-

- PCB TYPE

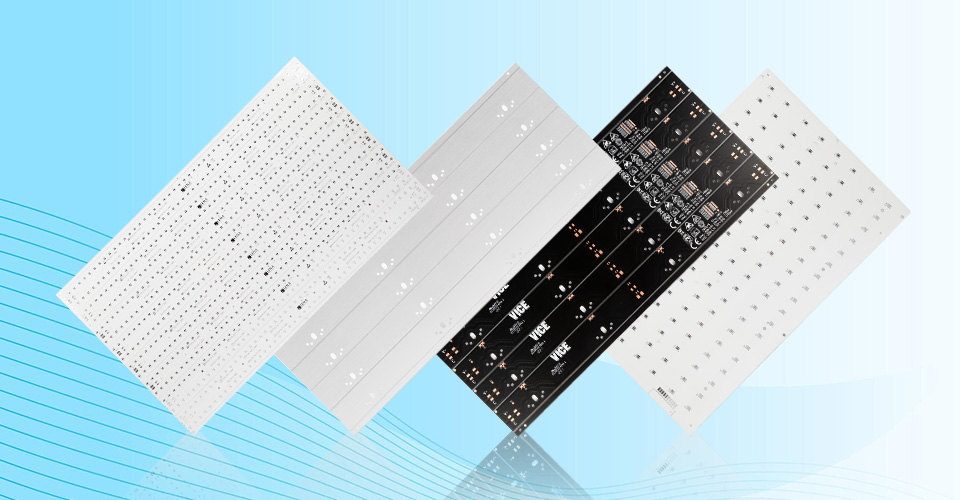

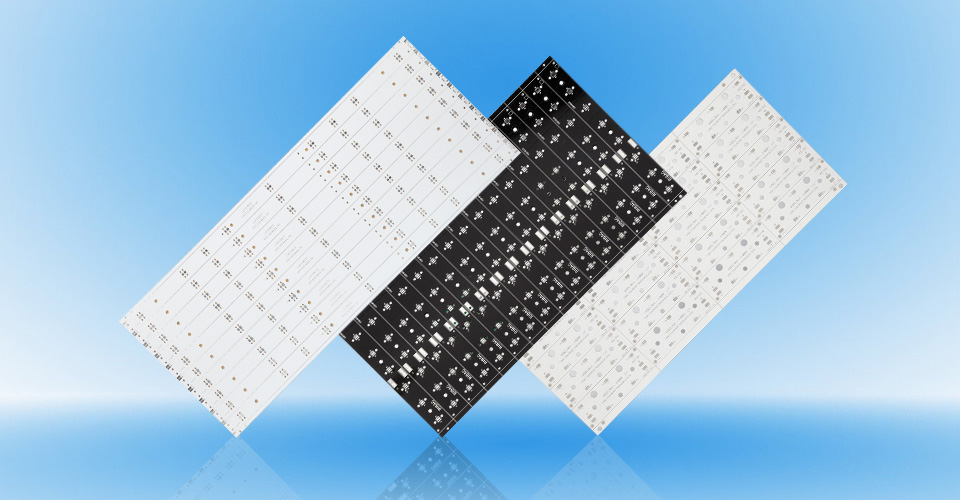

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 21. 2026, 11:17:21

For factory customers, the most expensive PCB is not the one with the highest unit price—it’s the one that causes delays, re-spins, assembly scrap, and field returns. Whether you’re building a new product prototype or scaling into monthly volume, selecting the right FR4 PCB manufacturer determines how fast you can validate designs, how stable your yields will be, and how consistently your boards will perform over time.

FR4 PCB remains the industry’s most common choice because it offers a strong balance of cost, electrical insulation, mechanical strength, and manufacturing maturity. But “FR4” is not one single grade. To build reliably from prototypes to mass production, you need to understand FR4 PCB material type, when to specify HIGH TG FR4 PCB, how to interpret fr4 pcb thermal conductivity, and how to define your FR4 PCB tempreture rating requirements clearly enough to avoid quoting ambiguity and production drift.

This guide is written for procurement teams, engineers, and project owners who need practical criteria—not generic marketing claims.

An FR4 printed circuit board is typically a glass-fiber reinforced epoxy laminate system. In practical manufacturing terms, FR4 is popular because it:

Handles standard SMT and lead-free assembly processes well (with the correct grade)

Provides stable electrical insulation for most general electronics

Offers predictable mechanical performance for enclosure integration

Scales efficiently from prototype panels to high-volume production

For many products—industrial controls, consumer electronics, power supplies, communication modules, and lighting control—FR4 is the most cost-effective and supply-stable platform.

If you want consistent results, define your FR4 PCB material type early. The key differentiators typically include:

Tg (glass transition temperature) is a critical performance divider. Standard FR4 and HIGH TG FR4 PCB differ in thermal stability during reflow and long-term operation.

Standard Tg FR4 is often suitable for many low-to-mid thermal stress products.

HIGH TG FR4 PCB is recommended when your board will see:

multiple lead-free reflow cycles

higher continuous operating temperatures

higher layer counts (more internal stress)

stricter reliability targets (industrial/automotive-adjacent)

Factory tip: If you don’t specify Tg class, suppliers may quote different laminates across builds—leading to changes in warpage behavior, via reliability, and long-term stability.

Different resin systems can impact:

delamination resistance

CAF (conductive anodic filament) risk under humidity/bias

drilling quality and smear behavior

long-term insulation stability

If your design includes high-speed interfaces, specify dielectric targets or tolerance expectations. Even for FR4, consistency matters more than “best-case” properties.

Many factory RFQs use “temperature rating” loosely. A clear FR4 PCB tempreture rating definition should include at least two parts:

Assembly temperature exposure

Lead-free reflow peak expectations

Number of reflow cycles (single, double-sided, rework allowance)

Operating temperature range and duty cycle

Ambient environment and internal heat rise

Continuous vs intermittent operation

Expected service life

Practical guidance: If your product is warm-running (power conversion, drivers, dense enclosures), specify HIGH TG FR4 PCB and provide the expected max board temperature region—especially near hot components. This helps your manufacturer recommend an appropriate laminate class.

People often expect FR4 to “solve heat.” It won’t—at least not like metal-core substrates. fr4 pcb thermal conductivity is generally much lower than aluminum or copper-based thermal solutions. However, FR4 can still be appropriate if:

the heat source is distributed (not a single hotspot)

your enclosure and airflow manage heat effectively

the board is primarily a control/driver board rather than the heat sink

you use design techniques to spread heat (copper pours, thermal vias to planes, thicker copper where appropriate)

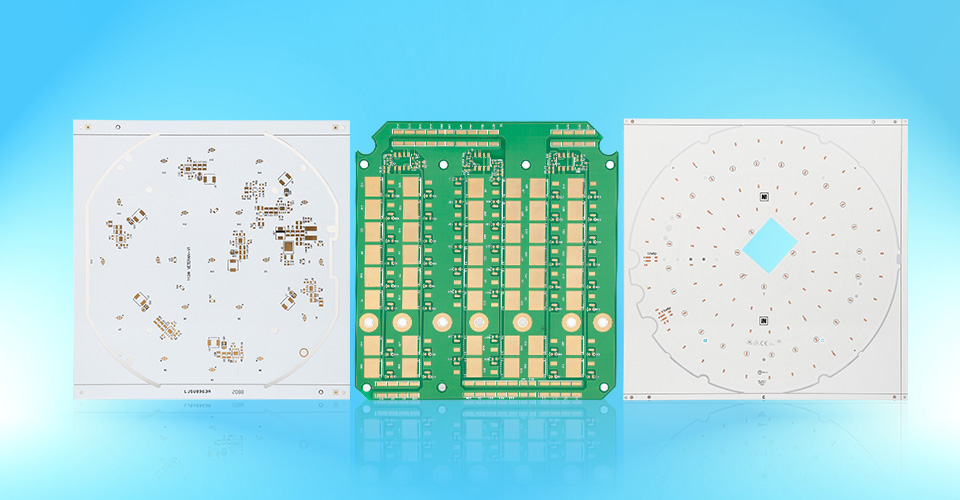

Factory tip: If you’re building a lighting product, it’s common to use FR4 for driver/control circuits while using an aluminum MCPCB only for the LED emitter board. This hybrid approach keeps cost controlled while meeting thermal needs.

When you discuss fr4 pcb thermal conductivity in your spec, treat it as one factor within a system-level thermal design—not a stand-alone guarantee.

A strong FR4 PCB manufacturer doesn’t just “print boards.” They provide a consistent path from first prototypes to stable mass production.

True fast prototyping includes:

DFM feedback that prevents re-spins (drill-to-copper, annular ring, solder mask clearance, copper balance)

stackup documentation so future builds match the prototype

panelization suggestions aligned to your SMT line

finish selection aligned with volume intent (not just fastest available)

Goal: prototypes that validate function and assembly.

For mass production, the manufacturer must control:

laminate lot consistency and traceability

lamination cycle stability and registration

drilling and via wall quality

copper plating thickness consistency

solder mask alignment and cure stability

electrical test coverage and defect containment rules

Factory reality: Most “mysterious” line issues are actually drift: a slightly different FR4 grade, a shifted process window, a changed mask thickness, or a small warpage increase.

Use HIGH TG FR4 PCB when your program has any of these risk flags:

multi-layer boards where Z-axis expansion stresses vias

dense BGA designs that are sensitive to warpage

higher power density and warmer internal temperatures

repeated reflow cycles or rework exposure

long-life industrial products (24/7 duty cycles)

environments with temperature swings (outdoor / transportation / factory floor)

Procurement tip: HIGH TG FR4 PCB often costs more per panel, but it can reduce the total cost of quality by improving assembly yield and reducing long-term returns.

To avoid quote delays and inconsistent builds, include a short “materials and reliability” section in your RFQ:

FR4 PCB material type: Standard Tg or HIGH TG FR4 PCB (state Tg class requirement)

Thickness and tolerance

Copper weight (outer/inner)

Layer count

Any impedance-control needs

Operating temperature range + duty cycle (your FR4 PCB tempreture rating intent)

Any special reliability requirements (humidity, bias, long life)

If you have a preferred laminate family, state it; if not, state performance targets so the supplier can recommend an equivalent.

Send these items to your FR4 PCB manufacturer:

Gerber + drill files

Board outline and any panelization requirements

Layer count + finished thickness

Copper weight (outer/inner)

FR4 PCB material type: standard vs HIGH TG FR4 PCB

Your FR4 PCB tempreture rating intent: reflow cycles + operating range

Notes about fr4 pcb thermal conductivity expectations (system-level thermal constraints)

Surface finish requirement (based on assembly and reliability targets)

Solder mask color and any special requirements

Testing requirement (electrical test coverage expectations)

Quantity plan: prototype / pilot / monthly volume

If you’re sourcing a reliable FR4 PCB manufacturer for fast prototypes and stable mass production, share your Gerber files and a clear materials section that includes FR4 PCB material type, whether HIGH TG FR4 PCB is required, and your FR4 PCB tempreture rating expectations. Clear requirements reduce quoting time, prevent material drift between builds, and improve long-term consistency—especially on programs where assembly yield and reliability matter most.

FR4 PCB material type refers to the specific FR4 grade (Tg class, resin system, and reliability characteristics). Specifying it prevents suppliers from switching laminates between prototype and volume builds, which can affect warpage, via reliability, and long-term stability.

Choose HIGH TG FR4 PCB for higher thermal stress programs: multiple reflow cycles, higher operating temperatures, higher layer counts, dense BGAs, or long-life industrial products. It improves thermal stability and reduces risk during production ramp.

Your FR4 PCB tempreture rating should cover both assembly exposure (lead-free reflow peaks and number of cycles) and operating conditions (expected ambient and maximum board temperature regions, duty cycle, service life targets).

fr4 pcb thermal conductivity is relatively low compared to metal-core solutions, but FR4 can still work for many products if the system-level thermal design is correct (copper spreading, airflow, enclosure design, distributed heat). For high-power LED emitters, many designs use aluminum MCPCB for LEDs and FR4 for driver/control circuits.

Work with an FR4 PCB manufacturer that documents the stackup and material grade, provides DFM feedback, and maintains material/process consistency. Clearly specify FR4 PCB material type, HIGH TG FR4 PCB (if needed), and test/inspection expectations from the first prototype build.

[Get a Free Quote & Thermal Analysis for Your Aluminum PCB Project Today]

Related Articles

FR4 PCB Prototype and Production Manufacturing Services

FR4 PCB Manufacturer for Prototype and Mass Production

FR4 PCB Manufacturer for Fast Prototyping and Volume Production

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB