-

- PCB TYPE

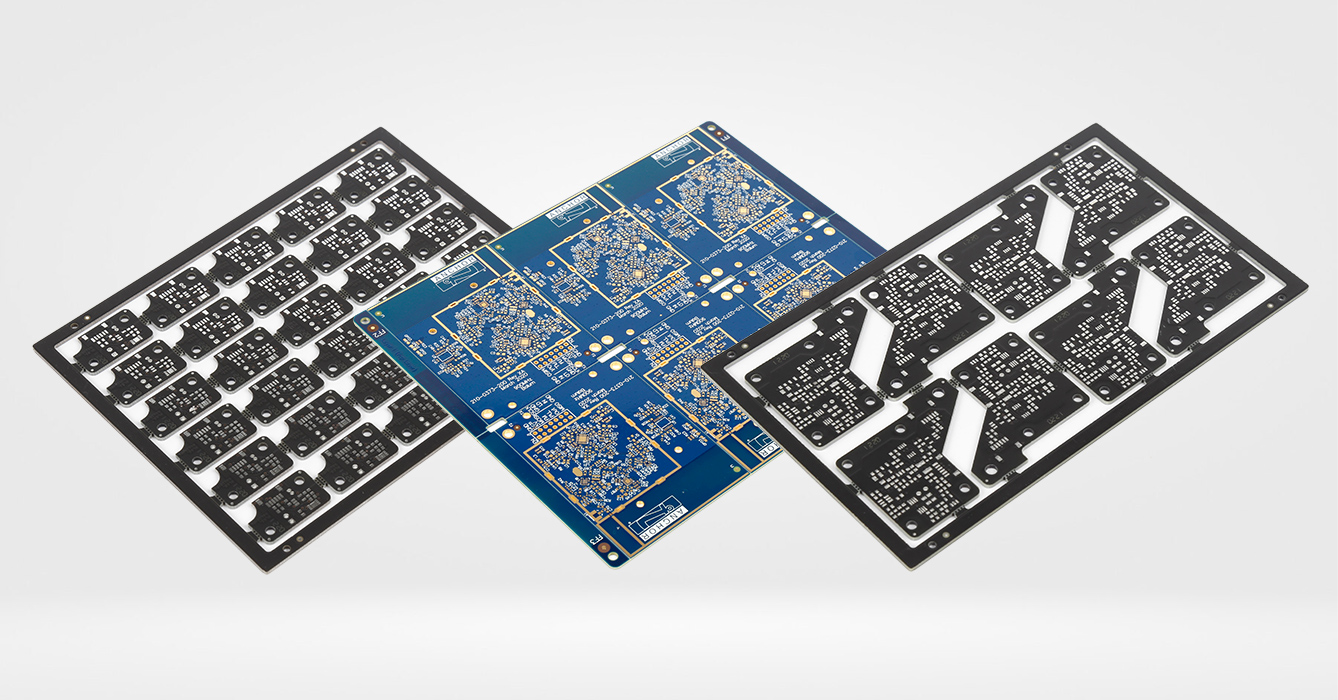

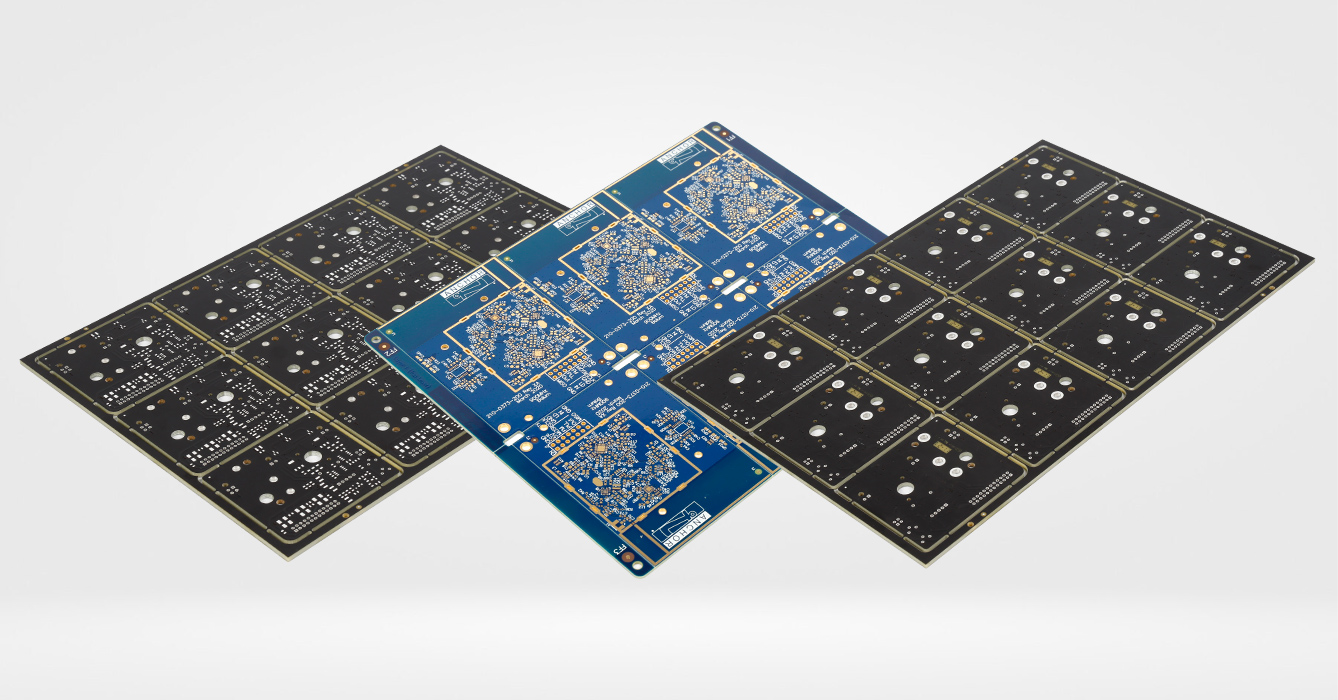

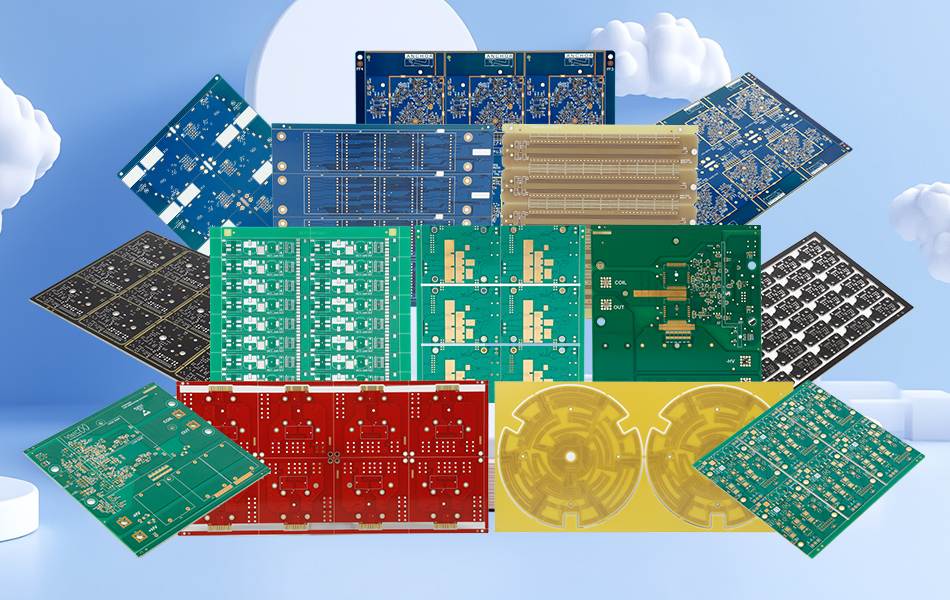

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 08. 2025, 17:03:17

The FR4 PCB temperature rating is a critical specification that dictates the operational limits of printed circuit boards in various thermal environments. This rating, primarily defined by the glass transition temperature (Tg) of the FR4 laminate, serves as a benchmark for engineers to determine if a PCB can withstand the heat generated by components and ambient conditions. Unlike specialized materials such as ceramics or polyimides, FR4 offers a range of temperature ratings—from 130°C for standard variants to 200°C+ for high-performance grades—making it adaptable to diverse applications. This article delves into the meaning of FR4 PCB temperature ratings, how they are measured, the factors that influence them, and their practical implications for design and reliability. By demystifying these ratings, we aim to provide engineers with the knowledge to select the right FR4 variant for their specific thermal needs.

At its core, the FR4 PCB temperature rating centers on the glass transition temperature (Tg), the threshold at which the epoxy resin in the laminate shifts from a rigid, glassy state to a flexible, rubbery one. However, the rating encompasses more than just Tg; it includes maximum continuous operating temperature (MCO), peak transient temperature, and thermal cycling endurance. These parameters collectively define how the PCB will perform under sustained heat, short-term spikes, and repeated temperature fluctuations.

Glass Transition Temperature (Tg): The most cited metric, Tg ranges from 130°C (standard FR4) to 200°C+ (high-temperature FR4). It indicates the point where the resin loses structural rigidity, affecting dimensional stability and mechanical strength.

Maximum Continuous Operating Temperature (MCO): Typically 20–50°C below Tg, this is the highest temperature the PCB can sustain indefinitely without degradation. For example, a 170°C Tg FR4 has an MCO of ~120–130°C.

Peak Transient Temperature: The maximum temperature the PCB can tolerate for short durations (seconds to minutes), often 10–30°C above MCO. This accounts for temporary spikes from component startup or environmental surges.

Understanding these distinctions is key to avoiding premature failure in applications ranging from consumer electronics to industrial machinery.

FR4 PCB temperature ratings are categorized based on Tg, with each class tailored to specific thermal demands:

Standard FR4 (130–140°C Tg): The most common variant, designed for low-heat environments. Its MCO is 100–110°C, making it suitable for consumer devices (smartphones, TVs), office equipment, and low-power IoT sensors. It uses bisphenol-A epoxy resins, balancing cost and basic thermal stability.

Mid-Temperature FR4 (150–160°C Tg): A step up from standard FR4, this class uses modified bisphenol-F resins to withstand higher heat. With an MCO of 110–120°C, it is ideal for LED drivers, small motor controllers, and automotive cabin electronics where ambient temperatures are moderate but consistent.

High-Temperature FR4 (170–180°C Tg): Formulated with novolac epoxies, this variant offers enhanced thermal resilience. Its MCO of 130–140°C suits industrial control systems, underhood automotive components (e.g., ECUs), and aerospace avionics near heat sources.

Extreme-Temperature FR4 (200°C+ Tg): Reserved for extreme environments, this class uses advanced cycloaliphatic epoxies and reinforced fibers. With an MCO of 150–160°C, it is deployed in downhole oil tools, furnace controllers, and high-power inverters where sustained heat is unavoidable.

Each class represents a tradeoff between thermal performance, cost, and processability, with higher Tg variants costing 15–100% more than standard FR4.

Accurate measurement of FR4 temperature ratings requires standardized testing to ensure consistency across manufacturers. Key methods include:

Differential Scanning Calorimetry (DSC): The primary method for determining Tg, DSC measures the heat flow into a sample as temperature increases. A sudden change in heat capacity indicates the glass transition, with results reported per IPC-TM-650 2.4.25.

Thermal Gravimetric Analysis (TGA): Evaluates thermal stability by measuring weight loss as the sample is heated. This identifies the temperature at which the resin begins to degrade (typically 5–10% weight loss), providing insights into long-term heat resistance.

Thermal Cycling Testing: PCBs are subjected to repeated cycles of low and high temperatures (e.g., -40°C to +150°C) to assess endurance. The number of cycles before failure (delamination, via cracking) helps define the rating for dynamic thermal environments.

High-Temperature Aging: Samples are exposed to constant elevated temperatures (e.g., 150°C for 1,000 hours) to simulate long-term operation. Post-aging tests for mechanical strength (flexural, peel) and electrical insulation ensure the rating is viable for sustained use.

These tests are critical for validating manufacturer claims and ensuring the PCB meets application requirements.

Several factors affect the temperature rating of an FR4 PCB, from material composition to manufacturing processes:

Resin Type: Epoxy resin chemistry is the primary driver. Bisphenol-A resins (standard FR4) offer lower Tg, while novolac and cycloaliphatic epoxies (high-temperature FR4) form denser cross-linked networks, enabling higher ratings.

Fiber Reinforcement: E-glass is standard, but S-glass or quartz fibers reduce thermal expansion and enhance mechanical strength at high temperatures, supporting higher ratings.

Fillers and Additives: Inorganic fillers (silica, alumina) reduce resin expansion and improve thermal conductivity, indirectly boosting the effective temperature rating by minimizing heat-induced stress. Flame retardants (phosphorus-based for high-temperature grades) must retain effectiveness at elevated temperatures.

Manufacturing Quality: Inadequate lamination (insufficient pressure or temperature) leaves voids in the resin, reducing thermal stability. Proper curing ensures full cross-linking, maximizing Tg and resistance to heat degradation.

Copper Cladding: Thick copper (2–4 oz) improves heat spreading, allowing the PCB to operate closer to its rating without hotspots. However, copper does not affect the intrinsic Tg of the FR4 laminate.

The temperature rating of an FR4 PCB dictates critical design decisions, from component selection to thermal management strategies:

Component Compatibility: High-power components (e.g., 10W+ MOSFETs) generate significant heat, requiring FR4 with a rating that exceeds the component’s junction temperature (Tj) by a safe margin. For example, a component with Tj = 150°C needs an FR4 rating of 170°C+ to account for heat transfer losses.

Thermal Management Integration: PCBs with lower ratings (130–150°C Tg) require aggressive cooling—thermal vias, heat sinks, and copper pours—to stay within MCO. Higher-rated FR4 (170°C+) reduces reliance on cooling but still benefits from these strategies for longevity.

Layout Considerations: Clustering heat-generating components increases local temperatures, necessitating a higher rating than the ambient environment. Spacing components and routing traces over copper planes distribute heat, leveraging the PCB’s intrinsic thermal capacity.

Solder Joint Reliability: Solder alloys must match the PCB rating. Lead-free solders (e.g., SAC305, melting point 217°C) are compatible with high-temperature FR4, while lower-melting alloys risk reflow in hot environments.

Ignoring these implications can lead to premature failures, including delamination, via cracking, and signal degradation.

Each FR4 temperature rating is suited to specific applications based on thermal demands:

130–140°C Tg FR4:

Consumer electronics (smartphones, laptops) with low-power ICs (1–3W).

Home appliances (refrigerators, microwaves) where ambient temperatures are <50°C.

Office equipment (printers, routers) with minimal heat generation.

150–160°C Tg FR4:

LED lighting (5–10W fixtures) where heat builds up in enclosed housings.

Automotive cabin electronics (infotainment, navigation) with ambient temperatures up to 80°C.

Industrial sensors in moderate environments (100°C max).

170–180°C Tg FR4:

Automotive underhood systems (ECUs, turbo controllers) with sustained temperatures up to 120°C.

Industrial motor drives and inverters with 10–50W components.

Aerospace cabin electronics near heat sources.

200°C+ Tg FR4:

Oil and gas downhole tools operating at 150–180°C.

Furnace controllers and high-temperature industrial ovens.

Military avionics with extreme thermal cycling requirements.

Several myths surround FR4 temperature ratings, leading to improper material selection:

"Tg equals maximum operating temperature": False. Operating temperatures should stay 20–50°C below Tg to avoid resin softening. A 170°C Tg FR4 is not designed for continuous operation at 170°C.

"Higher ratings are always better": Over-specifying (e.g., using 200°C Tg for a 80°C application) increases costs without benefits. Standard FR4 suffices for low-heat environments.

"All FR4 with the same Tg perform identically": Variations in resin quality, filler content, and manufacturing lead to differences in thermal stability. Datasheets should be verified for actual performance.

"Temperature ratings are irrelevant for low-power devices": Even 1W components can create hotspots (>100°C) in compact designs, requiring a rating that matches localized heat, not just ambient temperature.

To guarantee a PCB performs within its rated temperature range, engineers and manufacturers must:

Specify Clear Requirements: Include Tg, MCO, and thermal cycling needs in procurement documents to avoid mismatched materials.

Validate with Testing: Conduct DSC and thermal cycling tests on incoming laminates to confirm Tg and endurance.

Simulate Thermal Performance: Use finite element analysis (FEA) tools to model heat distribution, ensuring no area exceeds the MCO under worst-case conditions.

Monitor in Service: For critical applications, embed temperature sensors to track PCB temperatures during operation, verifying alignment with the rating.

Advancements in material science are expanding the temperature capabilities of FR4:

Nano-Enhanced Resins: Adding graphene or boron nitride nanoparticles improves thermal conductivity and stability, enabling 180–200°C Tg with better heat dissipation than traditional high-temperature FR4.

Sustainable High-Temperature Formulations: Bio-based epoxies (derived from plant oils) are being developed to achieve 150–170°C Tg with lower carbon footprints, aligning with eco-friendly manufacturing trends.

Hybrid Laminates: Combining FR4 with metal cores or ceramic layers creates "graded" temperature ratings, where critical areas (e.g., under a power transistor) have higher thermal resilience than the rest of the PCB.

These innovations aim to bridge the gap between FR4 and exotic materials, offering higher ratings at a fraction of the cost.

The FR4 PCB temperature rating is a cornerstone specification that ensures electronic devices operate reliably in their intended thermal environments. By understanding the nuances of Tg, MCO, and thermal cycling endurance, engineers can select the right FR4 variant—from standard 130°C Tg to extreme 200°C+ Tg—to balance performance, cost, and longevity. As electronics continue to miniaturize and generate more heat, the importance of accurate temperature rating selection will only grow. With ongoing material innovations, FR4 is poised to maintain its dominance as a versatile, cost-effective solution for thermal management, even in increasingly demanding applications. For designers, mastering FR4 temperature ratings is key to unlocking the full potential of printed circuit boards in a wide range of thermal conditions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB