-

- PCB TYPE

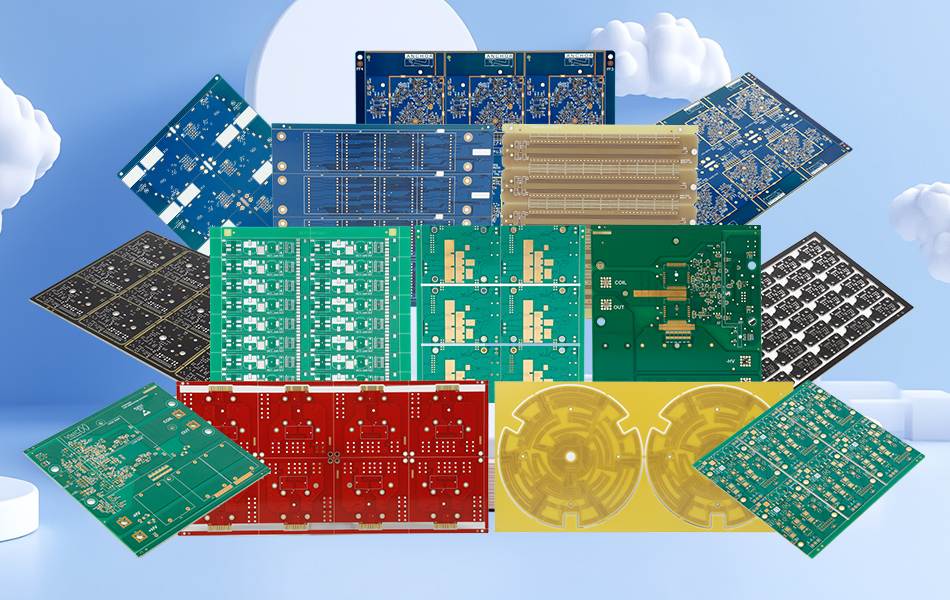

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 08. 2025, 16:57:06

In the realm of electronics, where devices are increasingly deployed in harsh environments—from automotive underhood systems to industrial furnaces—the demand for materials that can withstand elevated temperatures has never been greater. High Temperature FR4 PCB Material emerges as a critical solution, engineered to maintain structural integrity and electrical performance at temperatures far exceeding those tolerated by standard FR4. With glass transition temperatures (Tg) starting at 150°C and reaching up to 200°C or higher, this specialized material bridges the gap between conventional FR4 and exotic alternatives like ceramics or polyimides. This article explores the science behind high temperature FR4, its key properties, manufacturing innovations, design considerations, and real-world applications, highlighting why it has become indispensable for engineers designing electronics for extreme thermal conditions.

High Temperature FR4 PCB Material is distinguished by its elevated glass transition temperature (Tg), the point at which the epoxy resin matrix shifts from a rigid, glassy state to a flexible, rubbery one. While standard FR4 has a Tg of 130–140°C, high temperature variants are formulated to achieve Tg values of 150°C, 170°C, 180°C, or even 200°C+. This distinction is not merely incremental; it reflects a fundamental redesign of the material’s composition to resist softening and degradation in sustained high-heat environments.

Crucially, the Tg of high temperature FR4 is not an absolute upper limit but a threshold that influences performance. Engineers design systems using these materials to operate at 20–50°C below Tg, ensuring a safety margin for transient temperature spikes. For example, a 180°C Tg FR4 is typically specified for applications with continuous operating temperatures up to 130°C, with short-term spikes allowed up to 150°C. This balance of thermal resilience and practicality makes high temperature FR4 a versatile choice for demanding applications.

The enhanced thermal performance of high temperature FR4 stems from deliberate modifications to its composite structure, focusing on three key components:

Advanced Epoxy Resins: Unlike the bisphenol-A resins used in standard FR4, high temperature variants employ novolac epoxies, cycloaliphatic epoxies, or modified bisphenol-F resins. These resins form a denser, more cross-linked molecular network during curing, which resists thermal degradation and delays the glass transition. Novolac epoxies, for instance, offer superior heat resistance due to their aromatic ring structures, enabling Tg values of 170°C+.

Reinforcement Fibers: While E-glass remains common, high temperature FR4 often uses S-glass or quartz fibers for their lower thermal expansion and higher tensile strength at elevated temperatures. S-glass, with a tensile strength of ~4,500 MPa (vs. E-glass’s 3,400 MPa), enhances mechanical stability when the resin matrix softens near Tg.

Heat-Resistant Additives: Flame retardants in high temperature FR4 are selected for thermal stability. Phosphorus-based additives, which replace brominated compounds in eco-friendly formulations, maintain flame resistance (UL94 V-0) even after prolonged exposure to 150°C+. Additionally, inorganic fillers like silica or alumina are added to reduce thermal expansion and improve dimensional stability.

This combination creates a material that retains mechanical strength, electrical insulation, and structural integrity in environments where standard FR4 would fail.

High temperature FR4 exhibits a unique set of properties tailored to extreme thermal conditions:

Elevated Tg: As the defining characteristic, Tg values range from 150°C to 200°C+, measured via differential scanning calorimetry (DSC) per IPC-TM-650 2.4.25. This ensures the material remains rigid and stable in high-heat environments.

Thermal Dimensional Stability: Low coefficient of thermal expansion (CTE) is critical for preventing warpage and solder joint fatigue. High temperature FR4 typically has an in-plane CTE of 10–16 ppm/°C (vs. 12–18 ppm/°C for standard FR4), with z-axis CTE reduced to 40–60 ppm/°C through filler additions.

Mechanical Strength at High Temperatures: Retains 60–70% of room-temperature flexural strength (≥500 MPa) at 150°C, compared to 40–50% for standard FR4. This ensures the PCB withstands vibration and mechanical loads in hot operating conditions.

Electrical Performance Stability: Maintains stable dielectric constant (Dk = 4.2–4.8 at 1 MHz) and low dissipation factor (Df ≤0.025) up to 150°C, critical for high-speed signals in automotive and industrial electronics.

Moisture Resistance: Water absorption ≤0.1% (after 24-hour immersion) prevents hydrolysis of the resin matrix, a common failure mode in high-temperature, high-humidity environments.

Understanding how high temperature FR4 behaves at different temperature intervals is key to leveraging its capabilities:

Below Tg (e.g., ≤130°C for 170°C Tg): In this range, the material remains fully rigid, with stable mechanical and electrical properties. It resists warpage, delamination, and signal degradation, making it suitable for continuous operation.

Near Tg (e.g., 130–160°C for 170°C Tg): As temperatures approach Tg, the resin begins to soften, causing a gradual increase in CTE and a 20–30% drop in flexural strength. However, high temperature FR4 retains sufficient integrity for short-term exposure, such as transient spikes during device operation.

Above Tg (e.g., >170°C for 170°C Tg): Beyond the glass transition, the material becomes rubbery, with a significant CTE increase (≥50 ppm/°C) and severe strength loss. While brief exposure (seconds) may not cause immediate failure, prolonged exposure leads to permanent deformation, via cracking, and solder joint failure.

These behaviors underscore the importance of selecting the correct Tg for the application’s maximum operating temperature.

High temperature FR4 is indispensable in applications where sustained heat or frequent thermal cycling is unavoidable:

Automotive Underhood Electronics: Engine control units (ECUs), turbocharger controllers, and exhaust gas sensors operate in ambient temperatures up to 120°C, with transient spikes to 150°C. 170–180°C Tg FR4 ensures reliability under these conditions.

Industrial Furnace Controls: Controllers for kilns, ovens, and heat treatment systems are exposed to ambient temperatures of 100–130°C. 180°C Tg FR4 resists degradation from prolonged heat exposure.

Aerospace Avionics: Cabin electronics near engines or environmental control systems experience temperatures up to 120°C. High temperature FR4 (170°C Tg+) meets aerospace standards (e.g., AS9100) for thermal stability.

Oil and Gas Downhole Tools: Logging equipment operates at 150–180°C in deep wells, requiring 200°C Tg FR4 to maintain signal integrity and structural strength.

Power Electronics: Inverters, motor drives, and DC-DC converters with high-power components (10–50W) generate significant heat, necessitating 150–170°C Tg FR4 to dissipate thermal energy without degradation.

To maximize reliability with high temperature FR4, designers should adopt strategies that complement its thermal properties:

Tg Selection: Choose a Tg that provides a 20–50°C buffer above the maximum continuous operating temperature. For example, a device operating at 130°C should use 170°C Tg FR4 to account for spikes.

Thermal Management Integration: Combine high temperature FR4 with thermal vias (filled with conductive epoxy), thick copper planes (2–4 oz), and heat sinks to dissipate heat, reducing reliance on the material’s intrinsic thermal conductivity.

Component Placement: Locate high-power devices (e.g., MOSFETs, IGBTs) near PCB edges or heat sinks to minimize heat buildup. Avoid clustering hot components to prevent cumulative heating.

Solder Joint Design: Use lead-free solder alloys with high melting points (e.g., SAC305, melting point 217°C) to match the PCB’s thermal resilience. Ensure adequate solder fillet size to resist thermal fatigue.

Material Compatibility: Select solder masks and conformal coatings with Tg ≥200°C (e.g., polyimide-based) to prevent delamination in high-heat areas.

Producing high temperature FR4 PCBs requires specialized processes to ensure optimal thermal performance:

Lamination: Extended cure cycles (180–220°C for 120–180 minutes) are needed to fully cross-link the high-temperature resins. Higher pressure (400–500 psi) eliminates voids, ensuring uniform resin distribution.

Drilling and Routing: The dense resin matrix and reinforced fibers require carbide drill bits with diamond coatings to prevent chipping and ensure clean via walls. Lower feed rates (0.08–0.12 mm/rev) reduce heat generation during drilling.

Plating: Through-hole plating must adhere to the resin-fiber interface, which is more resistant to chemical etching. Extended desmearing (e.g., 30% longer permanganate exposure) ensures reliable copper adhesion in vias.

Soldering: Lead-free reflow profiles with peak temperatures ≤260°C and short dwell times (<10 seconds) prevent thermal degradation of the laminate. Slow ramp rates (≤2°C/sec) reduce thermal stress.

Rigorous testing ensures high temperature FR4 meets its thermal performance claims:

Tg Verification: DSC testing confirms Tg within the specified range (e.g., 170°C ±5°C) for each production batch, ensuring consistency.

Thermal Cycling: PCBs undergo 1,000–2,000 cycles of -55°C to +150°C (or higher, depending on Tg) to simulate extreme temperature swings. Post-test inspection checks for delamination, via cracking, and solder joint integrity.

High-Temperature Aging: Samples are exposed to 150–180°C for 1,000–2,000 hours to evaluate long-term stability. Weight loss (moisture/volatile release) must be <0.5%, and mechanical strength retention ≥60%.

IR Thermography: Operational testing with infrared cameras maps hotspots, ensuring no area exceeds the design temperature limit (e.g., 130°C for 170°C Tg FR4).

High temperature FR4 offers a balance of performance and cost that distinguishes it from alternatives:

vs. Standard FR4: Provides 20–70°C higher Tg but costs 15–50% more, justified for applications where standard FR4 would fail.

vs. Polyimide PCBs: Polyimide has Tg >250°C but costs 3–5x more than high temperature FR4, making it suitable only for extreme environments (>200°C).

vs. Ceramic Substrates: Alumina or aluminum nitride ceramics offer superior thermal conductivity but are brittle, expensive, and limited to simple designs. High temperature FR4 is preferable for complex, multi-layer PCBs.

vs. Metal-Core PCBs (MCPCBs): MCPCBs excel at heat dissipation but have lower Tg (130–150°C) and are less suitable for sustained high temperatures. High temperature FR4 combines thermal stability with better electrical performance.

Several myths can lead to improper use of high temperature FR4:

"Higher Tg is always better": Over-specifying Tg (e.g., using 200°C Tg for a 100°C application) increases costs unnecessarily without performance benefits.

"High temperature FR4 eliminates the need for cooling": While more resilient, it still requires thermal management for high-power components (>10W) to prevent hotspots.

"All high temperature FR4 is the same": Tg, resin type, and filler content vary by manufacturer—always verify datasheet specifications.

"Soldering at 260°C damages high temperature FR4": Short exposure (<10 seconds) is safe, as the material’s Tg is well above reflow temperatures.

Innovation continues to push the boundaries of high temperature FR4:

Nano-Enhanced Resins: Adding graphene or boron nitride nanotubes improves thermal conductivity (0.5–0.8 W/mK) while maintaining high Tg, reducing the need for thermal vias.

Sustainable Formulations: Bio-based novolac epoxies, derived from plant oils, are being developed to achieve 170°C Tg with 20–30% lower carbon footprints.

Hybrid Materials: Combining high temperature FR4 with metal cores or ceramic inserts creates "thermal bridges" for high-power components, merging thermal stability with enhanced heat dissipation.

High Temperature FR4 PCB Material represents a critical advancement in thermal management, enabling electronics to operate reliably in environments once reserved for exotic materials. By balancing elevated Tg, mechanical strength, and cost-effectiveness, it has become the material of choice for automotive, industrial, and aerospace applications. As electronics continue to miniaturize and operate at higher power densities, the demand for high temperature FR4 will only grow, driven by its unique ability to withstand extreme heat without sacrificing performance or affordability. For engineers, understanding its properties and design considerations is key to unlocking the full potential of electronics in the most challenging thermal environments.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB