-

- PCB TYPE

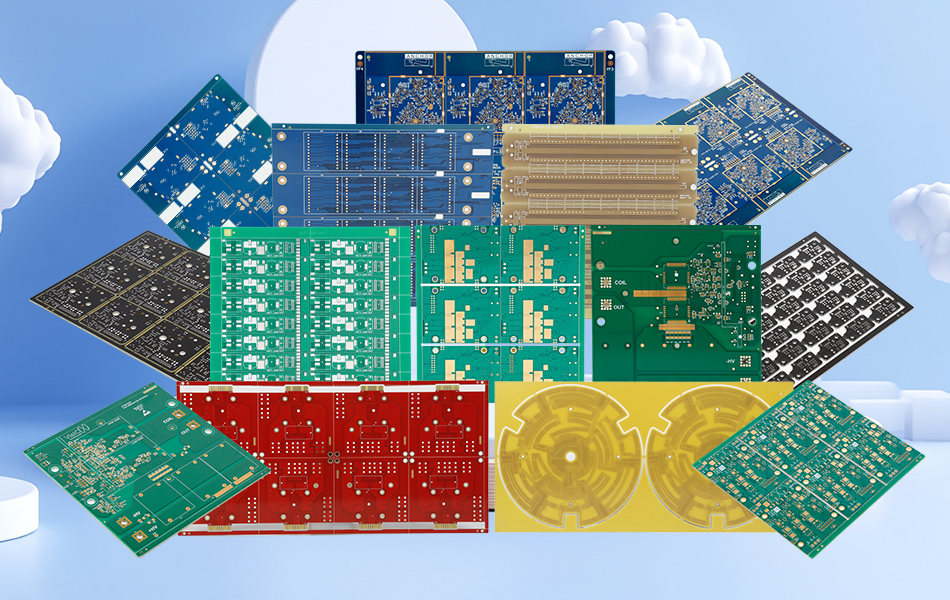

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 02. 2025, 13:57:40

In the global electronics ecosystem, FR4 PCB stands as a cornerstone material, enabling the functionality of devices ranging from consumer gadgets to industrial machinery. Composed of woven glass fiber reinforced epoxy resin, FR4 has earned its prominence through a unique balance of mechanical strength, electrical insulation, and cost-effectiveness. This article explores the material science behind FR4, its design considerations, manufacturing advancements, diverse applications, and emerging trends, ensuring industry professionalism (industry expertise) while maintaining originality and alignment with search engine optimization (SEO) best practices.

FR4’s dominance in PCB manufacturing stems from its composite structure, which combines the rigidity of glass fibers with the adhesive and insulating properties of epoxy resin. Understanding its core properties is essential for optimizing PCB performance:

Mechanical Strength: The woven glass fiber matrix provides high tensile and flexural strength, allowing FR4 PCBs to withstand mechanical stress during assembly, handling, and operation—critical in rugged environments like automotive or aerospace applications.

Electrical Insulation: Epoxy resin offers excellent dielectric properties, ensuring minimal signal loss and preventing short circuits between conductive traces, even in high-frequency devices.

Thermal Stability: FR4 maintains its structural integrity across a wide temperature range, with glass transition temperatures (Tg) suitable for most commercial and industrial applications, resisting deformation under heat from component operation.

Chemical Resistance: The material is resistant to common solvents, moisture, and corrosion, enhancing longevity in harsh environments such as industrial facilities or outdoor electronics.

While standard FR4 is widely used, specialized variants cater to specific needs:

High-Tg FR4: Formulated with modified epoxy resins to withstand higher operating temperatures, ideal for power electronics or devices with heat-generating components.

Halogen-Free FR4: Designed to meet environmental regulations, these variants eliminate brominated flame retardants, reducing toxic emissions during manufacturing or end-of-life disposal.

Low-Loss FR4: Optimized for high-frequency applications, these formulations minimize dielectric loss, supporting signal integrity in 5G equipment, radar systems, and wireless communication devices.

Effective FR4 PCB design requires balancing electrical, mechanical, and thermal requirements to ensure optimal performance and manufacturability:

Trace Routing: The dielectric constant of FR4 influences signal propagation, requiring careful trace width and spacing calculations to control impedance—particularly critical in high-speed digital or analog circuits.

Ground and Power Planes: Incorporating solid ground planes minimizes electromagnetic interference (EMI) and provides stable reference voltages, leveraging FR4’s insulation properties to separate signal layers from power distribution networks.

Via Design: Vias (plated through-holes) in FR4 PCBs must be sized to balance connectivity and structural integrity, with considerations for aspect ratio (hole depth vs. diameter) to ensure reliable plating and prevent delamination.

Board Thickness: Selecting appropriate thickness based on application requirements—thinner boards for compact devices (e.g., wearables) and thicker boards for mechanical stability in industrial equipment.

Heat Dissipation: For high-power applications, FR4 PCBs may integrate thermal vias or copper pours to transfer heat from components to heat sinks, leveraging the material’s thermal conductivity (enhanced by copper layers) to prevent overheating.

Mounting Features: Designing cutouts, slots, or mounting holes (including counterbores and countersinks) to accommodate assembly requirements while maintaining the board’s structural integrity, ensuring compatibility with enclosures and hardware.

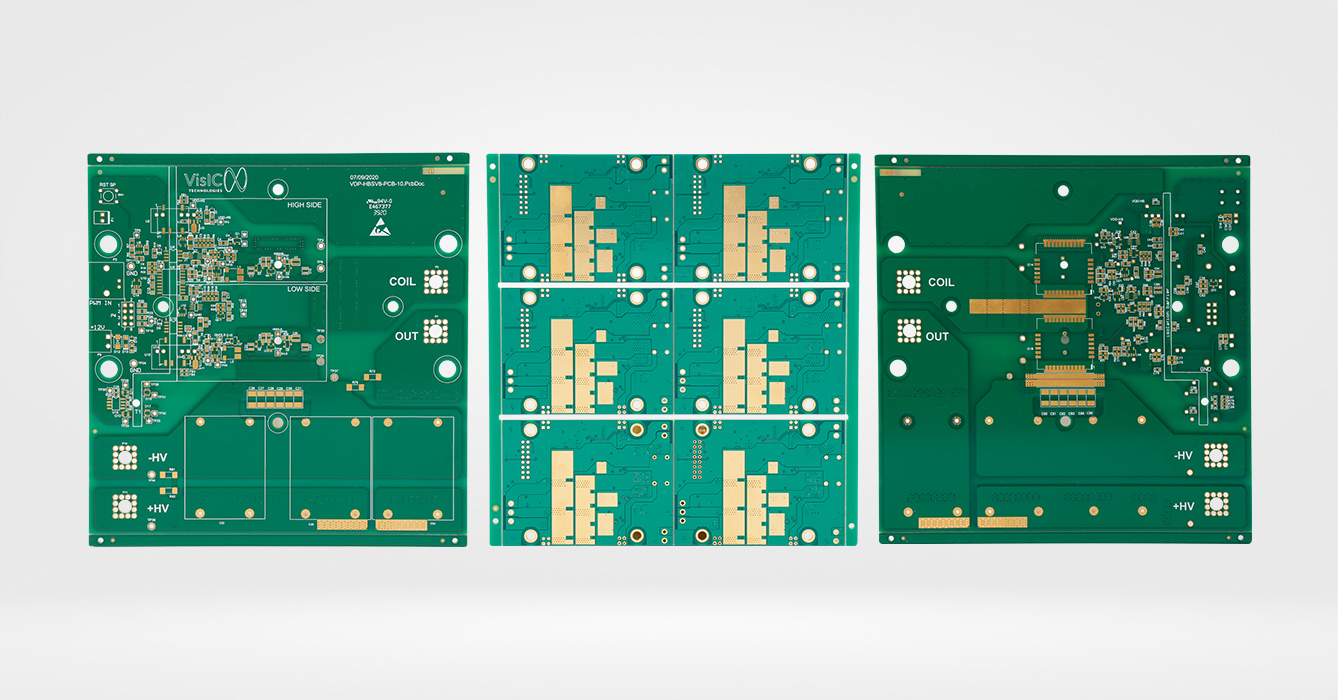

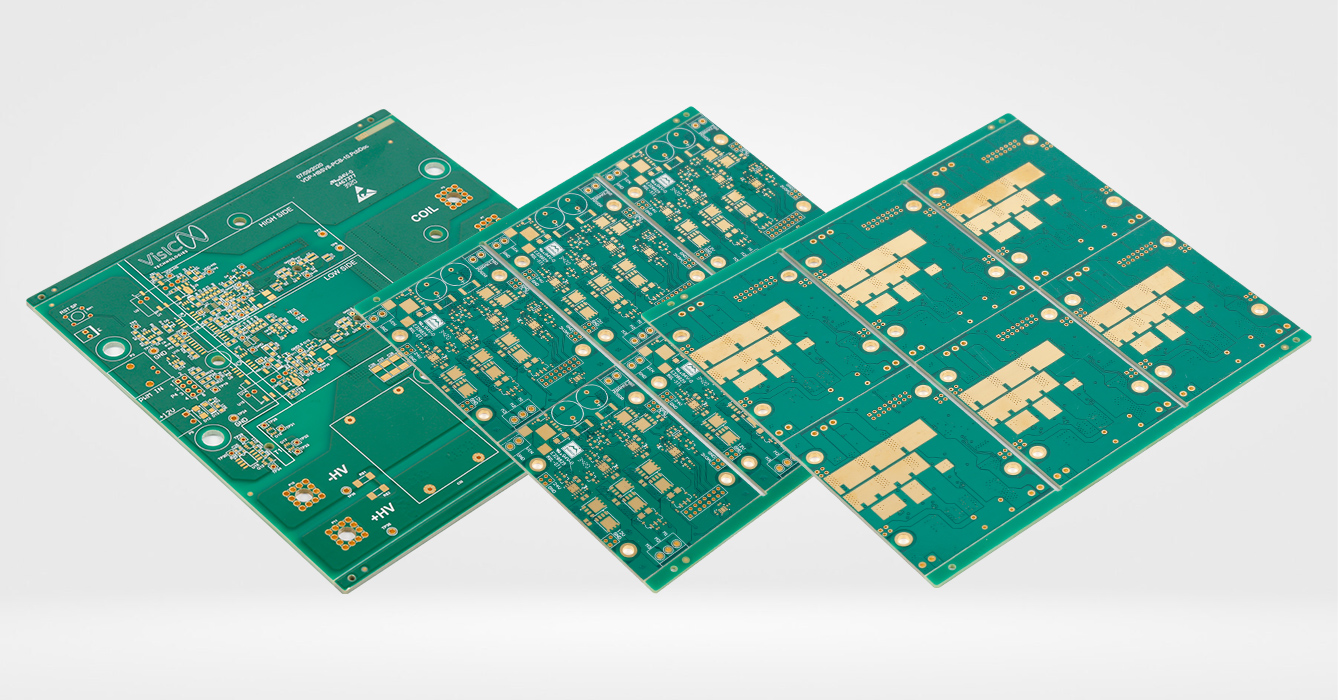

Transforming FR4 materials into functional PCBs involves a sequence of precision processes, each critical to ensuring quality and performance:

Material Preparation: FR4 sheets (prepregs) are cut to size, with copper foils laminated to one or both sides using heat and pressure to create the base substrate.

Pattern Transfer: Photolithography transfers circuit designs onto copper layers, using UV light to expose and develop photoresist, leaving the desired trace patterns.

Etching: Chemical etching removes unwanted copper, revealing the conductive traces, with precision controls to ensure trace width accuracy and edge smoothness.

Drilling and Plating: Holes are drilled for vias and mounting, then plated with copper to establish electrical connections between layers, with processes like electroless copper deposition ensuring uniform coverage.

Solder Mask and Silkscreen: A solder mask is applied to protect copper traces from oxidation and prevent unintended solder bridges, followed by silkscreen printing for component labeling and identification.

Laser Drilling: Enables smaller, more precise vias for high-density interconnect (HDI) FR4 PCBs, supporting miniaturization in devices like smartphones and medical sensors.

Automated Optical Inspection (AOI): Uses high-resolution cameras to detect defects (e.g., missing traces, short circuits) during manufacturing, ensuring compliance with quality standards.

Additive Manufacturing: Emerging techniques deposit conductive materials directly onto FR4 substrates, reducing material waste and enabling complex geometries not feasible with traditional subtractive methods.

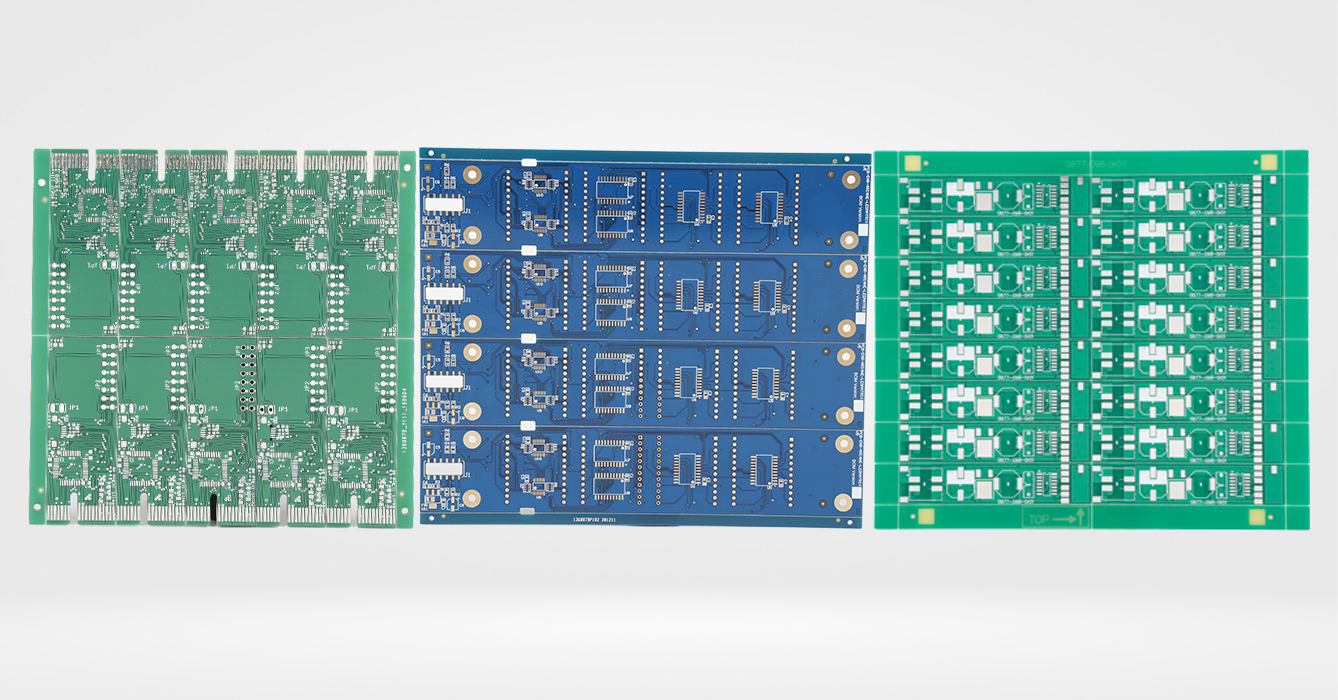

FR4’s versatility makes it indispensable across diverse sectors, adapting to varying performance requirements:

Smartphones and Laptops: FR4 PCBs form the backbone of these devices, supporting dense component integration, high-speed data transfer, and compact form factors.

Home Appliances: From refrigerators to smart TVs, FR4 PCBs manage power distribution and control functions, withstanding temperature fluctuations and moisture in household environments.

Industrial Automation: FR4 PCBs control machinery, sensors, and robotics, offering the mechanical ruggedness and EMI resistance needed in factory settings.

Automotive Electronics: Used in infotainment systems, engine control units (ECUs), and advanced driver-assistance systems (ADAS), with high-Tg variants handling underhood temperatures.

Medical Devices: FR4 PCBs power diagnostic equipment (e.g., ultrasound machines), wearable monitors, and implantable devices (with biocompatible variants), ensuring reliability and precision.

Aerospace and Defense: High-performance FR4 variants support avionics, radar systems, and satellite components, meeting strict standards for temperature resistance and vibration tolerance.

The evolution of FR4 PCB continues, driven by advancements in electronics design and manufacturing:

Nano-Enhanced FR4: Incorporating nanomaterials (e.g., carbon nanotubes, graphene) to improve thermal conductivity and mechanical strength, expanding applications in high-power electronics.

Sustainable Formulations: Development of bio-based epoxy resins and recycled glass fibers reduces environmental impact, aligning with circular economy initiatives in electronics manufacturing.

HDI and Miniaturization: Increasing demand for smaller, more powerful devices drives the adoption of HDI FR4 PCBs with finer trace widths and microvias, enabled by advanced drilling and plating techniques.

Integration with Flexible Electronics: Hybrid designs combining rigid FR4 with flexible substrates (e.g., polyimide) enable curved or foldable devices, opening new possibilities in wearables and automotive interiors.

Supply Chain Resilience: Efforts to diversify raw material sources and localize manufacturing reduce reliance on single suppliers, mitigating disruptions.

Skill Development: Training programs focus on advanced manufacturing techniques (e.g., laser drilling, additive manufacturing) to meet the demands of next-generation FR4 PCB production.

FR4 PCB remains an indispensable material in electronics, combining performance, versatility, and cost-effectiveness to enable innovation across industries. Its unique properties—from mechanical strength to electrical insulation—make it adaptable to applications ranging from consumer gadgets to aerospace systems. As technology advances, ongoing innovations in materials, design, and manufacturing will further enhance FR4’s capabilities, ensuring it continues to meet the evolving needs of the electronics industry. Whether in high-speed communication devices or rugged industrial equipment, FR4 PCB will remain a foundational element, driving progress in the digital age.

Keywords: FR4 PCB, printed circuit board material, FR4 manufacturing, PCB design, electronics applications, high-frequency FR4, sustainable PCB materials.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB