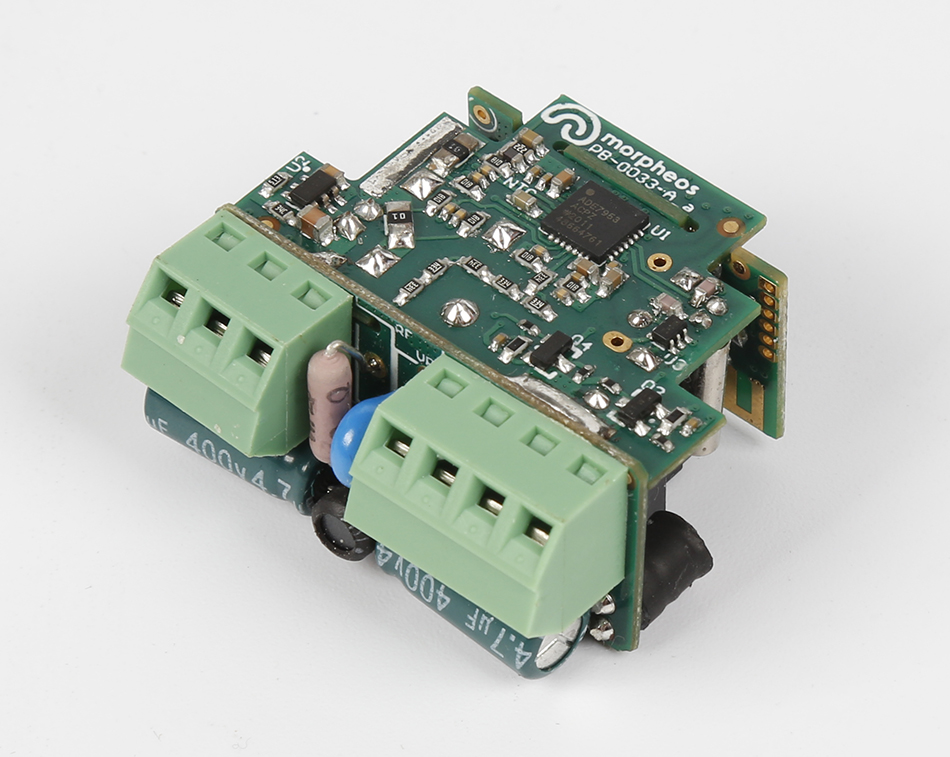

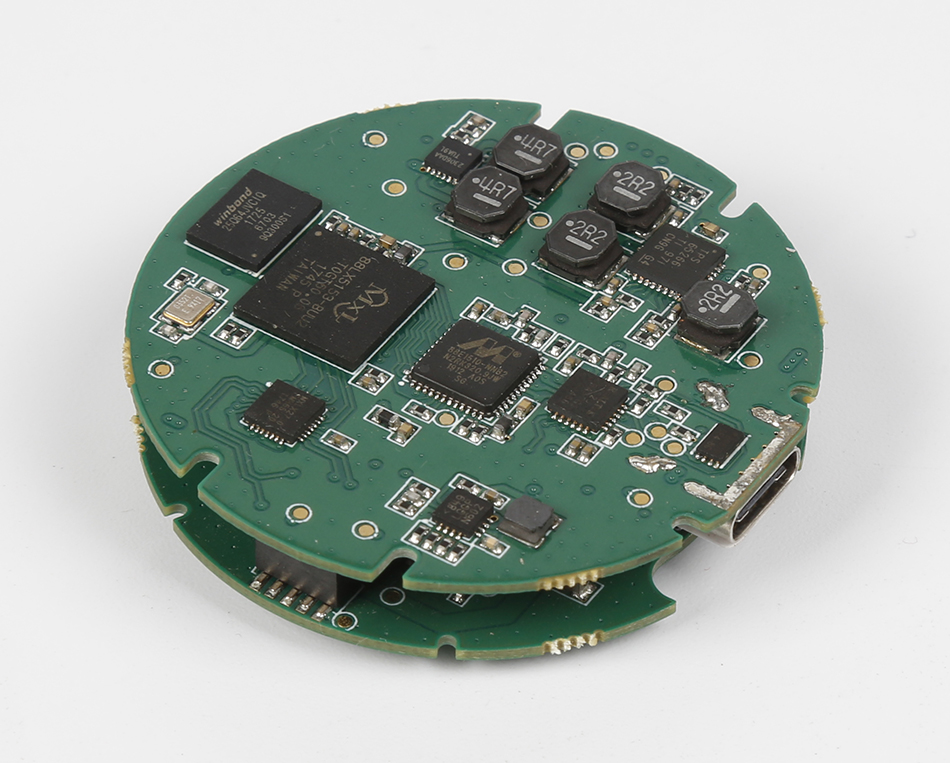

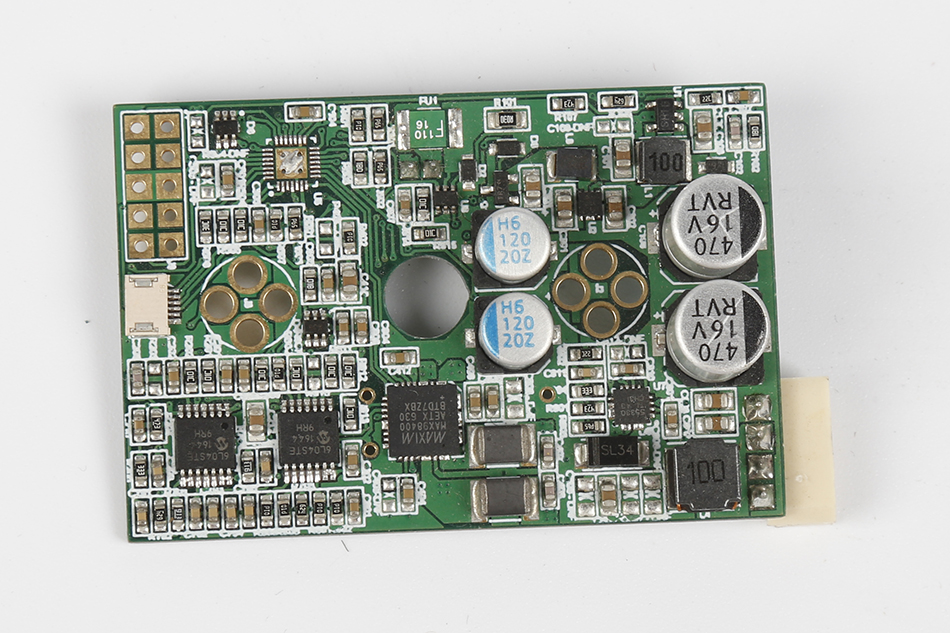

An LED PCB assembly comprises various components that work in harmony to ensure efficient LED performance. These include:

Substrate Material: The substrate forms the base of the PCB and is typically made of materials like aluminum or fiberglass. Aluminum is preferred for its excellent heat dissipation properties, which are crucial for maintaining LED performance.

Copper Traces: Copper traces are conductive pathways etched onto the substrate, connecting different components of the circuit. They enable the flow of electricity and are essential for the functioning of the LED circuit board.

Solder Mask: This protective layer is applied over the copper traces to prevent oxidation and short circuits. It also enhances the board's durability and reliability.

LEDs: The core components of the assembly, LEDs emit light when an electric current passes through them. Their arrangement on the PCB determines the overall illumination pattern and efficiency.

Resistors and Capacitors: These components regulate the flow of current, preventing damage to the LEDs and ensuring consistent performance.

Energy-efficient LED PCB assembly is crucial in reducing power consumption, making it an environmentally friendly and cost-effective solution. By optimizing the design and components of the PCB, manufacturers can minimize energy wastage and maximize the luminous efficacy of LEDs.

A well-designed LED PCB assembly enhances the overall performance of LED lighting systems. Efficient thermal management, achieved through proper substrate selection and copper trace design, prevents overheating and ensures the longevity of the LEDs. This, in turn, reduces maintenance costs and increases the lifespan of the lighting system.

Energy-efficient LED PCB assemblies contribute to a reduced carbon footprint. By consuming less power, these assemblies lower greenhouse gas emissions and decrease reliance on fossil fuels. This aligns with global efforts to combat climate change and promotes sustainable practices in the electronics industry.

The LED PCB assembly process begins with the design and prototyping phase. Engineers create detailed schematics and layouts, considering factors such as the number of LEDs, power requirements, and thermal management. Prototyping allows for testing and refinement before mass production.

During this phase, components such as LEDs, resistors, and capacitors are precisely placed on the PCB. Automated machines are often used to ensure accuracy and efficiency in component placement.

Soldering is a critical step in the assembly process, where components are securely attached to the PCB using solder paste. This ensures a strong electrical connection and mechanical stability. Different soldering techniques, such as reflow soldering, may be employed depending on the design requirements.

Before the LED PCB assemblies are released for use, they undergo rigorous quality control and testing procedures. These tests verify the functionality, reliability, and energy efficiency of the assemblies, ensuring they meet industry standards and customer expectations.

Recent advancements in thermal management techniques have significantly improved the energy efficiency of LED PCB assemblies. Technologies such as heat sinks, thermal vias, and thermal pads enhance heat dissipation, allowing LEDs to operate at optimal temperatures for extended periods.

The integration of smart technologies has revolutionized LED PCB assemblies. Features like dimming controls, motion sensors, and wireless connectivity enable users to customize lighting settings, further optimizing energy consumption and enhancing user experience.

The trend towards miniaturization has led to the development of compact and flexible LED PCB assemblies. These assemblies can be adapted to various applications, including wearable electronics, automotive lighting, and smart home devices, expanding their versatility and market reach.

Energy-efficient LED PCB assembly represents a significant advancement in electronic design and manufacturing. By prioritizing energy efficiency, these assemblies offer a sustainable solution that reduces power consumption, enhances performance, and minimizes environmental impact. As technology continues to evolve, innovations in LED PCB assembly will play a pivotal role in shaping the future of energy-efficient lighting solutions. Whether you're in the electronics industry or simply interested in sustainable practices, understanding the importance and impact of LED PCB assemblies is crucial for a brighter, more energy-efficient future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB