-

- PCB TYPE

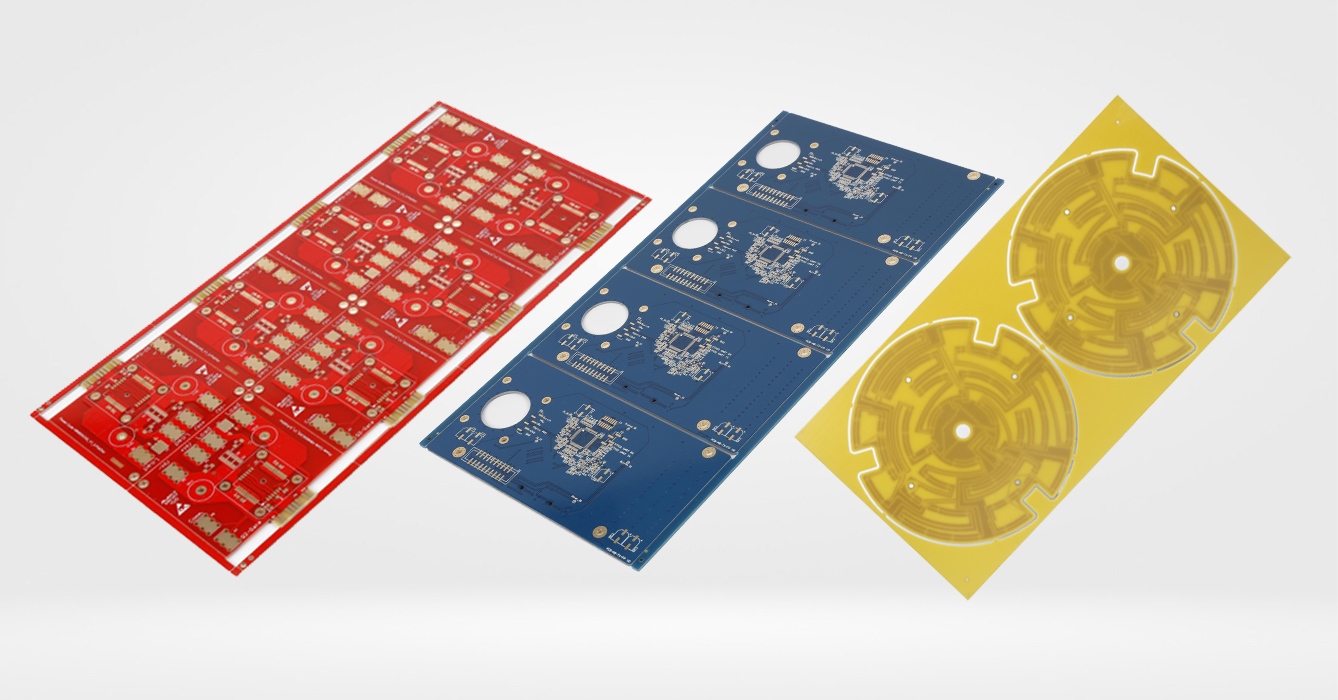

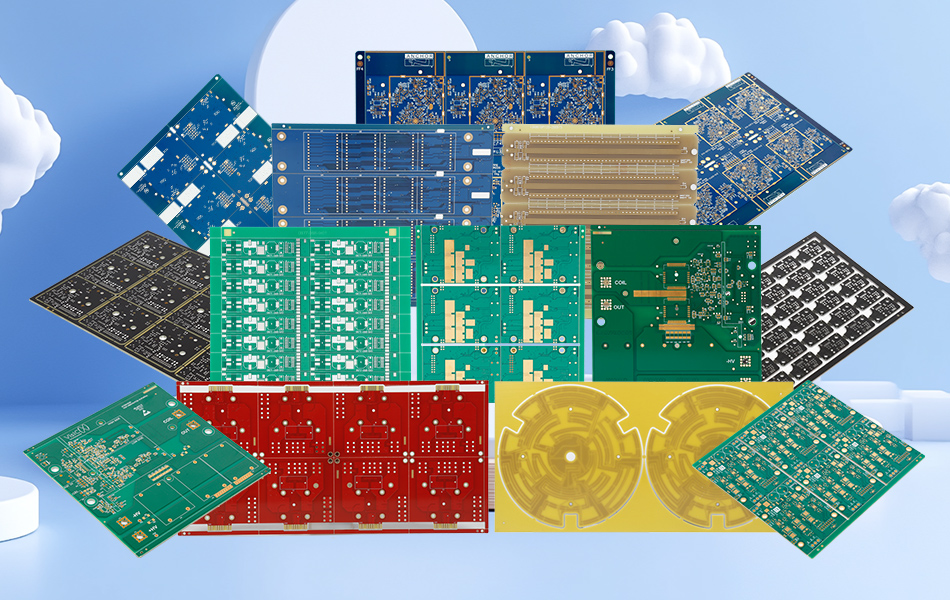

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 19. 2026, 11:59:37

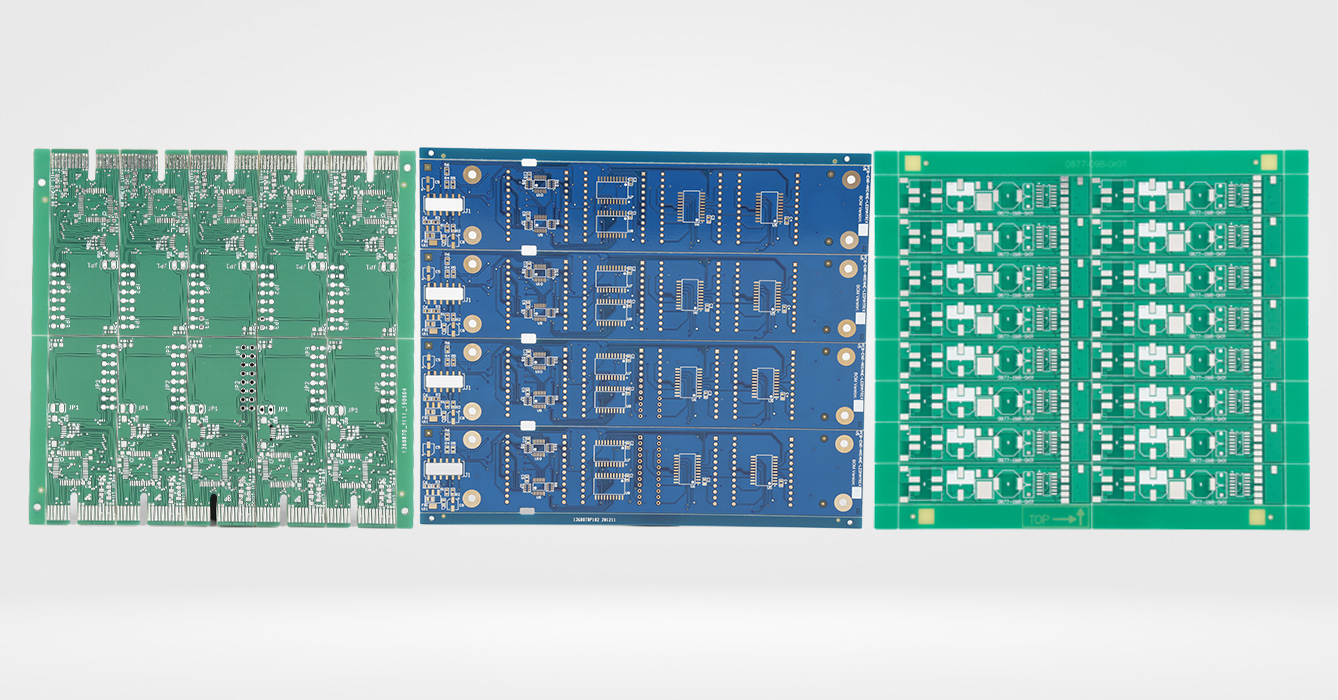

Speed and consistency are the two things factory customers need most from a PCB supplier. During NPI, you want prototypes fast enough to keep engineering moving. During ramp-up and volume production, you need repeatability—stable impedance, predictable solderability, controlled warpage, and reliable quality records.

That’s why selecting the right FR4 PCB manufacturer matters. FR4 PCB remains the most widely used substrate in electronics because it balances electrical performance, mechanical strength, manufacturability, and cost. Whether you’re building a consumer device, industrial controller, power supply, or LED Lighting FR4 PCB assemblies, the right supplier turns your Gerbers into production-ready boards that pass test, assemble cleanly, and stay reliable in the field.

This guie explains what an FR4 board is, how fr4 pcb material choices affect performance, what capabilities matter for prototype-to-volume programs, and when advanced processes like blind and buried vias FR4 PCB can be the difference between an easy build and a redesign.

An fr4 printed circuit board is built using FR4 laminate—typically a glass-fiber reinforced epoxy resin material. In practical terms, FR4 offers:

Good mechanical strength and stiffness

Reliable electrical insulation

Stable performance across common operating temperatures

Cost-effective mass production

FR4 is also flexible from a manufacturing standpoint: it supports single-layer through multilayer stackups, fine line routing, impedance control, and a wide range of finishes and solder mask options.

FR4 makes it easier to transition from prototype to volume because the process ecosystem is mature: material supply, process windows, assembly compatibility, and quality standards are well-established.

FR4 supports everything from low-cost two-layer boards to complex multi-layer designs with controlled impedance and advanced interconnects. If your product evolves during development, FR4 is forgiving and scalable.

While aluminum substrates are often used for high-power thermal demands, LED Lighting FR4 PCB is still common in LED drivers, control boards, sensors, dimming modules, communication boards, and lower-power LED assemblies—especially when layout complexity and cost are higher priorities than maximum heat dissipation.

“FR4” is not a single material grade—it’s a category. For reliable performance, factory programs should define key FR4 parameters early:

Tg affects thermal stability, especially for lead-free reflow and higher operating temps. If your assembly sees multiple reflow cycles or runs warm in the field, consider higher-Tg FR4.

For harsh environments or continuous operation, FR4 grade influences long-term reliability and delamination resistance.

For high-speed digital or RF-ish interfaces, tighter control of dielectric properties improves signal integrity and impedance stability.

Board thickness and copper weight impact:

current handling

voltage drop

thermal spreading (within FR4 limits)

stiffness and warpage risk

Factory tip: Many production issues come from under-specified materials. Defining fr4 pcb material requirements (Tg class, thickness tolerance, copper weight, and impedance needs) reduces quote ambiguity and avoids late-stage surprises.

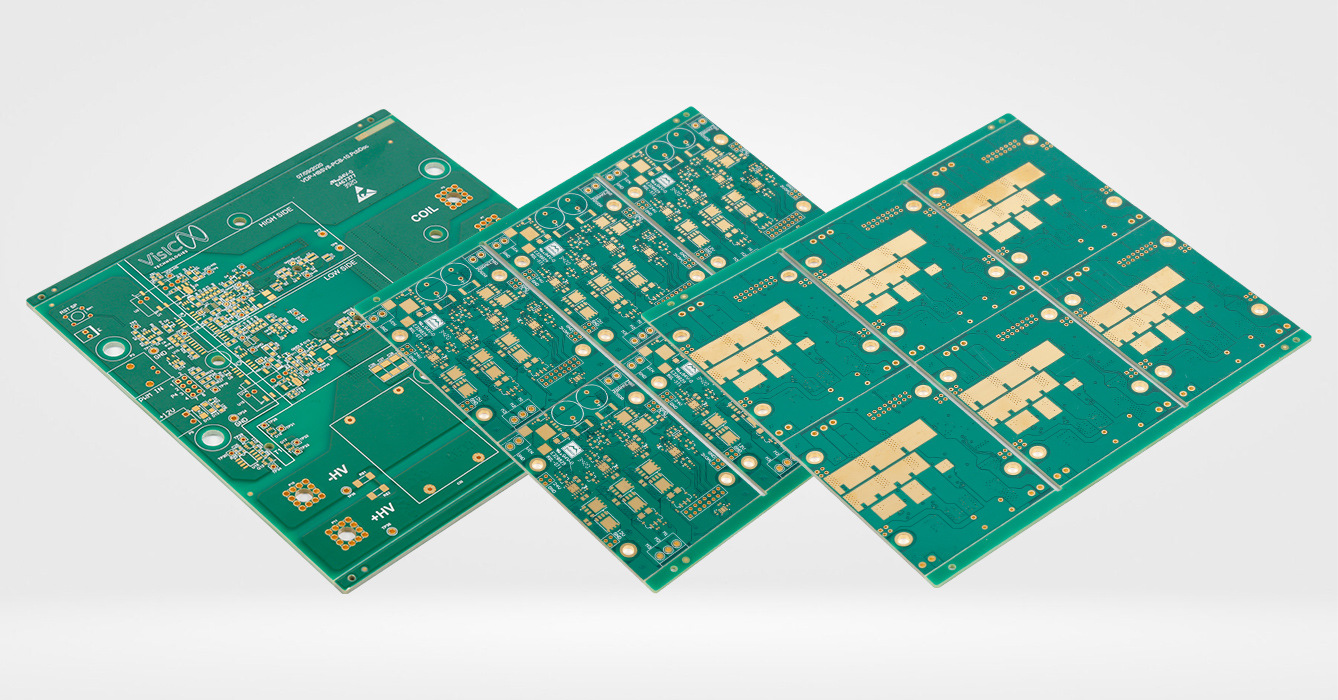

A fast prototype is valuable only if it behaves like the final production board. A strong FR4 PCB manufacturer should help you prototype with production intent:

DFM feedback on annular ring, solder mask slivers, drill-to-copper, and copper balance

Controlled impedance planning (if required)

Panelization suggestions to match future SMT flow

Finish selection aligned with production (ENIG vs OSP vs lead-free HASL)

Clear stackup documentation so revisions stay consistent

Goal: prototypes that validate electrical function and assembly process, so mass production doesn’t introduce new failure modes.

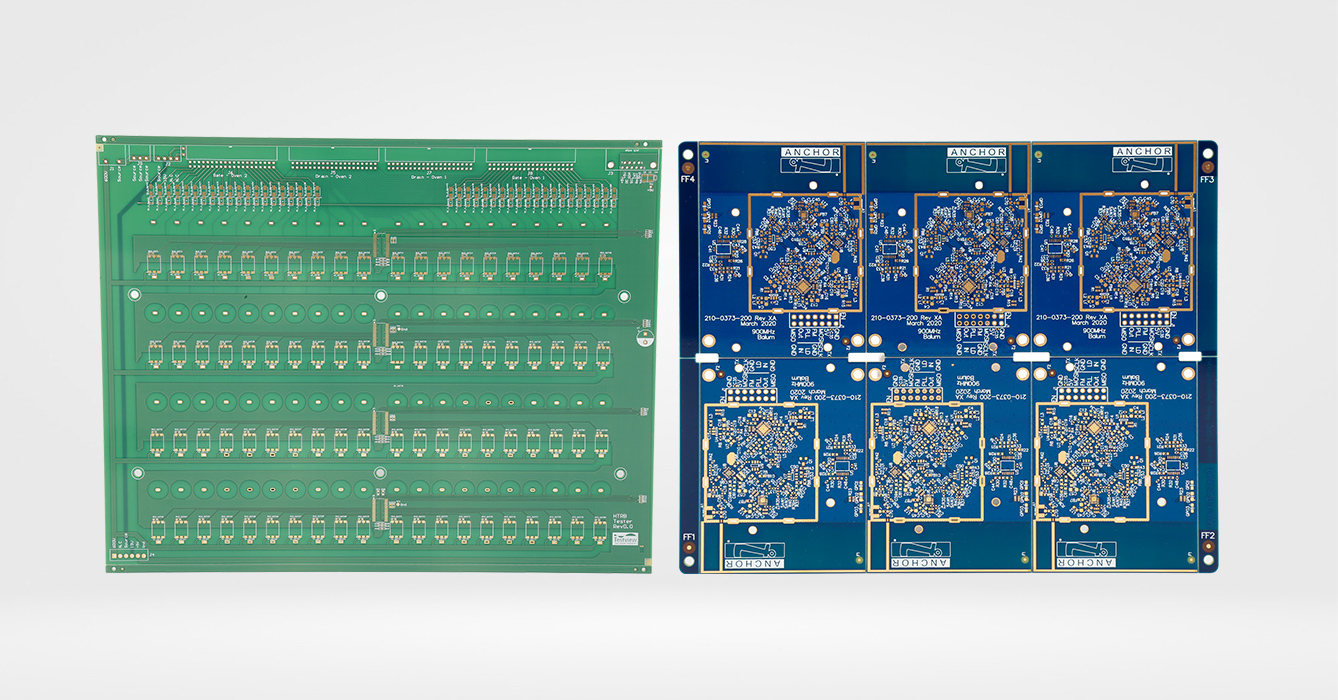

When you enter volume production, the key KPI is not “boards shipped.” It’s stable yields at your SMT line and low returns in the field. A production-ready FR4 supplier should demonstrate control in four areas:

Stable lamination cycles and material lots

Drill quality control (registration, burrs, smear control)

Plating thickness control for vias and through holes

Solder mask alignment and curing stability

Consistent impedance for high-speed lines

Consistent dielectric thickness and stackup

Clean reference planes and controlled return paths

AOI for pattern defects

Electrical test (flying probe or fixture)

Quality records and traceability for recurring programs

Packaging and cleanliness matter more than people expect. Poor packaging can cause oxidation, scratches, or warpage—leading to assembly issues that look like “PCB defects.”

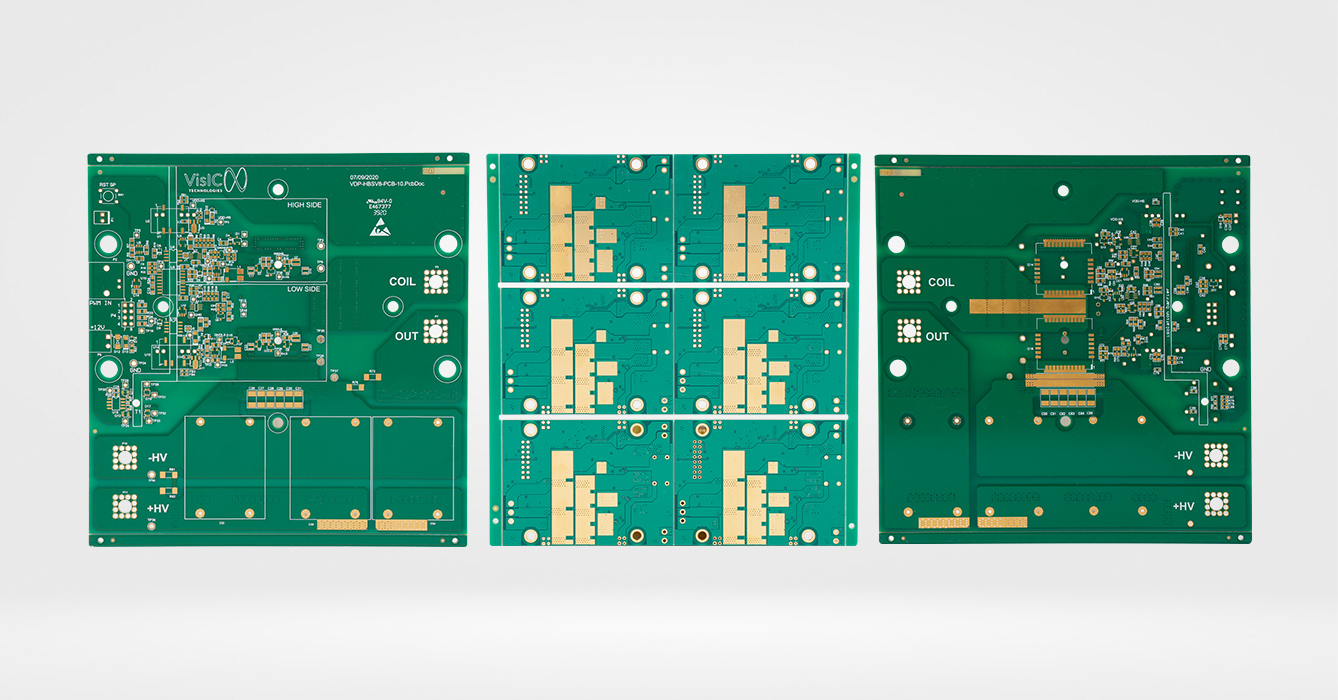

As products get smaller and routing becomes denser, through-hole vias can become the bottleneck. That’s where blind and buried vias FR4 PCB technology helps.

Blind vias connect an outer layer to one or more inner layers, without going through the entire board.

Buried vias connect inner layers only and are not visible from the outer surfaces.

More routing space for high-density designs

Improved signal integrity by reducing via stubs (in certain designs)

Better component placement flexibility

Smaller form factors without sacrificing functionality

Consider blind and buried vias FR4 PCB when:

you’re running out of routing space with conventional vias

you need finer pitch BGAs or dense connector regions

you want a smaller PCB outline without adding layers unnecessarily

Factory tip: Blind and buried vias increase process complexity. The supplier’s lamination control, registration capability, and quality discipline matter significantly more than on standard boards.

LED Lighting FR4 PCB commonly appears in:

LED driver control boards

sensor/dimming/communication boards (DALI, 0–10V control, Bluetooth/Wi-Fi modules)

low-to-mid power LED assemblies where thermal load is manageable

lighting system controllers and power distribution PCBs

If your LED product’s heat is concentrated at the LED emitters, you may use aluminum MCPCB for the LED array while still using FR4 for the driver and control electronics. This hybrid approach often provides the best cost/performance at scale.

When factory buyers evaluate an FR4 PCB manufacturer, use this checklist:

Layer count you need today and in the next revision

Controlled impedance (if applicable)

Fine line/space and drill capability

HDI options if roadmap requires it

Support for blind and buried vias FR4 PCB if density demands it

Clear QC checkpoints, test coverage

Ability to maintain stable stackups across repeated builds

Traceability and process documentation

DFM response speed

Clear questions and risk flags during quoting

Willingness to recommend improvements (panelization, copper balance, mask design)

Prototype lead time that matches your sprint cycles

Production lead time stability and capacity planning support

To reduce back-and-forth and avoid quote mismatches, provide:

Gerber + drill files

Board outline and any panel requirements

Layer count + target thickness

Copper weight (outer/inner)

Material requirements: Tg class, any Dk/Df targets (fr4 pcb material definition)

Controlled impedance requirements (if any)

Surface finish preference (ENIG/OSP/lead-free HASL, etc.)

Solder mask color and requirements

Special processes: blind and buried vias FR4 PCB, via-in-pad, back drilling, etc.

Quantity plan: prototype / pilot / monthly volume

If you’re looking for an FR4 PCB manufacturer that can support both rapid prototypes and stable mass production, send your Gerber files and requirements for a quick engineering review. A clear fr4 printed circuit board stackup definition—plus early DFM feedback—can shorten your product cycle, improve SMT yield, and reduce field failures, especially for complex designs that may require blind and buried vias FR4 PCB or tight impedance control.

Q1: What does FR4 PCB mean, and why is it so common?

FR4 PCB refers to boards built with glass-fiber reinforced epoxy laminate. It’s common because it offers strong mechanical properties, good electrical insulation, and cost-effective manufacturing from prototype to volume.

Q2: Is “fr4 printed circuit board” the same as FR4 PCB?

Yes. “fr4 printed circuit board” is simply a longer phrase describing the same product: a PCB manufactured using FR4 laminate.

Q3: How do I choose the right fr4 pcb material for mass production?

Define your Tg class (especially for lead-free assembly), thickness, copper weight, and any electrical requirements like controlled impedance. Clear fr4 pcb material specs reduce supplier ambiguity and improve build-to-build consistency.

Q4: When should I use LED Lighting FR4 PCB instead of aluminum MCPCB?

Use LED Lighting FR4 PCB for LED drivers, control boards, and low-to-mid power assemblies where thermal load is manageable. For high-power LED emitter arrays, aluminum MCPCB is often used for the LED board while FR4 is used for control/driver electronics.

Q5: What are blind and buried vias in FR4 PCB, and when do I need them?

Blind and buried vias FR4 PCB are advanced via structures used to increase routing density and support smaller form factors. They are recommended when through-hole vias limit routing space, especially around fine-pitch BGAs or dense connector regions.

Related Articles

FR4 PCB Manufacturer | High Tg & Reliable PCB Material FR4 Solutions

FR4 PCB Prototype and Production Manufacturing Services

FR4 PCB Manufacturer for Fast Prototyping and Volume Production

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB