-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 01. 2025, 10:02:38

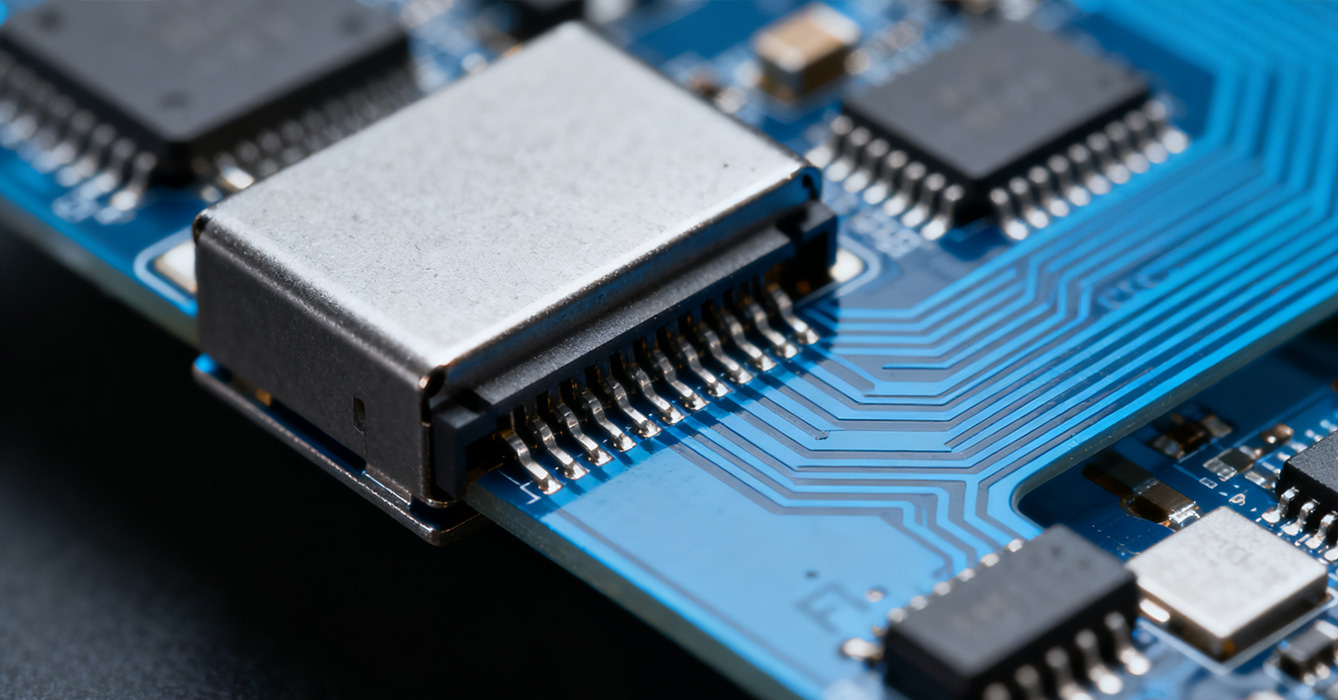

The global electronics industry’s shift toward flexibility, miniaturization, and intelligent integration has elevated the status of professional FPC manufacturers from mere component suppliers to strategic innovation partners. An FPC manufacturer specializes in the research, development, and production of flexible printed circuits (FPCs)—versatile components that enable seamless integration of electronic functions in constrained, curved, or dynamic environments. Unlike rigid PCB manufacturers, FPC manufacturers possess unique expertise in balancing mechanical flexibility with electrical performance, catering to the diverse needs of industries ranging from consumer electronics to industrial automation. For enterprises aiming to develop cutting-edge electronic products, partnering with a reputable FPC manufacturer is essential to translating design concepts into reliable, market-ready solutions.

The competitive edge of a top-tier FPC manufacturer lies in its comprehensive capabilities that cover the entire lifecycle of FPC development and production:

- Versatile Technical Adaptability: Leading FPC manufacturers excel in producing a wide range of FPC types, including single-layer, multi-layer, and rigid-flex circuits. They can adapt to diverse technical requirements—from ultra-thin FPCs for wearables to high-temperature-resistant variants for automotive under-hood applications. This versatility is supported by advanced manufacturing technologies such as precision etching, laser cutting, and high-reliability lamination, ensuring that FPCs meet the specific performance needs of different products.

- End-to-End Collaborative Service: Beyond production, FPC manufacturers offer full-process collaborative support. Their engineering teams engage with customers in the early design stage, providing design-for-manufacturability (DFM) insights to optimize circuit layouts, reduce material waste, and enhance production efficiency. They also support rapid prototyping, enabling customers to validate designs quickly, and scale seamlessly to mass production, ensuring consistent quality across small-batch and large-volume orders.

- Strict Quality Management Systems: Quality is foundational for FPCs, which are critical to electronic product reliability. Reputable FPC manufacturers implement rigorous quality control processes, including raw material inspection (substrates, conductive materials, adhesives), in-process testing (automated optical inspection, continuity testing), and final reliability validation (flex cycle testing, temperature cycling, moisture resistance testing). They comply with international standards such as IPC-6012/2221 and industry-specific certifications, ensuring that FPCs meet global market requirements.

- Material and Process Innovation: To keep pace with evolving electronic trends, FPC manufacturers invest in R&D to explore advanced materials and processes. This includes adopting low-loss substrates for high-frequency applications, biocompatible materials for medical devices, and eco-friendly materials to meet sustainability goals. Continuous process optimization also helps improve production efficiency, reduce lead times, and lower overall manufacturing costs for customers.

The flexible circuit solutions provided by FPC manufacturers address key challenges in modern electronic design, making them irreplaceable across industries:

1. Enabling Flexible and Compact Product Designs: Unlike rigid PCBs, FPCs can bend, twist, and conform to irregular shapes, enabling the development of compact, user-friendly products such as foldable smartphones, wearable health monitors, and slim smart home devices. FPC manufacturers’ ability to tailor FPC thickness, flexibility, and layout ensures that these design goals are achievable without compromising electrical performance.

2. Enhancing Product Reliability in Dynamic Environments: Many electronic products operate in dynamic or harsh conditions—such as automotive vibration, industrial dust and humidity, or frequent user movement for wearables. FPC manufacturers optimize materials and processes to enhance FPC durability, ensuring stable performance under these conditions. This reliability directly reduces product failure rates and warranty costs for customers.

3. Supporting Multi-Functional Integration: Modern electronic products often combine multiple functions (sensing, communication, power management) in a limited space. FPCs enable dense circuit routing and seamless integration of multiple components, reducing the number of interconnects and simplifying product assembly. FPC manufacturers’ technical expertise ensures that these integrated designs are both functional and manufacturable.

4. Driving Cost-Efficiency in Production: By optimizing designs and processes, FPC manufacturers help customers reduce production costs. FPCs’ lightweight and compact nature reduces material usage and transportation costs, while their integration capabilities simplify assembly workflows. Additionally, rapid prototyping and scalable production services minimize development cycles and initial investment risks, accelerating time-to-market.

FPC manufacturers support a broad range of industries, delivering tailored solutions to meet diverse application needs:

- Consumer Electronics: Powers smartphones, tablets, wearables, and VR/AR devices. FPCs enable slim designs, flexible displays, and seamless integration of sensors, cameras, and wireless modules, enhancing user experience and product competitiveness.

- Automotive Electronics: Supplies FPCs for in-vehicle infotainment systems, ADAS sensors, EV powertrain components, and lighting systems. These FPCs are designed to withstand extreme temperatures, vibration, and EMI, ensuring safe and reliable operation in automotive environments.

- Industrial Automation: Provides rugged FPCs for industrial sensors, robotic arms, and smart factory control systems. FPCs’ flexibility and durability enable reliable operation in harsh industrial conditions, supporting the digital transformation of manufacturing.

- Medical Devices: Delivers biocompatible, miniaturized FPCs for portable diagnostic equipment, wearable health monitors, and surgical instruments. Strict quality control ensures compliance with medical standards, safeguarding patient safety.

- Smart Home & IoT: Enables compact, flexible FPCs for smart speakers, home security sensors, and IoT gateways. These FPCs support seamless connectivity and integration in diverse home environments, driving the growth of the smart home ecosystem.

In conclusion, an FPC manufacturer is a core enabler of innovation in the global electronics industry, leveraging versatile technical capabilities, collaborative services, and strict quality control to deliver reliable flexible circuit solutions. As electronics continue to evolve toward flexibility, miniaturization, and intelligence, the role of FPC manufacturers will become increasingly critical. For enterprises seeking to develop competitive electronic products, partnering with a reputable FPC manufacturer is a strategic investment that ensures design feasibility, product reliability, and market success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB