-

- PCB TYPE

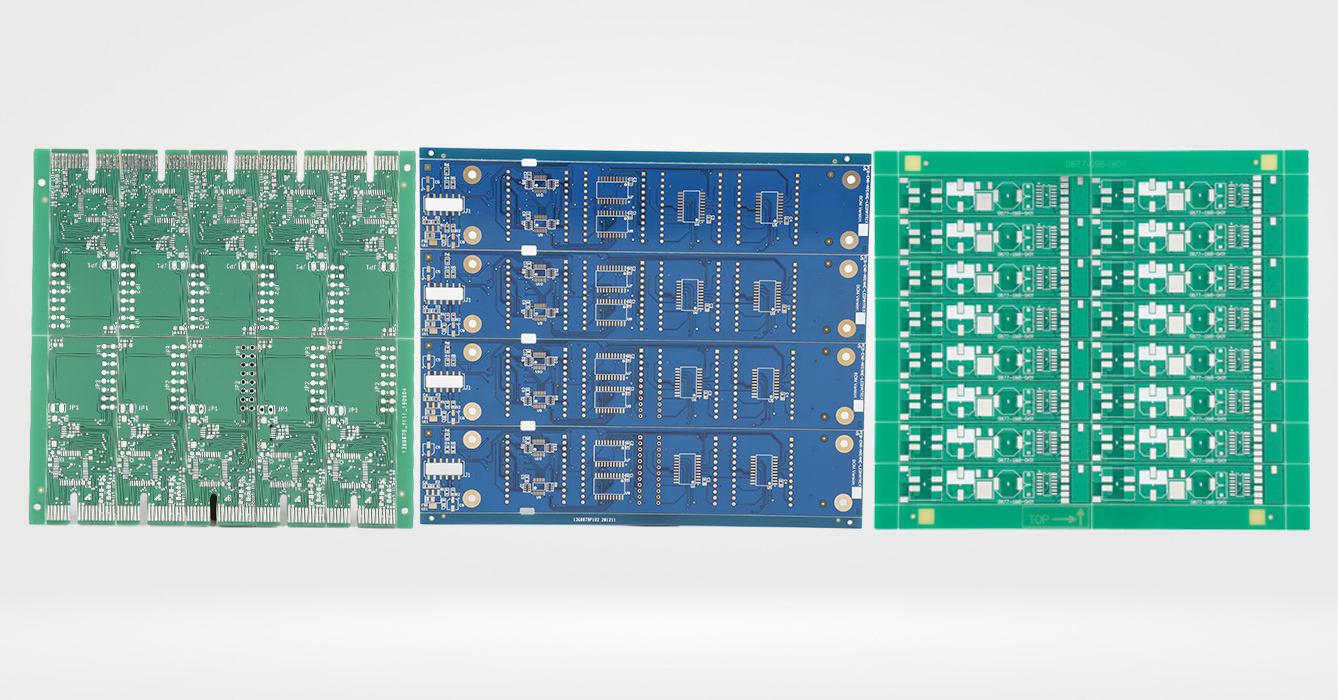

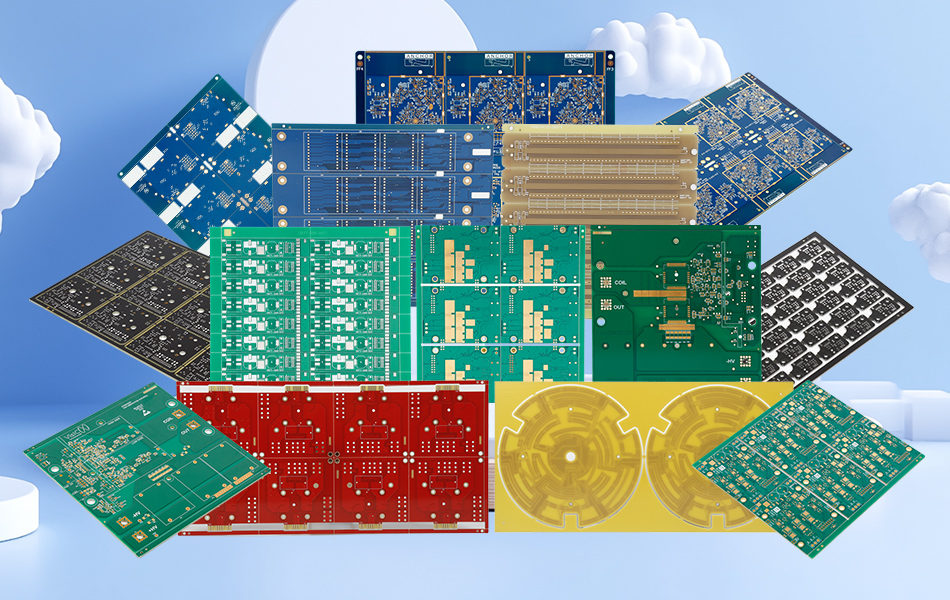

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 12. 2025, 11:59:45

In the vast ecosystem of electronic components, FR4 PCB stands as a testament to enduring innovation, having evolved from a functional substrate to a dynamic material that underpins nearly every electronic device. Unlike specialized materials designed for niche applications, FR4’s strength lies in its ability to adapt to changing technological demands while maintaining a balance of performance, cost, and manufacturability. From the earliest computing systems to today’s smart devices, FR4 has not merely kept pace with innovation but has often enabled it. This article explores the evolutionary journey of FR4 PCB, its role in enabling technological milestones, its current adaptations to modern challenges, and its potential to shape future electronics. By examining its past and present, we gain insight into why FR4 remains the most widely used PCB material globally.

The story of FR4 PCB is one of continuous refinement, driven by the need to support increasingly complex and powerful electronics.

FR4’s origins can be traced to the mid-20th century, a period when electronics were transitioning from bulky vacuum tube systems to smaller, transistor-based designs. Early PCBs relied on materials like phenolic resins, which were cheap but prone to burning and lacked the mechanical stability required for dense circuits. FR4 emerged as a solution: its glass fiber reinforcement provided rigidity, while epoxy resin offered electrical insulation and flame resistance. The “FR” in its name—short for “flame retardant”—highlighted a critical safety advantage over its predecessors, making it suitable for consumer and industrial applications alike.

Over the decades, FR4 has undergone incremental yet significant changes. In the 1980s, as personal computers gained popularity, manufacturers modified FR4 to support finer copper traces, enabling more compact designs. The 2000s saw the rise of high-temperature FR4 variants to meet the needs of power-dense devices like smartphones and laptops. More recently, halogen-free FR4 has emerged to address environmental concerns, while low-dielectric variants cater to the high-frequency demands of 5G technology. Each adaptation has ensured that FR4 remains relevant, proving that its evolution is as much a story of flexibility as it is of technological advancement.

FR4’s enduring popularity stems from a set of core attributes that make it uniquely suited to a wide range of applications:

FR4’s glass fiber-epoxy composite structure balances rigidity and durability, allowing it to withstand the physical stresses of manufacturing, assembly, and daily use. It resists bending, warping, and impact, ensuring that PCBs retain their shape even in harsh environments—from industrial factories to automotive engine bays. This mechanical stability also supports the precise alignment of components, critical for high-density circuits where even minor shifts can cause short circuits.

The epoxy resin matrix in FR4 acts as an excellent electrical insulator, preventing current leakage between copper traces. This property is foundational to PCB functionality, as it ensures that signals flow only along their intended paths. FR4’s insulation capabilities remain consistent across a wide range of temperatures and frequencies, making it reliable for both low-power devices (like remote controls) and high-performance systems (like server motherboards).

FR4’s inherent flame retardancy—achieved through additives in the epoxy resin—prevents it from sustaining combustion, reducing the risk of fires in electronic devices. This safety feature has made it a staple in consumer electronics, where devices are often used in homes and workplaces, and in industrial settings, where fire risks can have catastrophic consequences.

Compared to specialized materials like ceramics or PTFE, FR4 is relatively inexpensive to produce. Its manufacturing processes—from lamination to etching—are well-established and scalable, allowing for mass production at low cost. This affordability has democratized access to electronics, enabling the proliferation of devices from budget smartphones to educational tools in developing regions.

Perhaps FR4’s most valuable attribute is its adaptability. By modifying its composition—changing the type of epoxy resin, adjusting glass fiber weave, or adding specialized additives—manufacturers can tailor FR4 to meet specific needs, such as higher heat resistance or lower signal loss. This versatility ensures that FR4 can serve in applications as diverse as medical implants and space satellites.

Today, FR4 PCB is integral to virtually every sector of the electronics industry, enabling innovations that shape daily life:

From smartphones and tablets to smart TVs and gaming consoles, FR4 forms the core of consumer devices. Standard FR4 variants balance cost and performance for most applications, while thin-core FR4 enables the slim designs of modern smartphones. Halogen-free FR4 is increasingly used in devices sold in regions with strict environmental regulations, ensuring compliance without sacrificing functionality.

Factory robots, control systems, and sensors rely on FR4 for its durability and resistance to dust, moisture, and temperature fluctuations. High-temperature FR4 variants handle the heat generated by industrial motors and power supplies, while reinforced FR4 resists the vibration common in manufacturing environments.

Medical devices such as patient monitors, diagnostic equipment, and wearable health trackers use FR4 for its reliability and biocompatibility. Halogen-free FR4 is preferred in these applications to minimize toxic emissions, while flexible FR4 variants enable the development of conformable, body-worn devices.

Solar inverters, wind turbine controllers, and energy storage systems depend on FR4 to manage power conversion. High-temperature FR4 variants withstand the heat of power-dense components, ensuring efficient energy transfer and long-term reliability in outdoor installations.

Automotive, aerospace, and marine electronics use FR4 in navigation systems, engine controls, and communication modules. FR4’s ability to resist vibration, extreme temperatures, and corrosion makes it suitable for these demanding environments, where failure can have serious consequences.

In each of these sectors, FR4’s role is not merely passive; it actively enables technological 进步 by providing a stable, adaptable platform for innovation.

As electronics continue to evolve, FR4 is undergoing innovations that expand its capabilities and applications:

Manufacturers are developing epoxy resins with enhanced properties, such as higher glass transition temperatures (Tg) for improved heat resistance and lower dielectric constants for better high-frequency performance. These formulations allow FR4 to compete with specialized materials in applications like 5G base stations and electric vehicle (EV) charging systems.

The industry is moving toward more eco-friendly production processes for FR4. This includes using recycled glass fibers, bio-based epoxy resins derived from plant oils, and water-based etching solutions. These changes reduce FR4’s environmental footprint while maintaining its performance characteristics.

3D printing techniques are being adapted to produce FR4-based components, enabling rapid prototyping and custom designs. This shift from traditional subtractive manufacturing (etching) to additive processes reduces material waste and allows for more complex geometries, such as internal channels for heat dissipation.

Research is exploring the integration of sensors directly into FR4 laminates, creating “smart” PCBs that can monitor temperature, stress, or humidity in real time. These sensors enable predictive maintenance, allowing devices to alert users to potential failures before they occur—critical for applications like medical equipment and industrial machinery.

These innovations ensure that FR4 remains at the forefront of PCB technology, capable of meeting the demands of emerging technologies like artificial intelligence, IoT, and quantum computing.

Despite its versatility, FR4 faces challenges that drive ongoing research and development:

In applications requiring ultra-high frequencies (above 100 GHz) or extreme temperatures (above 200°C), FR4 is outperformed by specialized materials like PTFE or ceramic substrates. While advanced FR4 variants narrow this gap, they cannot match the performance of these niche materials, limiting their use in certain aerospace and defense applications.

Traditional FR4 contains halogenated flame retardants, which can release toxic gases when burned. While halogen-free alternatives exist, they are often more expensive and may have slightly different mechanical properties, requiring design adjustments. Additionally, recycling FR4 remains challenging, as separating glass fibers, epoxy resin, and copper is labor-intensive and costly.

As electronic components become smaller and more powerful, they generate more heat in less space. Standard FR4 has relatively low thermal conductivity, making it less effective at dissipating heat in power-dense devices like EV inverters. While high-temperature FR4 variants help, they are not a complete solution, often requiring additional heat sinks or thermal vias.

Emerging materials, such as metal-core PCBs and flexible polymers, are challenging FR4 in specific applications. For example, metal-core PCBs offer better thermal conductivity for LED lighting, while flexible polymers enable wearable devices with extreme bendability. FR4 must continue to evolve to maintain its market dominance.

FR4’s future lies in its ability to adapt to emerging trends while leveraging its core strengths:

As 6G networks, autonomous vehicles, and smart cities develop, FR4 will play a key role in supporting their electronics. Low-dielectric FR4 variants will enable faster data transmission in 6G, while high-temperature, halogen-free FR4 will meet the demands of EVs and sustainable infrastructure.

The industry will continue to focus on making FR4 more environmentally friendly, with advances in recyclable formulations, bio-based materials, and energy-efficient manufacturing. These efforts will align FR4 with global initiatives to reduce e-waste and carbon emissions.

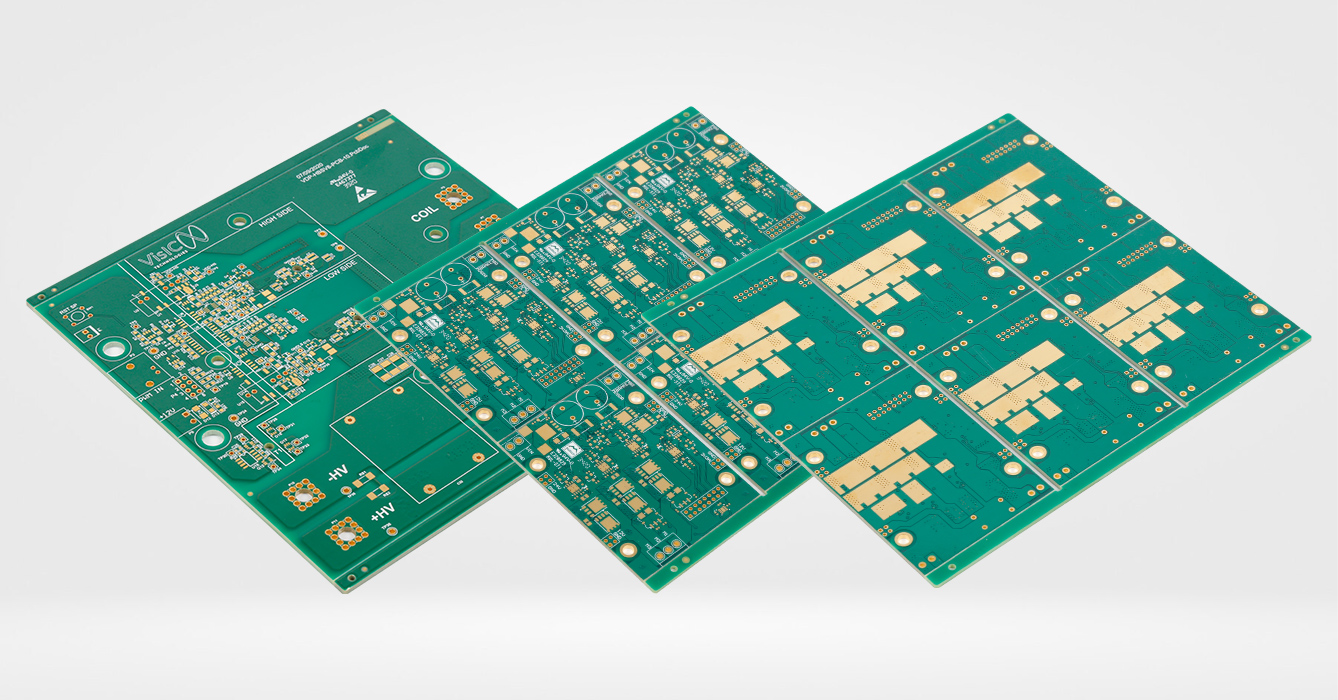

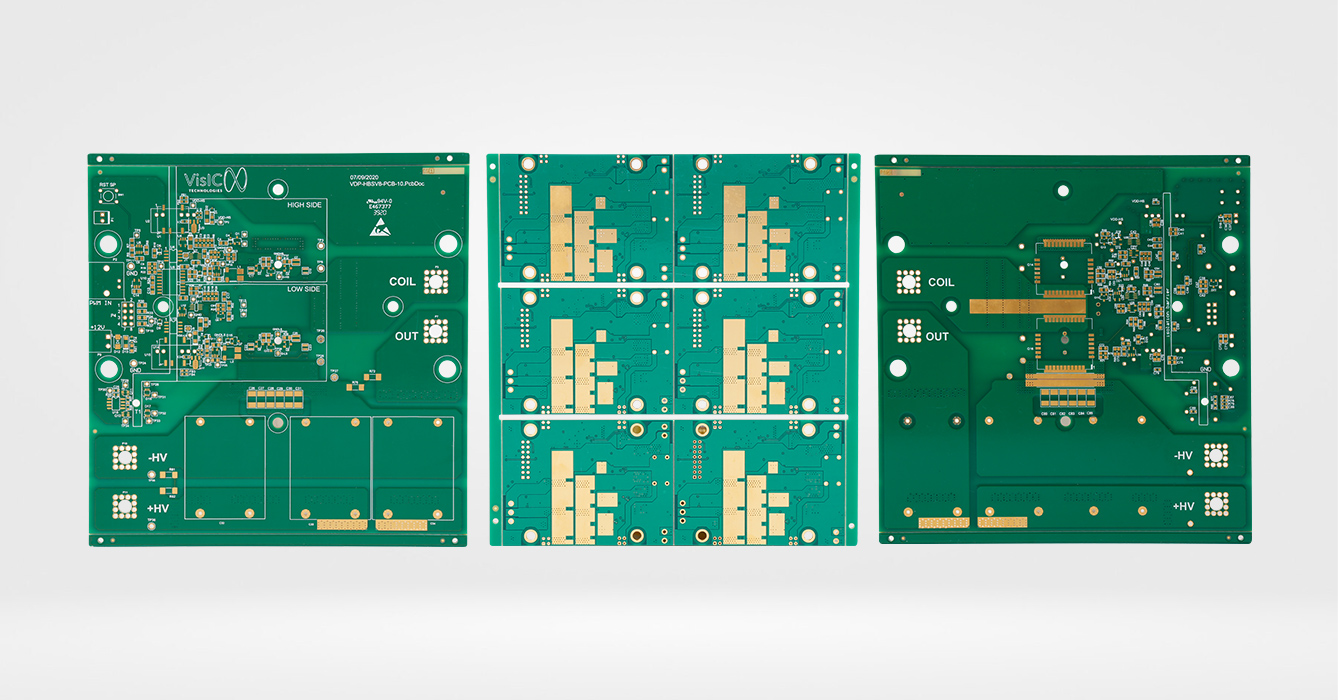

FR4 will increasingly be used in hybrid PCBs, combining its versatility with the strengths of other materials (like aluminum for thermal management or PTFE for high frequencies). These hybrid designs will enable devices that balance multiple performance needs, from heat dissipation to signal integrity.

As electronics shrink, FR4 will support finer copper traces, thinner substrates, and higher component densities. Advanced manufacturing techniques, such as laser drilling and nanoscale etching, will allow FR4 to meet the demands of microelectronics and IoT devices.

FR4 PCB has come a long way from its early days as a flame-resistant alternative to phenolic resins, evolving into a material that defines the possibilities of modern electronics. Its ability to balance performance, cost, and adaptability has made it indispensable across industries, from consumer gadgets to critical infrastructure. While challenges like extreme environment performance and sustainability remain, ongoing innovations in formulations, manufacturing, and hybrid designs ensure that FR4 will continue to evolve. As we look to the future, FR4 PCB is poised to remain a foundational technology, enabling the next generation of electronic devices that will shape our world. Its story is not just about a material, but about the ingenuity of engineers and manufacturers who have turned it into a cornerstone of innovation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB