-

- PCB TYPE

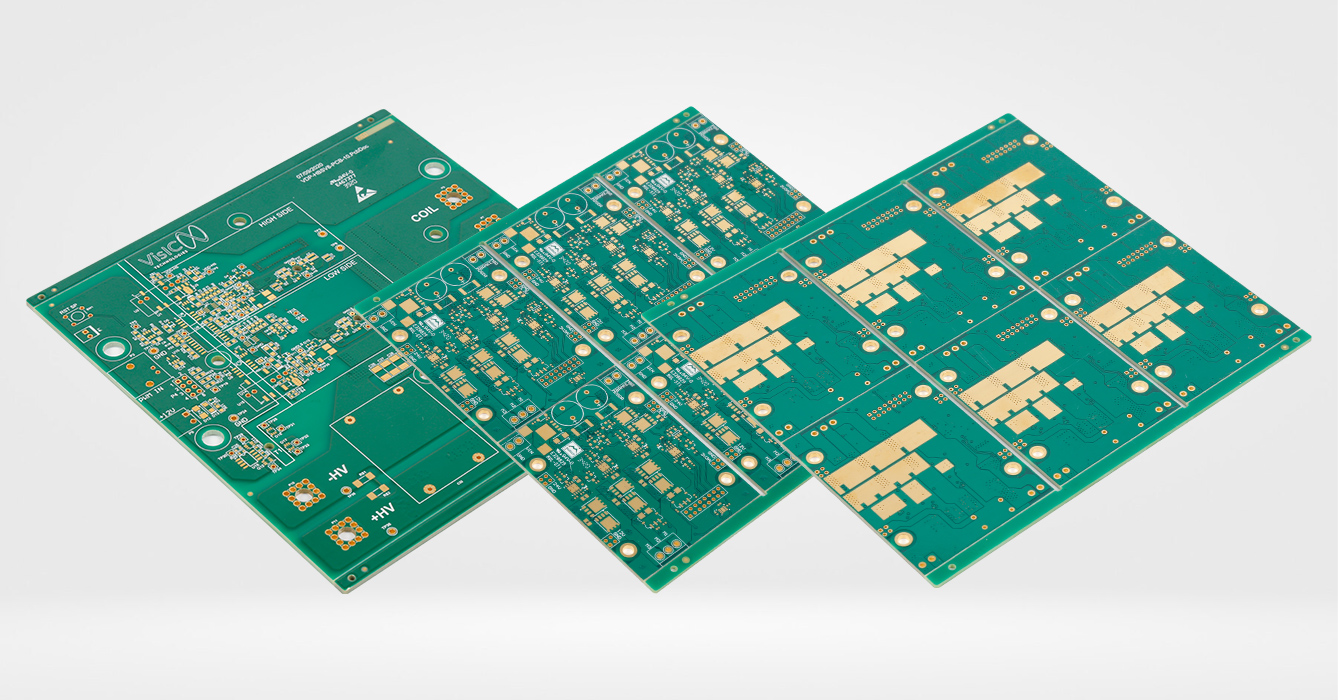

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 06. 2025, 09:35:58

FR4 PCB has long been the backbone of the electronics industry, a material whose versatility and reliability have enabled the proliferation of devices from simple calculators to complex 5G infrastructure. Yet, far from being a static technology, FR4 PCB continues to evolve, driven by demands for higher performance, greater sustainability, and compatibility with emerging technologies. This article explores the latest advancements in FR4 PCB, from material science breakthroughs to innovative manufacturing techniques, while examining its expanding role in cutting-edge applications. By delving into its evolving properties, competitive advantages over alternative materials, and future potential, we uncover why FR4 remains indispensable—even as electronics push into new frontiers of speed, power, and miniaturization.

The story of FR4 PCB is one of continuous refinement. Developed in the mid-20th century as a flame-retardant alternative to earlier laminates like G10, early FR4 was valued primarily for its cost-effectiveness and flame resistance (UL94 V-0 rating). Its composition—epoxy resin reinforced with E-glass fibers—was simple, designed to balance electrical insulation and mechanical strength for low-frequency, low-power applications.

Today’s FR4 PCB is a far cry from its predecessors. Modern formulations incorporate advanced resins (e.g., modified bisphenol-F epoxies) and engineered glass weaves to address specific challenges: high-frequency signal loss, thermal management in power electronics, and compatibility with lead-free soldering. For example, high-Tg FR4 (with glass transition temperatures ≥170°C) emerged to meet the needs of automotive and industrial devices operating in elevated temperatures, while low-Dk (dielectric constant) variants now support 5G’s millimeter-wave requirements. These advancements reflect a shift from FR4 as a "one-size-fits-all" material to a family of tailored solutions, each optimized for distinct use cases.

Recent innovations in material science have expanded FR4 PCB’s capabilities beyond traditional limits, addressing longstanding tradeoffs between performance, cost, and processability.

One key advancement is the development of nano-enhanced FR4. By incorporating carbon nanotubes (CNTs) or graphene into the epoxy matrix, manufacturers have improved thermal conductivity by up to 40% (from ~0.25 W/m·K to ~0.35 W/m·K) without sacrificing electrical insulation. This allows FR4 PCB to better dissipate heat from high-power components like GaN transistors, bridging the gap between standard FR4 and metal-core PCBs in mid-power applications (e.g., 50–100W LED drivers).

Another breakthrough is bromine-free flame retardancy. Traditional FR4 relies on brominated additives to achieve UL94 V-0 compliance, but growing environmental regulations (e.g., EU RoHS 2.0) have spurred the adoption of phosphorus-based alternatives. These formulations maintain flame resistance while reducing toxicity during recycling, making FR4 PCB more sustainable without compromising performance—a critical shift for consumer electronics and medical devices.

Additionally, engineered glass fibers (e.g., S-glass and quartz) are replacing standard E-glass in high-performance FR4 variants. S-glass, with 30% higher tensile strength and lower CTE (coefficient of thermal expansion), enhances dimensional stability in multi-layer PCBs, reducing signal skew in high-speed designs. Quartz fibers, with near-zero CTE, are used in ultra-precision applications like aerospace sensors, where even micron-level shifts can disrupt performance.

FR4 PCB’s adaptability has made it central to emerging technologies, where its balance of performance and cost outperforms specialized materials in many scenarios.

5G Infrastructure: While millimeter-wave (mmWave) 5G (24–40 GHz) once relied on PTFE-based laminates for low signal loss, advanced low-Dk FR4 variants (Dk ~3.8–4.0 at 28 GHz) now meet the needs of small-cell base stations. These FR4 PCBs, with optimized resin-fiber interfaces, reduce insertion loss by 20–30% compared to standard FR4, making them a cost-effective choice for dense urban deployments.

Internet of Things (IoT): IoT sensors, deployed in harsh environments (e.g., agricultural fields, industrial plants), require ruggedness and low power consumption. FR4 PCB’s moisture resistance (when paired with conformal coating) and compatibility with energy-harvesting components (e.g., solar cells, thermoelectric generators) make it ideal for these applications. Low-cost, thin-core FR4 (0.1–0.2 mm) also enables miniaturization, critical for wearable IoT devices.

Electric Vehicles (EVs): Beyond underhood electronics, FR4 PCB is now used in EV charging stations and battery management systems (BMS). High-Tg FR4 (Tg ≥180°C) withstands the thermal cycling of fast-charging systems, while thick-copper FR4 (4–6 oz) handles the high currents of 800V architectures, reducing the need for bulky busbars.

Quantum Computing: While quantum processors use specialized materials, the control electronics (e.g., signal generators, cryocooler controllers) rely on FR4 PCB. Low-outgassing FR4 variants, tested to MIL-STD-883 for vacuum compatibility, prevent contamination in cryogenic environments, ensuring reliable operation at near-absolute zero temperatures.

Advancements in manufacturing are making FR4 PCB more precise, efficient, and scalable—key for meeting the demands of high-volume, high-complexity devices.

AI-Driven Process Control: Machine learning (ML) algorithms now monitor lamination, drilling, and etching processes in real time. For example, ML models analyze infrared images of lamination presses to adjust temperature and pressure, reducing void formation by 50% in high-layer-count FR4 PCBs. Similarly, AI-optimized drilling parameters (speed, feed rate) minimize tool wear in nano-enhanced FR4, lowering production costs.

Additive Manufacturing for Prototyping: 3D printing with FR4-compatible inks (epoxy resins loaded with glass microfibers) is transforming prototyping. These inks cure at low temperatures (80–120°C) and mimic FR4’s mechanical properties, allowing designers to iterate complex geometries (e.g., integrated heat sinks, curved traces) in days instead of weeks. While not yet suitable for high-volume production, 3D-printed FR4 prototypes accelerate time-to-market for custom devices.

Sustainable Manufacturing Practices: FR4 PCB producers are adopting closed-loop recycling, where scrap laminate is ground into filler for new FR4 formulations. This reduces waste by 30–40% and lowers reliance on virgin materials. Additionally, water-based etchants and UV-cured solder masks are replacing solvent-based alternatives, cutting volatile organic compound (VOC) emissions by up to 70%.

Despite competition from specialized materials (e.g., PTFE, ceramic, polyimide), FR4 PCB retains its dominance due to unique advantages:

Cost-Effectiveness: FR4 PCB costs 50–70% less than PTFE or ceramic laminates, a critical factor for consumer electronics and high-volume IoT devices. Even high-performance FR4 variants (e.g., high-Tg, low-Dk) are significantly cheaper than alternatives with comparable properties.

Processability: FR4’s compatibility with standard PCB manufacturing equipment (CNC drills, plating lines) reduces setup costs. Unlike brittle ceramics or temperature-sensitive polyimides, FR4 tolerates common processes like reflow soldering (260°C for lead-free alloys) without degradation.

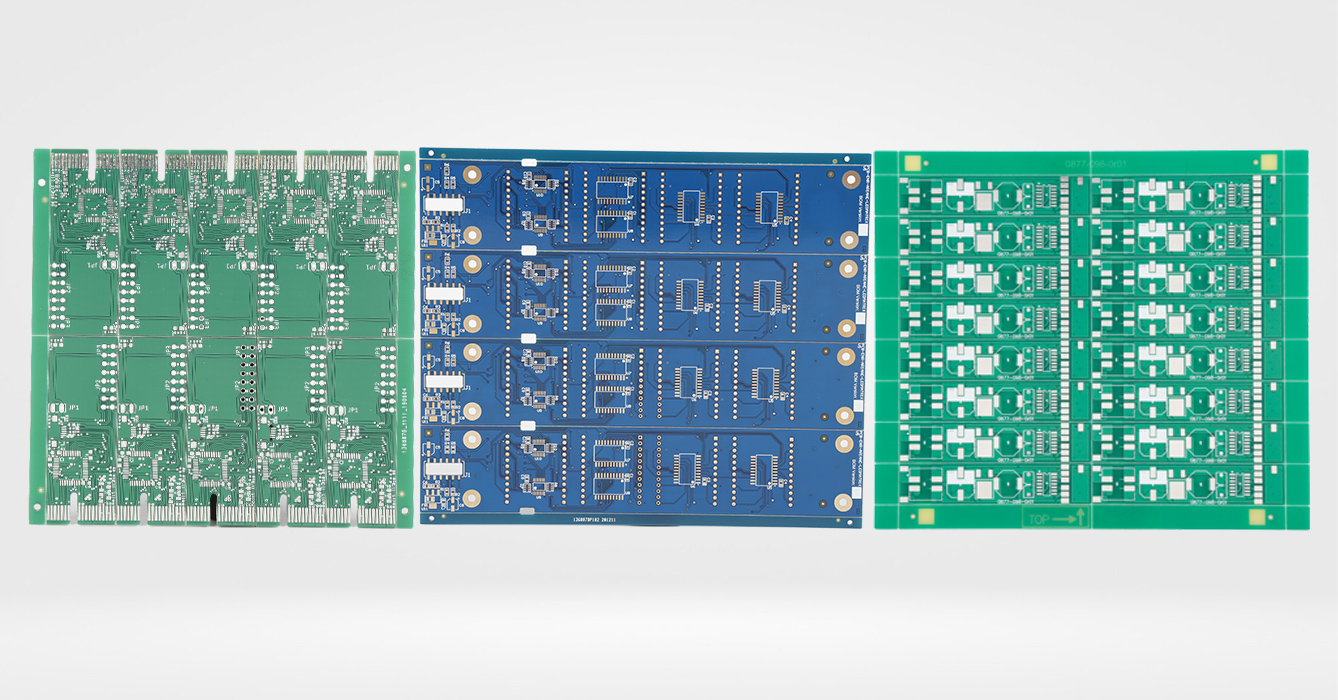

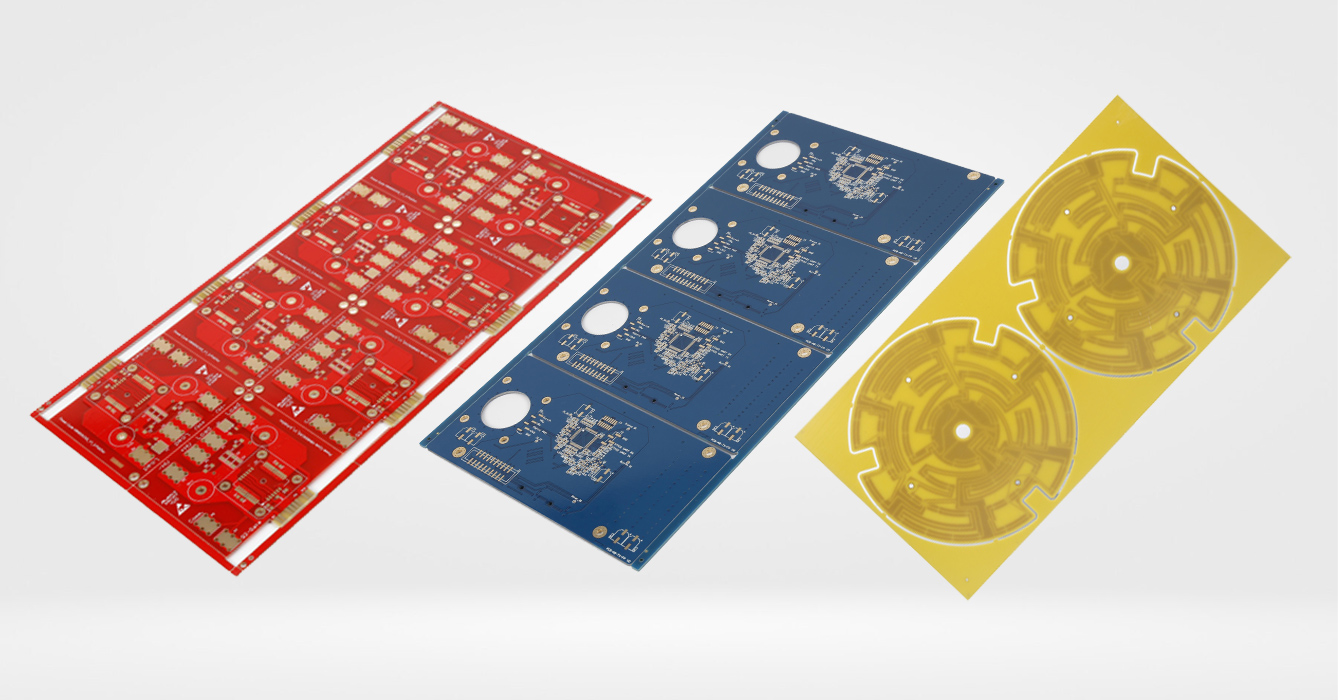

Scalability: FR4 PCB is available in a wide range of thicknesses (0.031–0.250 inches) and copper weights (0.5–10 oz), supporting designs from simple single-layer boards to 40+ layer HDI (high-density interconnect) PCBs. This scalability is unmatched by most specialized materials, which often have limited form factors.

Reliability in Moderate Environments: For applications operating within -40°C to 125°C (the sweet spot for most electronics), FR4 PCB’s performance—stable dielectric properties, adequate thermal resistance—meets or exceeds requirements, making specialized materials unnecessary.

As FR4 PCB enters more demanding environments, testing standards and quality control have grown more rigorous.

Advanced Thermal Cycling: Beyond traditional IPC-TM-650 tests (28 cycles of -55°C to +125°C), critical applications now require 1,000+ cycles (e.g., AEC-Q200 for automotive). High-Tg FR4 variants, with optimized resin-fiber bonds, consistently pass these tests with <1% via failure rates, outperforming standard FR4 by 3–5x.

High-Frequency Signal Integrity Testing: Network analyzers now characterize FR4 PCB performance up to 100 GHz, ensuring low-Dk variants meet 5G mmWave requirements. Tests measure insertion loss, return loss, and phase stability across temperatures, validating that signal integrity is maintained in real-world operation.

Moisture and Chemical Resistance: Pressure cooker tests (PCT) at 121°C, 2 atm, and 100% RH for 96 hours evaluate FR4’s resistance to hydrolysis. Modern FR4 formulations, with hydrophobic additives, show <0.1% weight gain and no delamination, making them suitable for marine and outdoor IoT sensors.

Sustainability Audits: Third-party certifications (e.g., UL 10B for flame retardancy, ISO 14001 for environmental management) ensure FR4 PCB meets eco-friendly standards. Manufacturers now publish "carbon footprints" for FR4 variants, helping clients meet their own sustainability goals.

Looking ahead, several trends will define the next generation of FR4 PCB:

Bio-Based Epoxies: Derived from plant oils (e.g., soybean, castor), these resins reduce reliance on petroleum while maintaining Tg and mechanical strength. Early prototypes show 30–40% lower carbon footprints than traditional FR4, with commercialization expected by 2025.

Integrated Thermal Management: FR4 PCB will incorporate embedded heat pipes or thermally conductive adhesives, eliminating the need for separate heat sinks in mid-power devices. This "all-in-one" approach reduces weight and size, critical for drones and wearable tech.

Smart FR4: Adding sensors (e.g., temperature, strain gauges) directly into the laminate during manufacturing will enable real-time health monitoring of PCBs in service. This "smart" FR4 could predict failures in automotive or aerospace systems, reducing maintenance costs.

High-Power Compatibility: Advances in ceramic-filled FR4 (with thermal conductivity up to 1.0 W/m·K) will extend its use in 200–500W applications, challenging metal-core PCBs in EV inverters and industrial power supplies.

FR4 PCB’s journey from a basic laminate to a high-performance material reflects the electronics industry’s relentless drive for innovation. Its ability to adapt—through material science, manufacturing advancements, and application-specific tailoring—ensures it will remain vital for decades to come. Whether enabling 5G networks, powering EVs, or supporting quantum computing infrastructure, FR4 PCB balances performance, cost, and sustainability in a way no alternative material can match. As technology evolves, so too will FR4, proving that even the most established materials can lead the charge into the future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB