-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 02. 2025, 11:41:50

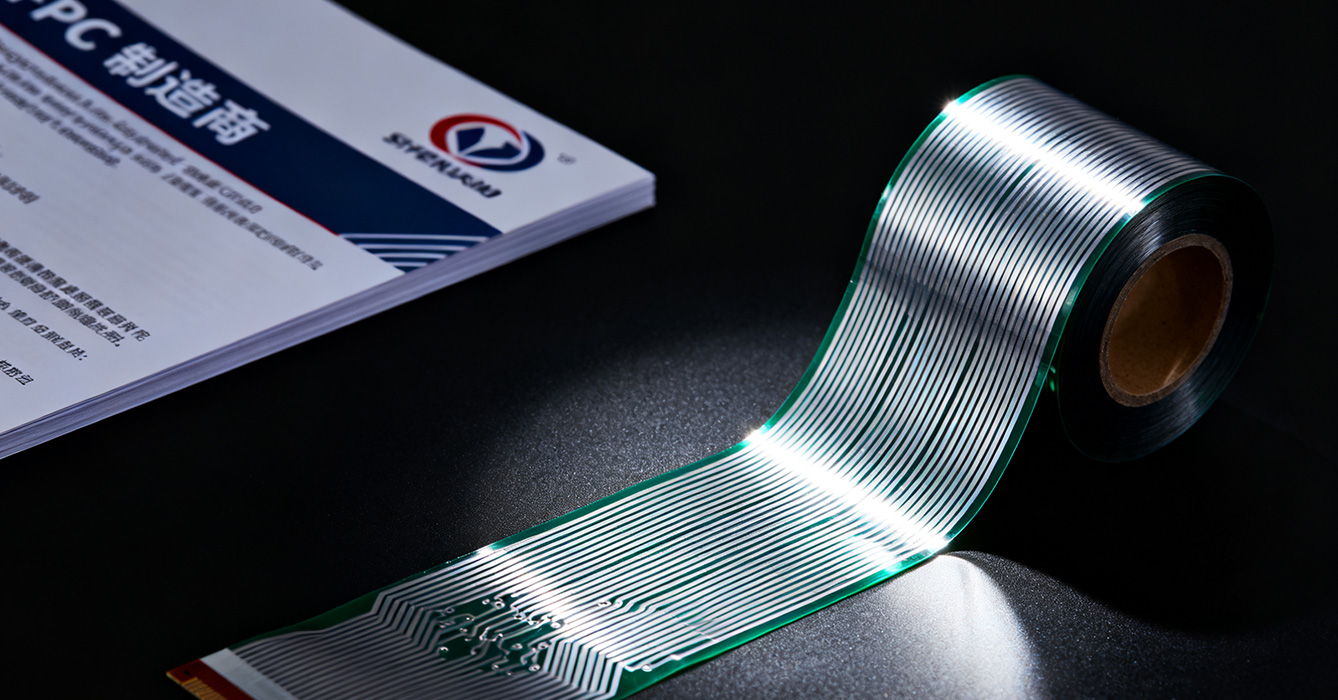

As the global electronics industry embraces the dual trends of digital transformation and green sustainability, the role of a professional FPC manufacturer has evolved beyond component production to become a catalyst for eco-friendly and technologically advanced flexible electronics. An FPC manufacturer specializing in sustainable innovation integrates environmentally responsible practices with cutting-edge manufacturing technologies, delivering flexible printed circuits (FPCs) that balance performance, reliability, and environmental impact. Unlike traditional FPC suppliers, these forward-thinking manufacturers prioritize green material adoption, energy-efficient processes, and circular economy principles, while adapting to the evolving needs of emerging technologies such as AIoT, 6G, and smart mobility. For enterprises pursuing carbon neutrality goals and technological leadership, partnering with a reputable FPC manufacturer with strong sustainability and innovation capabilities is a strategic imperative.

A leading FPC manufacturer distinguishes itself in the current market by combining sustainable manufacturing, technological innovation, and customer-centric flexibility:

- Sustainable Manufacturing Expertise: Modern FPC manufacturers leverage eco-friendly materials and processes to reduce environmental footprint. This includes adopting halogen-free, RoHS-compliant substrates, water-based soldering fluxes, and recyclable packaging materials. They also implement energy-efficient production lines—such as LED curing systems and waste heat recovery technology—and optimize water usage through closed-loop recycling systems. These practices not only meet global environmental regulations but also help customers achieve their own sustainability targets.

- Frontier Technology Co-innovation Capabilities: To keep pace with emerging electronic trends, top FPC manufacturers invest heavily in R&D and collaborate with customers on co-innovation. They specialize in developing FPC solutions tailored for cutting-edge applications, such as ultra-high-frequency 6G modules, AIoT sensors, and flexible displays for smart座舱 (cockpits). This includes integrating advanced technologies like AI-assisted circuit design, which optimizes layout efficiency and reduces material waste, and additive manufacturing for rapid prototyping of complex FPC structures.

- Resilient Global Supply Chain & Compliance: A reliable FPC manufacturer builds robust global supply chains with multiple certified material sources, ensuring stability amid market fluctuations and geopolitical risks. They also maintain strict compliance with industry-specific regulations across regions—such as REACH in the EU, CPSIA in the US, and China’s GB standards—simplifying customers’ market entry. Additionally, they offer flexible production models, from small-batch custom orders to large-scale mass production, to adapt to diverse customer needs.

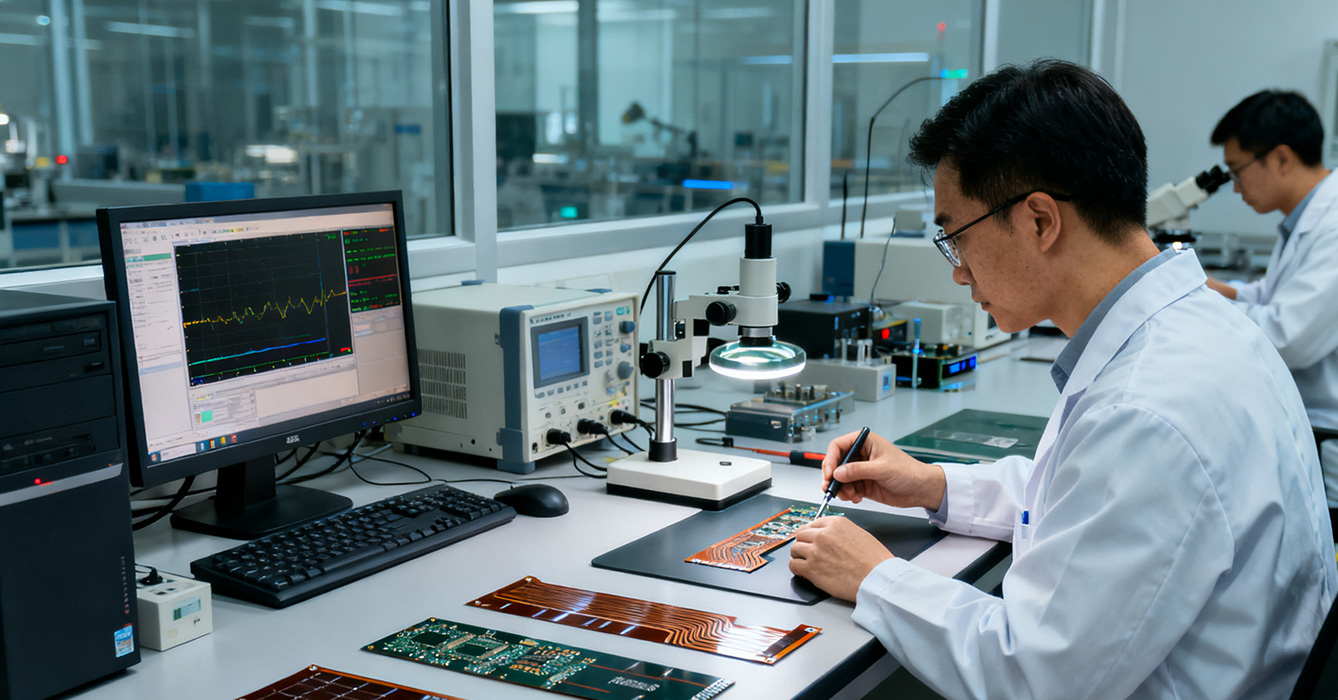

- Advanced Quality Assurance with Digitalization: Digital transformation enhances quality control for modern FPC manufacturers. They adopt digital quality management systems that integrate real-time data from automated optical inspection (AOI), X-ray testing, and production equipment. This enables full traceability of each FPC unit, from raw material input to final delivery, and allows for predictive maintenance of production lines to minimize defects. The digitalized QA process ensures consistent quality while improving production efficiency.

The unique capabilities of modern FPC manufacturers address the dual challenges of technological advancement and environmental sustainability, making them indispensable for future-oriented electronics enterprises:

1. Accelerating Green Transition in Electronics: With global governments and consumers increasingly prioritizing sustainability, electronic products must meet strict environmental standards. FPC manufacturers’ sustainable practices—from eco-friendly materials to low-carbon production—enable customers to launch greener products, enhancing brand reputation and market competitiveness.

2. Enabling Innovation in Emerging Technologies: Emerging fields like 6G, autonomous driving, and wearable healthcare require FPCs with unprecedented performance (e.g., higher frequency compatibility, better mechanical durability). FPC manufacturers’ R&D and co-innovation capabilities ensure that FPC solutions can keep up with these technological advancements, providing the hardware foundation for innovative products.

3. Enhancing Supply Chain Resilience: The global electronics supply chain is increasingly volatile, with risks such as material shortages and geopolitical disruptions. FPC manufacturers with diversified global supply chains and flexible production capabilities help customers mitigate these risks, ensuring stable supply and on-time delivery.

4. Optimizing Total Cost of Ownership: Sustainable manufacturing processes often reduce material waste and energy consumption, lowering production costs in the long run. Additionally, digitalized QA and production systems minimize defect rates and rework costs. For customers, partnering with such FPC manufacturers optimizes the total cost of ownership beyond initial procurement costs.

Modern FPC manufacturers support a range of forward-looking industries, delivering sustainable and high-performance FPC solutions:

- Smart Mobility & Electric Vehicles (EVs): Supplies lightweight, high-temperature-resistant FPCs for EV powertrains, smart cockpits, and autonomous driving sensors. These FPCs are manufactured with eco-friendly materials to align with the automotive industry’s carbon neutrality goals, while ensuring reliability under extreme operating conditions.

- AIoT & Smart Home: Enables compact, low-power FPCs for smart home sensors, connected devices, and edge computing modules. Manufacturers leverage AI-assisted design to optimize FPC layouts for energy efficiency, supporting the growing demand for intelligent, sustainable home electronics.

- Advanced Healthcare & Wellness: Provides biocompatible, miniaturized FPCs for wearable health monitors, portable diagnostic equipment, and telemedicine devices. These FPCs meet strict medical compliance standards and are manufactured with clean, sustainable processes to ensure patient safety.

- Next-Generation Consumer Electronics: Powers foldable smartphones, AR/VR devices, and 5G/6G-enabled gadgets with flexible, high-performance FPCs. Manufacturers focus on reducing the environmental impact of these consumer products through recyclable materials and energy-efficient production.

In conclusion, a modern FPC manufacturer is more than a component supplier—it is a strategic partner driving sustainability and innovation in the flexible electronics ecosystem. By integrating green manufacturing practices, co-innovating on frontier technologies, and building resilient supply chains, these manufacturers enable customers to develop high-performance, environmentally friendly products. As the electronics industry continues to prioritize sustainability and technological advancement, the role of a forward-thinking FPC manufacturer will become increasingly critical. For enterprises seeking to thrive in the future market, partnering with such a manufacturer is essential to achieving both environmental and business objectives.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB