-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 01. 2025, 10:01:23

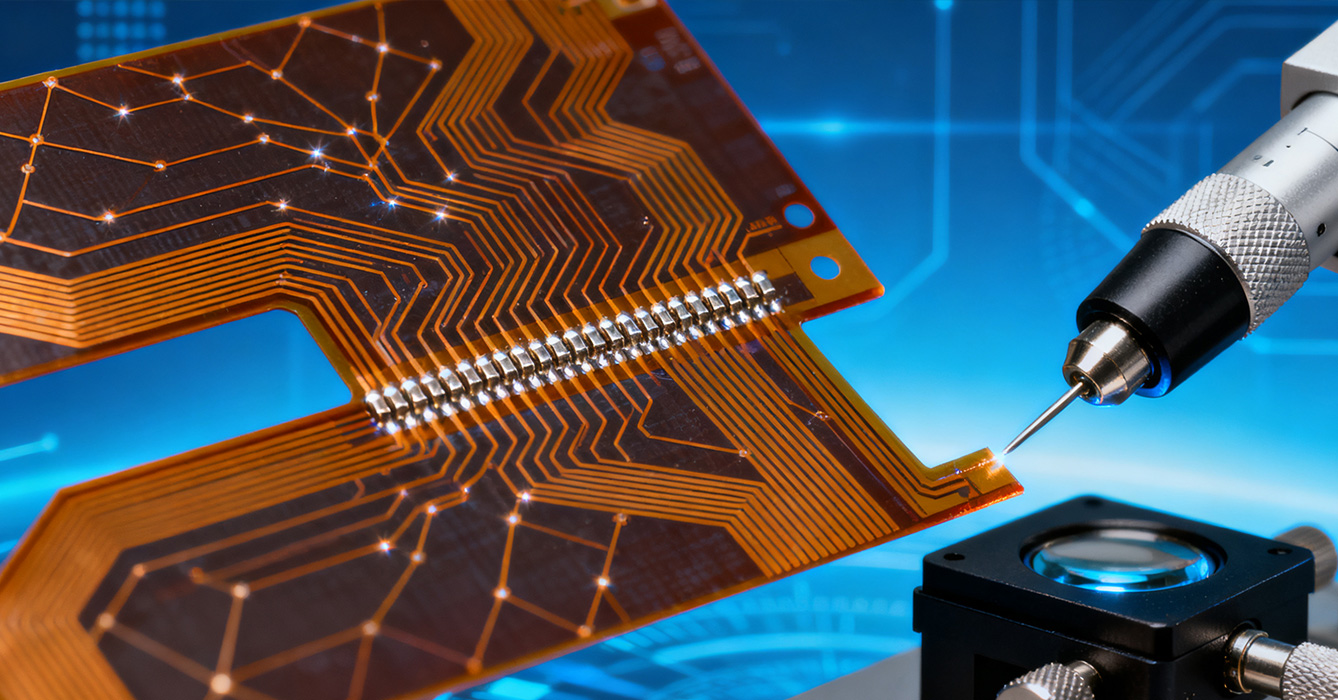

As high-end electronics continue to pursue miniaturization, high integration, and stable performance, the role of a professional HDI FPC Manufacturer has become increasingly vital in the global supply chain. An HDI FPC Manufacturer specializes in the design, development, and mass production of high-density interconnect flexible printed circuits (HDI FPCs), which are essential components for devices requiring compact layouts, high-speed signal transmission, and flexible installation. Unlike general FPC manufacturers, HDI FPC manufacturers possess specialized capabilities in balancing high-density routing with mechanical flexibility, ensuring that their products meet the stringent requirements of industries such as 5G communications, automotive electronics, and precision medical devices. For enterprises aiming to launch innovative electronic products, partnering with a reputable HDI FPC Manufacturer is a critical step to ensure production efficiency, product reliability, and market competitiveness.

The competitive advantage of an HDI FPC Manufacturer lies in its comprehensive capabilities covering the entire production lifecycle, from design consultation to mass delivery:

- End-to-End Customization Capabilities: Leading HDI FPC manufacturers offer tailored solutions based on customer needs, starting with in-depth design consultations. Their engineering teams collaborate closely with clients to optimize HDI FPC layouts, select appropriate materials, and determine the most suitable manufacturing processes—whether for ultra-miniaturized wearable devices or high-temperature-resistant automotive components. This customization extends beyond technical parameters to include production batch flexibility, supporting both small-batch prototyping and large-scale mass production.

- Advanced Manufacturing Process Control: Mastery of core HDI processes is fundamental for these manufacturers. They employ state-of-the-art equipment for micro via fabrication, fine-pitch trace etching, and multi-layer lamination, ensuring precise control over circuit density and connection reliability. Strict process monitoring systems prevent defects such as via blockages, trace short circuits, or layer delamination, guaranteeing consistent product quality across production runs. Additionally, they continuously optimize manufacturing workflows to improve production efficiency and reduce lead times.

- Comprehensive Quality Assurance Systems: Given the critical role of HDI FPCs in high-performance devices, quality control is a top priority for HDI FPC manufacturers. They implement a full-process quality management system, including raw material inspection (for substrates, conductive materials, and adhesives), in-process testing (using automated optical inspection and X-ray inspection), and final reliability validation (such as thermal cycling, humidity resistance, and flex endurance tests). Compliance with international standards like IPC-6012/2221 and industry-specific certifications (e.g., IATF 16949 for automotive, ISO 13485 for medical) further ensures product safety and reliability.

- Industry-Specific Expertise & Collaboration: Top HDI FPC manufacturers accumulate deep expertise in key application sectors. They understand the unique environmental and performance requirements of different industries—such as resistance to extreme temperatures and vibration for automotive electronics, biocompatibility for medical devices, and high-frequency signal stability for 5G products. This expertise enables them to collaborate effectively with customers, providing technical guidance that helps translate product concepts into practical, reliable solutions.

The specialized services and capabilities of HDI FPC manufacturers address critical challenges in modern electronic product development, making them irreplaceable partners:

1. Bridging the Gap Between Design and Production: Many innovative electronic designs feature complex HDI FPC requirements that general manufacturers cannot fulfill. HDI FPC manufacturers use their technical expertise to resolve design-for-manufacturability issues, ensuring that even highly complex high-density flexible circuits can be produced efficiently and reliably. This reduces the risk of design iterations and delays, accelerating time-to-market for new products.

2. Ensuring Product Reliability in Harsh Environments: Advanced electronic devices often operate in harsh conditions—such as high temperatures in automotive engines, moisture in wearable devices, or radiation in aerospace applications. HDI FPC manufacturers select appropriate materials and optimize manufacturing processes to enhance product durability, ensuring that HDI FPCs maintain stable performance under these challenging conditions. This reliability directly impacts the overall quality and lifespan of end products.

3. Supporting Cost-Effective Innovation: While HDI FPC production involves advanced technologies, professional manufacturers can optimize costs through efficient process control and material selection. They help customers avoid unnecessary expenses by recommending the most suitable HDI solutions based on product requirements, rather than over-engineering. Additionally, their scalable production capabilities allow customers to start with small-batch prototyping and scale up to mass production seamlessly, reducing initial investment risks.

4. Driving Technological Advancement in Electronics: HDI FPC manufacturers play an active role in advancing electronic technology by investing in research and development. They explore new materials, processes, and designs to improve HDI FPC performance—such as higher density routing, lower signal loss, and better mechanical flexibility. These innovations enable the development of more advanced electronic products, from foldable smartphones to autonomous driving systems.

HDI FPC manufacturers cater to a wide range of high-tech industries, providing tailored solutions for diverse application needs:

- Consumer Electronics: Supplies HDI FPCs for 5G smartphones, foldable devices, premium smartwatches, and VR/AR headsets. These HDI FPCs enable compact designs, high-speed data transmission, and seamless integration of multiple sensors and modules, supporting advanced user experiences.

- Automotive Electronics: Delivers HDI FPCs for advanced driver assistance systems (ADAS), electric vehicle (EV) powertrain components, and in-vehicle infotainment systems. These products are designed to withstand extreme temperatures, vibration, and electromagnetic interference (EMI), ensuring safe and reliable operation in automotive environments.

- Medical Devices: Provides biocompatible, miniaturized HDI FPCs for implantable sensors, portable diagnostic equipment, and surgical robots. Strict quality control and compliance with medical standards ensure patient safety and device reliability in critical healthcare applications.

- Aerospace & Industrial IoT: Manufactures high-reliability HDI FPCs for aerospace avionics, satellite communication systems, and industrial IoT sensors. These HDI FPCs feature lightweight designs, radiation resistance, and high signal integrity, meeting the rigorous requirements of extreme and harsh environments.

In conclusion, an HDI FPC Manufacturer is a key enabler of advanced electronic products, combining specialized manufacturing capabilities, comprehensive quality control, and industry-specific expertise to deliver reliable high-density flexible circuits. As the electronics industry continues to evolve toward miniaturization, intelligence, and connectivity, the demand for professional HDI FPC manufacturers will only grow. For enterprises seeking to innovate and compete in high-end markets, partnering with a reputable HDI FPC Manufacturer is a strategic investment that ensures product quality, accelerates time-to-market, and drives long-term success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB