-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 22. 2025, 13:13:19

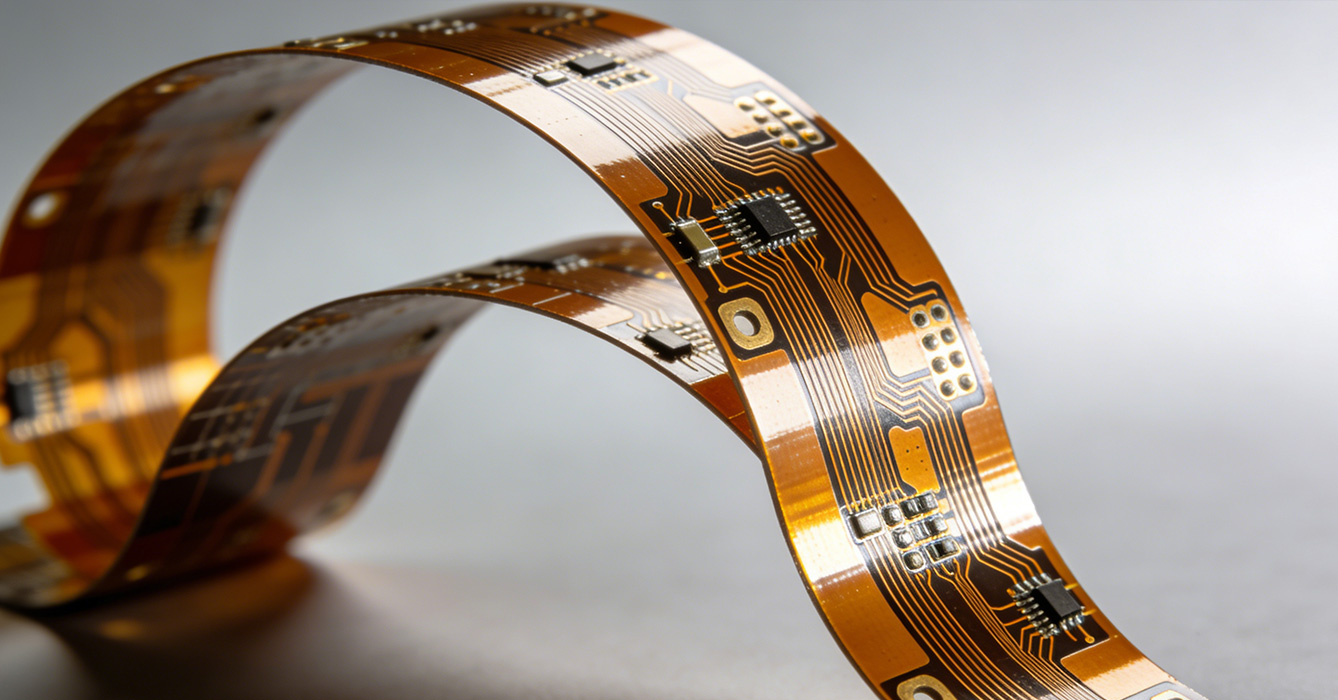

In the era of smart, compact, and multi-functional electronics, Flexible Printed Circuit Boards (FPCB) have emerged as a transformative technology, redefining the boundaries of device design and performance. Unlike traditional rigid printed circuit boards (PCBs), FPCB leverages flexible substrate materials to deliver unparalleled adaptability, enabling electronic components to fit into curved, confined, or irregular form factors. As industries ranging from consumer tech to automotive and healthcare pursue innovation, FPCB has become a core enabler, powering products that are lighter, thinner, and more reliable. The unique combination of flexibility, miniaturization, and electrical stability makes FPCB a cornerstone of modern electronics, driving advancements that were once deemed impossible.

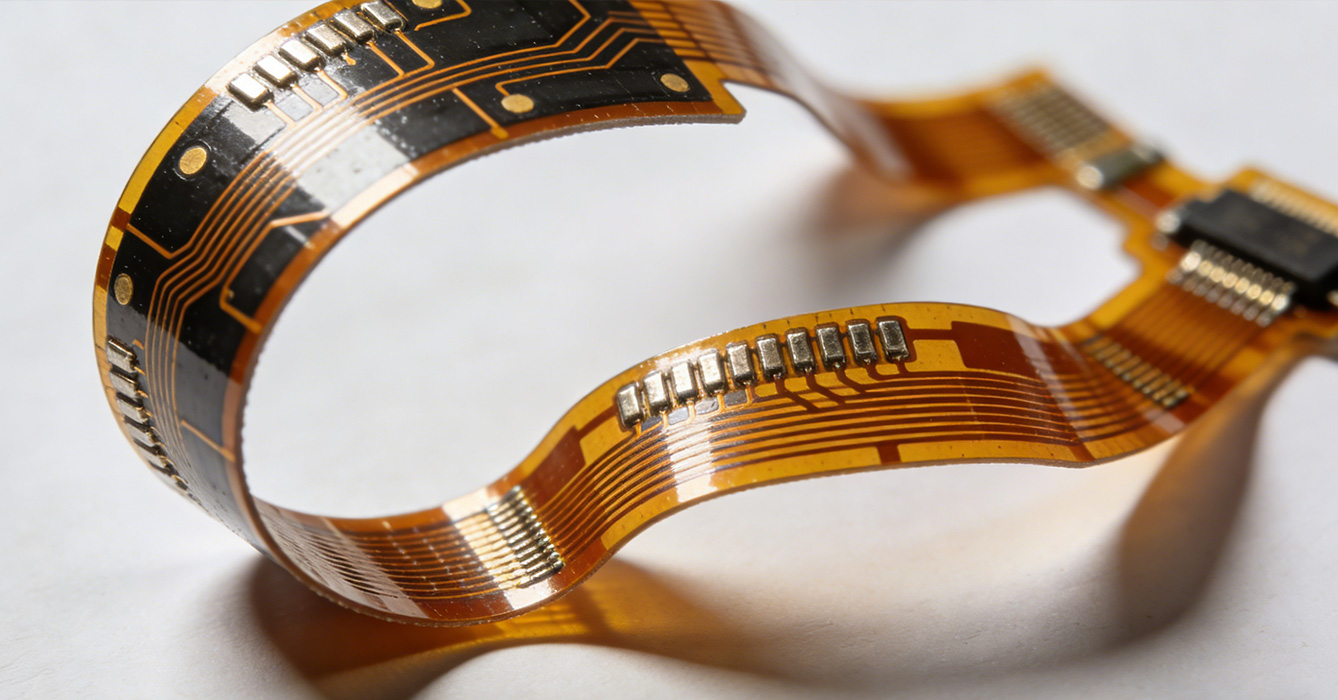

FPCB, short for Flexible Printed Circuit Board, is a type of circuit board fabricated on flexible insulating substrates such as polyimide or polyester. This fundamental difference from rigid PCBs endows FPCB with distinct technical advantages that make it indispensable in modern device design. The most prominent feature is flexibility: FPCB can be bent, folded, or twisted repeatedly without damaging the circuit or compromising electrical performance. This flexibility eliminates the spatial constraints of rigid boards, allowing engineers to integrate circuits into shapes that align with the functional and aesthetic needs of products.

Beyond flexibility, FPCB offers exceptional miniaturization and lightweight properties. By replacing bulky wiring harnesses and multiple rigid PCB modules with a single flexible board, FPCB significantly reduces the overall size and weight of electronic devices. This is particularly valuable in applications where portability and compactness are critical, such as wearable technology and portable medical devices. Additionally, FPCB boasts excellent electrical performance, with low signal loss and high stability, ensuring reliable data transmission even in dynamic environments. These core characteristics collectively make FPCB a superior alternative to traditional rigid PCBs in countless innovative electronic products.

The versatility of FPCB has made it a catalyst for innovation across a wide spectrum of industries, each leveraging its unique properties to solve design challenges and enhance product performance. In the consumer electronics sector, FPCB is the backbone of foldable smartphones and tablets, enabling seamless bending of screens while maintaining full functionality. It also powers wireless earbuds, smartwatches, and fitness trackers, where its compact size and flexibility allow for ergonomic designs that conform to the human body, improving user comfort and product usability.

The automotive industry is another major adopter of FPCB, as it supports the shift toward intelligent and electric vehicles. FPCB is used in advanced driver-assistance systems (ADAS), in-vehicle infotainment, and electric vehicle (EV) powertrain components. Its ability to withstand high temperatures, vibrations, and humidity makes it ideal for the harsh automotive environment, while its compact design helps optimize space in crowded engine bays and vehicle interiors. In healthcare, FPCB plays a life-enhancing role in wearable medical devices, such as continuous glucose monitors and heart rate sensors, as well as portable diagnostic equipment, where its miniaturization and biocompatibility ensure safe and reliable operation.

Even in industrial and aerospace sectors, FPCB is making its mark. It is used in industrial IoT sensors, robotic arms, and automation control systems, where its flexibility allows for integration into complex machinery without hindering movement. In aerospace applications, FPCB’s lightweight properties help reduce aircraft weight, improving fuel efficiency, while its durability ensures performance in extreme temperature and pressure conditions.

For electronic engineers and product designers, FPCB unlocks a new realm of creative possibilities by addressing key pain points of traditional rigid PCB design. One of the most significant advantages is design flexibility: FPCB can be tailored to the exact contours of a product, whether it’s a curved smartphone casing, a wearable device’s band, or a compact medical implant. This eliminates the need to compromise on design for the sake of circuit integration, allowing products to be both functional and aesthetically pleasing.

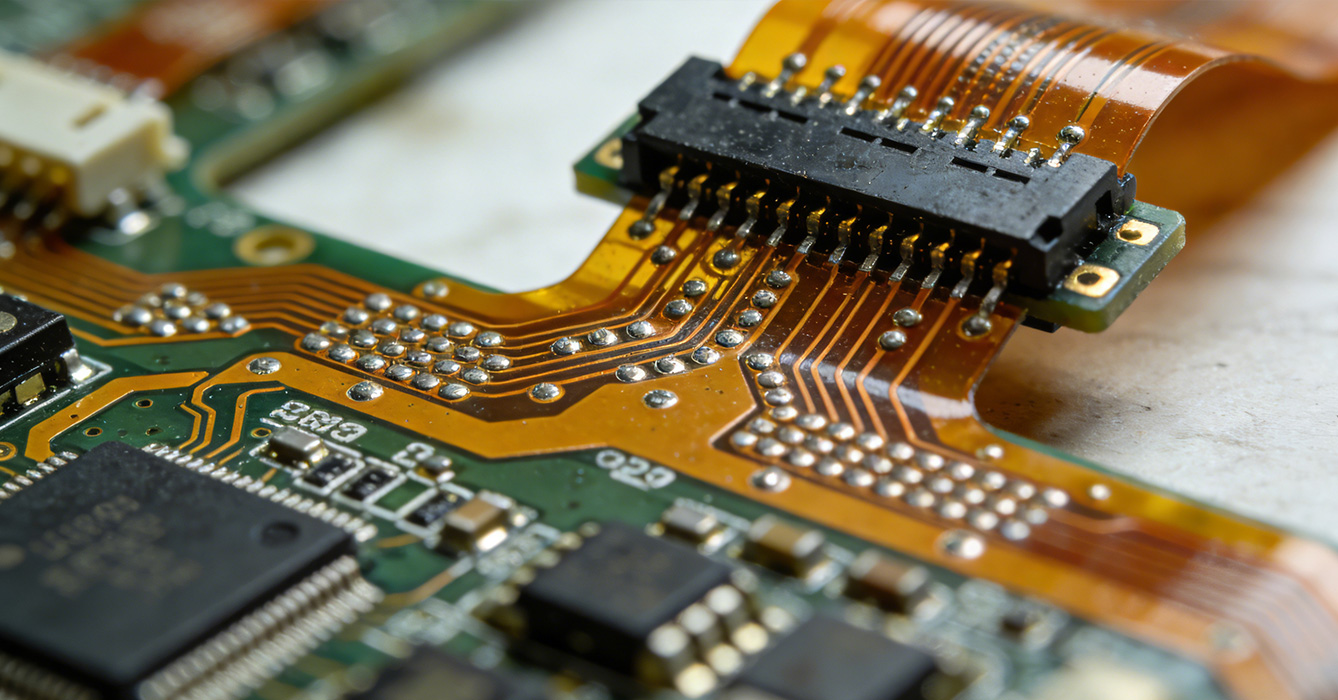

FPCB also simplifies product assembly and reduces manufacturing complexity. By integrating multiple circuit functions into a single flexible board, it eliminates the need for numerous connectors, wires, and rigid PCB modules, streamlining the assembly process and reducing the risk of connection failures. This not only improves production efficiency but also lowers manufacturing costs in the long run. Additionally, FPCB’s durability enhances product reliability: its flexible substrate can absorb shocks and vibrations, reducing the risk of circuit damage caused by accidental drops or environmental stress, which is a critical advantage for portable and industrial devices.

As technology continues to advance, the role of FPCB is set to expand even further, driven by emerging trends in electronics innovation. The rise of the Internet of Things (IoT) is fueling demand for compact, low-power FPCB that can power the growing network of smart devices, from home sensors to industrial monitors. The development of wearable technology and augmented reality (AR) devices is pushing the boundaries of FPCB design, requiring thinner, more flexible boards that can integrate with soft, skin-friendly materials.

Sustainability is another key trend shaping the future of FPCB. Manufacturers are increasingly adopting eco-friendly substrate materials and production processes, such as recyclable polyimides and lead-free manufacturing, to reduce the environmental impact of electronic components. Additionally, advancements in FPCB technology, such as the integration of flexible batteries and printed sensors, are opening up new possibilities for self-powered, intelligent devices that offer greater convenience and functionality.

In conclusion, FPCB has revolutionized the electronics industry by offering unmatched flexibility, miniaturization, and reliability. Its ability to adapt to diverse design needs and harsh environments has made it an essential component in a wide range of products, from consumer gadgets to life-saving medical devices and advanced automotive systems. As emerging technologies continue to drive demand for more innovative and compact electronic solutions, FPCB will remain at the forefront of innovation, empowering engineers to create products that redefine the way we live, work, and interact with technology. For businesses looking to stay competitive in the fast-paced electronics market, embracing FPCB technology is not just a choice but a strategic imperative to unlock new design possibilities and drive product innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB