-

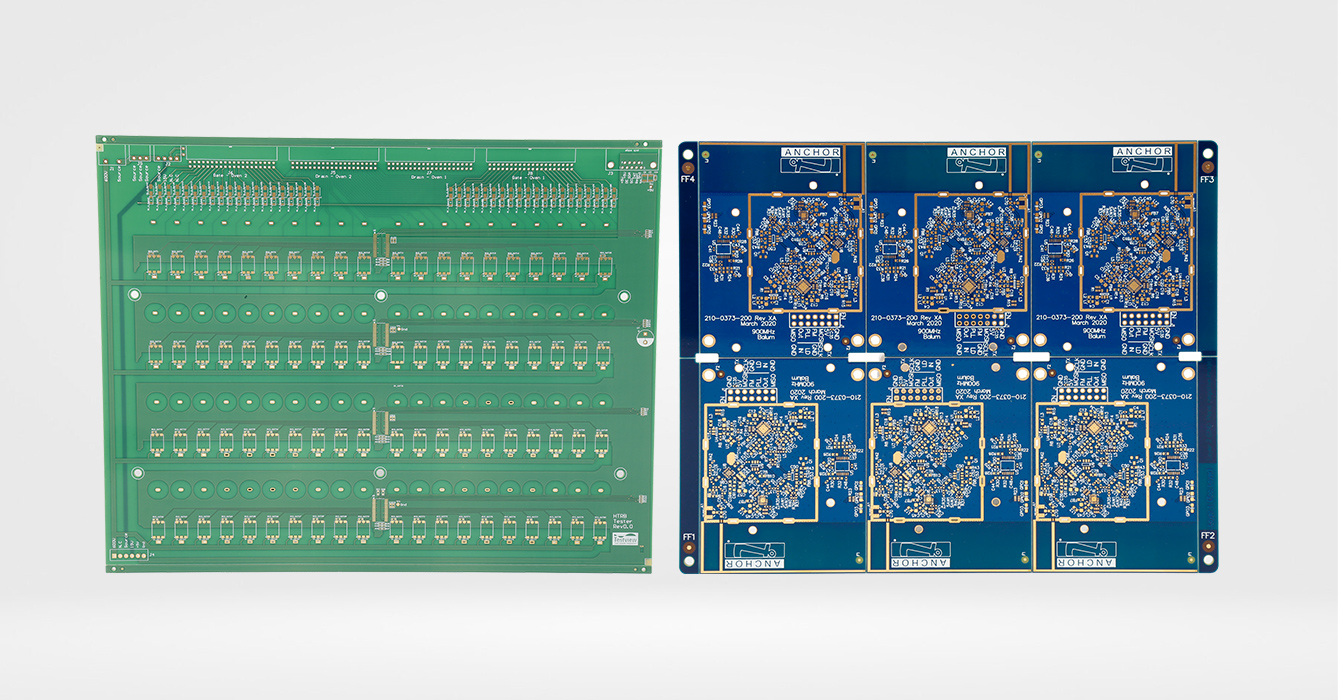

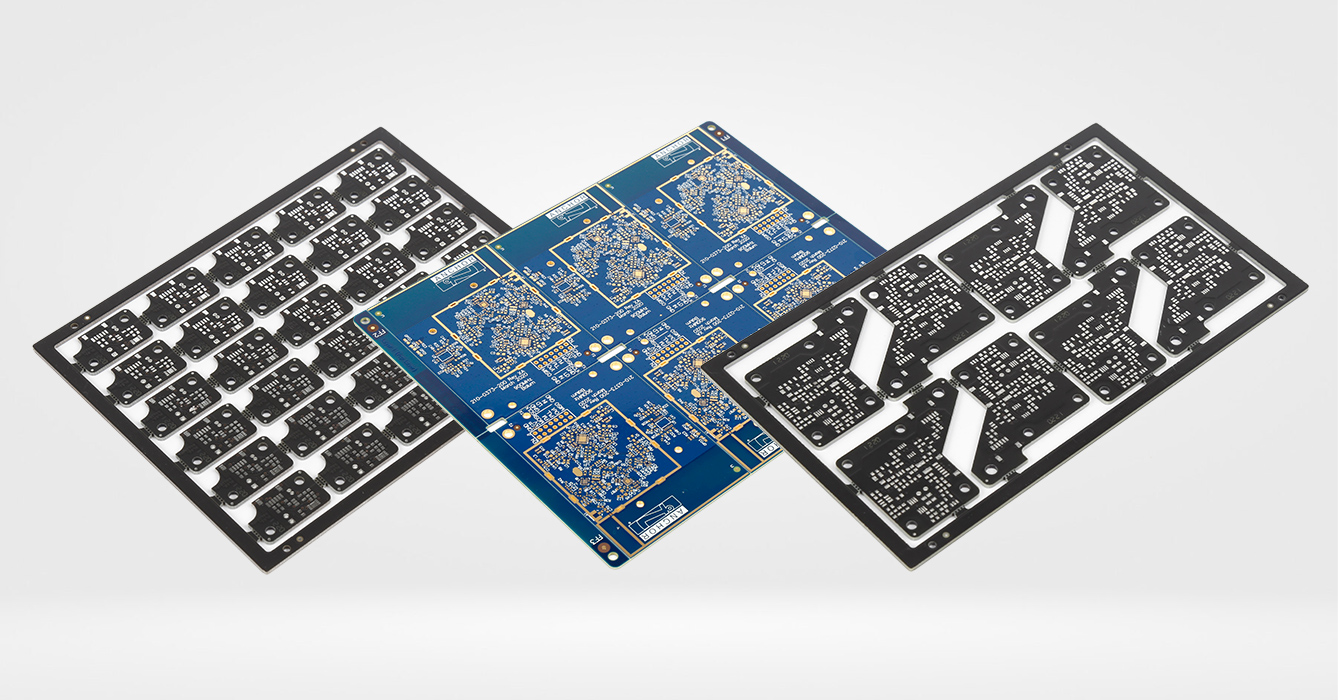

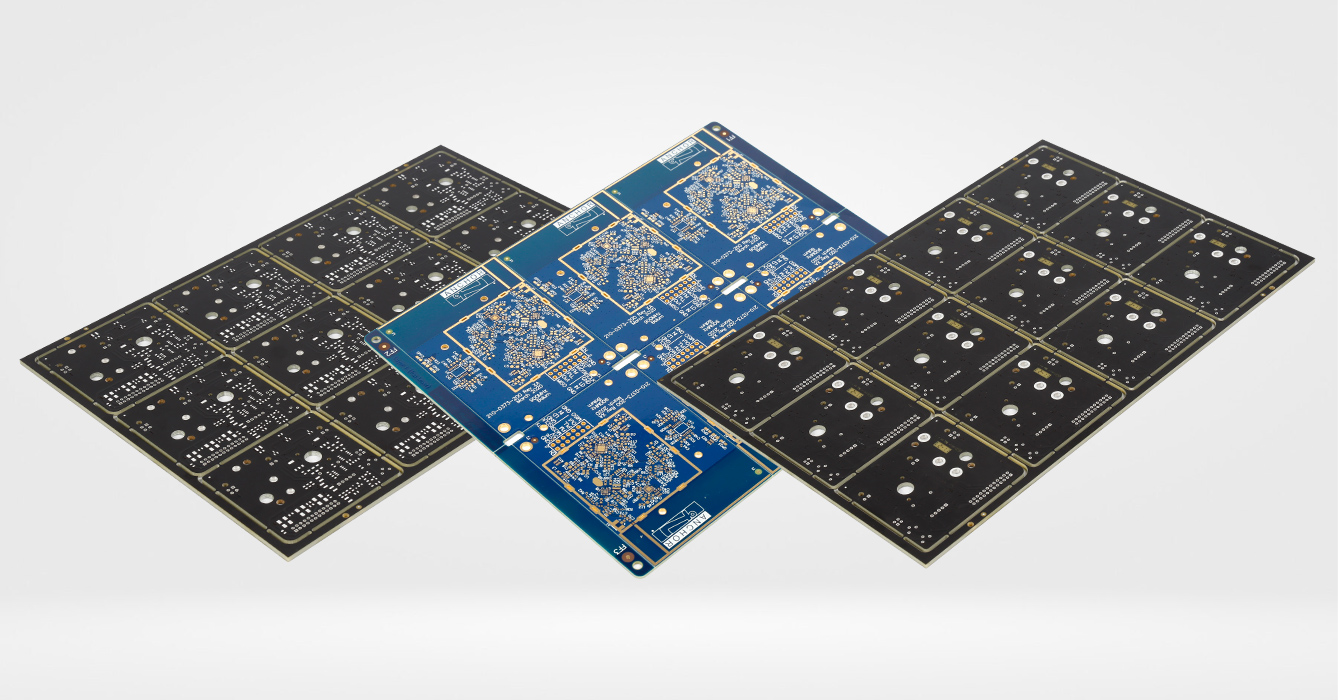

- PCB TYPE

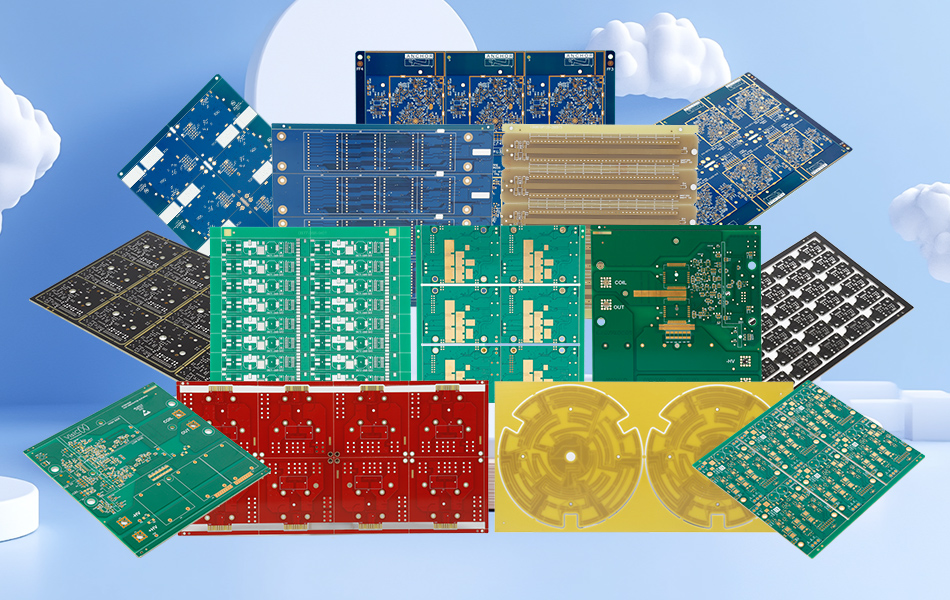

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 01. 2025, 09:23:15

In the realm of high-precision electronics, Precision Countersink FR4 PCB emerges as a critical solution for applications demanding seamless mechanical integration and surface uniformity. Combining the structural reliability of FR4 with specialized countersink machining, these PCBs enable secure, flush-mounted component installation, preventing mechanical interference and enhancing operational stability. This article explores the design principles, manufacturing techniques, application ecosystems, quality standards, and technical advantages of Precision Countersink FR4 PCBs, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Precision countersinking in FR4 PCBs involves creating conical recesses around mounting holes, engineered to accommodate fastener heads (screws, rivets) or component bases, ensuring they sit flush with the PCB surface. This design feature addresses key challenges in electronic assembly:

Mechanical Integration: Countersinks allow fasteners to sit below or flush with the PCB surface, eliminating protrusions that could interfere with adjacent components, enclosures, or external interfaces. This is critical in compact devices where space constraints demand tight tolerances between parts.

Stress Distribution: By distributing clamping force evenly around the fastener, precision countersinks reduce localized stress on the FR4 substrate, preventing cracks or delamination in high-vibration environments.

Surface Protection: Flush-mounted components minimize snagging risks, protecting both the PCB and surrounding equipment from mechanical damage during handling or operation.

FR4’s glass fiber-epoxy composite structure makes it uniquely suited for precision countersinking. Its mechanical rigidity ensures consistent material removal during machining, while its dimensional stability maintains countersink geometry under thermal and mechanical stress. Unlike softer substrates, FR4 resists deformation around countersunk holes, preserving tolerance integrity over the product lifecycle.

Achieving precision countersinks in FR4 PCBs requires specialized machining processes, balancing accuracy, surface finish, and material integrity:

Mechanical Drilling with Tapered Tools: High-speed carbide or diamond-tipped countersink tools are used to create conical recesses after initial hole drilling. CNC (Computer Numerical Control) machines ensure consistent depth and angle control, with adaptive feed rates to prevent glass fiber pull-out or resin smearing.

Laser Machining: For ultra-precise applications, laser systems ablate material to form countersinks, offering superior control over surface finish and geometry. Laser machining minimizes mechanical stress on the FR4 substrate, reducing the risk of microcracks in sensitive areas.

Hybrid Processes: Combining mechanical drilling for initial holes with laser refinement for countersink surfaces optimizes efficiency and precision, balancing production speed with accuracy for high-volume applications.

In-Process Metrology: Automated optical inspection (AOI) and coordinate measuring machines (CMMs) verify countersink dimensions, angles, and surface flatness during production, ensuring compliance with design specifications.

Tooling Maintenance: Regular calibration and replacement of countersink tools prevent wear-induced dimensional variations, critical for maintaining consistency across production batches.

Material Preparation: Proper FR4 substrate conditioning—including controlled storage to prevent moisture absorption—ensures uniform machining behavior, reducing defects like chipping or uneven material removal.

Precision Countersink FR4 PCBs are integral to industries where mechanical precision and reliability are non-negotiable:

In avionics and defense systems, these PCBs enable secure mounting in vibration-prone environments. Countersunk fasteners ensure PCBs remain firmly anchored in aircraft instrumentation, radar modules, and communication systems, where loose components could compromise mission-critical operations.

Medical equipment—such as diagnostic scanners, surgical tools, and patient monitors—relies on Precision Countersink FR4 PCBs for sterile, snag-free assembly. Flush surfaces prevent debris accumulation, simplifying cleaning protocols and reducing contamination risks in clinical settings.

In robotic arms, sensor arrays, and factory control systems, precision countersinks facilitate compact, rigid PCB mounting. This stability is essential for maintaining alignment in high-precision motion control systems, where even minor component displacement can cause operational errors.

Premium devices like high-end cameras, wearable tech, and professional audio equipment use these PCBs to achieve sleek, durable designs. Countersunk components contribute to slim form factors while ensuring structural integrity during daily use.

Beyond mechanical integration, these specialized PCBs offer distinct benefits for electronic systems:

Enhanced Reliability in Dynamic Environments

The combination of flush mounting and FR4’s mechanical resilience reduces fatigue on solder joints and component leads, extending product lifespan in applications subject to vibration, shock, or thermal cycling.

Precision countersinks enable denser component placement by eliminating the space required for protruding fasteners. This supports miniaturization trends in electronics, allowing engineers to pack more functionality into smaller enclosures.

Improved EMC and Signal Integrity

By minimizing gaps between PCBs and enclosures, countersunk mounting reduces electromagnetic leakage paths, enhancing electromagnetic compatibility (EMC) performance. This is particularly valuable in high-frequency applications where signal integrity is critical.

Precision Countersink FR4 PCBs must adhere to stringent standards to ensure performance consistency:

IPC Standards: Compliance with IPC-2221 (Generic Standard on Printed Board Design) and IPC-A-600 (Acceptability of Printed Boards) ensures countersink quality, including surface finish, dimensional accuracy, and freedom from defects like burrs or delamination.

Application-Specific Certifications: Aerospace applications may require compliance with AS9100, while medical devices follow ISO 13485, each imposing additional controls on countersink precision and material traceability.

Mechanical Stress Testing: Samples undergo vibration, shock, and thermal cycling tests to verify countersink integrity, ensuring no loosening or substrate damage under extreme conditions.

Dimensional Verification: Optical profilometers and 3D scanners validate countersink geometry, confirming angles, depths, and surface flatness meet design intent without relying on numerical tolerances.

Advancements in manufacturing and material science are expanding the capabilities of Precision Countersink FR4 PCBs:

AI-driven CNC systems with real-time feedback loops are optimizing countersink processes, adjusting tool paths based on material variations in FR4 substrates to maintain consistent precision across production runs.

Eco-friendly coolants and lubricants for machining, combined with energy-efficient laser systems, are reducing the environmental impact of precision countersink production, aligning with global sustainability goals.

Hybrid FR4 substrates, reinforced with carbon fiber or ceramic particles, are enabling higher precision countersinks in extreme environments, extending applications to high-temperature industrial systems and space electronics.

Precision Countersink FR4 PCB represents a critical intersection of mechanical engineering and electronic design, enabling secure, high-integrity assemblies in demanding applications. By leveraging FR4’s structural properties and advanced machining techniques, these PCBs address key challenges of compactness, reliability, and surface uniformity. From aerospace systems to medical devices, their role in ensuring mechanical stability while supporting electronic functionality makes them indispensable in modern precision electronics. As manufacturing technologies continue to advance, Precision Countersink FR4 PCBs will remain at the forefront of innovation, enabling the next generation of tightly integrated, high-performance electronic systems.

Keywords: Precision Countersink FR4 PCB, countersink machining, FR4 mechanical properties, aerospace electronics, medical device PCBs, high-precision assembly, CNC drilling, flush mounting.

This article provides a technically rigorous, industry-focused overview of Precision Countersink FR4 PCBs, emphasizing their unique design benefits, manufacturing nuances, and application value while ensuring originality and SEO alignment.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB