-

- PCB TYPE

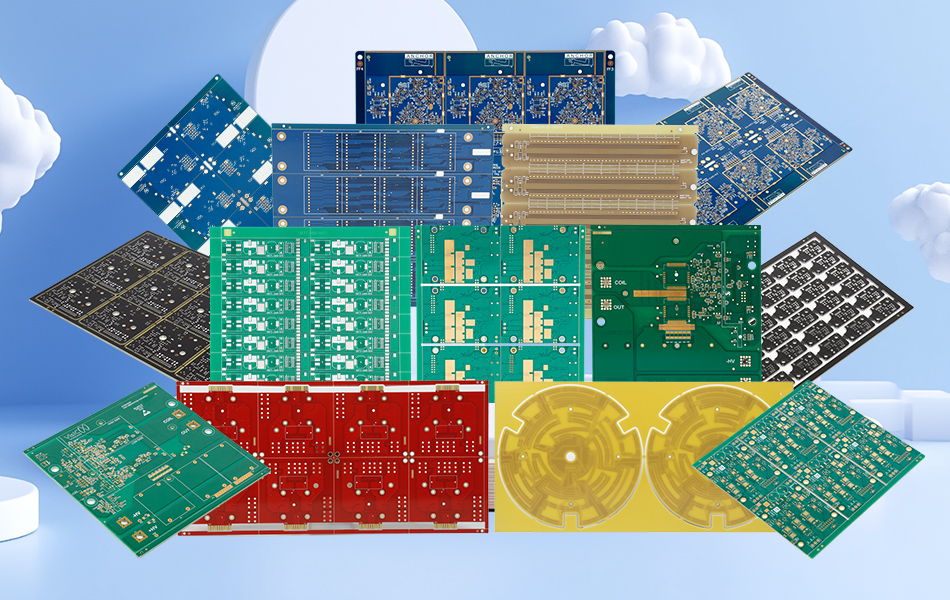

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 09. 2025, 16:23:42

In the realm of printed circuit boards (PCBs), the FR4 PCB Material Type encompasses a diverse family of glass-reinforced epoxy laminates that form the foundation of modern electronics. From simple consumer devices to complex industrial systems, FR4 materials have proven their adaptability, reliability, and cost-effectiveness across decades of technological advancement. Unlike specialized substrates designed for niche applications, the FR4 family is defined by its versatility, with each variant tailored to meet specific performance needs while retaining core properties like flame resistance and mechanical stability. This article explores the various types of FR4 PCB materials, their defining features, ideal applications, and the factors that guide their selection, offering a clear understanding of how this material family continues to shape the electronics industry.

The FR4 PCB Material Type is not a single material but a category of laminates united by their use of epoxy resin and glass fiber reinforcement, along with flame-retardant properties. The term "FR4" itself reflects these core traits: "FR" denotes flame resistance, while the classification underscores its position as a standardized, widely accepted material in electronics manufacturing.

What distinguishes the variants within the FR4 family is their customization to address specific challenges, such as high temperatures, environmental safety, signal speed, or mechanical stress. Each type retains the basic structure of epoxy resin and glass fibers but modifies components like resin formulations, flame retardants, or fiber types to enhance particular properties. This flexibility allows FR4 to serve as a solution for both everyday electronics and more demanding applications, making it the most widely used PCB material globally.

The FR4 family includes several key variants, each engineered to excel in distinct scenarios:

Standard FR4: The most common variant, designed for general-purpose use in moderate environments. It balances cost and performance, making it ideal for applications where temperatures, signal speeds, and mechanical stress are not extreme. Its formulation prioritizes ease of manufacturing and affordability, ensuring it remains the default choice for most consumer electronics and low-complexity devices.

High-Temperature FR4: Modified to withstand elevated temperatures, this variant uses advanced epoxy resins that resist softening or degradation under sustained heat. It is tailored for applications like automotive underhood systems, industrial ovens, and power electronics, where operating temperatures exceed the limits of Standard FR4.

Low-Dielectric FR4: Optimized for high-speed signal transmission, this type minimizes signal loss and distortion, making it suitable for 5G infrastructure, radar systems, and high-frequency communication devices. Its resin formulations and fiber types are chosen to reduce electrical interference and maintain signal integrity at fast data rates.

Halogen-Free FR4: Developed to meet strict environmental regulations, this variant replaces halogenated flame retardants with safer alternatives, reducing toxic emissions during combustion. It is preferred in medical devices, automotive cabins, and consumer products sold in regions with stringent environmental standards.

Thin-Core FR4: Designed for compact, lightweight applications, this variant uses ultra-thin glass fibers and resin layers to enable flexible or miniaturized PCBs. It is commonly found in wearables, foldable devices, and IoT sensors where space is limited.

Each variant builds on FR4’s core strengths while addressing specific needs, ensuring the material family remains relevant across industries.

While all FR4 types share basic properties, their unique characteristics set them apart:

Thermal Performance: High-Temperature FR4 is distinguished by its ability to maintain structural integrity at elevated temperatures, resisting warping or insulation breakdown. In contrast, Standard FR4 performs reliably in moderate thermal conditions but may struggle in extreme heat.

Electrical Properties: Low-Dielectric FR4 minimizes signal loss and interference, critical for high-frequency applications. Its design ensures that electrical signals travel efficiently without degradation, a trait less emphasized in Standard or Halogen-Free variants.

Environmental Safety: Halogen-Free FR4 prioritizes low toxicity and compliance with regulations restricting hazardous substances, making it suitable for applications where human exposure to fumes is a concern. This focus on safety differentiates it from other FR4 types that use traditional flame retardants.

Mechanical Flexibility: Thin-Core FR4 balances rigidity and flexibility, allowing it to withstand bending or shaping without cracking—an attribute not required of thicker, more rigid variants like Standard or High-Temperature FR4.

Cost and Availability: Standard FR4 leads in affordability and widespread availability, while specialized variants like High-Temperature or Low-Dielectric FR4 often come at a premium due to advanced formulations and manufacturing processes.

These characteristics guide engineers in selecting the right FR4 type for their specific application, ensuring optimal performance without unnecessary expense.

Producing FR4 PCBs requires adjustments based on the specific variant, as each type has unique processing needs:

Lamination: High-Temperature FR4 often requires higher curing temperatures and longer dwell times to ensure its advanced resins fully set, while Thin-Core FR4 demands precise control to avoid damaging ultra-thin layers.

Drilling and Routing: Halogen-Free FR4 may require specialized tooling due to the abrasiveness of its flame retardants, while Low-Dielectric FR4 needs careful handling to preserve its electrical properties during machining.

Surface Treatment: Low-Dielectric and Thin-Core variants often require specialized cleaning or coating processes to maintain their performance characteristics, such as signal integrity or flexibility.

Quality Control: Each FR4 type undergoes testing tailored to its intended use—thermal cycling for High-Temperature FR4, signal loss measurements for Low-Dielectric FR4, and toxicity assessments for Halogen-Free FR4.

Manufacturers leverage their expertise in handling these nuances to produce consistent, reliable PCBs across all FR4 variants, ensuring each type meets its performance claims.

The versatility of FR4 PCB material types ensures their use in diverse applications:

Consumer Electronics: Standard FR4 dominates in smartphones, laptops, and home appliances, where its balance of cost and performance meets basic needs. Thin-Core FR4 is increasingly used in wearables and foldable devices, while Halogen-Free FR4 appears in eco-friendly products.

Automotive: High-Temperature FR4 is critical for underhood electronics exposed to heat, while Halogen-Free FR4 is preferred in cabin systems to reduce toxic risks. Low-Dielectric variants may be used in advanced driver-assistance systems (ADAS) requiring high-speed data transmission.

Industrial and Manufacturing: High-Temperature FR4 withstands the heat of industrial ovens and motor controllers, while Low-Dielectric FR4 supports communication in factory automation systems. Standard FR4 is used in less demanding control panels and sensors.

Healthcare: Halogen-Free FR4 is favored in medical devices like monitors and diagnostic equipment, where safety and low toxicity are paramount. Its compliance with regulations ensures it meets healthcare standards for patient and staff protection.

Telecommunications: Low-Dielectric FR4 enables efficient signal transmission in 5G towers and routers, while Standard FR4 handles basic circuitry in less demanding network components.

In each industry, the choice of FR4 type is driven by the application’s specific requirements, from thermal resistance to environmental safety.

Choosing the right FR4 variant involves evaluating several key factors:

Operating Environment: Applications in high-heat settings (e.g., industrial ovens) demand High-Temperature FR4, while those in cold or moderate conditions may suffice with Standard FR4.

Signal Requirements: High-speed or high-frequency devices (e.g., 5G modems) require Low-Dielectric FR4 to maintain signal integrity, whereas low-speed electronics (e.g., remote controls) work well with Standard FR4.

Regulatory Compliance: Products sold in regions with strict environmental laws (e.g., the EU) often require Halogen-Free FR4 to meet RoHS or REACH standards.

Form Factor: Compact or flexible designs (e.g., smartwatches) benefit from Thin-Core FR4, while larger, rigid PCBs (e.g., server motherboards) use Standard or High-Temperature variants.

Budget Constraints: Cost-sensitive projects prioritize Standard FR4, while specialized applications justify the higher expense of variants like Low-Dielectric or Halogen-Free FR4.

By weighing these factors, engineers ensure that their choice of FR4 material aligns with both technical needs and practical constraints.

Several myths surround FR4 PCB materials, often leading to improper selection:

"All FR4 types are interchangeable": This is false, as each variant is engineered for specific conditions. Using Standard FR4 in a high-temperature industrial setting, for example, can lead to premature failure.

"Specialized FR4 is always better": Over-specifying—using High-Temperature FR4 for a low-heat consumer device—adds unnecessary cost without benefit. Standard FR4 often suffices for non-critical applications.

"Halogen-Free FR4 sacrifices performance": Modern formulations ensure Halogen-Free FR4 matches the flame resistance and mechanical strength of traditional FR4, dispelling the myth that safety comes at the cost of functionality.

"Thin-Core FR4 is weak": Advanced manufacturing techniques ensure Thin-Core FR4 retains sufficient strength for its intended applications, though it is not designed for heavy mechanical stress.

Understanding these misconceptions helps avoid costly mistakes and ensures the right FR4 type is chosen for each use case.

The FR4 family continues to evolve, driven by technological advancements and industry demands:

Sustainable Formulations: Research into bio-based resins and recycled glass fibers is reducing the environmental impact of all FR4 types, aligning with global efforts to promote circular economies.

Multifunctional Variants: New FR4 types combine traits—such as High-Temperature and Halogen-Free properties—to serve hybrid applications like electric vehicle charging systems, which require both heat resistance and environmental safety.

Enhanced Performance: Innovations in resin chemistry are pushing the limits of Low-Dielectric FR4, enabling even faster signal speeds, while High-Temperature variants are being engineered to withstand more extreme thermal conditions.

Integration with Additive Manufacturing: 3D printing techniques are being adapted to produce FR4-based PCBs, allowing more complex designs and reducing waste compared to traditional manufacturing.

These trends ensure that FR4 remains at the forefront of PCB materials, adapting to the needs of emerging technologies like AI, renewable energy, and smart infrastructure.

The FR4 PCB Material Type family is a testament to the adaptability and innovation of electronics materials, offering solutions for applications ranging from simple consumer devices to advanced industrial systems. By understanding the unique characteristics, manufacturing needs, and ideal uses of each variant—from Standard to Halogen-Free, High-Temperature to Thin-Core—engineers can select the optimal material for their design. As technology advances, the FR4 family continues to evolve, integrating sustainability, enhanced performance, and new functionalities to meet future challenges. Its enduring role in electronics underscores the importance of this material family, ensuring it remains indispensable for decades to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB