-

- PCB TYPE

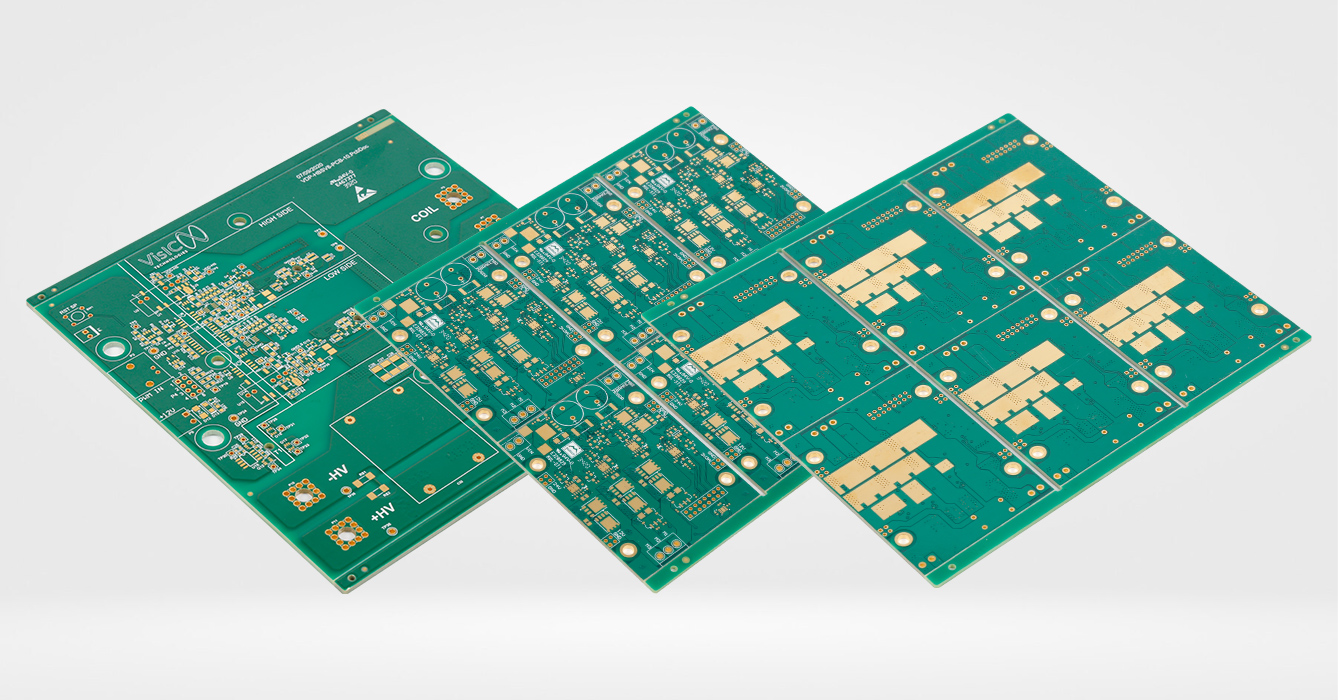

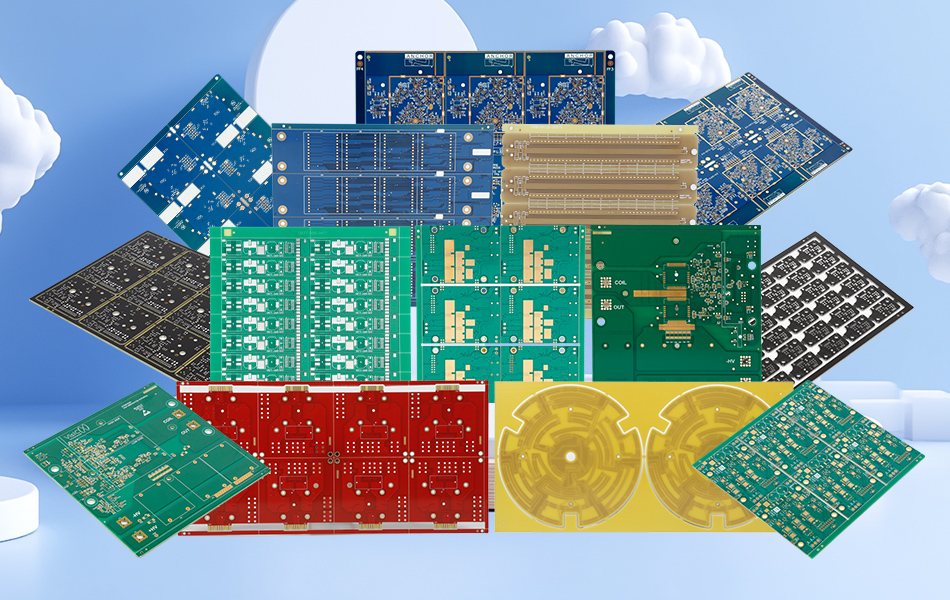

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 06. 2025, 09:33:17

In the world of electronics, where devices are increasingly pushed to operate in extreme environments, HIGH TG FR4 PCB has emerged as a game-changing material. TG, or glass transition temperature, is the critical point at which a material shifts from a rigid, glassy state to a flexible, rubbery one. For PCBs, this transition can lead to dimensional instability, signal degradation, and mechanical failure—issues that are magnified in high-temperature applications. HIGH TG FR4 PCB, with a glass transition temperature of 150°C or higher, is engineered to resist this transition, making it indispensable for electronics in automotive underhood systems, industrial machinery, and aerospace equipment. This article explores the science behind HIGH TG FR4 PCB, its key properties, manufacturing considerations, and diverse applications, highlighting why it has become the material of choice for engineers designing for thermal resilience.

HIGH TG FR4 PCB represents a significant advancement over standard FR4, which typically has a TG of 130–140°C. The "high TG" designation is not arbitrary; it denotes a laminate specifically formulated to maintain structural integrity at elevated temperatures. At its core, HIGH TG FR4 PCB is a composite material consisting of glass fibers woven into a fabric and impregnated with a high-performance epoxy resin. What sets it apart is the resin system—often a blend of novolac epoxies and advanced hardeners—that forms a denser cross-linked molecular structure. This structure resists softening even as temperatures rise, delaying the glass transition and ensuring the PCB remains stable in environments where standard FR4 would fail.

The benefits of this enhanced thermal stability are multifaceted. In addition to resisting dimensional change, HIGH TG FR4 PCB maintains better mechanical strength and electrical performance at high temperatures, reducing the risk of solder joint fatigue, via cracking, and delamination. These attributes make it particularly valuable in applications where operational temperatures regularly exceed 100°C, such as electric vehicle (EV) powertrains and industrial oven controllers.

The performance of HIGH TG FR4 PCB is defined by a unique set of properties that make it suitable for high-temperature environments:

Elevated Glass Transition Temperature: The defining characteristic is a TG of 150°C or higher, with common grades offering 170°C, 180°C, or even 200°C. This ensures the PCB remains rigid and dimensionally stable in temperatures up to 120–150°C, well above the operational range of standard FR4.

Thermal Dimensional Stability: Below TG, HIGH TG FR4 PCB exhibits low coefficient of thermal expansion (CTE), with in-plane CTE of 10–14 ppm/°C and z-axis CTE of 50–70 ppm/°C. This minimizes stress on solder joints and vias during thermal cycling, a critical factor in preventing failures in automotive and aerospace applications.

Mechanical Strength at High Temperatures: At 150°C, HIGH TG FR4 retains 70–80% of its room-temperature flexural strength (≥500 MPa), compared to 50–60% for standard FR4. This strength ensures the PCB can withstand vibration and mechanical loads even in hot environments.

Electrical Performance Stability: The dielectric constant (Dk) of HIGH TG FR4 remains stable (4.3–4.8 at 1 MHz) across a wide temperature range, with variations of ≤3% between 25°C and 150°C. This stability is essential for maintaining impedance control in high-speed designs, such as 5G base station PCBs.

Chemical Resistance: The dense resin matrix of HIGH TG FR4 PCB resists degradation from automotive fluids, industrial solvents, and moisture, making it suitable for harsh environments like underhood compartments and chemical processing plants.

The superior performance of HIGH TG FR4 PCB stems from its carefully engineered composition, which balances resin, reinforcement, and additives to enhance thermal stability:

Advanced Epoxy Resins: HIGH TG FR4 uses novolac-based epoxies or cycloaliphatic epoxies, which form a more cross-linked molecular structure than standard bisphenol-A epoxies. These resins require higher curing temperatures (180–200°C) and longer cure times to fully polymerize, resulting in a matrix that resists softening at high temperatures.

High-Strength Glass Fibers: The reinforcement is typically E-glass or S-glass fibers woven into tight patterns (e.g., 2116, 7628). S-glass, with higher tensile strength and lower CTE than E-glass, is used in ultra-high-performance grades to further enhance dimensional stability.

Flame Retardants: To meet UL 94 V-0 standards, HIGH TG FR4 incorporates brominated compounds or phosphorus-based additives. Bromine-free formulations are available for applications requiring compliance with strict environmental regulations (e.g., EU RoHS).

Fillers: In some grades, inorganic fillers like silica are added to reduce CTE and improve thermal conductivity. These fillers are carefully dispersed to avoid compromising the resin’s mechanical properties or processability.

Producing HIGH TG FR4 PCB requires specialized processes to leverage its material properties while avoiding defects:

Lamination: The high TG resin system demands precise control over temperature and pressure during lamination. Manufacturers use computer-controlled presses to ramp temperature gradually (2–3°C/min) to 190–220°C, maintaining pressure (300–500 psi) for 120–180 minutes to ensure full curing. This slow process prevents under-curing, which would reduce thermal stability, and over-curing, which can make the laminate brittle.

Moisture Control: HIGH TG FR4 is more sensitive to moisture than standard FR4, so laminates are dried (80–100°C for 12–24 hours) before processing. This prevents void formation during lamination, which can lead to delamination in high-temperature operation.

Drilling and Routing: The dense resin matrix requires carbide drill bits with diamond coatings to reduce wear. Drill speeds are slower (15,000–40,000 RPM) than for standard FR4, with feed rates of 0.08–0.15 mm/rev to prevent resin smearing and edge chipping.

Plating and Surface Treatment: Desmearing processes (e.g., permanganate etching) are extended to remove resin residues from via walls, ensuring reliable copper adhesion. Surface finishes like ENIG (Electroless Nickel Immersion Gold) are preferred for their high-temperature oxidation resistance, compatibility with lead-free soldering, and flat profile for fine-pitch components.

Rigorous testing ensures HIGH TG FR4 PCB meets its performance claims, with protocols tailored to its high-temperature applications:

TG Verification: Differential Scanning Calorimetry (DSC) measures the glass transition temperature, ensuring it falls within the specified range (e.g., 170°C ±5°C). This test is performed on each production lot to detect batch-to-batch variations.

Thermal Cycling: PCBs are subjected to 500–1,000 cycles of -55°C to +150°C, with post-test inspections using X-ray and ultrasonic scanning to check for delamination, via cracking, or solder joint fatigue. HIGH TG FR4 typically exhibits <5% failure rates, compared to 15–20% for standard FR4.

High-Temperature Mechanical Testing: Peel strength tests (per IPC-TM-650 2.4.8) are conducted after thermal aging (150°C for 1,000 hours) to verify copper adhesion. A minimum peel strength of 1.0 N/mm for 1 oz copper is required to ensure reliability.

Electrical Performance at Elevated Temperatures: Network analyzers measure insertion loss and return loss at 125°C and 150°C, confirming that impedance remains stable. This is critical for high-speed designs in radar systems and 5G infrastructure.

HIGH TG FR4 PCB is available in multiple grades, each optimized for specific temperature ranges and performance requirements:

Standard High TG (150–160°C): Suitable for applications with moderate high-temperature needs, such as LED lighting drivers and consumer electronics operating in enclosed spaces. Offers a balance of performance and cost.

Ultra-High TG (170–180°C): Designed for automotive underhood electronics (e.g., ECUs, BMS) and industrial motor drives, where sustained temperatures up to 150°C are common. This grade uses advanced resins and tighter manufacturing controls.

Extreme TG (200°C+): Reserved for extreme environments like downhole oil and gas tools, aerospace engine sensors, and furnace controllers. These PCBs use specialized resins and S-glass reinforcement to withstand prolonged exposure to 170–180°C.

Halogen-Free High TG: Complies with RoHS and REACH regulations by using phosphorus-based flame retardants instead of bromine. Ideal for medical devices and environmentally sensitive applications.

HIGH TG FR4 PCB is indispensable in applications where high temperatures are unavoidable, providing reliability where standard materials fail:

Automotive Electronics: Underhood components like engine control units (ECUs), transmission controllers, and EV battery management systems (BMS) rely on HIGH TG FR4 (170–180°C) to withstand temperatures up to 150°C. Its stability prevents solder joint failures and via cracking, extending vehicle service life.

Industrial Automation: Motor drives, PLCs, and sensor interfaces in factories and processing plants use HIGH TG FR4 to operate in ambient temperatures up to 120°C. Its resistance to industrial fluids and vibration ensures consistent performance.

Aerospace and Defense: Avionics systems, missile guidance modules, and satellite electronics use ultra-high TG FR4 (180–200°C) to withstand extreme temperature swings (-55°C to +100°C) and radiation exposure.

Oil and Gas Equipment: Downhole logging tools and wellhead monitors operate at 150–180°C, requiring extreme TG FR4 PCB to maintain signal integrity and structural stability in harsh, high-pressure environments.

To maximize the benefits of HIGH TG FR4 PCB, designers should follow these guidelines:

Thermal Management Integration: Use thermal vias (0.2–0.3 mm diameter) beneath high-power components to dissipate heat to internal ground planes. HIGH TG FR4’s compatibility with conductive epoxy filling enhances heat transfer.

Layer Stackup Optimization: Incorporate additional ground planes (every 2–3 signal layers) to improve heat spreading and reduce EMI, which becomes more pronounced at high temperatures.

Component Placement: Cluster heat-generating components (e.g., MOSFETs, voltage regulators) near board edges or thermal vias to leverage HIGH TG FR4’s thermal conductivity. Avoid placing sensitive components (e.g., crystals, sensors) in hot zones.

Trace and Via Design: Use thicker copper (2–4 oz) for power traces to handle high current and improve heat dissipation. Specify filled and capped vias to prevent resin outgassing during soldering and enhance mechanical strength.

While highly effective, HIGH TG FR4 PCB has limitations that guide material selection:

Cost: 30–50% more expensive than standard FR4 due to advanced resins and specialized manufacturing. This restricts its use to high-reliability applications where failure costs outweigh material expenses.

Thermal Conductivity: With 0.3–0.4 W/m·K, it is less effective at heat dissipation than metal-core PCBs (1–2 W/m·K) or ceramic substrates (10–300 W/m·K). For ultra-high-power applications (e.g., 200W+ inverters), hybrid designs combining HIGH TG FR4 with metal cores are used.

Brittleness: The dense resin matrix makes HIGH TG FR4 more brittle than standard FR4, increasing the risk of cracking during handling. Designers mitigate this with rounded board edges and reinforced mounting holes.

Alternatives include polyimide-based PCBs (for temperatures >200°C) and ceramic-filled laminates (for better thermal conductivity), though these are significantly more expensive than HIGH TG FR4.

Advancements in material science and manufacturing are expanding the capabilities of HIGH TG FR4 PCB:

Nano-Reinforced Resins: Adding graphene or carbon nanotubes to the epoxy matrix increases thermal conductivity (up to 0.6 W/m·K) while maintaining high TG, reducing the need for thermal vias in mid-power designs.

Sustainable Formulations: Bio-based novolac epoxies derived from plant oils are being developed, reducing carbon footprints without sacrificing thermal performance. These align with global sustainability initiatives.

3D-Printed Prototypes: High TG epoxy inks enable 3D printing of PCB prototypes, allowing rapid iteration of complex designs (e.g., integrated heat sinks) before full-scale production.

AI-Driven Material Optimization: Machine learning algorithms analyze resin formulations and manufacturing parameters to predict TG and mechanical properties, accelerating the development of new high-performance grades.

HIGH TG FR4 PCB has revolutionized the design of electronics for high-temperature environments, offering a unique combination of thermal stability, mechanical strength, and electrical performance. By delaying the glass transition and resisting dimensional change, it prevents failures in applications ranging from automotive underhood systems to aerospace avionics. While more costly than standard FR4, its reliability benefits make it indispensable for safety-critical and high-value electronics. As material innovations continue to push TG limits and improve thermal conductivity, HIGH TG FR4 PCB will remain a cornerstone of high-performance electronics, enabling technologies that operate in the most challenging environments. For engineers, understanding its properties and design considerations is key to unlocking its full potential in next-generation devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB