-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 02. 2025, 11:40:03

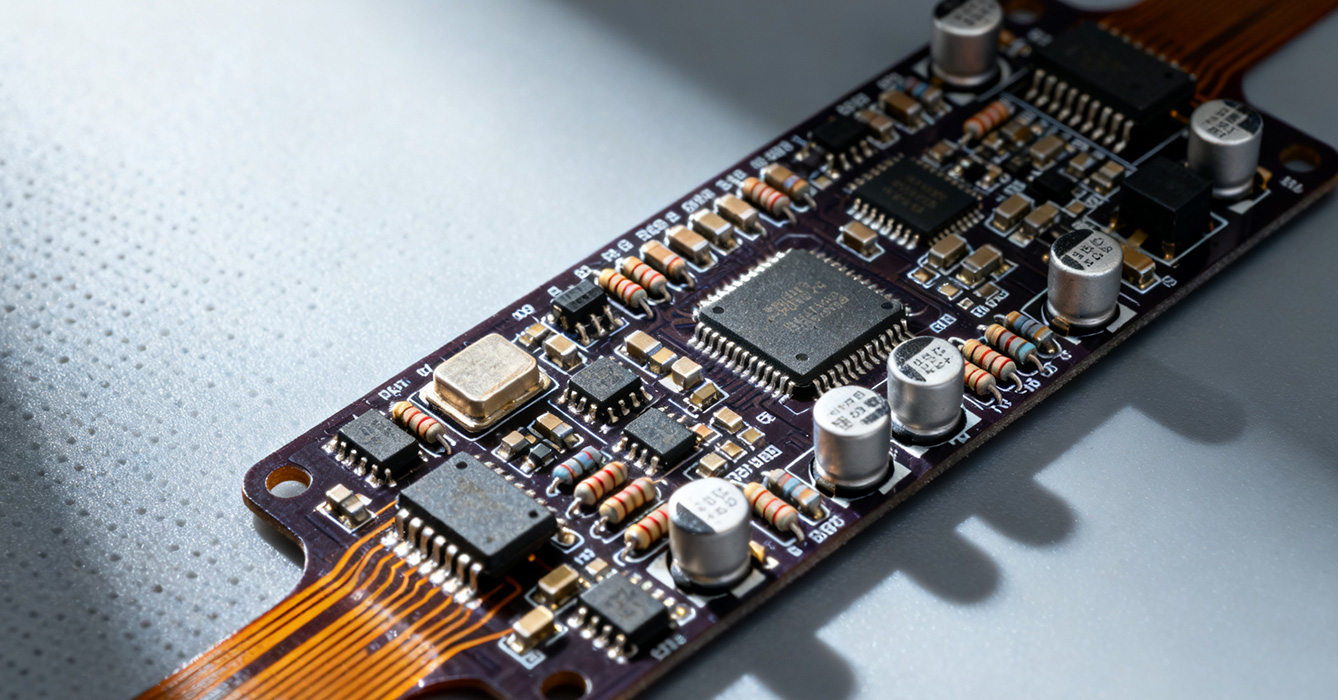

The global electronics industry’s unrelenting pursuit of miniaturization, multi-functionality, and energy efficiency has positioned FPC High Density Component Assembly as a transformative manufacturing technology. This specialized process focuses on integrating a high concentration of electronic components—including active devices, passive components, and functional modules—onto flexible printed circuits (FPCs) while maintaining mechanical flexibility and electrical reliability. Unlike standard FPC assembly, which prioritizes basic component connectivity, FPC High Density Component Assembly emphasizes optimizing interconnect density, thermal management, and assembly consistency to support the next generation of compact, high-performance devices. For industries spanning 5G communications, electric vehicles (EVs), and advanced medical equipment, this assembly technology is a critical enabler of product innovation and market competitiveness.

FPC High Density Component Assembly delivers unique value propositions that address the core demands of modern electronic product design:

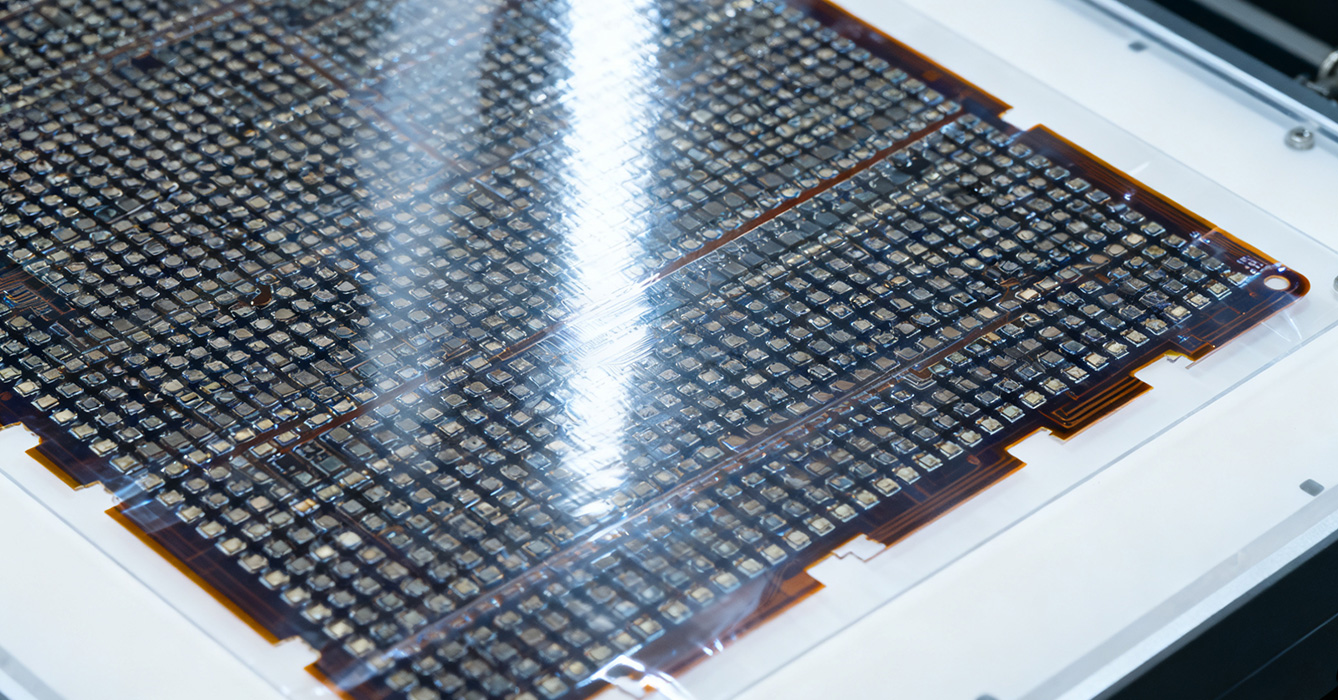

- Ultra-High Component Integration: This assembly process enables the dense placement of components on FPC substrates, significantly increasing the number of functional units per unit area. By leveraging advanced interconnect designs (such as micro vias and high-density routing), it eliminates redundant wiring and reduces the overall footprint of FPC assemblies. This is pivotal for compact devices like 5G millimeter-wave modules, miniaturized EV battery management systems (BMS), and portable diagnostic equipment, where space is at a premium.

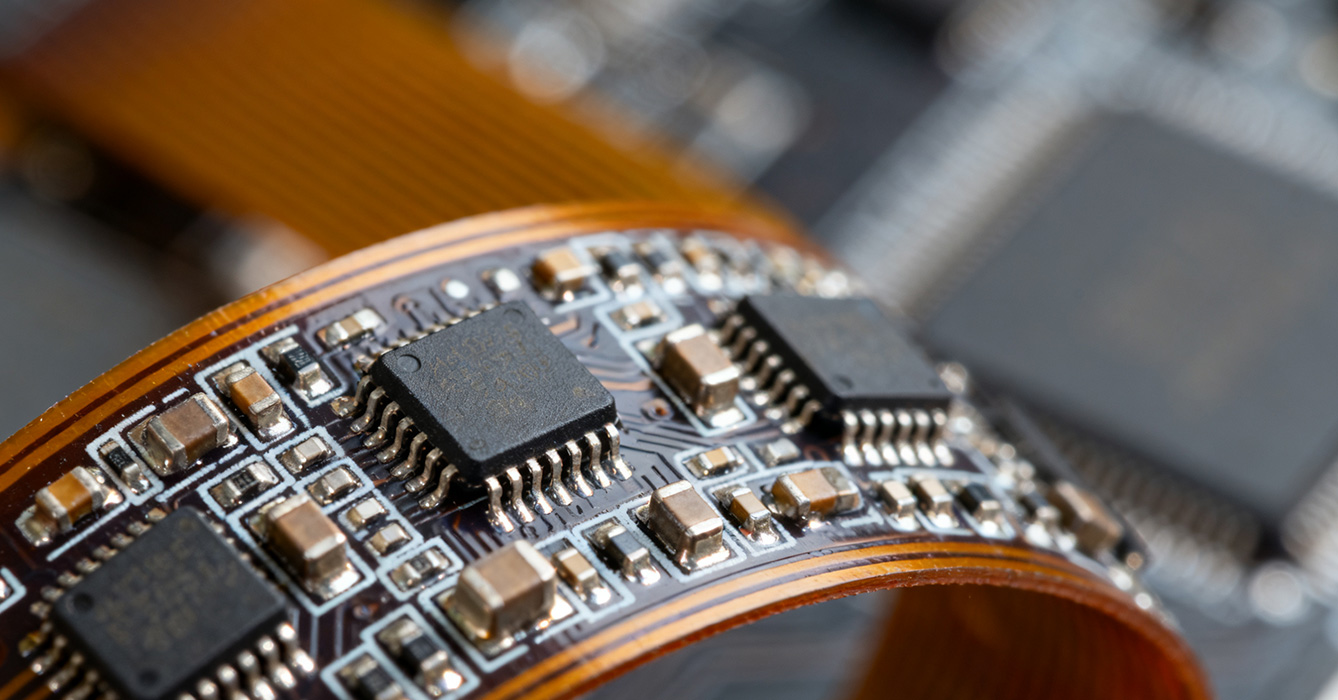

- Flexibility with Uncompromised Performance: Unlike rigid PCB high-density assembly, FPC High Density Component Assembly preserves the inherent flexibility of FPCs. The assembled circuits can bend, twist, or conform to curved surfaces—critical for applications such as foldable smartphone hinges, robotic joint sensors, and wearable health monitors. This flexibility does not come at the cost of performance; optimized assembly processes ensure stable signal transmission and reliable component connections even under dynamic mechanical stress.

- Enhanced Thermal Management Capabilities: High-density component integration inevitably generates more heat, which can degrade device performance and lifespan. Professional FPC High Density Component Assembly services incorporate targeted thermal management solutions, such as high-thermal-conductivity solder paste, thermal vias, and conformal coatings. These measures efficiently dissipate heat from dense component clusters, ensuring stable operation of high-power devices like EV powertrain components and industrial IoT sensors.

- Scalable Consistency for Mass Production: Advanced automation technologies—including high-precision SMT placement systems, automated optical inspection (AOI), and X-ray inspection—are central to FPC High Density Component Assembly. These tools ensure consistent component placement accuracy and solder joint quality across large production batches, reducing defect rates and improving manufacturing efficiency. This scalability is essential for meeting the high-volume demands of consumer electronics and automotive industries.

Integrating high-density components on flexible substrates presents unique technical hurdles, requiring tailored solutions from experienced service providers:

- Interconnect Density & Signal Integrity: High component density increases the risk of electromagnetic interference (EMI) and crosstalk between adjacent circuits. Solutions include implementing ground planes and signal shielding layers in FPC designs, using low-loss dielectric materials, and optimizing component placement to minimize signal path lengths. Advanced electromagnetic simulation tools are also used to predict and mitigate interference issues before production.

- FPC Substrate Stability During Assembly: Flexible substrates are prone to warping or stretching under the thermal and mechanical stress of high-density assembly. Service providers use custom vacuum fixtures to secure FPCs during processing, optimize reflow soldering profiles to reduce thermal expansion, and select high-stability polyimide substrates with minimal warpage. These measures ensure precise component alignment even in dense layouts.

- Reliability of Dense Solder Joints: High-density assemblies feature numerous small solder joints, which are vulnerable to fatigue and failure under thermal cycling or mechanical bending. Solutions include using lead-free solder alloys with enhanced ductility, applying selective underfill to reinforce critical components (e.g., microcontrollers, BGA chips), and conducting rigorous reliability testing (thermal cycling, flex endurance tests) to validate joint integrity.

- Quality Inspection of Dense Layouts: Traditional visual inspection cannot detect defects in hidden or densely packed solder joints. Service providers employ 3D AOI for surface defect detection and X-ray inspection (including computed tomography) to examine solder joints under components. This comprehensive inspection ensures that even the most complex high-density assemblies meet strict quality standards.

This specialized assembly technology is indispensable in industries that demand compact, high-performance, and flexible electronic systems:

- 5G Communications & Consumer Electronics: Powers 5G smartphones, tablets, and millimeter-wave modules. FPC High Density Component Assembly enables the integration of multiple communication modules, sensors, and power management units into compact, flexible form factors, supporting high-speed data transmission and multi-functional user experiences.

- Electric Vehicles (EVs) & Automotive Electronics: Supports EV BMS, ADAS (Advanced Driver Assistance Systems), and in-vehicle infotainment systems. The high-density assembly allows for compact, lightweight FPCs that fit into tight automotive spaces, while thermal management solutions ensure reliable operation under extreme temperatures and vibration.

- Advanced Medical Devices: Enables miniaturized implantable sensors, portable diagnostic equipment, and surgical robots. The technology’s high integration density and flexibility allow devices to conform to anatomical structures, while strict quality control ensures compliance with medical standards (e.g., ISO 13485) and patient safety.

- Industrial IoT & Automation: Assembles FPCs for industrial sensors, robotic control systems, and edge computing devices. High-density component integration supports multi-sensing capabilities, while ruggedized assembly processes ensure reliability in harsh industrial environments (dust, humidity, temperature fluctuations).

In conclusion, FPC High Density Component Assembly is a cornerstone technology for modern flexible electronics, enabling the integration of more functions into smaller, more adaptable form factors. By addressing the unique challenges of high-density component placement on flexible substrates—through advanced interconnect design, thermal management, and quality control—it delivers reliable, high-performance assemblies that power innovation across critical industries. As the demand for compact, intelligent, and flexible electronic devices continues to grow, partnering with a professional FPC High Density Component Assembly service provider will remain a strategic imperative for manufacturers seeking to gain a competitive edge in global markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB