-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 29. 2025, 16:17:51

In the interconnected global electronics ecosystem, the role of an FPCB manufacturer extends far beyond component production—it serves as a critical link that bridges design innovation, production efficiency, and market accessibility. As flexible printed circuit boards (FPCBs) become ubiquitous in electronic devices ranging from consumer gadgets to industrial equipment, an FPCB manufacturer’s ability to deliver consistent, adaptable, and cost-effective solutions directly impacts the competitiveness of brands worldwide. Unlike niche specialized manufacturers, a versatile FPCB manufacturer caters to diverse market demands, integrating advanced production capabilities with flexible supply chain management to support both small-batch prototyping and large-scale mass production. This adaptability has made FPCB manufacturers indispensable partners for businesses navigating the fast-paced and ever-evolving electronics industry.

A reputable FPCB manufacturer distinguishes itself through three foundational capabilities that underpin its value in the global supply chain. First and foremost is comprehensive supply chain integration. From sourcing high-quality flexible substrates and conductive materials to collaborating with component suppliers, an FPCB manufacturer streamlines the material procurement process, ensuring stable supply and consistent material quality. This integration minimizes supply chain disruptions, a critical advantage in an era where global logistics challenges and material shortages are common.

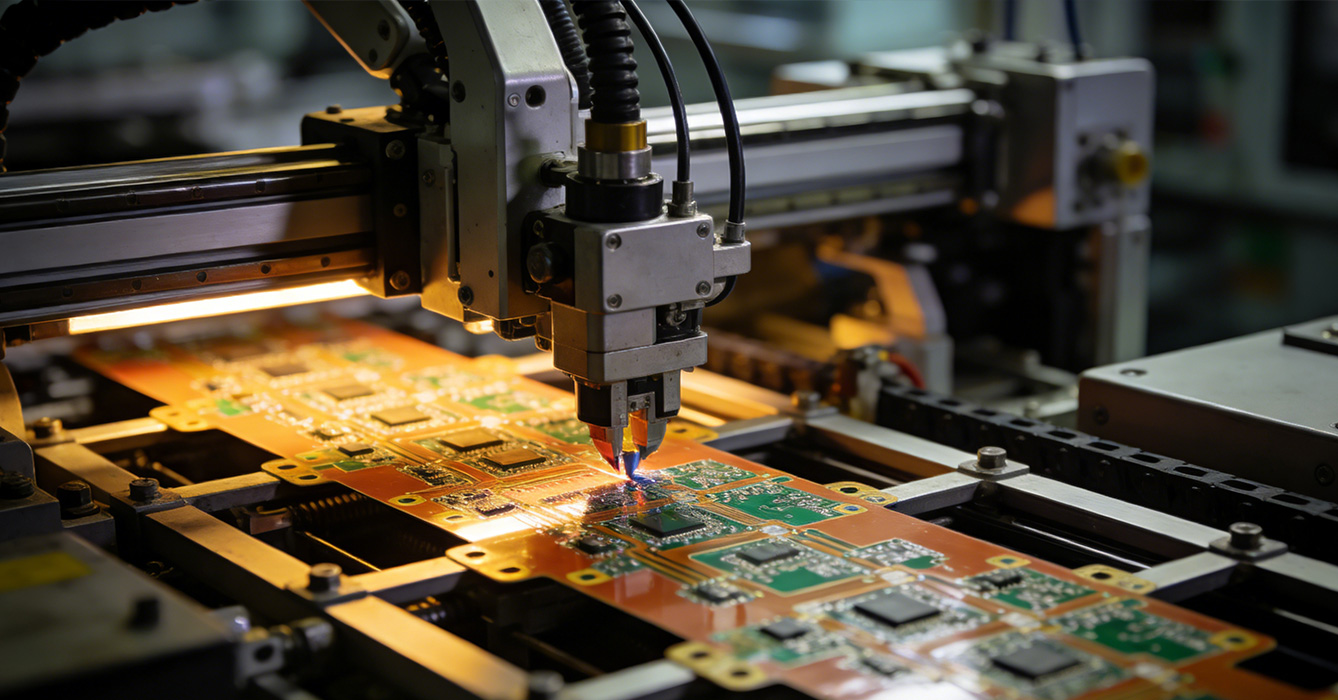

Secondly, technical versatility and customization adaptability are key. A leading FPCB manufacturer possesses the expertise to handle diverse FPCB designs, accommodating different flexibility requirements, layer configurations, and application-specific performance needs. Whether it’s a simple single-layer FPCB for a basic wearable device or a complex multi-layer design for industrial control systems, the manufacturer can adjust production processes to meet client specifications. This versatility is supported by ongoing investment in production technology, such as automated circuit patterning and precision testing equipment, which enhances production accuracy and efficiency.

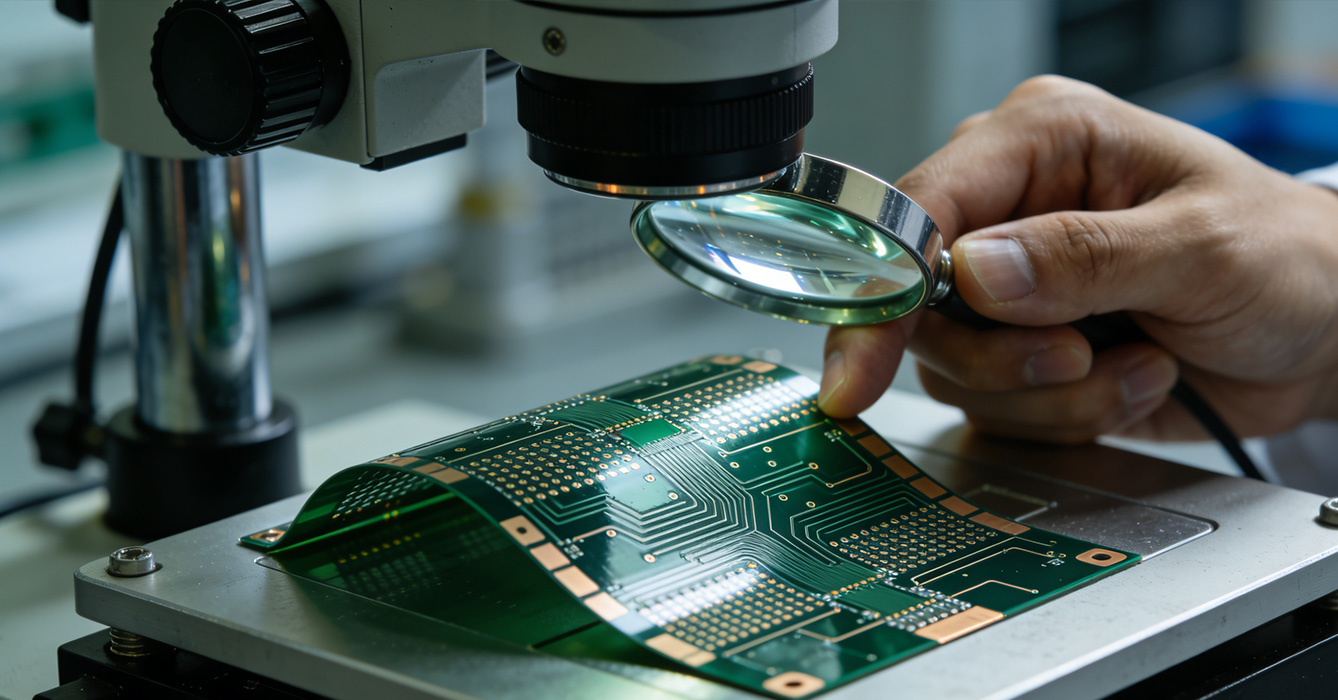

Thirdly, robust quality assurance and regulatory compliance are non-negotiable. A reliable FPCB manufacturer implements standardized quality control processes across all production stages, from raw material inspection to final product testing. Compliance with international standards such as ISO 9001 and RoHS ensures that FPCBs meet global market requirements, enabling clients to expand their products to international markets without regulatory barriers. This commitment to quality also reduces the risk of defective components, protecting clients from production delays and reputational damage.

The versatility of FPCB manufacturers enables them to support innovation across a wide range of industries, each with unique requirements. In the consumer electronics sector, FPCB manufacturers are instrumental in the production of smartphones, tablets, and wireless accessories. They deliver FPCBs that enable compact, lightweight designs and support high-speed data transmission, a key factor in the success of modern consumer devices. For emerging consumer tech trends such as foldable devices, FPCB manufacturers provide specialized solutions that balance flexibility and durability, driving product innovation.

In the industrial sector, FPCB manufacturers supply components for industrial automation systems, sensors, and control modules. These applications require FPCBs that can withstand harsh industrial environments, including high temperatures, humidity, and vibrations. FPCB manufacturers meet these demands through specialized material selection and design optimization, ensuring reliable performance in critical industrial operations. The healthcare industry also benefits from FPCB manufacturers, who produce biocompatible FPCBs for medical devices such as diagnostic equipment, wearable health monitors, and implantable devices—supporting advancements in personalized medicine and remote patient care.

The automotive and IoT (Internet of Things) sectors are additional key beneficiaries. FPCB manufacturers supply components for in-vehicle electronics and IoT sensors, enabling the development of smart vehicles and connected devices. Their ability to scale production to meet the growing demand for these sectors makes them strategic partners in the expansion of the smart technology ecosystem.

Selecting the right FPCB manufacturer is a critical decision that impacts a business’s production efficiency, product quality, and market competitiveness. Firstly, evaluate the manufacturer’s production capacity and scalability. Ensure they can accommodate your production volume needs, from initial prototyping to mass production, and adapt to changes in demand. This scalability is essential for businesses looking to grow or respond to market fluctuations.

Secondly, assess their technical expertise and industry experience. Look for an FPCB manufacturer with a proven track record in your specific industry, as they will better understand your unique requirements and challenges. Request case studies or client testimonials to verify their ability to deliver solutions that meet your needs. Thirdly, consider their supply chain stability and logistics capabilities. A manufacturer with a robust supply chain and efficient logistics can ensure timely delivery, even in complex global logistics environments.

Finally, evaluate their communication and collaboration capabilities. A reliable FPCB manufacturer should maintain open communication channels, providing regular updates on production progress and addressing any issues promptly. Collaborative support, such as design for manufacturability (DFM) advice, can also help optimize your FPCB design, reducing production costs and improving product performance.

As the electronics industry evolves, FPCB manufacturers are adapting to emerging trends to stay competitive. One key trend is digitalization, with manufacturers integrating smart manufacturing technologies such as IoT, AI, and big data into their production processes. These technologies enable real-time production monitoring, predictive maintenance, and process optimization, improving production efficiency and quality control.

Sustainability is another major trend shaping the future of FPCB manufacturers. Many manufacturers are adopting eco-friendly materials and production processes, such as recyclable substrates and lead-free manufacturing, to reduce their environmental impact. This shift aligns with global efforts to promote sustainable electronics and meets the growing demand for eco-friendly products from consumers and regulators. Additionally, the development of energy-efficient FPCBs is expanding their application in renewable energy systems, further driving the transition to a sustainable future.

In conclusion, an FPCB manufacturer is a strategic pillar of the global electronics supply chain, providing the essential components and expertise that drive innovation across industries. Their core capabilities in supply chain integration, technical versatility, and quality assurance make them indispensable partners for businesses worldwide. By carefully evaluating a manufacturer’s production capacity, technical expertise, supply chain stability, and collaboration capabilities, businesses can select a partner that aligns with their goals and supports their growth. As digitalization and sustainability continue to reshape the electronics industry, FPCB manufacturers will play an increasingly critical role in enabling the development of innovative, efficient, and sustainable electronic products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB