-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 31. 2025, 14:59:53

In today's fast-paced world, high-brightness LED technology is leading the charge in lighting solutions. From streetlights to televisions, the applications are endless. Central to these innovations is the LED PCB assembly, which ensures the functionality and efficiency of these powerful lights. In this article, we will explore what high-brightness LED PCB assembly entails, its importance, and the services available for businesses seeking these solutions.

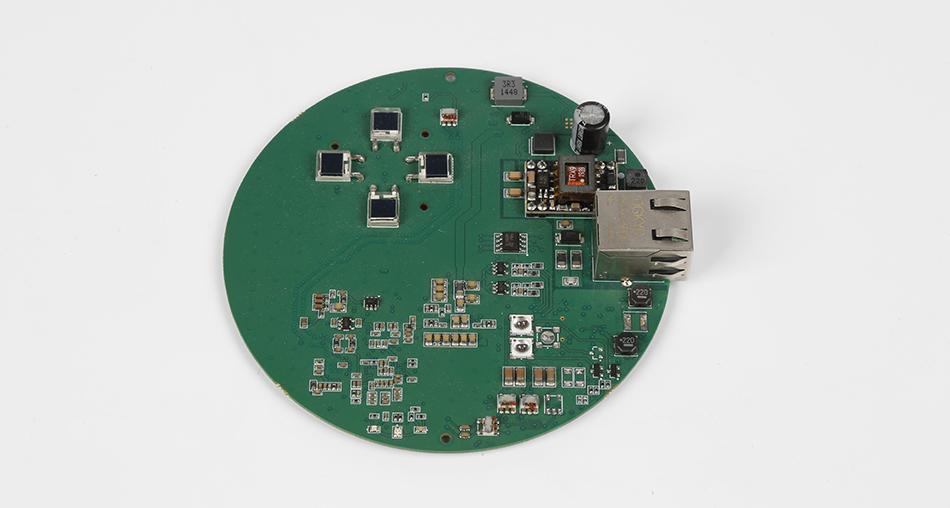

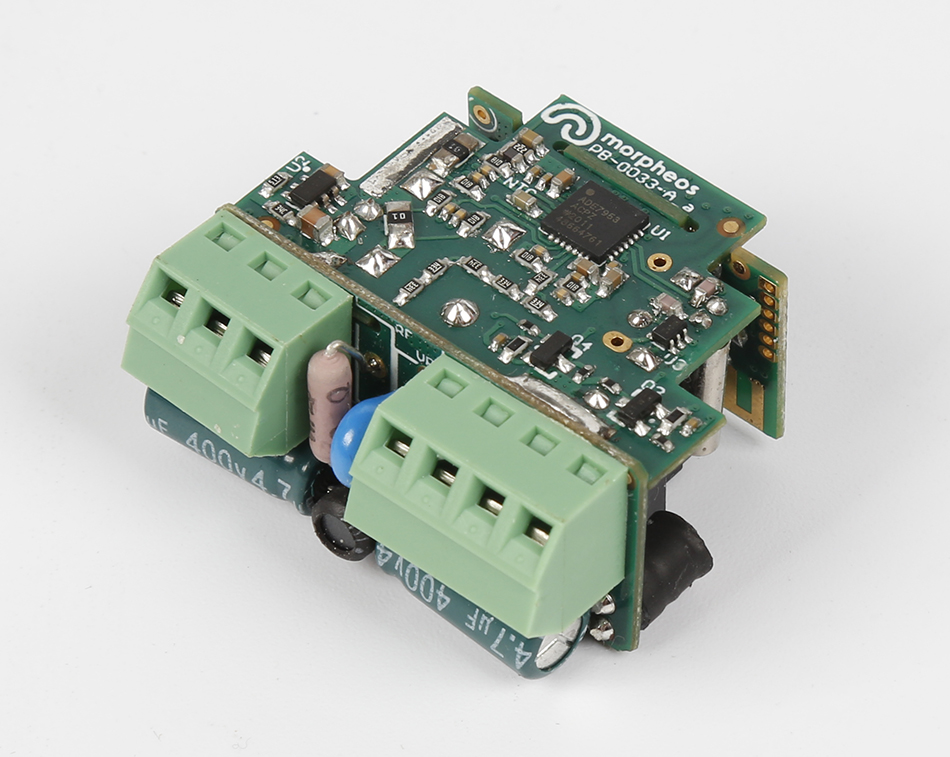

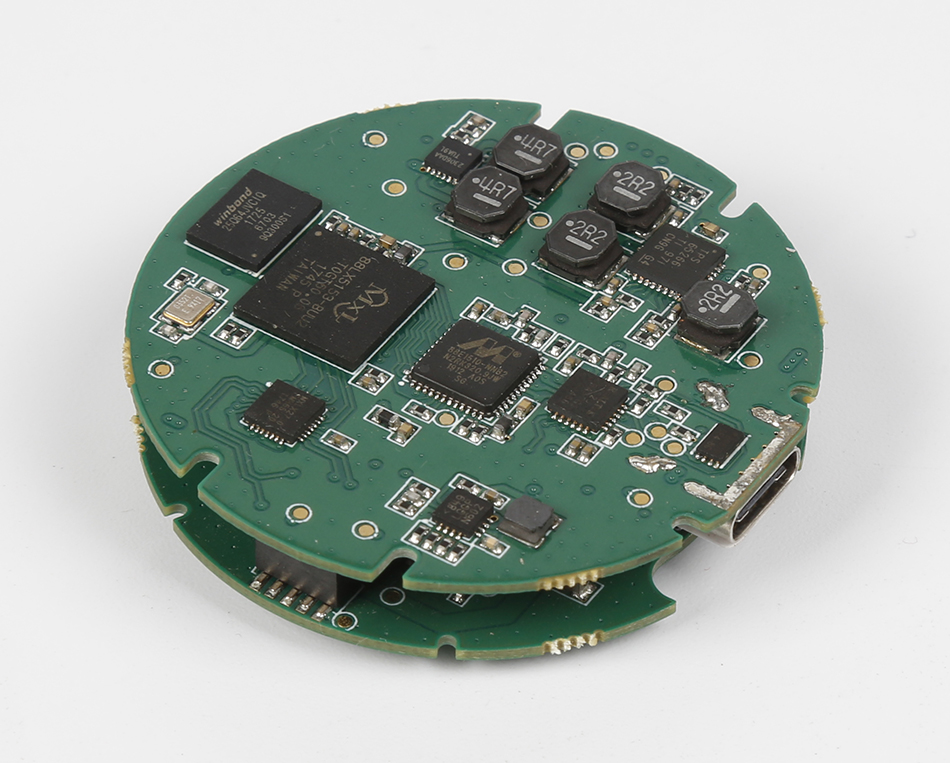

High-brightness LED PCB assembly refers to the process of mounting high-power LEDs onto a printed circuit board (PCB). This setup is essential because it provides the electrical connection and mechanical support needed for the LEDs to function optimally. The assembly process involves several steps, including designing the circuit, placing the LEDs, soldering, and testing.

The main components of a high-brightness LED PCB assembly include:

High-Power LEDs: These are the light-emitting diodes that produce bright light. They are more powerful than standard LEDs and are used in applications requiring high-intensity lighting.

Printed Circuit Board (PCB): A PCB is a board that holds the LEDs in place and connects them electrically. The board is typically made of materials that can handle high temperatures, such as aluminum, to dissipate the heat generated by the LEDs.

Thermal Management Systems: High-power LEDs generate a lot of heat. Efficient thermal management systems, like heat sinks, are crucial to dissipate this heat and prevent damage to the LEDs and the PCB.

High-brightness LED PCB assemblies play a critical role in various industries. Here’s why they are important:

High-power LEDs are known for their energy efficiency. They consume less power while providing brighter light compared to traditional lighting solutions. This makes them ideal for both commercial and residential applications where energy savings are a priority.

LEDs have a longer lifespan than conventional light sources. A well-assembled LED PCB can last for tens of thousands of hours. This durability reduces the need for frequent replacements, saving money and resources in the long run.

High-brightness LED PCB assemblies are used in a wide range of applications. These include street lighting, automotive lighting, indoor and outdoor displays, and even in electronic devices like smartphones and TVs.

For businesses looking to leverage high-power LED technology, finding the right PCB assembly services is crucial. Here are some aspects to consider:

Every application has unique requirements. Custom PCB design services allow businesses to create PCBs that meet their specific needs. This includes the size, shape, and layout of the PCB, as well as the type of materials used.

Before mass production, it's essential to prototype the PCB assembly. Prototyping allows for testing and verification of the design to ensure it meets the desired specifications and performance standards. Testing also helps identify any potential issues that could affect the functionality of the LEDs.

Quality assurance is a vital part of PCB assembly services. It involves rigorous testing and inspection to ensure that the final product is free from defects and operates as intended. High-quality assembly services will follow industry standards and certifications to guarantee reliability.

While high-brightness LED PCB assemblies offer many benefits, they also come with challenges:

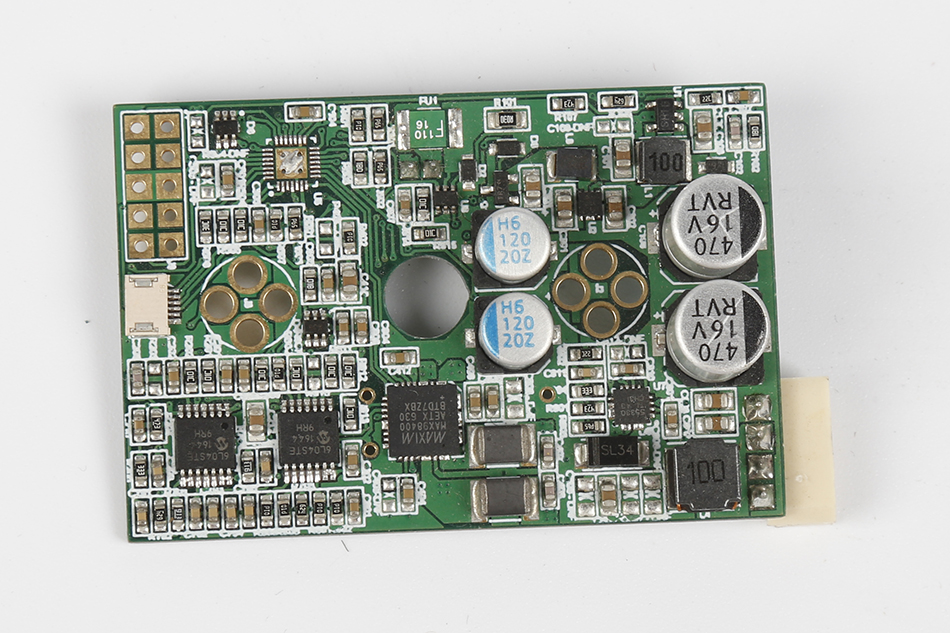

Managing heat is one of the biggest challenges in high-power LED assemblies. Poor thermal management can lead to overheating, which can damage the LEDs and reduce their lifespan. Advanced cooling solutions and materials with high thermal conductivity are essential to address this issue.

The soldering process must be precise to ensure a strong connection between the LEDs and the PCB. Any mistakes can lead to malfunctioning LEDs or connection failures. As such, using advanced soldering techniques and equipment is crucial.

As technology advances, there is a trend towards smaller and more compact devices. This requires miniaturized PCBs with precise assembly techniques. Achieving this without compromising performance or reliability is a significant challenge.

The future of high-brightness LED PCB assemblies looks promising, with ongoing advancements in technology. Here's what we can expect:

As smart technologies become more prevalent, we can expect high-brightness LED PCB assemblies to integrate with smart systems. This includes smart lighting solutions that can be controlled remotely and adapt to environmental conditions.

Research and development in LED technology continue to focus on improving energy efficiency. Future LED assemblies are likely to consume even less power while providing brighter light, which will further enhance their appeal across various sectors.

With improvements in LED technology and PCB assembly techniques, we can anticipate new applications for high-brightness LEDs. This could include more widespread use in consumer electronics, healthcare devices, and other innovative fields.

High-brightness LED PCB assemblies are at the forefront of modern lighting solutions. They offer numerous benefits, including energy efficiency, durability, and versatility. However, they also present challenges that require careful consideration and expertise in assembly services. As technology continues to evolve, the potential for high-power LEDs and their applications will only grow, making them an exciting area for businesses to explore.

By understanding the importance and intricacies of high-brightness LED PCB assembly, businesses can make informed decisions that align with their lighting needs and goals.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB