-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 31. 2025, 10:44:43

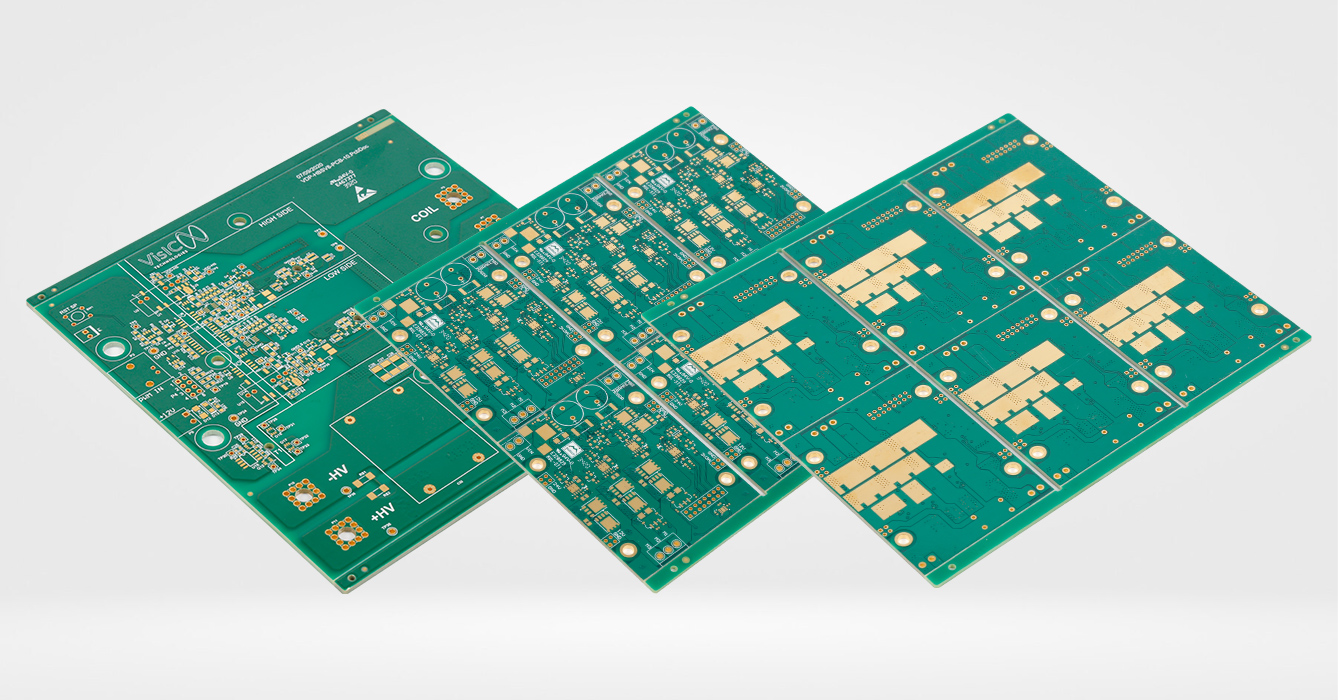

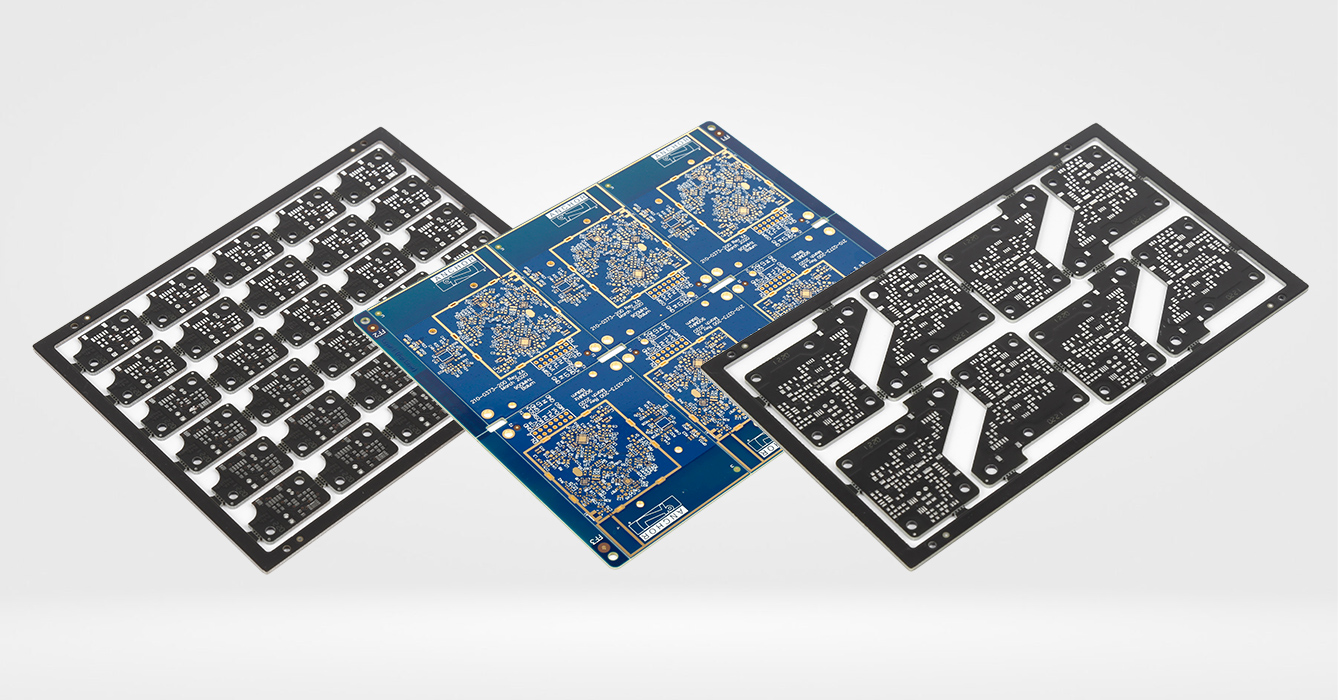

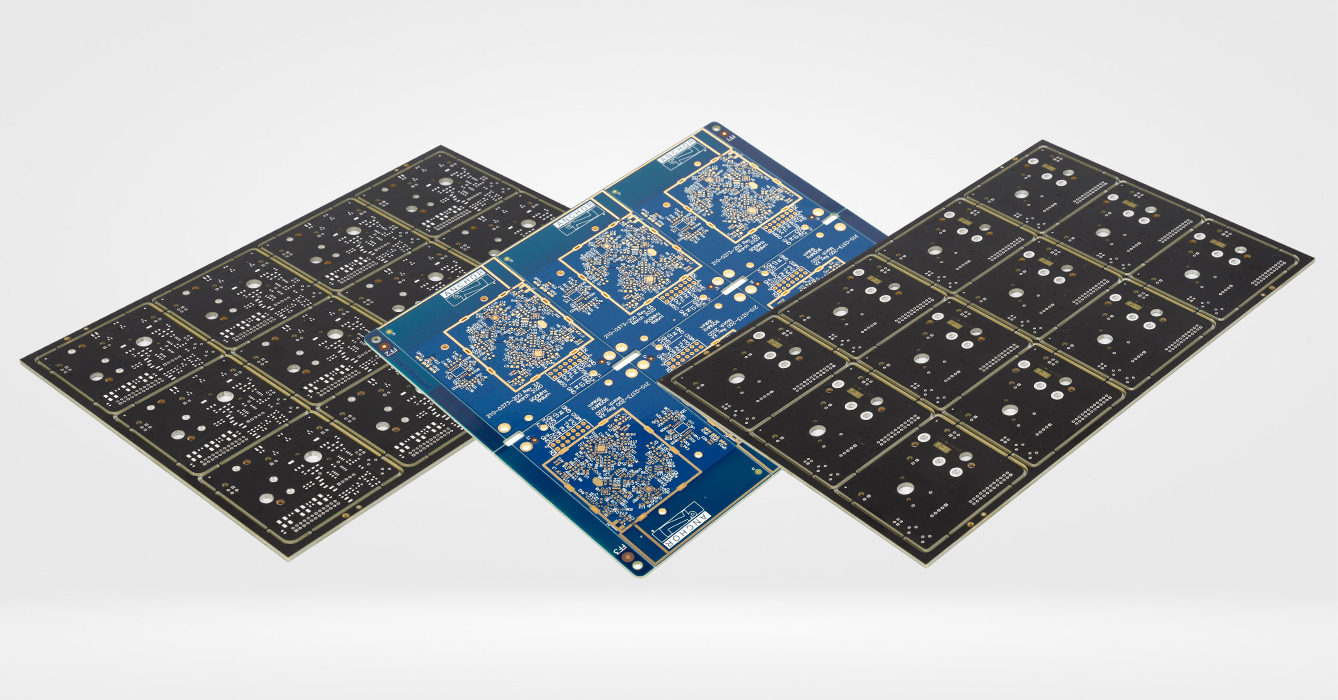

As the most widely adopted substrate in electronics manufacturing, FR4 PCB (Flame Retardant 4 Printed Circuit Board) continues to evolve, adapting to the demands of miniaturization, high performance, and sustainability. Beyond its foundational role as a mechanical and electrical platform, modern FR4 PCB technology integrates advanced material science, design optimization, and eco-conscious manufacturing to support emerging technologies from 5G networks to smart infrastructure. This article explores FR4 PCB’s material innovations, design strategies for diverse applications, sustainability advancements, and performance validation methods, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

FR4’s enduring relevance stems from continuous advancements in material composition, enhancing performance without sacrificing its core advantages of cost-effectiveness and processability:

High-Performance Epoxies: Modified epoxy resins with enhanced cross-linking structures improve thermal stability, extending FR4’s operating range for applications with moderate heat loads. These formulations maintain dielectric stability across frequencies, supporting reliable signal transmission in communication modules and industrial controls.

Eco-Friendly Variants: Halogen-free FR4 variants, compliant with RoHS and REACH standards, eliminate brominated flame retardants while retaining UL94 V-0 flame resistance. Emerging bio-based epoxy resins, derived from renewable feedstocks, reduce petroleum reliance and lower carbon footprints in manufacturing.

Nano-Enhanced Composites: Integration of ceramic nanoparticles or graphene into the glass fiber-epoxy matrix boosts thermal conductivity and mechanical strength. These additives minimize thermal resistance, enabling better heat dissipation in compact designs without compromising electrical insulation.

Low-Loss Modifications: FR4 formulations optimized for reduced dielectric loss (Df) cater to high-frequency applications, supporting signal integrity in 5G sub-6 GHz systems and IoT edge devices traditionally reliant on specialized substrates.

Effective FR4 PCB design balances electrical performance, manufacturability, and application-specific requirements through targeted engineering strategies:

Application-Tailored Lamination: Custom layer configurations—from 2-layer to high-density multi-layer designs—optimize signal, power, and ground distribution. For high-speed circuits, dedicated ground planes minimize crosstalk, while power layers with strategic decoupling enhance stability in digital systems.

Thermal Management Integration: Embedded thermal vias and copper pours in FR4 layouts create heat dissipation pathways, directing energy away from hot components like processors or power regulators. This passive cooling strategy reduces reliance on active fans in compact enclosures.

Controlled Impedance Routing: FR4’s consistent dielectric properties enable precise impedance control, critical for high-speed signals in data transmission and communication interfaces. Design tools leverage material Dk values to calculate trace dimensions, ensuring minimal reflection and signal loss.

Noise Mitigation: Strategic placement of components and grounding techniques in FR4 layouts reduce electromagnetic interference (EMI). Shielding layers and filtered connectors further isolate sensitive analog circuits from digital noise, enhancing performance in medical and measurement devices.

FR4 PCB’s versatility supports a broad spectrum of industries, with tailored solutions meeting unique operational demands:

Smart Devices: FR4 enables compact, high-density designs in smartphones, wearables, and home automation systems, balancing component density with power efficiency. Its lightweight properties and cost-effectiveness align with mass-production requirements for consumer markets.

Audio-Visual Equipment: In TVs, sound systems, and gaming consoles, FR4’s stable dielectric performance ensures clean signal transmission for audio and video processing, while thermal management features prevent overheating during extended use.

Industrial Automation: FR4 PCBs power sensors, controllers, and motor drives in factory environments, with ruggedized variants resisting vibration, humidity, and temperature fluctuations. Their mechanical durability ensures reliability in continuous-operation machinery.

Smart Grid Technology: In energy management systems and utility infrastructure, FR4 supports power distribution circuits and communication modules, with flame-retardant properties enhancing safety in high-voltage environments.

5G and Edge Computing: Low-loss FR4 variants enable cost-effective 5G small cells and edge devices, supporting mid-band frequency operations with minimal signal degradation. Their manufacturability accelerates deployment of next-generation networks.

Medical Electronics: Biocompatible and halogen-free FR4 options meet stringent regulatory requirements in diagnostic tools and wearable health monitors, ensuring safety while maintaining electrical performance for precision sensing.

The electronics industry’s shift toward circular economy principles drives innovations in FR4 production and lifecycle management:

Eco-Conscious Production

Energy-Efficient Processes: Manufacturers optimize lamination and curing stages with renewable energy sources and heat recovery systems, reducing carbon emissions. Precision manufacturing techniques minimize material waste in etching and drilling processes.

Closed-Loop Recycling: Advanced recycling technologies recover copper, glass fibers, and epoxy components from end-of-life FR4 PCBs. Recycled glass fibers are reused in new substrates, while copper is refined for reintroduction into the supply chain, reducing raw material demand.

Extended Lifespan Design

Durability Engineering: FR4 PCBs are designed for longevity through robust material selection and stress-testing, reducing the frequency of replacements. Enhanced corrosion resistance and thermal cycling tolerance extend service life in harsh environments.

Upgradable Architectures: Modular FR4 designs facilitate component replacement and upgrades, extending product lifecycles and reducing electronic waste in applications like industrial controllers and communication hardware.

Rigorous testing ensures FR4 PCBs meet application demands for reliability and consistency:

Environmental Stress Testing: FR4 samples undergo thermal cycling, humidity exposure, and vibration testing to simulate real-world operating conditions, validating structural integrity and electrical performance over time.

Signal Integrity Verification: Network analyzers and time-domain reflectometers (TDR) assess impedance matching and signal loss, ensuring FR4 layouts meet high-speed communication requirements without degradation.

Industry Standards Adherence: FR4 PCBs comply with IPC-A-600 (print board acceptability) and UL standards, ensuring consistent quality across manufacturing batches. Specialized certifications address automotive (IATF 16949) and medical (ISO 13485) requirements.

Traceability Systems: Digital tracking of material sources, production parameters, and test results enables full lifecycle transparency, supporting quality control and regulatory compliance in critical applications.

FR4 PCB continues to evolve, driven by emerging electronics trends and material science breakthroughs:

Additive Manufacturing: 3D printing techniques for FR4 prototypes enable rapid iteration of complex geometries, including internal cooling channels and custom component cavities, accelerating design cycles.

AI-Optimized Design: Machine learning algorithms analyze FR4 performance data to optimize layer stacks, trace routing, and thermal management, reducing design time and improving first-pass yield.

Hybrid Substrates: FR4 is increasingly combined with flexible polymers or metal cores to create semi-rigid PCBs, supporting conformable designs in automotive interiors and wearable devices while retaining structural strength.

Smart Materials: FR4 integrating self-healing epoxy resins or conductive nanocomposites could enable self-diagnostic capabilities, detecting and mitigating minor defects to extend operational lifespans.

FR4 PCB remains an indispensable foundation of modern electronics, evolving through material innovation, design optimization, and sustainable manufacturing to meet the demands of next-generation technologies. Its unique balance of performance, cost-effectiveness, and adaptability ensures relevance across consumer, industrial, and emerging sectors, from 5G infrastructure to medical devices. As engineers continue to push the boundaries of miniaturization and efficiency, FR4 PCB technology will remain a critical enabler, bridging traditional reliability with future-ready innovation. By prioritizing material advancements, eco-conscious practices, and application-specific design, FR4 PCB solidifies its role as a cornerstone of electronics manufacturing for years to come.

Keywords: FR4 PCB, material innovation, sustainable manufacturing, signal integrity, emerging electronics, design optimization, high-density interconnect, eco-friendly PCB.

This article provides a forward-looking, technically rigorous overview of FR4 PCB, emphasizing innovation, sustainability, and adaptability to ensure industry relevance and search engine visibility while maintaining originality.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB