-

- PCB TYPE

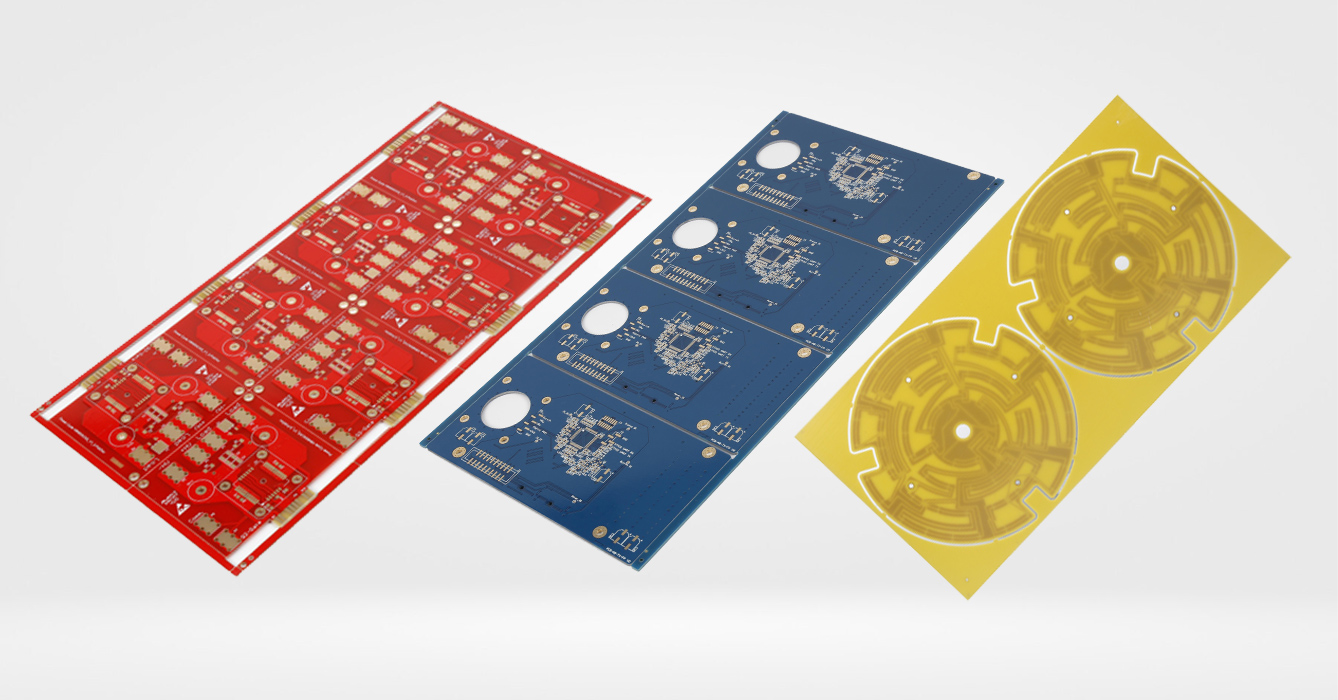

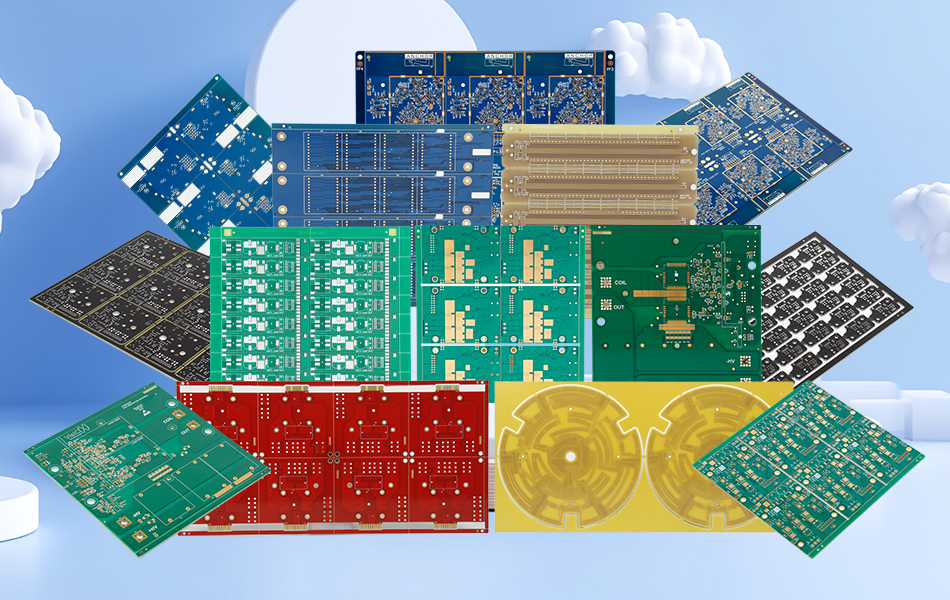

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 20. 2026, 13:50:28

For factory customers, “fast” and “reliable” are not competing goals—they’re the baseline. In the prototype phase, you need quick turns to validate function and move engineering forward. In volume production, you need repeatability: stable materials, consistent stackups, predictable solderability, controlled warpage, and quality records that support long-term supply.

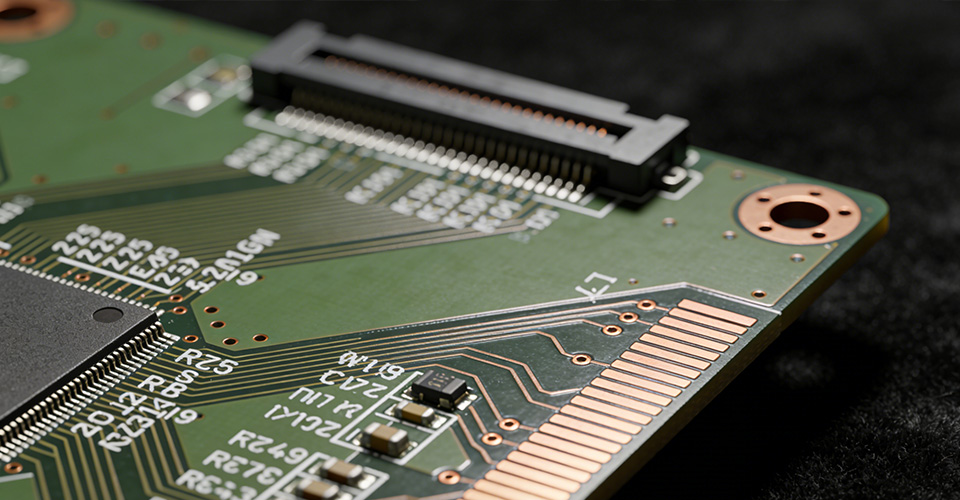

That’s exactly why choosing the right FR4 PCB manufacturer matters. FR4 PCB remains the most widely used board type in the electronics industry because it balances electrical performance, mechanical strength, and cost across a huge range of products—from industrial control and consumer electronics to power supplies and lighting control. If your program is moving from rapid iteration to monthly volume, a manufacturing partner must support both ends of the lifecycle without forcing design rework.

This article explains what makes a production-ready FR4 supplier, how to use low CTE fr4 to improve reliability, and how to specify mechanical features like Countersink Holes in fr4 PCB and Counterbore holes in fr4 PCB correctly—so your boards assemble cleanly and fit perfectly in the final enclosure. We’ll also show what a practical fr4 pcb datesheet should include to reduce quote delays and prevent mismatches.

FR4 has a stable and widely supported process ecosystem: materials are available across many grades, manufacturing windows are well-known, and assembly compatibility is proven. This reduces risk when transitioning from prototype to volume.

An FR4 PCB is made from glass-fiber reinforced epoxy. That gives it:

Good stiffness and dimensional stability for assembly

Strong electrical insulation

Cost-effective multilayer manufacturing options

Compatibility with common surface finishes and solder masks

Many designs start on FR4, then selectively upgrade to specialized materials only where needed. This is especially common when teams are still validating thermals, EMI, and enclosure constraints.

A fast prototype only helps if it behaves like the eventual production build. The best FR4 PCB manufacturer treats prototyping as production-intent validation, not a separate “cheap build.”

DFM checks for drill-to-copper, annular ring, solder mask slivers, and copper balance

Stackup alignment with future mass production (thickness, copper weights, dielectric targets)

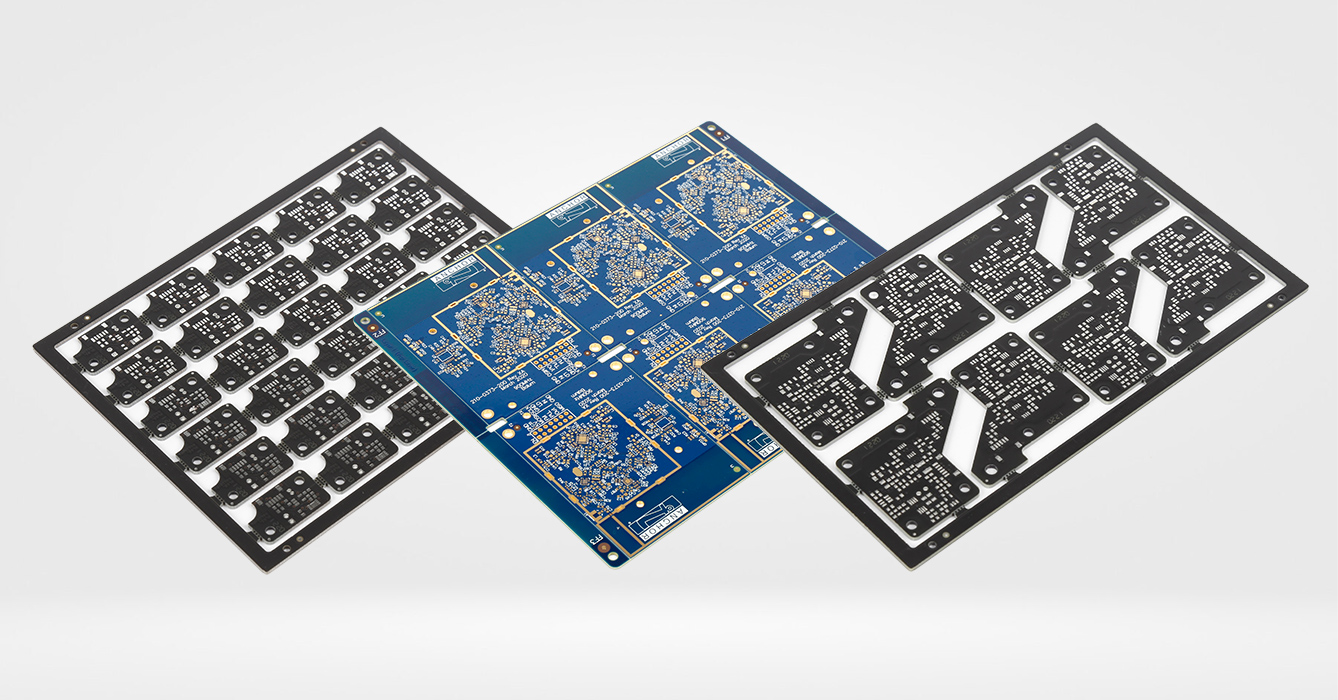

Panelization strategy that can scale to your SMT line

Finish selection that matches volume expectations (rather than “whatever is quickest”)

Clear revision control and build notes

Factory reality: Most prototype failures are not electrical—they’re mechanical fit issues, assembly yield issues, or process mismatch issues. A manufacturer who asks the right questions early saves days (and sometimes weeks) later.

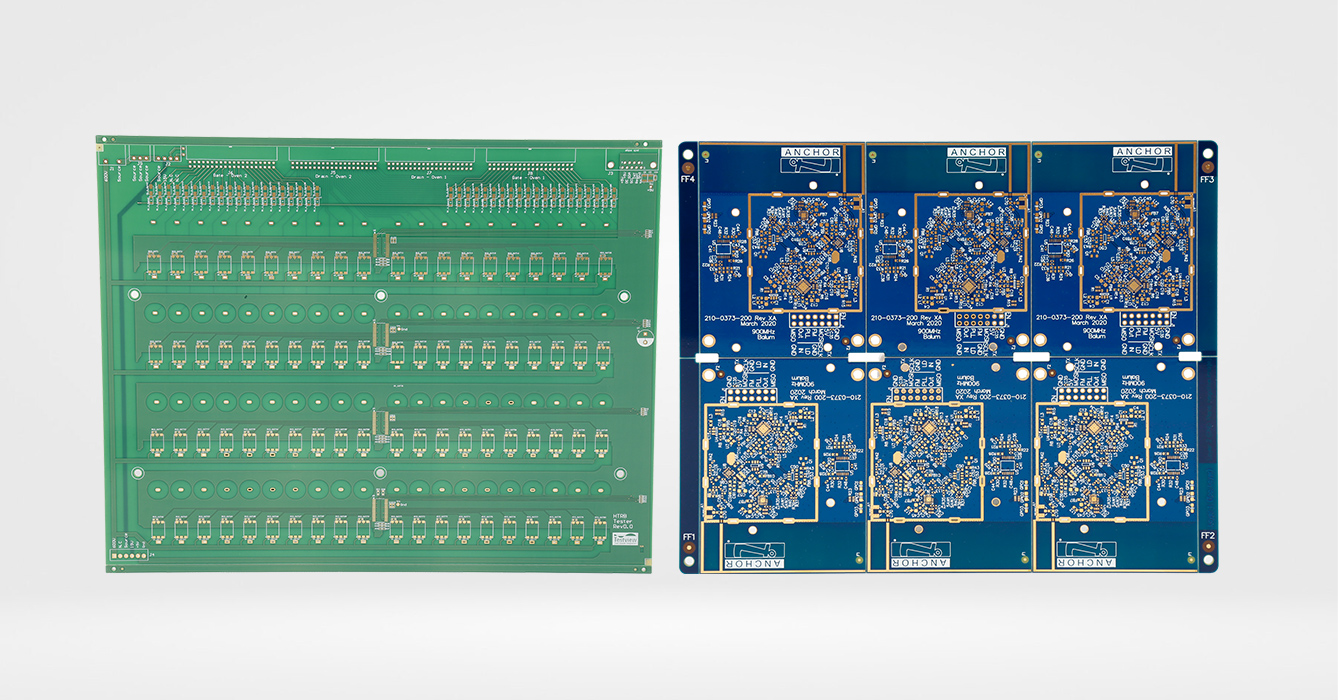

Once you move to volume, small variations become expensive. A reliable FR4 PCB manufacturer should demonstrate consistency in:

Stable laminate sourcing and lot traceability

Clear definition of the FR4 grade used (especially Tg/CTE class)

Repeatable prepreg and core selection for the same stackup

Multilayer FR4 relies on consistent lamination cycles and accurate layer registration. Poor control shows up as impedance drift, misregistration, and via reliability issues.

Via wall quality and plating thickness influence both electrical continuity and long-term reliability—especially in higher layer counts.

A robust supplier supports AOI (pattern inspection) and electrical test coverage appropriate for your risk profile and volume plan.

CTE (Coefficient of Thermal Expansion) describes how much a material expands with temperature. In real factory products, thermal cycles happen everywhere:

Lead-free reflow

Power cycling in the field

Hot/cold environmental changes

High current traces heating locally

Using low CTE fr4 can help:

Reduce mechanical stress on plated through holes and vias during thermal cycling

Improve dimensional stability for tight mechanical tolerances

Reduce warpage risk on larger panels or thinner boards

Improve long-term reliability in harsher duty cycles

When to consider low CTE fr4

High layer count boards

High thermal cycling products (industrial, automotive-adjacent, outdoor)

Designs with dense via fields or fine-pitch BGAs

Larger boards where warpage impacts SMT yield

Factory assemblies often require mechanical features that go beyond standard drilled holes. Two of the most common are countersinks and counterbores—both critical for enclosure fit, grounding hardware, and flush mounting.

Countersink holes have a conical recess that allows flat-head screws to sit flush with the PCB surface.

Common use cases

Flush mounting to avoid interference with covers or adjacent boards

Mechanical alignment in tight enclosures

Aesthetic and safety requirements (no protruding fasteners)

Design notes for factory success

Specify the countersink angle (commonly 82° or 90°, depending on screw standard)

Define the top diameter and the finished depth (not only the drill diameter)

Keep adequate copper clearance and mask clearance around the recess

Confirm whether the supplier performs countersink by CNC routing or controlled-depth tooling

Including the exact callout “Countersink Holes in fr4 PCB” in your fabrication notes helps avoid misinterpretation during quoting and CAM review.

Counterbore holes have a flat-bottomed cylindrical recess. They’re typically used when you need a bolt or screw head to sit below or flush with the surface, but with a straight wall rather than a cone.

Common use cases

Socket head cap screws with a flat seat

Controlled standoff height

Hardware pockets for mechanical rigidity

Design notes

Define counterbore diameter + depth + tolerance

Clarify if the counterbore is on top, bottom, or both sides

Keep copper away from the pocket edge to reduce delamination or exposure risk

Consider fiberglass weave and routing direction on tight mechanical tolerances

Adding the phrase “Counterbore holes in fr4 PCB” in your fab drawing and notes reduces the chance that the recess is missed or built incorrectly.

Many delays in PCB quoting happen because the supplier must “guess” missing requirements. A practical fr4 pcb datesheet (spelled as you prefer in your internal docs) should clearly define the build intent.

Board basics

Layer count

Finished thickness and tolerance

Finished copper weights (outer/inner)

Minimum trace/space and minimum drill

Material

FR4 grade / Tg class

Whether low CTE fr4 is required

Any dielectric targets (for impedance-controlled designs)

Mechanical

Outline tolerance requirements

Slots/cutouts and their tolerances

Countersink Holes in fr4 PCB: angle, top diameter, depth

Counterbore holes in fr4 PCB: diameter, depth, side, tolerance

Finish & protection

Surface finish preference (based on assembly/reliability targets)

Solder mask color and requirements

Legend requirements

Test & acceptance

Electrical test requirements

Any special acceptance criteria for critical nets or high voltage

A clear fr4 pcb datesheet shortens quote time, improves first-pass yield, and prevents costly assumptions from creeping into production.

When your goal is fast prototypes and stable volume, evaluate suppliers on:

Can they support your current layer count and future revisions?

Do they support controlled impedance if needed?

Can they meet your mechanical features and tolerances (countersink/counterbore)?

Fast DFM feedback that’s specific (not generic)

Clear questions about missing specs

Practical solutions to improve yield and reduce cost

Material lot control and traceability

Stable process documentation

Defined inspection and test flow appropriate to your volume

Fast, accurate quoting that doesn’t change after CAM review

Clear lead time commitments and production updates

Send this package to get accurate pricing and avoid back-and-forth:

Gerber + drill files

Board outline + panel requirement (if any)

Stackup target, thickness, copper weights

Material requirement: FR4 grade + whether low CTE fr4 is needed

Any impedance requirements

Finish and solder mask requirements

Mechanical callouts: Countersink Holes in fr4 PCB and/or Counterbore holes in fr4 PCB with dimensions

Quantity plan: prototype / pilot / monthly volume

Testing requirement (electrical test coverage)

If you’re sourcing a dependable FR4 PCB manufacturer for fast prototyping and volume production, share your Gerber files and a clear fr4 pcb datesheet including material class (especially low CTE fr4 when required) and mechanical callouts such as Countersink Holes in fr4 PCB and Counterbore holes in fr4 PCB. Clear build intent up front shortens your NPI cycle, improves SMT yield, and reduces the risk of redesign during ramp-up.

Q1: What is FR4 PCB and why is it used so widely?

FR4 PCB is a glass-fiber reinforced epoxy laminate board. It’s widely used because it offers strong mechanical stability, good electrical insulation, and cost-effective manufacturing from prototypes to mass production.

Q2: What does low CTE fr4 mean, and when should I choose it?

low CTE fr4 expands less with temperature changes. It’s recommended for higher layer counts, dense via designs, and products exposed to thermal cycling where dimensional stability and via reliability are critical.

Q3: How should I specify Countersink Holes in fr4 PCB for manufacturing?

For Countersink Holes in fr4 PCB, specify the countersink angle, top diameter, and depth (plus which side). Also include copper and solder mask clearance rules to prevent exposure or mechanical damage near the recess.

Q4: What is the difference between counterbore and countersink in FR4 PCB?

A countersink is a conical recess for flat-head screws. A counterbore is a flat-bottom cylindrical recess often used for socket head screws. Correct callouts for Counterbore holes in fr4 PCB should include diameter, depth, side, and tolerances.

Q5: What should be included in an fr4 pcb datesheet to speed up quoting?

A good fr4 pcb datesheet includes layer count, thickness, copper weights, FR4 grade/Tg, whether low CTE fr4 is required, finish/mask requirements, test expectations, and mechanical callouts like countersink/counterbore dimensions.

Related Articles

FR4 PCB Prototype and Production Manufacturing Services

FR4 PCB Manufacturer for Prototype and Mass Production

FR4 PCB Manufacturer for PCB Prototypes and Mass Production

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB