-

- PCB TYPE

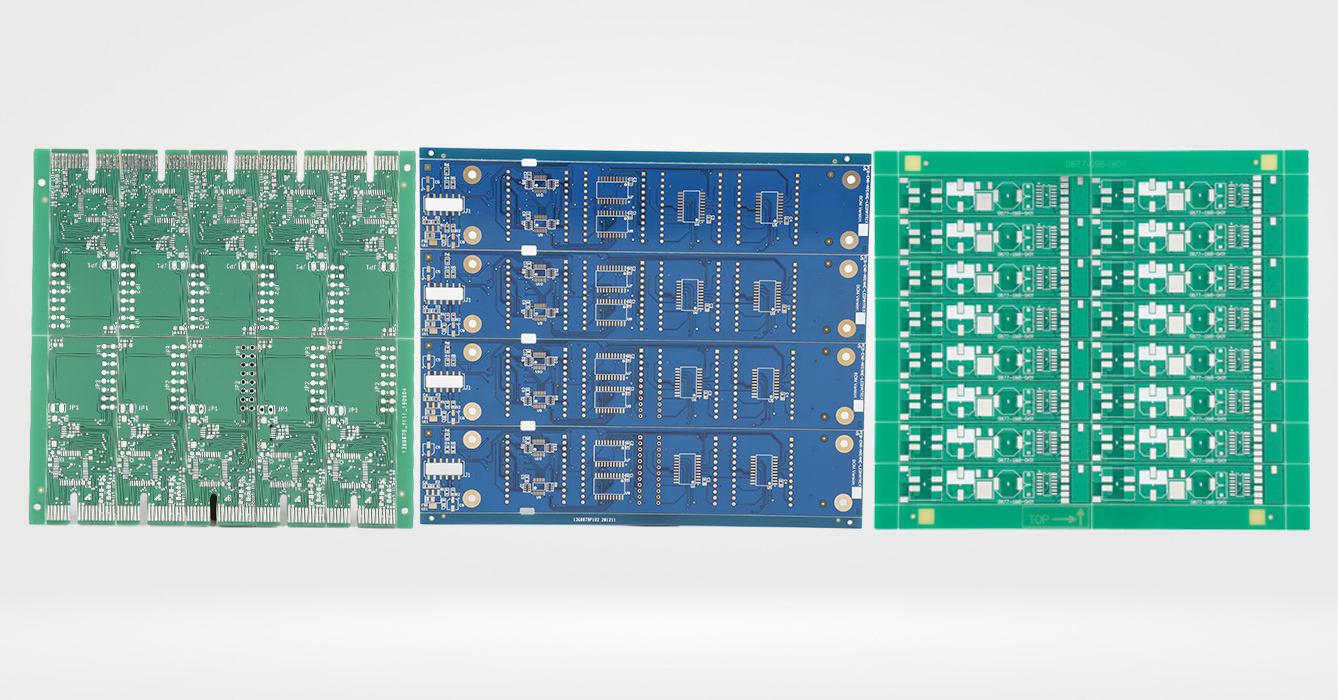

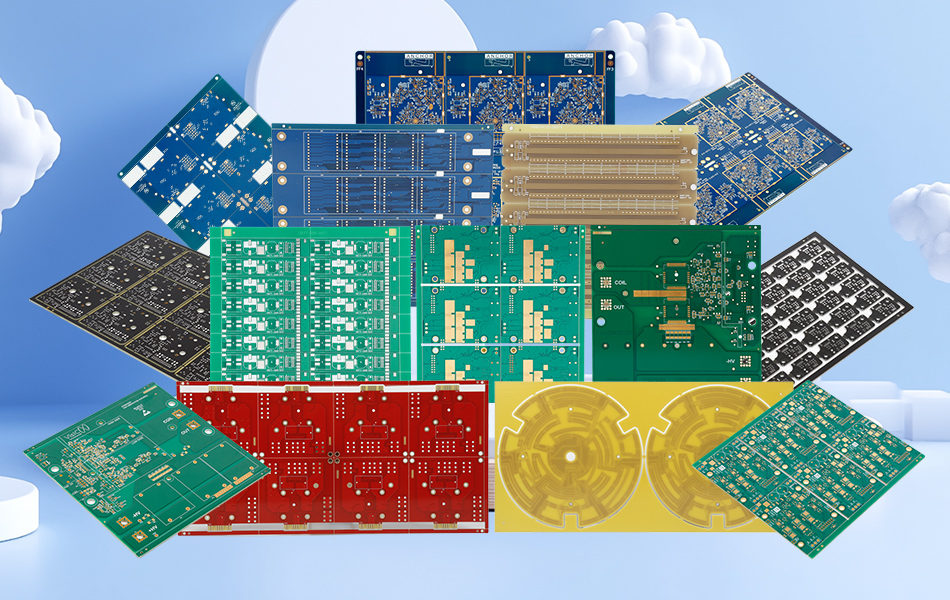

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 12. 2025, 11:57:01

In the dynamic landscape of electronics, Hybrid PCB has emerged as a transformative solution, breaking the limitations of single-material printed circuit boards by combining distinct substrates to achieve multifunctional performance. Unlike traditional PCBs that rely on a single material (such as FR4 or aluminum), hybrid PCBs merge two or more materials—each chosen for its unique properties—to address complex challenges like thermal management, high-frequency signal integrity, and mechanical durability. This integration allows engineers to optimize for multiple performance metrics simultaneously, making hybrid PCBs indispensable in applications ranging from consumer electronics to industrial machinery. This article explores the core concepts, structural configurations, design strategies, manufacturing processes, and real-world applications of hybrid PCBs, highlighting their role in pushing the boundaries of electronic design.

A Hybrid PCB is defined by its intentional use of multiple distinct materials in its construction, each contributing specific functionalities that a single material cannot provide alone. The key principle behind hybrid PCBs is synergy: combining materials with complementary strengths to offset each other’s weaknesses.

For example, FR4 offers excellent electrical insulation and cost-effectiveness but struggles with heat dissipation, while aluminum excels at thermal conductivity but lacks electrical insulation. A hybrid PCB pairing these two materials can manage both electrical signals and heat, making it suitable for power-dense devices. Similarly, combining low-dielectric polymers (for high-frequency signals) with ceramic composites (for thermal stability) creates a substrate ideal for 5G transceivers, where both signal integrity and heat management are critical.

Hybrid PCBs are not limited to two materials; some designs integrate three or more substrates, such as FR4, aluminum, and PTFE, to address overlapping requirements in complex systems like automotive radar or medical imaging equipment. This versatility has made hybrid PCBs a cornerstone of modern electronics, enabling innovations that would be impossible with single-material boards.

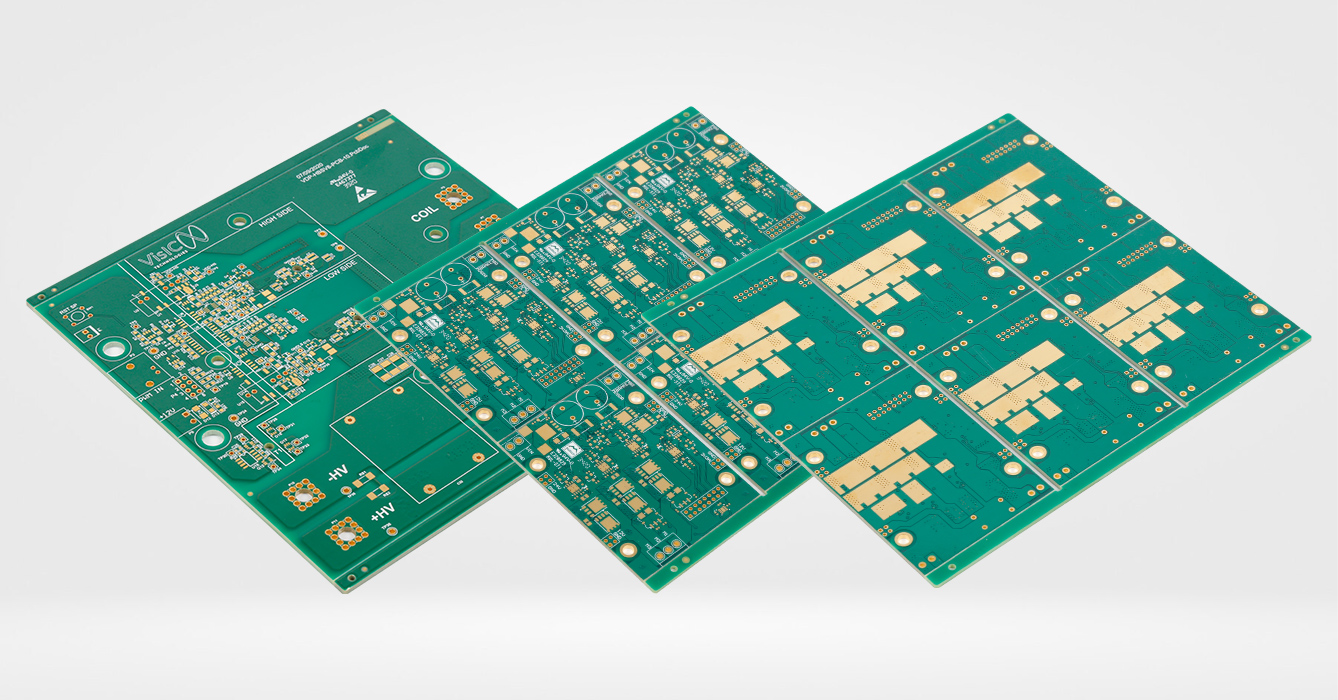

Hybrid PCBs adopt various structural designs, each tailored to specific performance goals. The choice of configuration depends on the application’s requirements for thermal conductivity, signal speed, mechanical strength, and cost:

The most common configuration, layered hybrids stack different materials vertically, with each layer serving a distinct purpose. For example:

A bottom layer of aluminum provides thermal dissipation.

An intermediate insulating layer (often epoxy with ceramic fillers) prevents electrical conduction.

A top layer of FR4 or PTFE supports copper traces and components.

This structure is widely used in LED lighting and power supplies, where heat management and electrical insulation are equally important.

In segmented designs, different materials occupy separate regions of the PCB, each optimized for the components they support. For instance, a section of low-dielectric PTFE may host high-frequency RF components, while an adjacent FR4 segment holds digital control circuits. This configuration reduces material costs by using specialized substrates only where necessary, making it popular in mixed-signal devices like IoT gateways.

Embedded hybrids integrate discrete material elements—such as metal cores or ceramic inserts—within a base substrate (typically FR4). These inserts enhance localized performance: a copper core under a power transistor improves heat dissipation, or a ceramic insert under a high-frequency oscillator stabilizes signal propagation. This design is favored in compact devices like smartphones, where space constraints demand targeted performance enhancements.

Combining flexible materials (like polyimide) with rigid substrates (like FR4 or aluminum), these hybrids enable PCBs that can bend, fold, or conform to irregular shapes while maintaining structural stability in critical areas. They are widely used in wearable technology and automotive dashboards, where flexibility and durability are essential.

Designing hybrid PCBs requires careful coordination of material properties, component placement, and manufacturing constraints to ensure optimal performance:

The chosen materials must work together without chemical incompatibility or mechanical stress. For example, materials with vastly different coefficients of thermal expansion (CTE) can delaminate when heated, so designers often select substrates with matching CTE or use intermediate layers to absorb stress. Similarly, adhesives used to bond layers must be compatible with all materials to prevent degradation over time.

Hybrid PCBs are often designed to address a primary challenge (e.g., heat, signal loss) while balancing secondary needs (e.g., cost, weight). For instance, a hybrid for a radar system might prioritize low dielectric loss (using PTFE) and thermal conductivity (using ceramic) over cost, while a consumer device hybrid might balance thermal performance with affordability by limiting expensive materials to critical areas.

Components are strategically placed to leverage the strengths of each material region. High-heat components (e.g., power amplifiers) are positioned over thermally conductive layers (aluminum or copper), while high-frequency components (e.g., antennas) are placed on low-dielectric substrates (PTFE). This ensures that each component operates in an environment optimized for its function.

In hybrids containing high-frequency or mixed-signal components, maintaining signal integrity is critical. Designers use ground planes, shielding, and controlled impedance routing to minimize interference between sections. For example, a segmented hybrid with both analog and digital circuits will separate these sections with ground planes to prevent noise coupling.

Hybrid PCBs often require specialized manufacturing processes, so designs must align with production capabilities. For example, drilling through aluminum and FR4 layers may require different tooling, and lamination temperatures must be compatible with all materials to avoid warping or degradation. Early collaboration with manufacturers is essential to ensure the design is producible at scale.

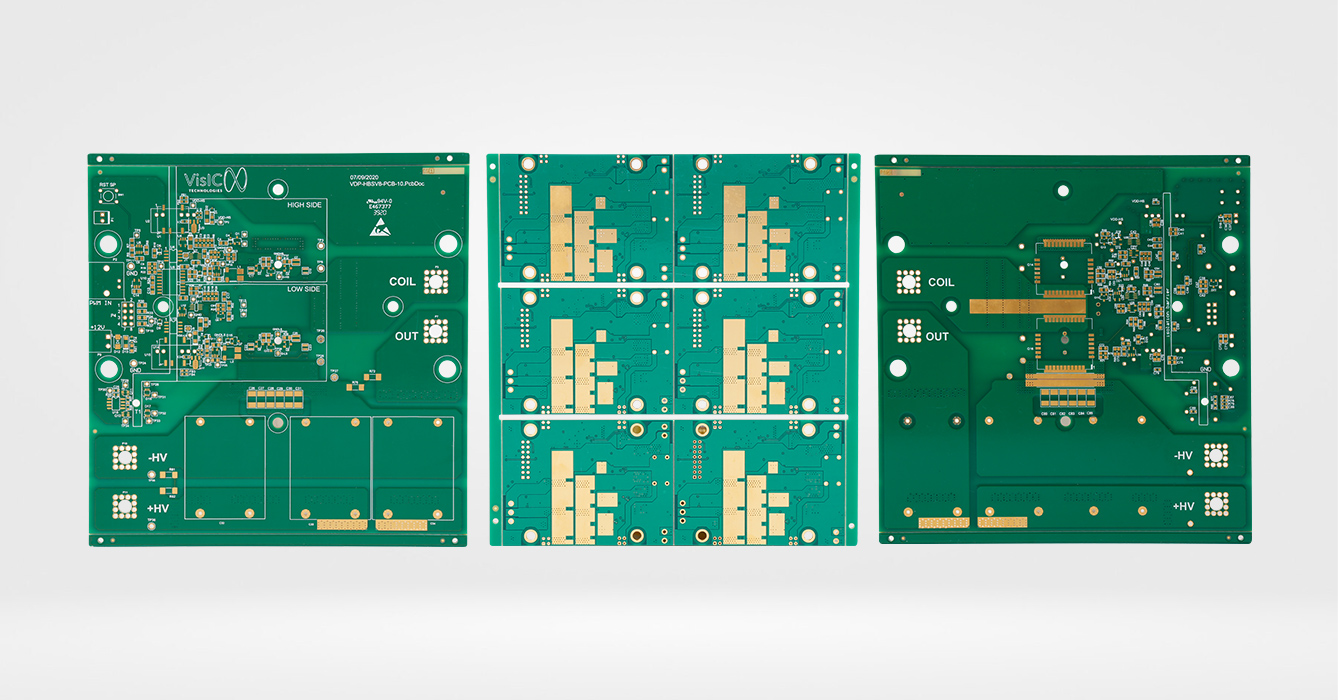

Producing hybrid PCBs involves adapting traditional PCB manufacturing techniques to accommodate multiple materials, requiring precision and flexibility:

Each material is prepared separately: rigid substrates (FR4, aluminum) are cut to size, flexible materials (polyimide) are rolled or sheeted, and adhesives are applied in controlled thicknesses. For layered hybrids, this step ensures that each material is clean, flat, and ready for bonding.

Layers are stacked and bonded under heat and pressure, with parameters adjusted for each material. For example, bonding FR4 to aluminum may require lower temperatures than bonding PTFE to ceramic to avoid damaging heat-sensitive substrates. Some processes use vacuum lamination to eliminate air bubbles, which can cause delamination or signal loss.

Holes for vias and component leads are drilled using tools suited to each material: carbide drills for metals, diamond-tipped tools for ceramics, and laser drilling for fine features in polymers. Care is taken to avoid burring or material chipping, which can affect electrical connections or layer adhesion.

Copper layers are patterned using photolithography, with etchants selected to match the substrate material. For example, etchants for aluminum-backed hybrids must not corrode the metal layer, while those for PTFE-based hybrids may require plasma etching to achieve precise trace definitions.

Protective coatings (solder mask, conformal coating) are applied to ensure corrosion resistance and electrical insulation. The choice of coating is material-dependent: some flexible hybrids use UV-cured masks, while high-temperature hybrids require heat-resistant coatings compatible with all substrate materials.

Hybrid PCBs undergo rigorous testing to verify performance: thermal cycling to check for delamination, signal integrity tests (using network analyzers) for high-frequency sections, and mechanical stress tests for flexible-rigid designs. Only boards meeting all specifications proceed to assembly.

Hybrid PCBs are transforming industries by enabling devices that balance multiple performance needs:

Smartphones, laptops, and wearables use flexible-rigid hybrids to combine compact design with durability. For example, a smartphone’s main PCB may use FR4 for digital circuits, aluminum for heat management under the processor, and flexible polyimide for connections to the display.

Vehicles rely on hybrid PCBs for systems like ADAS (Advanced Driver-Assistance Systems), where radar modules use low-dielectric substrates for signal integrity and aluminum cores for heat dissipation. Hybrid designs also withstand vibration and temperature extremes in engine control units.

Industrial controllers and robotics use hybrid PCBs to manage high power and precision sensing. A typical design might pair FR4 (for logic circuits) with copper-core substrates (for motor drivers) to handle both low-voltage signals and high-current loads.

Portable medical equipment (e.g., ultrasound machines, patient monitors) uses hybrid PCBs to balance compact size, low weight, and reliability. Flexible-rigid hybrids allow devices to conform to body contours, while ceramic-FR4 hybrids manage heat from high-power components.

Satellite communication systems and radar use hybrid PCBs with low-dielectric polymers (for signal integrity) and radiation-resistant materials (for space environments). These designs must withstand extreme temperature swings and maintain performance in vacuum conditions.

Hybrid PCBs offer compelling benefits that make them increasingly popular in modern electronics:

By combining materials, hybrid PCBs address multiple challenges—heat, signal loss, flexibility—simultaneously, eliminating the need for separate components (e.g., external heat sinks) and reducing system complexity.

Hybrid designs use expensive specialized materials only where necessary, reducing overall costs compared to using high-performance materials for the entire PCB. This makes advanced performance accessible for mid-range devices.

Integrating functions into a single hybrid PCB reduces the number of components and interconnects, shrinking device size and weight—a critical advantage in portable electronics, aerospace, and automotive applications.

By matching materials to component needs, hybrid PCBs reduce failure risks like overheating, signal degradation, or mechanical stress. This improves long-term reliability in harsh or mission-critical environments.

Engineers can tailor hybrid PCBs to specific applications by selecting materials for their unique properties, enabling innovations that would be impossible with single-material boards.

Despite their advantages, hybrid PCBs face challenges that drive ongoing innovation:

Ensuring strong, durable bonds between dissimilar materials remains a hurdle, particularly for high-temperature or flexible designs. New adhesives and surface treatments—such as plasma etching to improve layer adhesion—are addressing this issue.

Hybrid PCBs require more complex manufacturing processes than traditional boards, increasing production time and costs. Automation and advanced manufacturing techniques (e.g., 3D printing of hybrid layers) are streamlining production and reducing costs.

Lack of universal standards for hybrid PCB design and testing can complicate qualification and scaling. Industry organizations are working to develop guidelines for material compatibility, performance testing, and reliability assessment.

Many hybrid materials (e.g., certain polymers, adhesives) are difficult to recycle. Research into bio-based substrates and recyclable bonding agents is making hybrid PCBs more environmentally friendly.

Future trends will focus on smarter material combinations—such as integrating sensors into hybrid layers for real-time performance monitoring—and expanding into new applications like quantum computing, where extreme precision and thermal control are required.

Hybrid PCB represents a paradigm shift in electronic design, leveraging the strengths of diverse materials to create multifunctional, efficient, and innovative solutions. By breaking free from the limitations of single-material substrates, hybrid PCBs enable devices that balance thermal management, signal integrity, flexibility, and cost—critical for meeting the demands of modern technology. From consumer electronics to aerospace systems, their applications continue to expand as manufacturing processes improve and material science advances. As engineers and manufacturers embrace the versatility of hybrid designs, these PCBs will play an increasingly central role in shaping the next generation of electronic devices, driving progress in connectivity, efficiency, and functionality.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB