-

- PCB TYPE

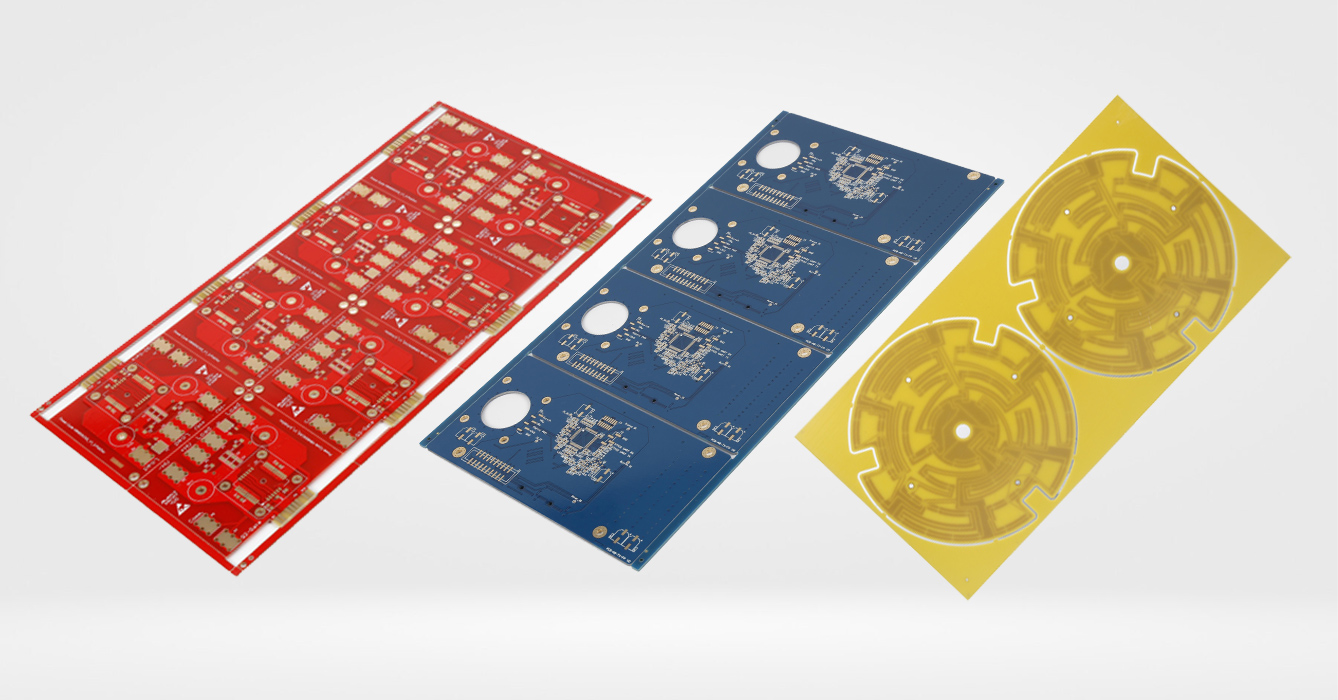

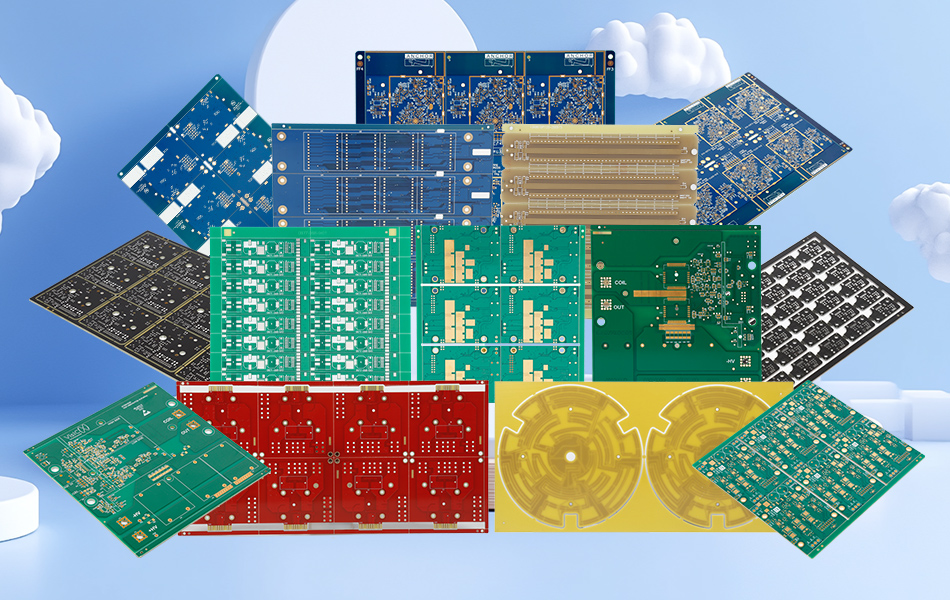

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 13. 2025, 10:57:34

FR4 PCB has transcended its origins as a functional substrate to become a linchpin of modern technology, underpinning innovations that span consumer electronics, renewable energy, and advanced manufacturing. Unlike specialized materials designed for niche applications, FR4’s enduring success lies in its ability to adapt to evolving demands while retaining core strengths: mechanical resilience, electrical stability, and cost efficiency. This article examines FR4 PCB through a holistic lens, exploring its historical evolution, material science advancements, global supply chain dynamics, and role in enabling emerging technologies. By moving beyond technical specifications, we uncover how FR4 has shaped—and continues to shape—the electronics industry’s trajectory.

FR4’s journey from laboratory innovation to industrial standard reflects the electronics industry’s own growth, marked by a relentless pursuit of reliability and affordability.

In the mid-20th century, early PCBs relied on phenolic resins, which offered low cost but suffered from poor heat resistance and mechanical fragility. These limitations became problematic as electronics transitioned from vacuum tubes to transistors, demanding substrates that could handle higher component densities and moderate temperatures. The 1960s saw the introduction of FR4, a glass fiber-reinforced epoxy laminate engineered to address these gaps. Its flame-retardant properties (meeting UL94 V-0 standards) and improved mechanical stability quickly made it a favorite for military and aerospace applications, where safety and durability were non-negotiable.

The 1980s and 1990s marked FR4’s democratization, as mass production techniques reduced costs, making it accessible for consumer electronics like personal computers and televisions. This era also saw refinements in FR4 formulations, including thinner laminates for compact devices and high-temperature variants for power supplies. By the 2000s, FR4 had become the default PCB material, with global production exceeding billions of units annually. Today, it remains the benchmark against which new materials are measured, a testament to its adaptability and enduring relevance.

FR4’s performance stems from a sophisticated blend of materials, each contributing to its unique properties:

The backbone of FR4 is woven glass fiber cloth, typically made from E-glass—a boron-free silica-alumina composite. This material choice is deliberate: E-glass offers high tensile strength (to resist bending), chemical inertness (to withstand manufacturing solvents), and low dielectric loss (to preserve signal integrity). The weave pattern—from tight plain weaves for rigidity to loose twill weaves for controlled flexibility—can be tailored to specific applications, such as thin, flexible FR4 for wearable devices or thick, dense weaves for industrial machinery.

The glass fibers are bonded with a thermosetting epoxy resin, a polymer that cures into a rigid, cross-linked structure under heat and pressure. Modern epoxy formulations include flame-retardant additives (such as brominated compounds or phosphorus-based alternatives) to meet safety standards without compromising electrical insulation. For high-temperature applications, modified epoxies with higher glass transition temperatures (Tg) ensure stability in environments like automotive engine bays, where operating temperatures exceed 150°C.

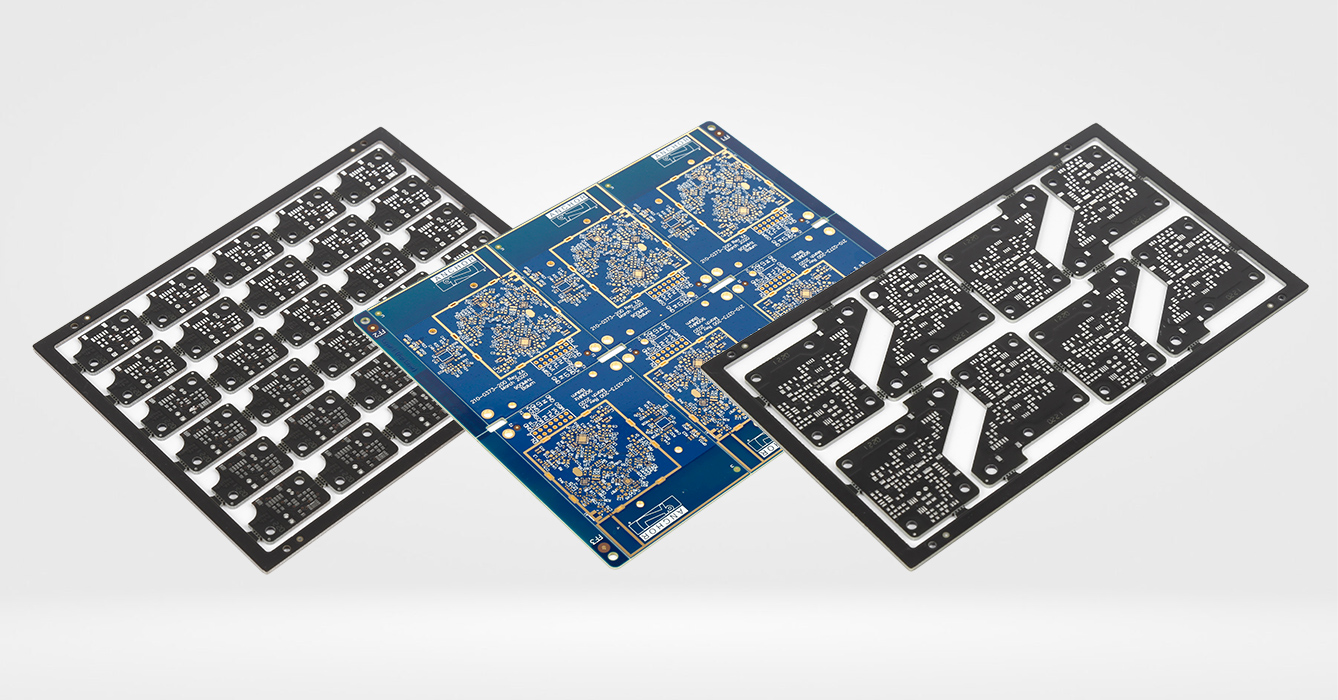

Thin copper foils—bonded to the FR4 substrate—form the conductive pathways that enable electrical signaling. The copper’s purity (typically 99.9%+) and surface treatment (e.g., roughened textures to enhance adhesion) are critical: impurities can increase resistance, while poor adhesion leads to delamination. In multi-layer FR4 PCBs, copper layers are separated by FR4 prepregs, creating a sandwich structure that balances conductivity and insulation.

This material synergy—glass fibers for strength, epoxy for insulation, copper for conductivity—makes FR4 a “total solution” substrate, capable of meeting diverse performance requirements without sacrificing cost or manufacturability.

FR4’s ubiquity has fostered a complex, interconnected global supply chain that spans raw material extraction to final assembly:

Glass Fiber: Produced primarily in China, the United States, and Europe, with raw materials (silica sand, alumina) sourced from mining operations worldwide.

Epoxy Resins: Dominated by chemical giants in Asia and Europe, with formulations tailored to PCB-specific needs (e.g., low halogen content for environmental compliance).

Copper Foils: Major producers in Japan, South Korea, and China supply ultra-thin foils (down to 12μm) for high-density PCBs, with recycled copper increasingly used to reduce environmental impact.

Asia—particularly China, Taiwan, and South Korea—accounts for over 80% of global FR4 PCB production, driven by economies of scale, advanced manufacturing infrastructure, and proximity to electronics assembly centers. Regional clusters, such as the Pearl River Delta in China, integrate raw material processing, PCB fabrication, and component assembly, reducing lead times and logistics costs. In contrast, North American and European manufacturers focus on high-value, low-volume FR4 PCBs for aerospace, defense, and medical applications, where certification and quality control are paramount.

The 2020s highlighted FR4’s supply chain vulnerabilities, from resin shortages during the COVID-19 pandemic to copper price volatility amid global economic shifts. In response, manufacturers are diversifying suppliers, investing in local production capabilities, and developing circular economy models—such as recycling FR4 scrap to recover copper and glass fibers. These efforts aim to ensure a stable supply of FR4 PCBs, which are critical for essential electronics like medical devices and communication infrastructure.

FR4’s versatility enables its use in sectors as diverse as healthcare and heavy industry, each leveraging its unique properties:

Solar inverters and wind turbine controllers rely on FR4 PCBs to manage power conversion, with high-temperature variants handling the heat generated by efficient energy transfer. FR4’s durability in outdoor environments—resisting UV radiation and moisture—ensures long-term reliability in solar farms and wind parks, where maintenance is costly and infrequent.

Smart grids, traffic management systems, and building automation use FR4 PCBs to process and transmit data. Their ability to support both low-power sensors and high-voltage control circuits makes them ideal for these integrated systems, while their cost-effectiveness enables large-scale deployment across cities and municipalities.

From smartwatches to home appliances, FR4 PCBs enable compact, affordable devices. Thin-core FR4 (as thin as 0.2mm) supports slim designs in smartphones, while multi-layer FR4 (up to 40 layers) in gaming consoles manages the complex signaling between processors, memory, and graphics cards.

Diagnostic equipment, such as ultrasound machines and PCR testers, uses FR4 PCBs for their precision and biocompatibility. Low-outgassing FR4 variants—designed to release minimal volatile compounds—are used in MRI machines and cleanroom environments, where contamination must be avoided.

In each application, FR4’s role is not passive: it actively enables innovation by providing a reliable, adaptable platform that reduces development time and costs, allowing engineers to focus on breakthrough functionalities rather than substrate limitations.

As electronics demand higher performance, FR4 continues to evolve through material and process innovations:

Integrating nanoparticles—such as alumina or carbon nanotubes—into epoxy resins enhances FR4’s thermal conductivity, allowing it to dissipate heat more effectively. These nanocomposites maintain FR4’s electrical insulation and mechanical properties while narrowing the performance gap with metal-core PCBs, making them suitable for power-dense applications like electric vehicle chargers.

Environmental regulations in Europe, China, and California are driving the adoption of halogen-free FR4, which replaces brominated flame retardants with phosphorus or nitrogen-based alternatives. These formulations meet strict eco-label requirements without compromising flame resistance or signal integrity, aligning with global sustainability goals.

Laser Direct Imaging (LDI): Replaces traditional photomasks with laser-based pattern transfer, enabling finer trace widths (down to 25μm) for high-density PCBs.

3D Printing: Additive manufacturing processes are being adapted to print FR4-like composites, allowing for complex geometries—such as internal cooling channels—that are impossible with traditional lamination.

Automated Optical Inspection (AOI) with AI: Machine learning algorithms enhance defect detection, ensuring higher quality in mass-produced FR4 PCBs.

These innovations ensure that FR4 remains competitive with specialized materials, extending its relevance into emerging technologies like 6G and quantum computing peripherals.

FR4’s environmental footprint is under increasing scrutiny, driving efforts to make its lifecycle more sustainable:

Traditional PCB recycling focuses on copper recovery, but new processes—such as pyrolysis and chemical dissolution—extract epoxy resin and glass fibers for reuse in new FR4 laminates. Pilot projects in Europe and Asia have achieved material recovery rates exceeding 90%, reducing reliance on virgin resources.

Manufacturers are adopting renewable energy—solar, wind, and hydroelectric power—for PCB fabrication, cutting carbon emissions from energy-intensive processes like lamination and copper plating. Energy management systems also optimize power use during idle periods, further reducing environmental impact.

Electronics manufacturers are designing products with FR4 PCBs that are easier to disassemble and recycle, incorporating features like snap-fit connectors (instead of adhesives) and clearly marked recycling indicators. This shift toward circular design ensures that FR4 PCBs contribute to closed-loop material systems.

Despite its adaptability, FR4 confronts challenges that may limit its use in certain applications:

At frequencies above 28 GHz (critical for 6G and satellite communication), FR4’s dielectric loss increases significantly, causing signal degradation. While low-loss FR4 variants mitigate this issue, they cannot match the performance of PTFE or ceramic substrates, which remain the choice for ultra-high-frequency applications.

FR4’s inflexibility makes it unsuitable for wearable electronics or flexible displays, where bendability is essential. While thin, flexible FR4 exists, it cannot compete with polyimide-based flexible PCBs in applications requiring repeated bending.

Raw material volatility—particularly copper and epoxy resin prices—can increase FR4 PCB costs, challenging its position as a low-cost alternative. Manufacturers are responding by optimizing material usage and investing in automation to reduce labor costs.

FR4 PCB has earned its status as the electronics industry’s workhorse through a rare combination of versatility, reliability, and affordability. From its early days in military hardware to its role in powering smart cities, FR4 has proven capable of adapting to each era’s technological demands. Innovations in materials, manufacturing, and sustainability are extending its capabilities, ensuring it remains relevant in an era of 5G, renewable energy, and AI. While specialized materials will continue to dominate niche applications, FR4’s balance of performance and cost guarantees its place as a foundational technology for decades to come. Its story is not just about a material, but about the ingenuity of engineers and manufacturers who have harnessed its potential to drive progress in electronics and beyond.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB