-

- PCB TYPE

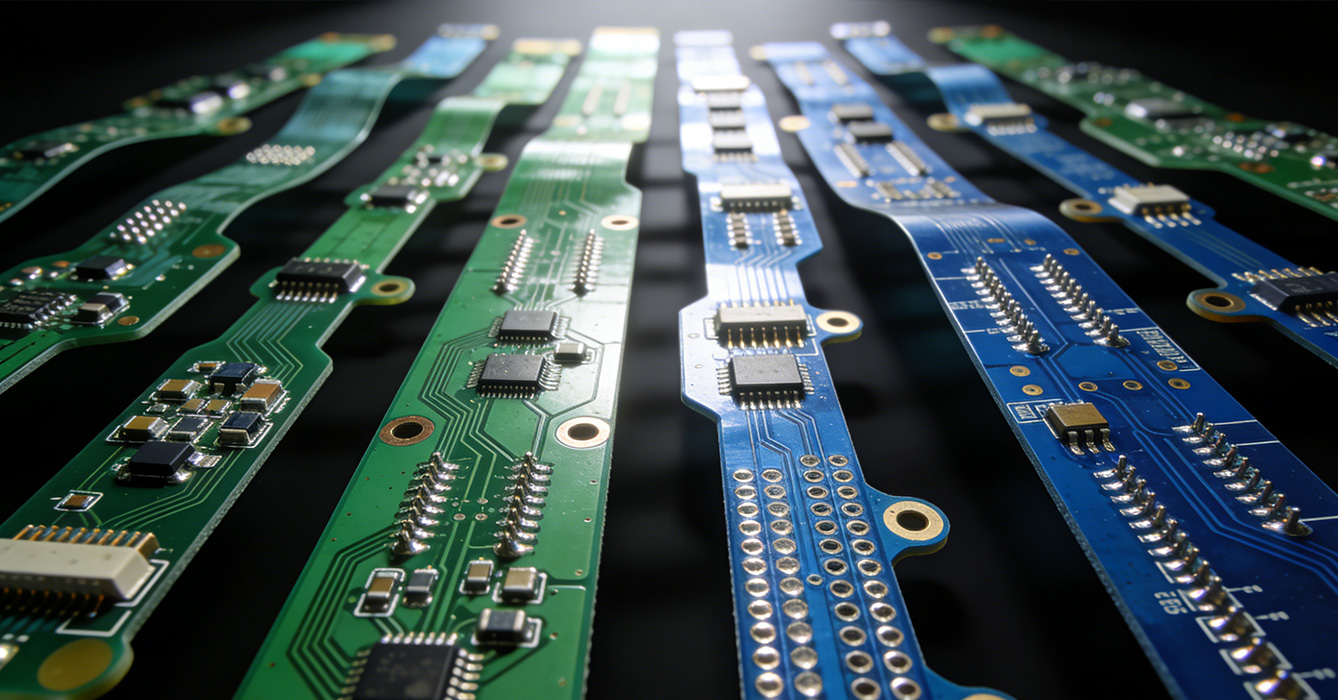

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 22. 2025, 13:12:19

As the electronics industry evolves toward miniaturization, portability, and versatility, flexible printed circuit boards (FPCBs) have become a staple in modern device design. At the heart of bringing these flexible components to life lies FPCB Assembly—a specialized process that combines precision engineering with adaptive manufacturing to ensure FPCBs deliver reliable performance across diverse applications. FPCB Assembly is not merely a production step; it is a critical enabler of innovation, allowing engineers to translate bold design concepts into functional products that shape industries from consumer tech to automotive and industrial automation. In a market where device functionality and form factor are key differentiators, the quality and efficiency of FPCB Assembly directly impact a product’s success.

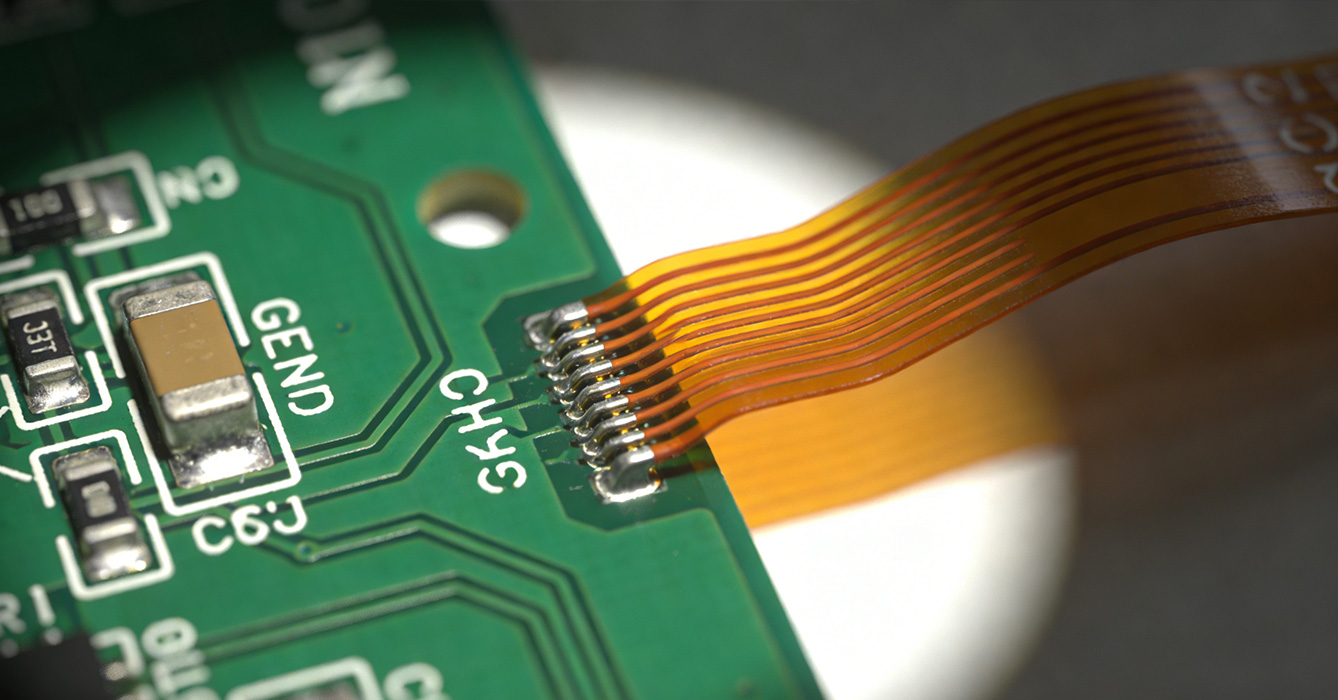

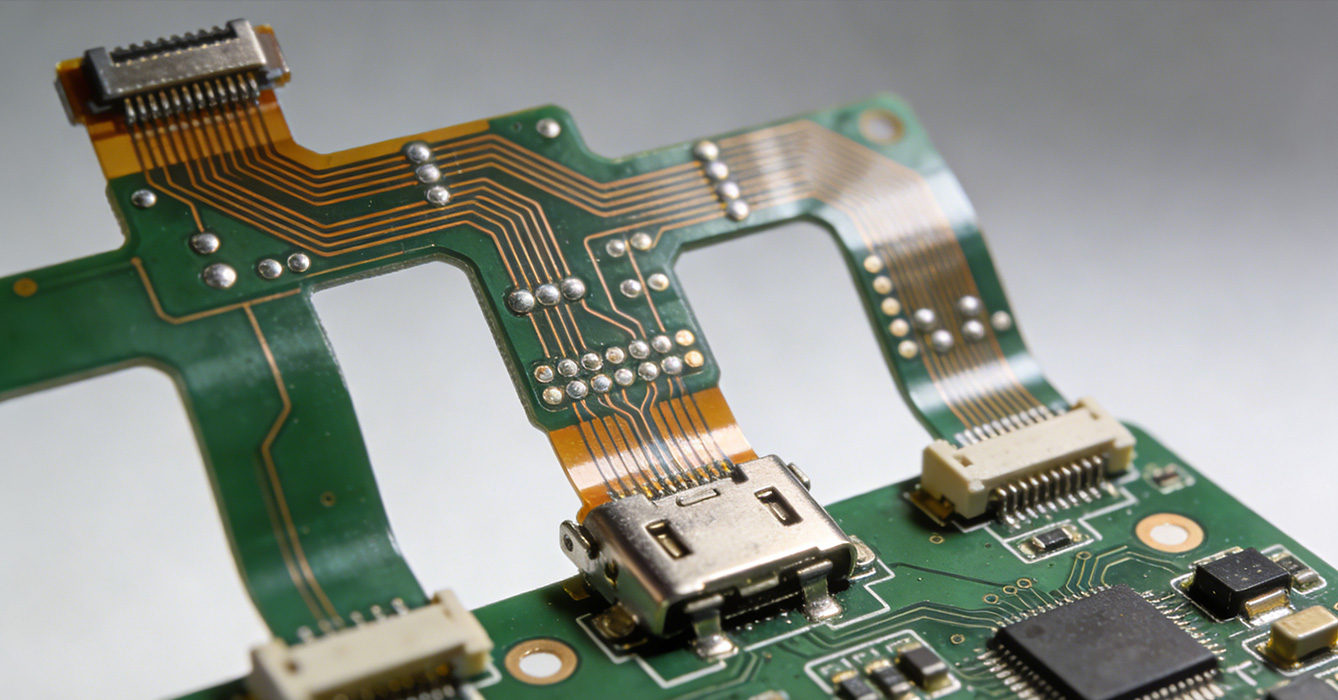

Unlike rigid PCB assembly, FPCB Assembly requires specialized expertise to handle the unique properties of flexible substrates, which are thinner, lighter, and more prone to damage if not processed correctly. The flexibility of FPCBs allows them to fit into curved, confined, or irregular spaces—an advantage that is impossible to replicate with traditional rigid boards. However, this flexibility also presents challenges during assembly, such as ensuring component placement accuracy, maintaining signal integrity, and preventing substrate warpage. FPCB Assembly addresses these challenges through tailored processes, including precision soldering, automated component placement, and specialized handling techniques, ensuring that the final product retains its flexibility while meeting strict performance standards.

Beyond overcoming technical hurdles, FPCB Assembly also enhances design flexibility and production efficiency. By enabling the integration of FPCBs into compact devices, it supports the development of sleek, user-friendly products such as foldable smartphones, wireless earbuds, and wearable fitness trackers. Additionally, FPCB Assembly streamlines production by reducing the need for connectors and wiring harnesses, which are often required when using multiple rigid PCBs. This not only simplifies the manufacturing process but also reduces the risk of connection failures, improving overall product reliability.

The versatility of FPCB Assembly makes it invaluable across a wide range of industries, each leveraging its unique benefits to enhance product performance. In the consumer electronics sector, FPCB Assembly is the backbone of foldable devices, where it enables seamless bending without compromising electrical functionality. It also powers wearable devices, such as smartwatches and health monitors, by providing lightweight, flexible components that conform to the human body, ensuring comfort and accurate data collection.

The automotive industry is another major adopter of FPCB Assembly, using it to produce components for advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) powertrains. In these applications, FPCB Assembly ensures that components can withstand the harsh conditions of automotive environments—including temperature fluctuations, vibrations, and humidity—while maintaining reliable performance. Industrial automation also benefits from FPCB Assembly, as it enables the production of compact, flexible sensors and control modules that can be integrated into complex machinery, improving operational efficiency and reducing downtime.

Even in specialized sectors such as aerospace and marine electronics, FPCB Assembly plays a critical role. It supports the development of lightweight, durable components for satellite systems, avionics, and marine navigation devices, where weight reduction and resistance to extreme environmental conditions are paramount.

Investing in high-quality FPCB Assembly yields numerous benefits for electronic device manufacturers. First and foremost is enhanced product reliability. By using specialized assembly processes and quality control measures, FPCB Assembly ensures that components are securely attached, signals are transmitted accurately, and the FPCB retains its flexibility over time. This reduces the risk of product failures, lowers maintenance costs, and enhances consumer trust.

Another key advantage is improved space efficiency. FPCB Assembly allows for the integration of multiple functions into a single flexible board, eliminating the need for bulky wiring and connectors. This enables the development of smaller, more compact devices that align with consumer preferences for portability. Additionally, FPCB Assembly supports cost savings in the long run. While the initial assembly process may require specialized equipment, the reduction in components and assembly steps simplifies production, lowering overall manufacturing costs.

Selecting a reliable FPCB Assembly partner is crucial for ensuring product quality and production efficiency. When evaluating potential providers, several key factors should be considered. First, technical expertise is essential: the provider should have experience handling flexible substrates and assembling FPCBs for your specific industry and application. Look for providers with a proven track record of delivering high-quality products and adhering to industry standards.

Quality control processes are another critical consideration. A reputable FPCB Assembly provider will implement rigorous QC measures at every stage of the assembly process, from material inspection to final testing. This includes automated optical inspection (AOI), x-ray inspection, and functional testing to detect defects and ensure performance. Additionally, communication and collaboration are key: the provider should work closely with your engineering team to optimize designs for assembly, offer technical guidance, and provide regular updates on production progress.

In conclusion, FPCB Assembly is a cornerstone of modern electronics innovation, enabling the development of flexible, compact, and reliable devices across industries. Its ability to overcome the unique challenges of flexible substrates and support diverse design needs makes it an essential process for manufacturers looking to stay competitive in a rapidly evolving market. By choosing a qualified FPCB Assembly partner and prioritizing quality, businesses can unlock the full potential of FPCB technology, bringing innovative products to market that meet the demands of today’s consumers and industries. As the trend toward flexible electronics continues to grow, the role of FPCB Assembly will only become more vital, shaping the future of electronic device design and manufacturing.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB