-

- PCB TYPE

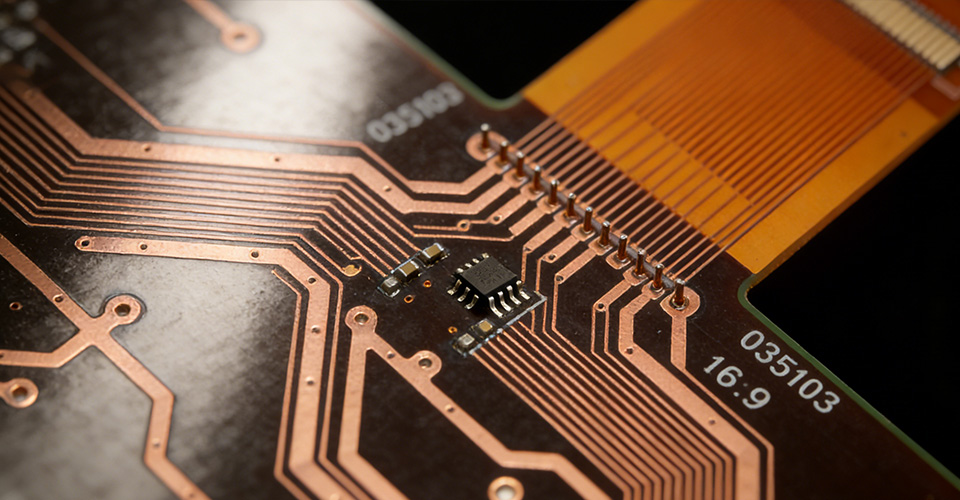

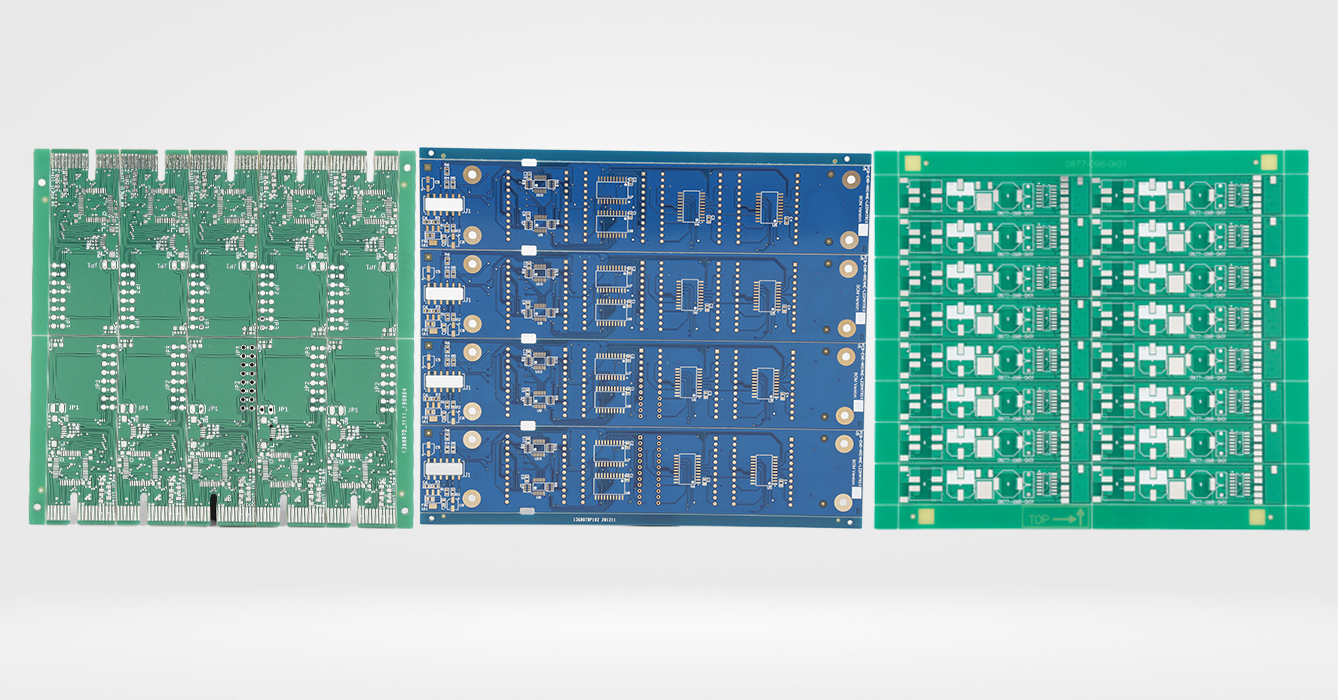

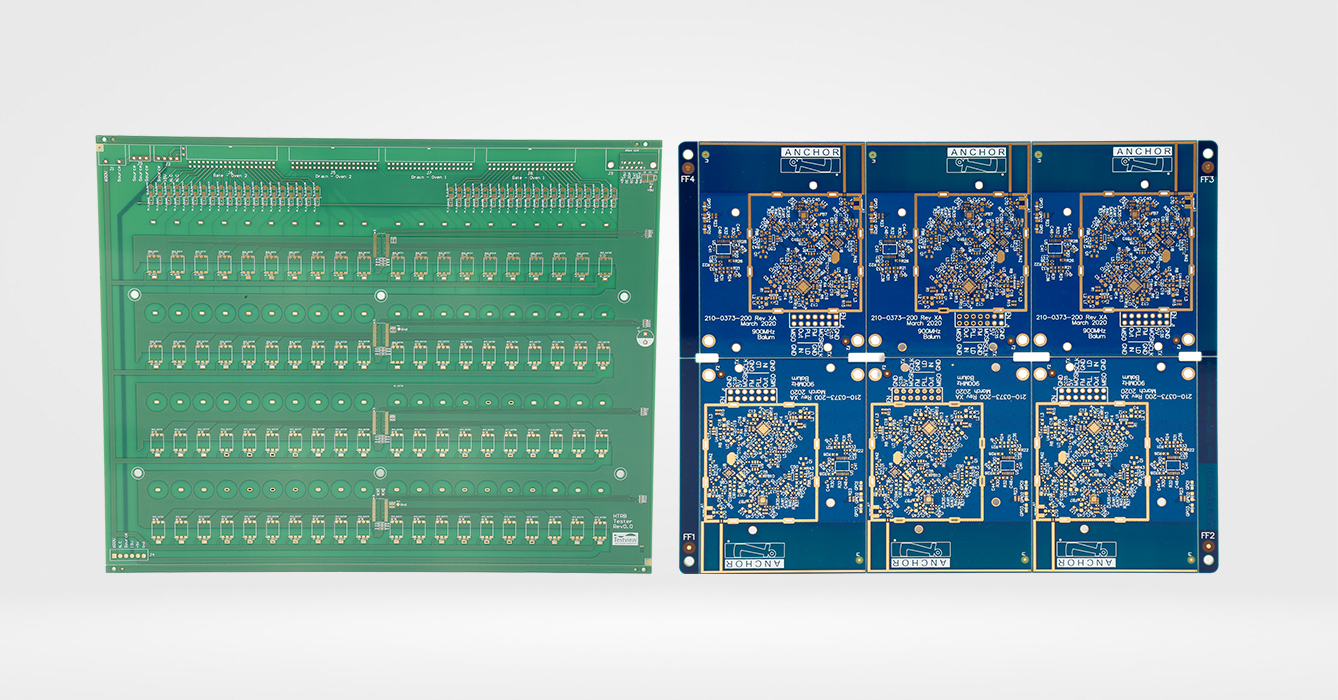

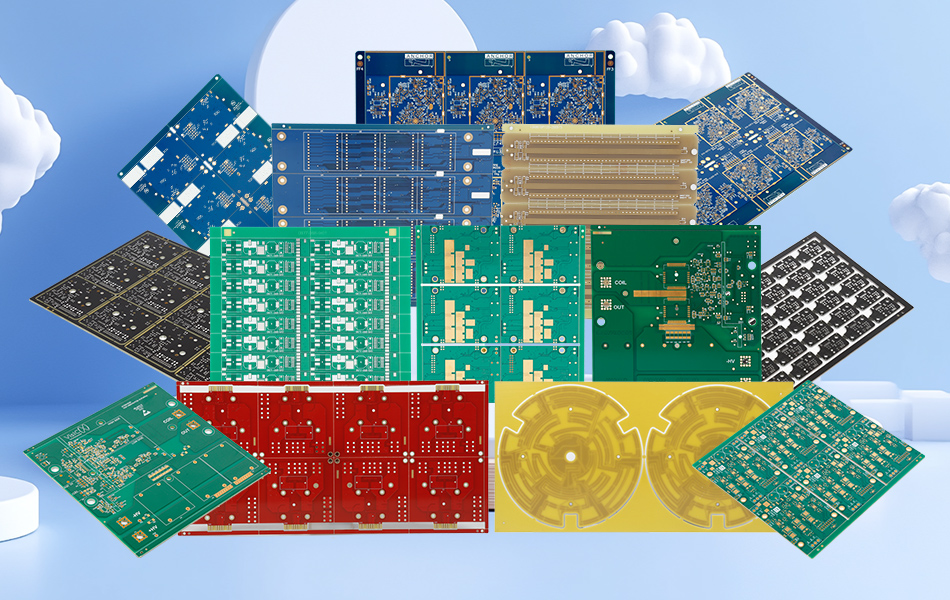

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 22. 2026, 11:34:47

For factory customers, PCB sourcing is never just about price per board. The real cost shows up in time-to-market delays, prototype re-spins, assembly yield losses, and inconsistent performance between “sample builds” and volume production.

That’s why selecting a manufacturing partner who can support both FR4 PCB prototyping and long-term production is critical. A strong supplier helps you move fast during development without creating hidden risks that appear later—like warpage, impedance drift, solderability issues, or mechanical misfit. At the same time, they keep production stable through clear documentation, repeatable processes, and disciplined change control.

This article explains what factory buyers should expect from FR4 PCB prototype and production manufacturing services, how to define an accurate FR4 PCB material specification, when a rigid fr4 pcb is the best fit, and when you should consider a Hybrid PCB approach to balance cost and performance.

FR4 is a glass-fiber reinforced epoxy laminate system used to build the majority of printed circuit boards worldwide. The reasons are practical:

Strong mechanical properties (stiffness and durability)

Reliable electrical insulation for most electronics

Mature supply chain and well-understood manufacturing processes

Scales efficiently from prototypes to mass production

Cost-effective across a wide range of layer counts and finishes

For most factory products—industrial control, power supplies, consumer electronics, lighting controllers, communication modules—FR4 PCB is the default platform because it offers predictable results at scale.

A fast prototype is only valuable if it predicts volume behavior. Many projects lose time because early prototypes were built with “whatever is available” materials or loose process assumptions, then volume boards behave differently.

1) DFM feedback that prevents re-spins

A qualified manufacturer should review and flag risks like:

drill-to-copper and annular ring limits

solder mask slivers and mask alignment risk

copper balance that can cause warpage

spacing limitations for your target finish and assembly method

2) Clear stackup definition from the start

Even during prototyping, a supplier should confirm:

layer count, finished thickness, copper weights

dielectric thickness targets (especially for controlled impedance)

whether the design should be treated as a standard or higher-reliability build

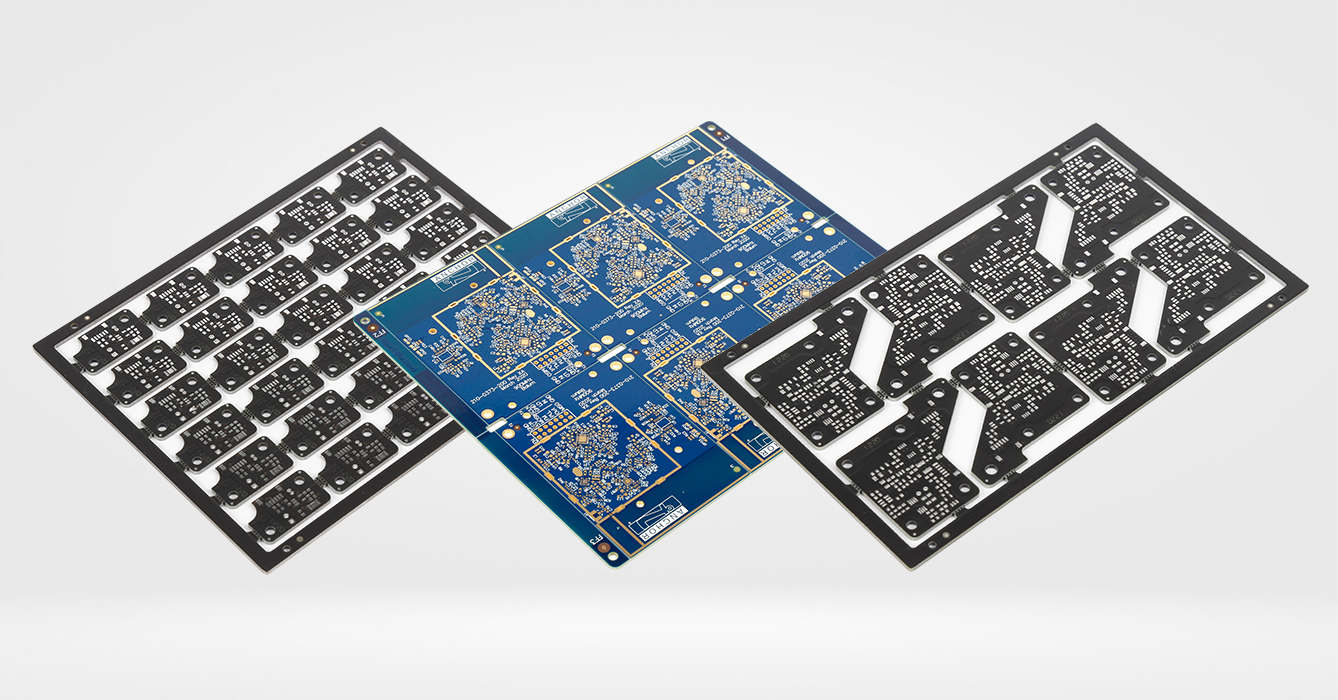

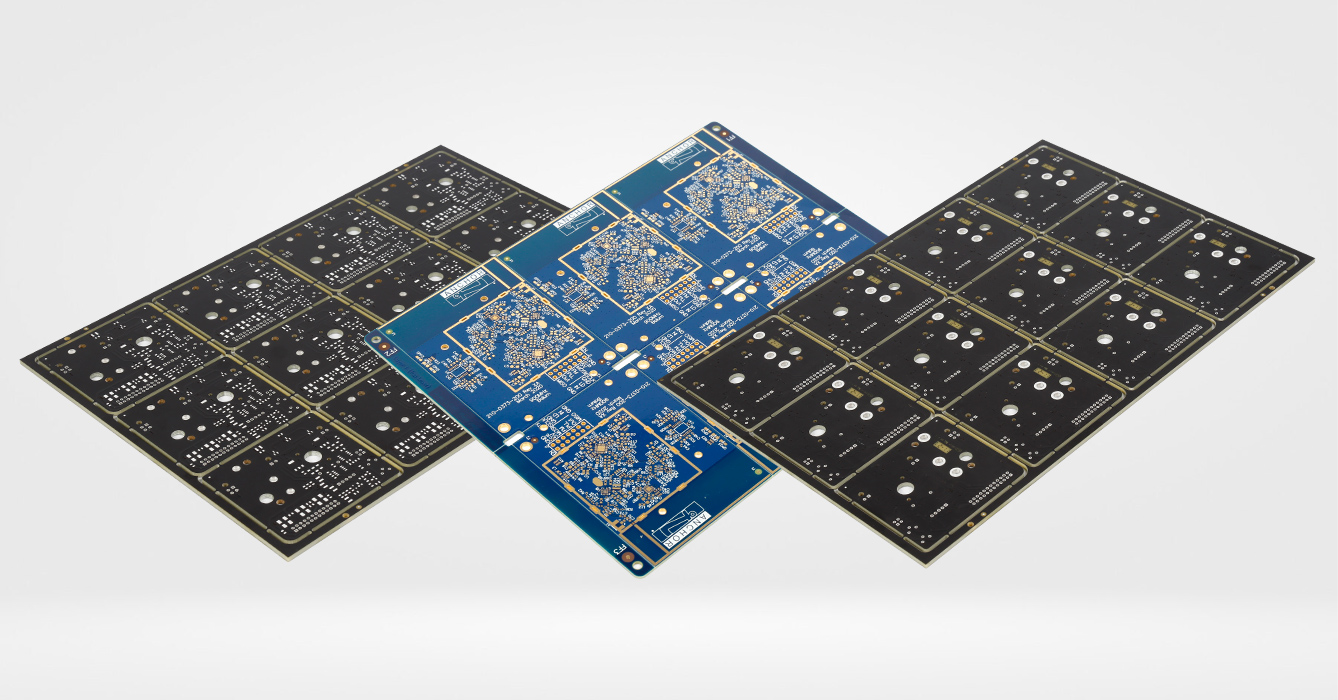

3) Panelization suggestions aligned to SMT

Factory builds depend on how boards run through paste printing, pick-and-place, and reflow. Good prototype services treat panel strategy as part of manufacturability, not an afterthought.

4) Finish and mask choices that match volume

If your volume plan requires consistent solderability and repeatable assembly yield, prototype finishes should match that direction—so you validate the real process early.

Factory tip: Prototypes should validate function + assembly + mechanical fit. If a prototype can’t be assembled and mounted the same way as production, it’s not saving time.

Once you move into ramp and monthly volume, small variations become expensive. A true FR4 PCB production service focuses on repeatability in four areas:

stable laminate sourcing and lot tracking

controlled prepreg/core usage per stackup

clear and consistent FR4 PCB material specification across builds

lamination cycle stability and registration control

drilling quality and smear control

copper plating thickness control (vias and through holes)

solder mask alignment and curing stability

AOI for pattern defects

electrical test coverage appropriate for your risk level

defined acceptance criteria for recurring part numbers

The fastest way to create field failures is silent changes—materials, process windows, mask type, finish chemistry, or panel tooling. Production-grade services should keep changes visible, documented, and approved.

“FR4” is not one single grade. For consistent outcomes, factory buyers should define an explicit FR4 PCB material specification—especially when transitioning from prototype to production.

Core parameters

Tg class (standard vs high Tg)

finished thickness and tolerance

copper weights (outer/inner)

laminate type and resin system class (if your program requires it)

Electrical performance (when needed)

controlled impedance targets and tolerance

dielectric requirements (if high-speed or sensitive RF regions exist)

Thermal and reliability intent

operating temperature range and duty cycle

number of reflow cycles expected

long-life requirement (industrial 24/7, outdoor, etc.)

Factory tip: If you don’t define the FR4 PCB material specification, suppliers may choose different laminates across builds to optimize price or availability—causing drift in warpage, impedance, and long-term reliability.

Most conventional FR4 boards are rigid by design, but it’s still useful to call out rigid fr4 pcb when the product depends on structural stability and mechanical alignment.

Common rigid fr4 pcb use cases include:

control boards mounted to metal chassis

power supply boards with heavy components

lighting controllers and drivers (non-emitter boards)

industrial I/O and communications boards

products requiring stable connector alignment or mounting holes

A rigid FR4 PCB is typically preferred when:

you need predictable board stiffness for connectors and mechanical fit

the assembly includes heavier components (transformers, inductors, relays)

the board is part of a structural subsystem inside the enclosure

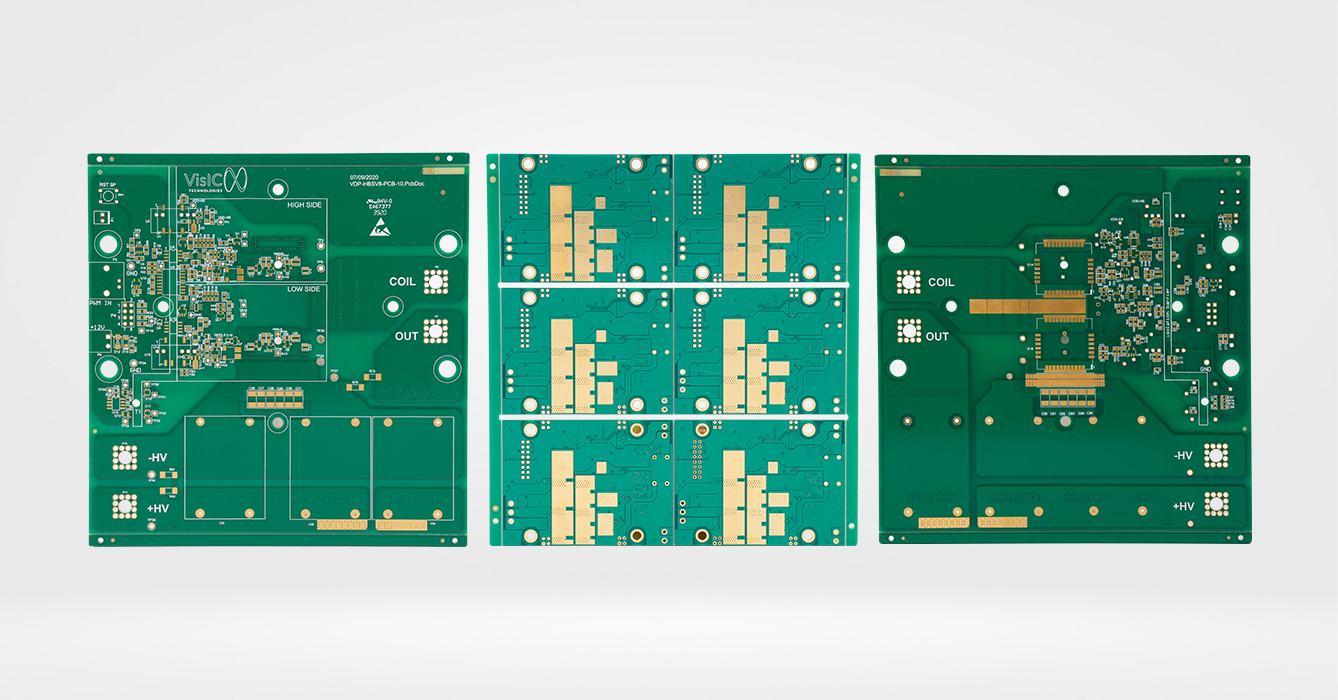

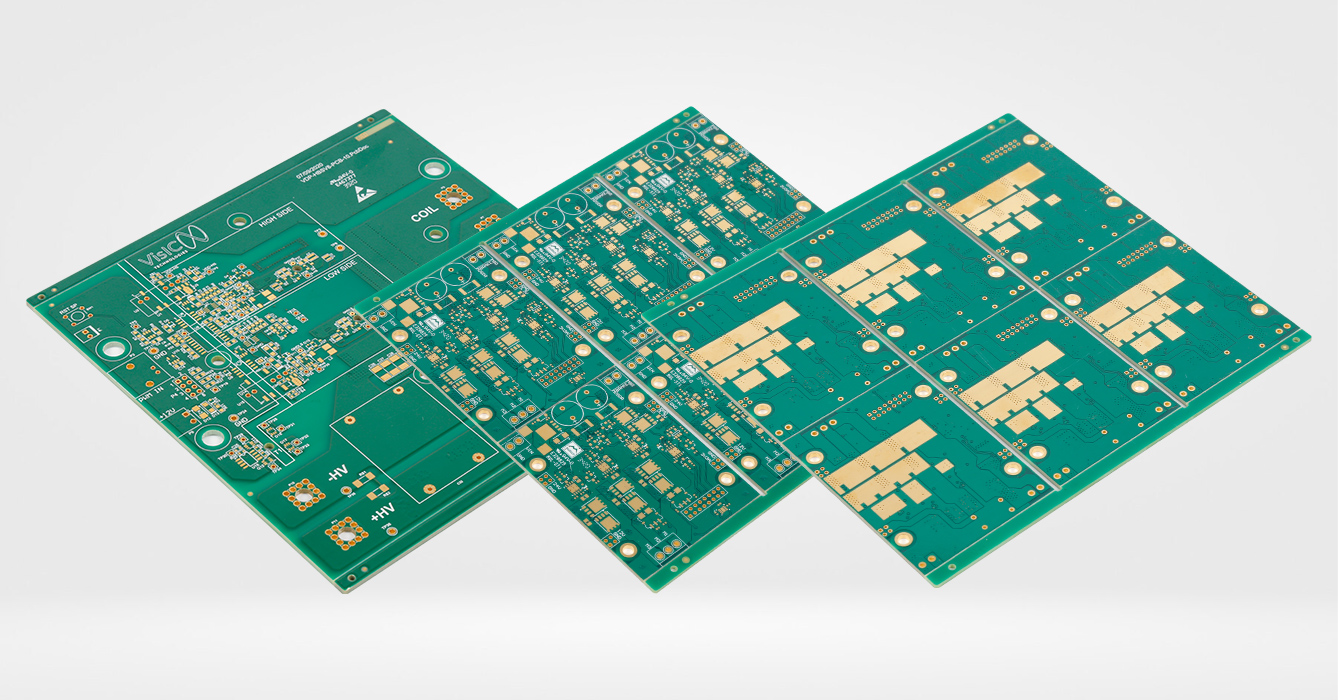

Not every product should be “all FR4” or “all metal-core.” Many factory designs perform best with a Hybrid PCB approach—using different board types where they deliver the most value.

A Hybrid PCB strategy combines different substrate types or board roles within the same product to optimize cost and performance. For example:

FR4 for control/communication/driver electronics

metal-core (aluminum) for high-power LED emitter boards

specialized high-frequency material only where RF performance demands it

Cost control: use premium materials only where needed

Better thermal performance: isolate hotspots to a thermal board

Better routing complexity: keep dense logic on FR4

Faster iteration: revise control boards more frequently than thermal boards

If your product includes both power-dense sections and complex control, a Hybrid PCB approach can reduce total cost while improving reliability.

Many factory products outgrow simple two-layer boards as soon as:

EMC/EMI constraints tighten

power distribution becomes more complex

connector count increases

product size shrinks

A strong FR4 PCB manufacturing service should support:

double-sided FR4 for balanced cost and routing

multilayer FR4 for improved grounding, power integrity, and signal return paths

process controls that keep registration and impedance stable across volume

Factory tip: The goal isn’t “more layers.” The goal is stable routing, clean return paths, and predictable assembly yield.

Use this checklist to evaluate fit for factory programs:

supports your current layer count and likely next revision

can meet your min trace/space and drill requirements

can support controlled impedance if needed

has experience scaling from prototypes to volume without drift

fast, specific DFM feedback

clear questions that prevent assumptions

practical cost-down suggestions after the design stabilizes

consistent FR4 PCB material specification enforcement

traceability and process documentation for recurring builds

inspection and test appropriate to your defect risk

fast quoting with clear assumptions

transparent lead time and build notes

predictable response during ramp-up and production changes

To minimize back-and-forth, send:

Gerber + drill files

Board outline and any panelization requirements

Layer count + finished thickness

Copper weights (outer/inner)

FR4 PCB material specification (Tg class, thickness tolerance, any electrical targets)

Surface finish preference + solder mask requirements

Special processes (controlled impedance, via-in-pad, etc.) if applicable

Quantity plan: prototype / pilot / monthly volume

If using Hybrid PCB approach, clarify which boards are FR4 vs other substrates

Assembly requirement (if needed): BOM, pick&place, assembly drawing, test requirements

If you need a manufacturing partner for FR4 PCB prototypes and stable volume builds, send your files along with a clear FR4 PCB material specification. Early DFM alignment helps prototypes behave like production, while disciplined process control protects yield at scale. If your product has both thermal hotspots and complex control logic, ask about a Hybrid PCB strategy—often the best path to balance cost, reliability, and time-to-market.

A production-ready FR4 PCB material specification should include Tg class, finished thickness/tolerance, copper weights, any controlled impedance targets, reflow cycle expectations, and operating conditions. Clear specs prevent material drift between prototype and volume builds.

Yes. A rigid fr4 pcb is commonly used for industrial control and power assemblies because it provides stiffness and stable mechanical alignment for connectors, mounting holes, and heavier parts.

Choose a supplier that documents stackup and materials from the first prototype, provides DFM feedback, and keeps the same FR4 PCB material specification through pilot and volume. Avoid “prototype-only” shortcuts that change finishes or laminate grades.

Consider a Hybrid PCB approach when different parts of your product have very different needs—such as high heat at LED emitters but complex control logic elsewhere. Using FR4 for control/driver boards and a thermal substrate for hotspots often improves reliability and cost efficiency.

Yes, but switching materials late can introduce risk. It’s usually better to define the FR4 PCB material specification early and use a Hybrid PCB approach if thermal or RF needs demand specialized materials only in certain sections.

[Get a Free Quote & Thermal Analysis for Your Aluminum PCB Project Today]

Related Articles

FR4 PCB Manufacturer for Prototype and Mass Production

FR4 PCB Manufacturer for Fast Prototyping and Volume Production

FR4 PCB Manufacturer for PCB Prototypes and Mass Production

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB