-

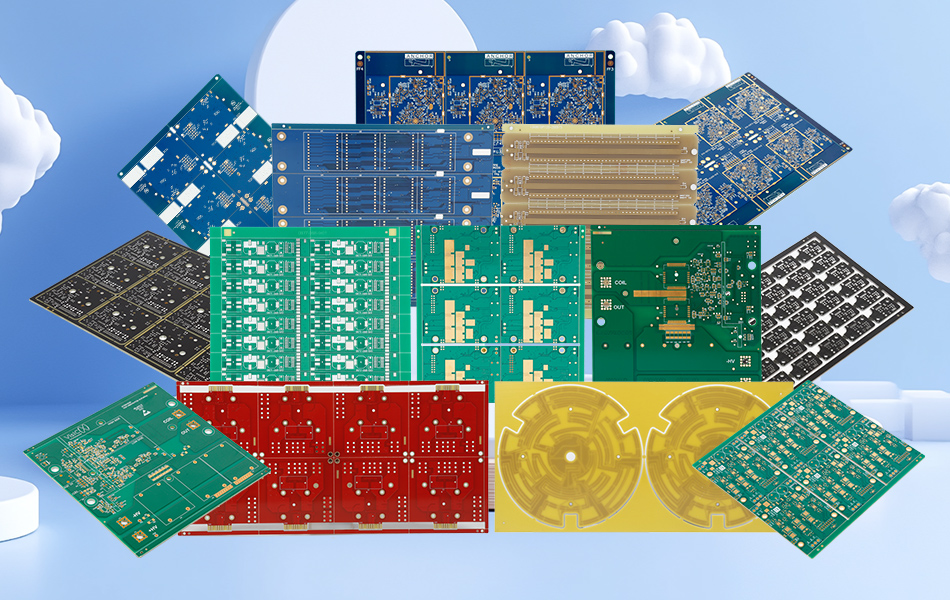

- PCB TYPE

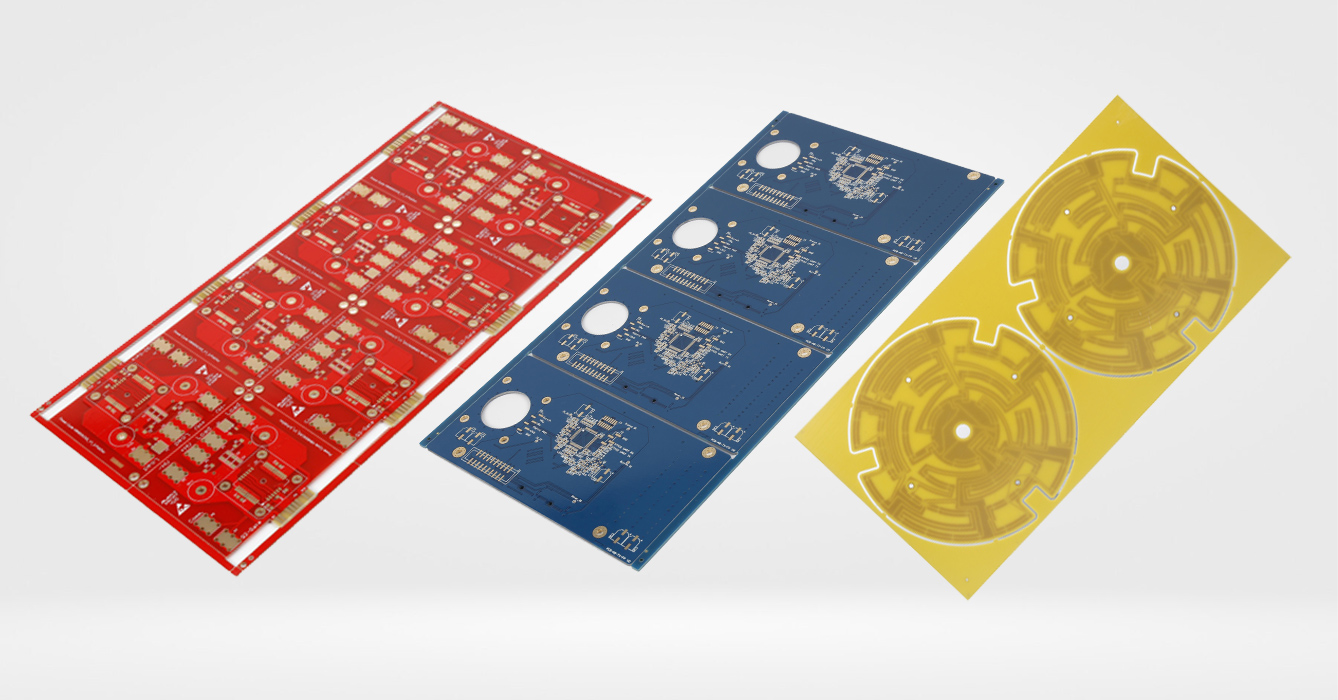

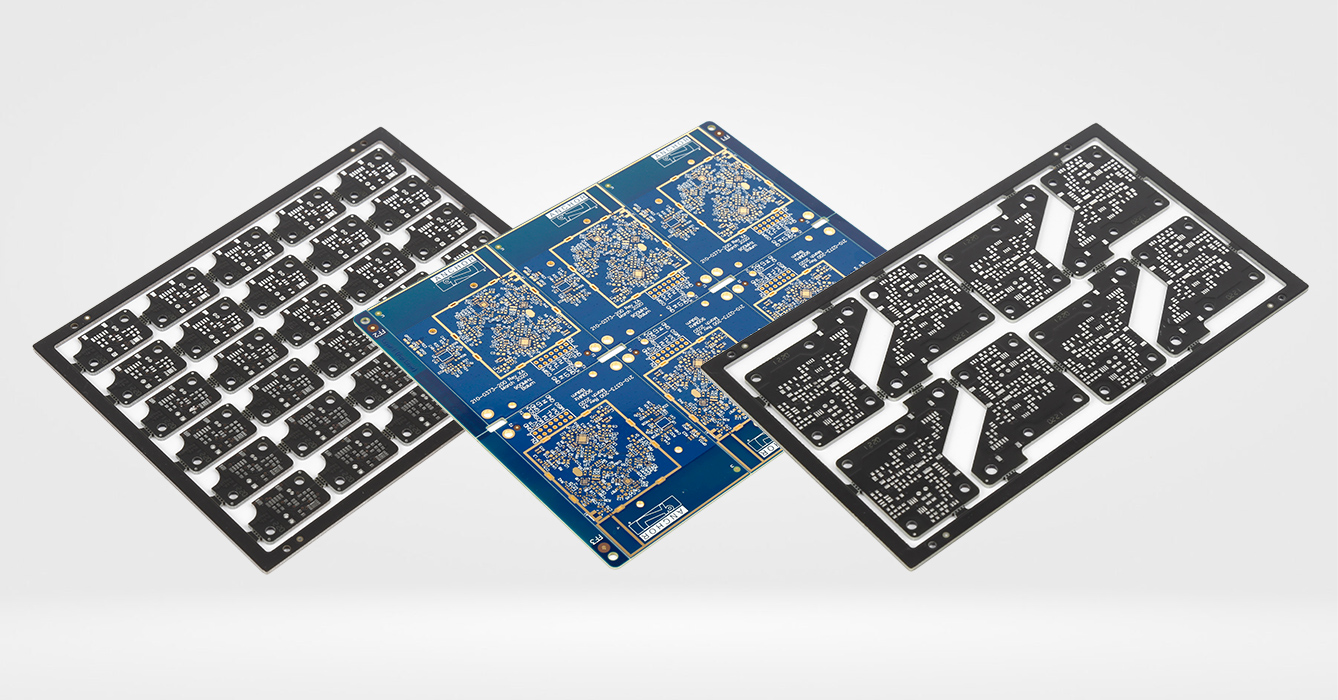

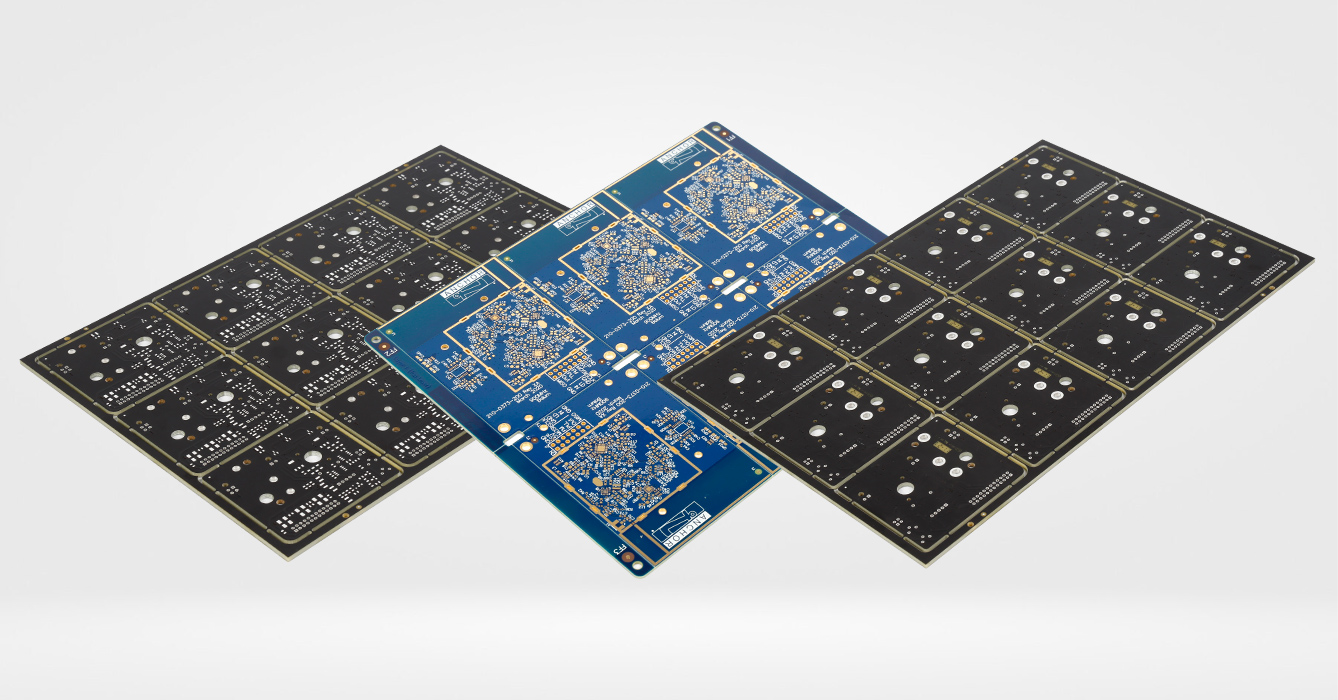

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 13. 2025, 10:53:52

Rigid FR4 PCB stands as the most widely used printed circuit board type in the electronics industry, valued for its exceptional balance of mechanical strength, electrical insulation, and cost-effectiveness. Unlike flexible PCBs that prioritize bendability or specialized high-frequency substrates designed for niche applications, rigid FR4 PCBs offer a stable, versatile platform suitable for everything from simple consumer devices to complex industrial machinery. The term “rigid” refers to its inflexible nature, providing structural integrity that ensures components remain securely mounted and signals propagate reliably. This article delves into the material composition, key characteristics, manufacturing processes, and diverse applications of rigid FR4 PCBs, highlighting why they have become the backbone of modern electronics.

At the core of a rigid FR4 PCB is its unique material composition, which combines glass fibers and epoxy resin to create a substrate that excels in both mechanical and electrical performance.

FR4 is a grade of flame-retardant laminate, with “FR” standing for “flame resistant” and “4” indicating its specific resin system. The base material consists of:

Glass Fiber Cloth: Woven glass fibers form a reinforcing matrix that gives the PCB its rigidity and dimensional stability. This cloth is typically made from E-glass, a type of glass known for its high strength, chemical resistance, and low cost. The weave pattern (e.g., plain, twill) can vary to adjust properties like flexibility or thickness.

Epoxy Resin: A thermosetting epoxy resin binds the glass fibers together, creating a solid, insulating substrate. The resin is formulated to be flame-retardant, meeting safety standards such as UL94 V-0, which ensures the material self-extinguishes when exposed to fire.

Copper Foil: Thin layers of copper are bonded to one or both sides of the FR4 substrate (or between layers in multi-layer boards) to form conductive traces that carry electrical signals and power.

This composite structure results in a PCB that is rigid, lightweight, and resistant to heat, moisture, and chemicals—qualities that make it ideal for a wide range of operating environments.

Rigid FR4 PCBs derive their popularity from a set of defining characteristics that address the needs of most electronic applications:

The glass fiber-epoxy composite provides exceptional rigidity, preventing the PCB from bending, warping, or deforming under mechanical stress. This stability ensures that components remain properly aligned, solder joints stay intact, and electrical connections are maintained—critical for reliability in devices subjected to vibration, shock, or temperature fluctuations.

Epoxy resin is an excellent electrical insulator, preventing current leakage between copper traces and layers. This property is essential for maintaining signal integrity, as it ensures that electrical signals flow only along their intended paths, reducing the risk of short circuits or interference.

The flame-retardant formulation of FR4 minimizes fire risk, a key safety feature for consumer electronics, industrial equipment, and aerospace systems. Unlike non-flame-retardant materials, FR4 does not support combustion, limiting damage in the event of overheating or electrical faults.

While not as thermally conductive as metal-core PCBs, rigid FR4 PCBs can withstand moderate temperatures, making them suitable for most applications. They maintain their structural and electrical properties across a typical operating range of -55°C to 130°C (with high-temperature variants offering extended ranges), ensuring reliability in environments like automotive engine bays or industrial control rooms.

Compared to specialized substrates (e.g., ceramic, PTFE), FR4 is inexpensive to produce, with well-established manufacturing processes that enable mass production at low cost. This affordability makes rigid FR4 PCBs accessible for everything from budget consumer devices to high-volume industrial components.

Rigid FR4 PCBs can be manufactured as single-layer, double-layer, or multi-layer boards, accommodating designs ranging from simple circuits (e.g., remote controls) to complex systems (e.g., server motherboards). They support various surface finishes, solder masks, and component mounting techniques, making them adaptable to diverse design requirements.

The production of rigid FR4 PCBs involves a series of precise steps to transform raw materials into functional circuit boards:

Material Preparation

FR4 laminates (pre-pregs) are cut to the desired size, with copper foil bonded to one or both sides. The copper thickness varies based on the design’s current-carrying requirements, from thin foils for signal traces to thicker foils for power circuits.

The circuit design (created using CAD software) is transferred onto the copper-clad FR4 substrate using photolithography. A photosensitive resist is applied to the copper surface, exposed to UV light through a mask of the circuit pattern, and developed to leave the resist only on areas where copper should remain.

The substrate is immersed in an etching solution (typically ferric chloride or ammonium persulfate) that removes unprotected copper, leaving behind the desired circuit traces. The remaining resist is then stripped away, revealing the copper pattern.

Holes (vias) are drilled through the substrate to connect circuits between layers (in multi-layer boards) or to mount through-hole components. Drilling is done using precision machinery, with laser drilling used for small vias in high-density designs.

Vias are plated with copper to ensure electrical conductivity between layers. This process involves electroless copper deposition (to create a thin conductive layer) followed by electrolytic plating (to build up copper thickness).

A protective solder mask (typically green, though other colors are available) is applied to the board, covering all areas except component pads and connectors. This mask prevents solder bridges during assembly and protects copper traces from oxidation and environmental damage.

A silkscreen layer is added to print component labels, reference designators, and company logos, aiding in assembly and troubleshooting.

A surface finish is applied to component pads to ensure solderability and prevent copper oxidation. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

The finished PCBs undergo rigorous testing, including continuity checks, insulation resistance tests, and visual inspection (using automated optical inspection, AOI) to detect defects like short circuits, open traces, or misaligned features.

This standardized process ensures consistent quality, making rigid FR4 PCBs reliable and scalable for mass production.

Rigid FR4 PCBs are used across virtually every industry, thanks to their versatility and reliability:

Smartphones, laptops, televisions, and home appliances rely on rigid FR4 PCBs for their main circuits. Their compact size, cost-effectiveness, and ability to support dense components make them ideal for these devices, where space and affordability are key.

Factory controllers, motor drives, and sensor systems use rigid FR4 PCBs for their mechanical stability and resistance to harsh environments. They withstand dust, moisture, and temperature fluctuations, ensuring reliable operation in industrial settings.

In-vehicle systems such as infotainment units, engine control modules (ECUs), and safety sensors depend on rigid FR4 PCBs. High-temperature FR4 variants are used in underhood applications, where they resist heat from engines and exhaust systems.

Patient monitors, diagnostic equipment, and medical implants utilize rigid FR4 PCBs for their biocompatibility, reliability, and ability to support precise circuitry. Low-outgassing FR4 variants are used in devices requiring cleanroom compatibility.

Avionics systems, radar equipment, and military communication devices use rigid FR4 PCBs for their durability and flame resistance. They meet strict aerospace standards for performance in extreme temperatures and radiation environments.

Routers, modems, and 5G base stations employ rigid FR4 PCBs (often multi-layer) to manage high-speed signals and dense component layouts. Their electrical insulation properties ensure minimal signal interference, critical for reliable communication.

Rigid FR4 PCBs offer distinct benefits compared to other PCB types, solidifying their position as the industry standard:

Mechanical Strength: Rigid FR4 PCBs provide superior structural support, making them better suited for devices where stability is critical (e.g., industrial machinery).

Cost: Rigid FR4 is cheaper to manufacture than flexible PCBs, which require specialized materials like polyimide.

Thermal Resistance: Rigid FR4 withstands higher temperatures than most flexible substrates, expanding its use in heat-generating applications.

Electrical Insulation: Rigid FR4 offers better electrical insulation than metal-core PCBs, which conduct electricity and require additional insulating layers.

Cost and Complexity: Metal-core PCBs are more expensive and complex to produce, making rigid FR4 preferable for applications where extreme thermal conductivity is not required.

Cost-Effectiveness: Rigid FR4 is significantly cheaper than PTFE or ceramic substrates, making it ideal for low-to-moderate frequency applications.

Manufacturability: FR4’s compatibility with standard manufacturing processes simplifies production, reducing lead times and costs compared to specialized high-frequency materials.

As electronics evolve, rigid FR4 PCBs are adapting to meet new demands through ongoing innovations:

New formulations with higher glass transition temperatures (Tg) enable rigid FR4 PCBs to withstand elevated temperatures, expanding their use in power-dense applications like electric vehicle (EV) chargers and industrial inverters.

Environmental regulations are driving the adoption of halogen-free FR4, which replaces brominated flame retardants with safer alternatives (e.g., phosphorus-based compounds). These variants meet strict eco-friendly standards without sacrificing performance.

Advances in manufacturing allow for finer trace widths, smaller vias, and higher layer counts in rigid FR4 PCBs, supporting high-density components like microchips and sensors. This trend enables miniaturization in devices like wearables and IoT sensors.

Producers are adopting eco-friendly practices, such as using recycled glass fibers, water-based etchants, and energy-efficient machinery, to reduce the environmental impact of rigid FR4 PCB production. Recycling programs for end-of-life FR4 PCBs are also emerging, recovering copper and glass fibers for reuse.

While versatile, rigid FR4 PCBs face certain limitations that guide their application:

Rigid FR4 has lower thermal conductivity than metal-core or ceramic PCBs, making it less suitable for extreme heat-generating components (e.g., high-power LEDs or large processors) without additional cooling solutions like heat sinks.

At very high frequencies (above 10 GHz), FR4’s dielectric properties can cause signal loss, limiting its use in specialized applications like radar or satellite communication, where PTFE or ceramic substrates are preferred.

Its inflexible nature makes rigid FR4 unsuitable for applications requiring bendability, such as wearable devices or curved displays, where flexible PCBs are necessary.

While resistant to moisture and chemicals, prolonged exposure to harsh environments (e.g., saltwater, extreme humidity) can degrade FR4 over time, requiring protective conformal coatings in such applications.

Rigid FR4 PCB remains the cornerstone of the electronics industry, offering a winning combination of mechanical stability, electrical performance, and cost-effectivenesrical performance, and cost-effectiveness. Its adaptability to diverse applications—from consumer gadgets to aerospace systems—speaks to its versatility, while ongoing innovations in materials and manufacturing ensure it continues to meet evolving demands. While specialized substrates may outperform rigid FR4 in specific areas (e.g., extreme heat or high frequencies), its balance of properties makes it the default choice for most electronic designs. As technology advances, rigid FR4 PCBs will undoubtedly remain a critical component, enabling the next generation of reliable, efficient, and affordable electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB