-

- PCB TYPE

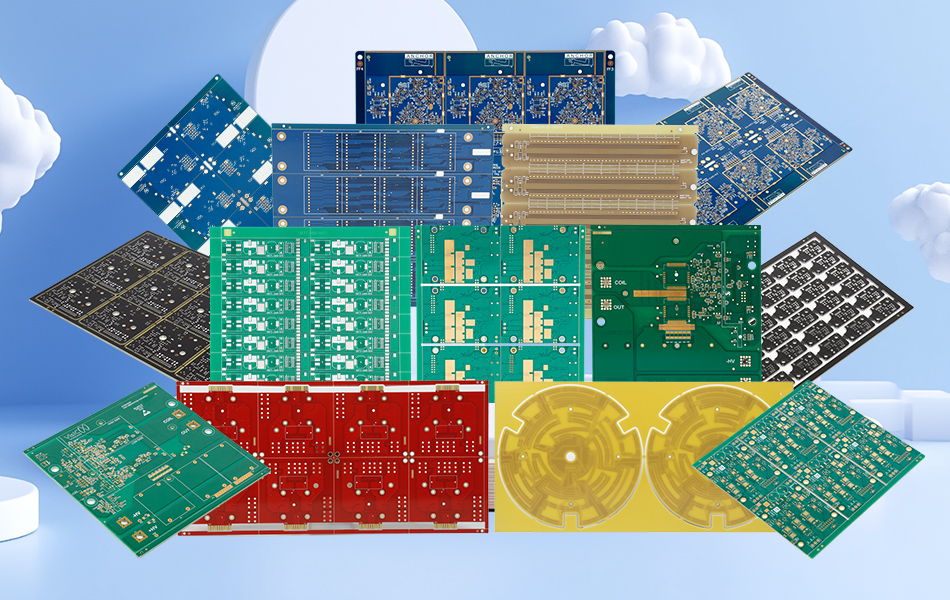

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 09. 2025, 16:19:22

The Halogen Free FR4 PCB Type represents a significant shift in printed circuit board materials, prioritizing environmental safety and regulatory compliance without compromising the core functionality that has made FR4 a staple in electronics. As global regulations tighten and consumer awareness of environmental issues grows, this variant has emerged as a critical solution for manufacturers seeking to reduce hazardous substances in their products. Unlike traditional FR4, which relies on halogenated compounds for flame resistance, Halogen Free FR4 achieves fire safety through alternative additives, eliminating the release of toxic gases during combustion and aligning with strict environmental standards. This article explores the defining characteristics, manufacturing considerations, applications, and benefits of Halogen Free FR4, highlighting its role in driving a more sustainable and safe electronics industry.

At its core, Halogen Free FR4 PCB Type is defined by two key attributes: the absence of halogens and maintained flame retardancy.

Halogen-Free Certification: This material strictly limits the presence of halogens—including chlorine, bromine, fluorine, iodine, and astatine—to trace amounts, as specified by international standards. These standards ensure that halogen content is low enough to prevent the release of toxic gases when the material is exposed to high temperatures or fire.

Flame Resistance: Despite the removal of halogenated additives, Halogen Free FR4 retains the flame-retardant properties necessary for electronic safety, typically meeting the same fire safety ratings as traditional FR4. This balance of safety and sustainability is what distinguishes it from other environmentally focused materials that may sacrifice performance.

By combining these attributes, Halogen Free FR4 addresses both regulatory requirements and ethical concerns, making it a preferred choice for industries where safety and environmental responsibility are paramount.

The most significant distinction between Halogen Free FR4 and traditional FR4 lies in its approach to flame retardancy, achieved through innovative material science:

Epoxy Resin Matrix: Like traditional FR4, Halogen Free FR4 uses an epoxy resin as its base, providing structural integrity and electrical insulation. However, the resin formulation is adjusted to work with non-halogen flame retardants, ensuring compatibility and maintaining mechanical strength.

Alternative Flame Retardants: To achieve fire resistance without halogens, manufacturers use a range of additives:

Phosphorus-Based Compounds: These are the most common alternatives, working by forming a protective char layer when exposed to heat, which insulates the material and slows combustion.

Nitrogen-Containing Additives: These enhance flame retardancy by releasing inert gases that dilute oxygen, suppressing fire spread.

Metal Hydroxides: These additives release water vapor when heated, cooling the material and reducing flammability, though they require careful integration to avoid impacting other properties.

Glass Fiber Reinforcement: Woven glass fibers remain a key component, providing mechanical rigidity and dimensional stability, much like in traditional FR4. The fiber weave and resin-fiber bonding are optimized to ensure the material retains strength despite the new flame retardant formulations.

This composition ensures that Halogen Free FR4 meets performance expectations while eliminating the environmental and safety risks associated with halogens.

Producing Halogen Free FR4 PCBs requires adjustments to traditional manufacturing processes to accommodate the unique properties of non-halogen materials:

Resin Handling: The epoxy resins used in Halogen Free FR4 often have different viscosity and curing profiles compared to those in traditional FR4. This requires recalibrating lamination equipment to ensure proper resin flow and curing, preventing voids and ensuring uniform layer bonding.

Lamination Conditions: Achieving full curing of the resin matrix may require slightly higher temperatures or longer dwell times, as non-halogen flame retardants can affect the curing kinetics. Manufacturers must optimize these parameters to maintain material integrity and performance.

Drilling and Machining: The presence of certain flame retardants, such as metal hydroxides, can make the material more abrasive. This necessitates the use of specialized tooling—often with harder coatings—to ensure clean cuts and prevent excessive tool wear during drilling and routing.

Surface Preparation: Halogen Free FR4 may have different surface energy compared to traditional FR4, requiring adjustments in cleaning and treatment processes to ensure proper adhesion of solder masks, adhesives, and other finishes.

While these adjustments add some complexity, they are manageable with modern manufacturing techniques, allowing Halogen Free FR4 to be produced at scale for high-volume applications.

Halogen Free FR4 is particularly valuable in applications where human exposure to toxic substances is a concern, or where regulatory compliance is mandatory:

Medical Devices: Equipment such as patient monitors, defibrillators, and diagnostic tools relies on Halogen Free FR4 to minimize toxic risks in healthcare environments. In the event of a fire, the reduction of harmful gas emissions protects patients and medical staff.

Automotive Electronics: Modern vehicles, especially electric and hybrid models, incorporate increasing numbers of electronic components. Halogen Free FR4 is used in cabin electronics—including infotainment systems and airbag controllers—where fire safety and compliance with automotive standards are critical.

Consumer Electronics: Smartphones, laptops, and home appliances sold in regions with strict environmental regulations (such as the European Union, Japan, and China) often use Halogen Free FR4 to meet RoHS, REACH, and similar standards. This not only ensures market access but also appeals to eco-conscious consumers.

Aerospace and Rail: Cabin electronics in aircraft and trains prioritize low-toxicity materials to protect passengers and crew in enclosed spaces. Halogen Free FR4 meets the stringent safety requirements of these industries, where fire risks must be managed with minimal harm.

Industrial Equipment: In factories and manufacturing facilities, Halogen Free FR4 is used in control systems and sensors, aligning with workplace safety regulations that limit exposure to hazardous substances.

In each of these applications, the material’s ability to balance performance, safety, and sustainability makes it an ideal choice.

Halogen Free FR4 offers a range of benefits that extend beyond regulatory compliance:

Reduced Toxicity: The most significant advantage is the elimination of halogenated gases—such as hydrogen bromide—released during combustion. These gases are corrosive and harmful to humans, making Halogen Free FR4 a safer choice in enclosed spaces.

Regulatory Compliance: By design, this material meets global standards restricting hazardous substances, simplifying market access and reducing the risk of non-compliance penalties.

Environmental Sustainability: Halogen Free FR4 supports circular economy goals, as it is often easier to recycle than traditional FR4, with fewer toxic byproducts. Additionally, many formulations use more sustainable raw materials, reducing the overall environmental footprint.

Brand Reputation: Using Halogen Free FR4 aligns with corporate social responsibility initiatives, enhancing brand image among environmentally conscious consumers and stakeholders.

Performance Parity: Modern formulations ensure that Halogen Free FR4 matches traditional FR4 in key mechanical and electrical properties, eliminating the need for performance compromises in most applications.

Despite its advantages, Halogen Free FR4 is sometimes subject to misconceptions that hinder adoption:

"Inferior Flame Resistance": Critics once argued that non-halogen flame retardants could not match the fire safety of halogenated ones. However, advances in material science have proven this false, with Halogen Free FR4 now meeting the same flame ratings as traditional variants.

"Prohibitive Cost": While Halogen Free FR4 may have a slightly higher production cost, economies of scale and improved manufacturing processes have narrowed the gap. The long-term benefits—including regulatory compliance and brand value—often outweigh the initial expense.

"Limited Availability": Early in its development, Halogen Free FR4 was less accessible, but it is now produced by major manufacturers worldwide, ensuring stable supply chains and consistent quality.

"Processing Complexity": While manufacturing requires adjustments, these are manageable with existing equipment and trained personnel, making large-scale production feasible.

Halogen Free FR4 is governed by international standards that ensure consistency and compliance:

IEC 61249-2-21: This standard defines halogen-free requirements for printed circuit board materials, setting strict limits on halogen content and specifying test methods to verify compliance.

UL 94: Halogen Free FR4 must meet flame retardancy ratings—typically V-0—under Underwriters Laboratories’ standards, ensuring it self-extinguishes quickly and does not support sustained combustion.

RoHS and REACH: These European regulations restrict the use of hazardous substances, including certain halogens, making Halogen Free FR4 a preferred choice for products sold in the EU and globally.

Automotive Standards: Specifications such as IATF 16949 include requirements for low-toxicity materials in vehicles, further driving the adoption of Halogen Free FR4 in automotive electronics.

Adherence to these standards provides confidence to manufacturers and consumers alike, ensuring that Halogen Free FR4 delivers on its promises of safety and sustainability.

The future of Halogen Free FR4 is marked by ongoing innovation aimed at enhancing performance and sustainability:

Bio-Based Additives: Research is focused on incorporating plant-derived flame retardants, reducing reliance on petroleum-based chemicals and further lowering environmental impact.

Improved Thermal Performance: Formulations are being developed to enhance heat resistance, expanding Halogen Free FR4’s use in higher-temperature applications such as industrial controllers.

Integration with Advanced Manufacturing: Additive manufacturing techniques are being adapted to work with Halogen Free FR4, enabling more complex designs and reducing material waste.

Circular Economy Integration: Manufacturers are exploring closed-loop recycling systems for Halogen Free FR4, ensuring that end-of-life PCBs can be processed safely and their materials reused.

These advancements will solidify Halogen Free FR4’s role as a sustainable, high-performance material for the next generation of electronics.

The Halogen Free FR4 PCB Type is more than a material innovation; it is a reflection of the electronics industry’s commitment to safety and sustainability. By eliminating halogens and using alternative flame retardants, it addresses critical environmental and health concerns while maintaining the performance that has made FR4 indispensable. From medical devices to consumer electronics, its applications continue to expand as regulations tighten and consumer demand for eco-friendly products grows. As manufacturing processes improve and formulations advance, Halogen Free FR4 is poised to become the new standard, replacing traditional FR4 in an increasing number of applications. For manufacturers and engineers, embracing this material is not just a compliance measure but a step toward a more responsible and sustainable future for electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB