-

- PCB TYPE

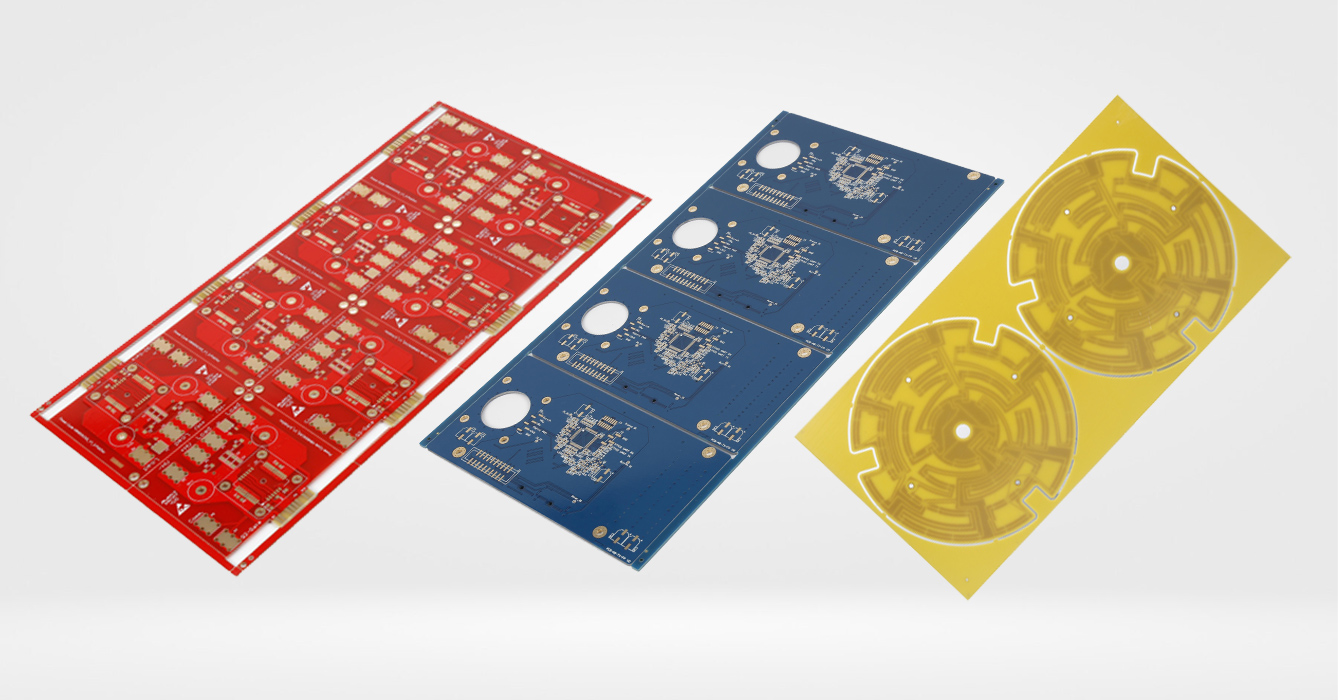

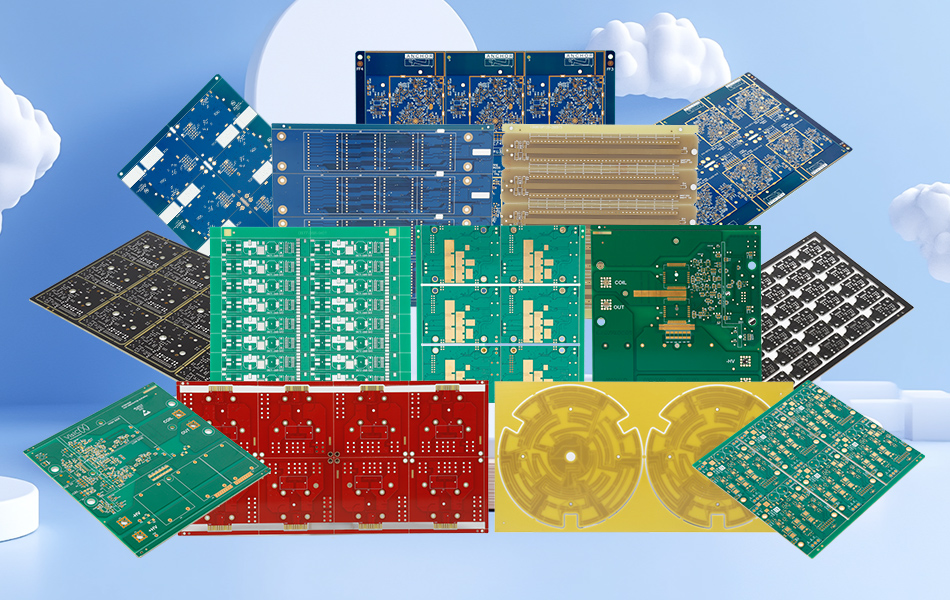

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 28. 2025, 10:10:55

In the intricate ecosystem of electronics manufacturing, FR4 PCB manufacturers serve as critical pillars, translating design concepts into tangible circuit boards that power devices across consumer, industrial, medical, and communication sectors. Renowned for their expertise in leveraging FR4—glass-reinforced epoxy laminate—as a foundational substrate, these manufacturers combine material science, precision engineering, and quality control to deliver PCBs that balance electrical performance, mechanical durability, and cost efficiency. This article explores the core capabilities, manufacturing excellence, quality standards, industry applications, and innovation focus of FR4 PCB manufacturers, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

Core Manufacturing Capabilities of FR4 PCB Manufacturers

FR4 PCB manufacturers distinguish themselves through advanced production processes and technical proficiency, ensuring consistency and performance in every board:

Material Expertise in FR4 Substrates

At the heart of their operations lies deep knowledge of FR4 substrates—composed of woven glass fiber cloth impregnated with epoxy resin. Manufacturers select FR4 variants tailored to application needs: high-temperature formulations for industrial use, flame-retardant grades for safety-critical devices, and thin-core options for compact electronics. This material choice delivers inherent advantages: excellent electrical insulation, mechanical rigidity, and stability across temperature fluctuations, making it ideal for diverse electronics.

Precision Production Workflows

Layer Stackup and Lamination: Manufacturers design custom layer configurations (from single-layer to multi-layer) based on circuit complexity. Lamination processes bond layers using controlled heat and pressure, ensuring uniform adhesion and eliminating voids that could compromise insulation or thermal conductivity.

Advanced Etching and Routing: Computer-aided design (CAD) and automated etching systems create precise circuit traces, vias, and component pads. Laser or mechanical routing ensures clean, accurate cuts, supporting high-density designs with fine line widths.

Surface Finishing: Application of solder masks, conformal coatings, or finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) enhances solderability, corrosion resistance, and long-term reliability.

These processes are optimized for efficiency and precision, enabling manufacturers to meet tight tolerances and diverse design requirements.

Quality Assurance: The Foundation of Reliable FR4 PCBs

FR4 PCB manufacturers prioritize quality at every stage, ensuring boards meet stringent industry standards and customer specifications:

Rigorous Testing Protocols

Automated Optical Inspection (AOI): High-resolution cameras scan boards post-etching to detect defects like missing traces, short circuits, or pad misalignment, ensuring visual quality before assembly.

Electrical Testing: Flying probe or bed-of-nails testing verifies continuity, isolation, and impedance, confirming no electrical faults in signal paths or power layers.

Environmental and Mechanical Validation: Samples undergo thermal cycling, humidity testing, and vibration analysis to simulate real-world operating conditions, ensuring durability in harsh environments.

Compliance with Global Standards

Leading manufacturers adhere to internationally recognized certifications, including:

IPC Standards: Compliance with IPC-A-600 (Printed Board Acceptability) and IPC-2221 (Design Standards) ensures consistency in manufacturing quality.

ISO Certifications: ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) demonstrate commitment to quality and sustainability.

Industry-Specific Compliance: Certifications like IATF 16949 (automotive) or ISO 13485 (medical) validate capability to serve regulated sectors.

Industry Applications: Tailoring Solutions to Diverse Sectors

FR4 PCB manufacturers adapt their capabilities to meet the unique needs of key industries, leveraging FR4’s versatility:

Consumer Electronics

Manufacturers produce compact, high-density FR4 PCBs for smartphones, laptops, and smart home devices, prioritizing miniaturization, signal integrity, and cost efficiency. Custom designs support wireless connectivity, touch interfaces, and power management in sleek form factors.

Industrial Automation

In industrial settings, FR4 PCBs must withstand vibration, temperature extremes, and electrical noise. Manufacturers deliver ruggedized boards for motor drives, PLCs (Programmable Logic Controllers), and sensor networks, with thick copper traces for power handling and EMI-shielded layers for signal clarity.

Medical Electronics

Medical devices demand precision and reliability. FR4 PCB manufacturers produce boards for diagnostic equipment, patient monitors, and wearable health tech, ensuring biocompatible materials, low noise levels, and compliance with strict regulatory requirements (e.g., FDA, CE).

Communication and Networking

For 5G base stations, routers, and data center hardware, manufacturers focus on high-frequency performance. FR4 PCBs with controlled impedance, low dielectric loss, and optimized layer stacks support fast data transmission, minimizing latency in global communication networks.

Customization and Design Collaboration

Top FR4 PCB manufacturers differentiate themselves through collaborative design support and flexible production:

Design for Manufacturability (DFM) Support

Engineering teams work with clients to optimize layouts for production, advising on trace routing, layer stackup, and material selection to reduce costs and improve yield. This collaboration ensures designs are manufacturable without compromising performance.

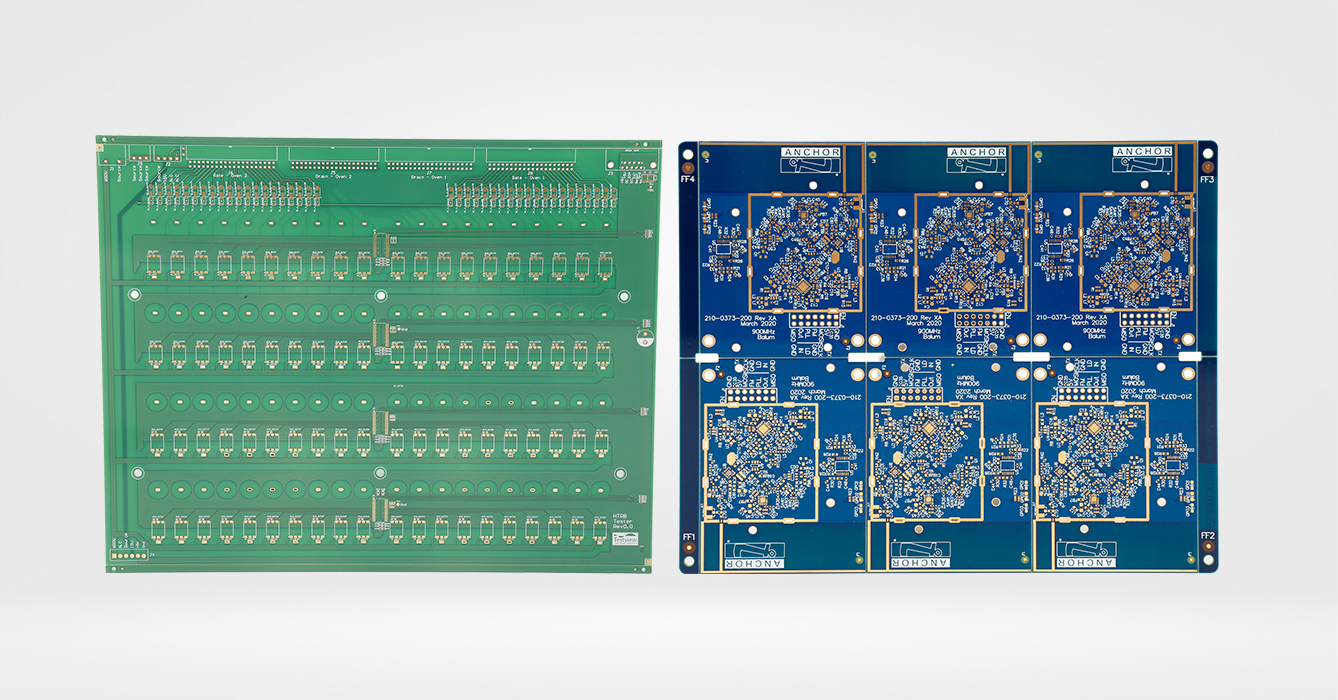

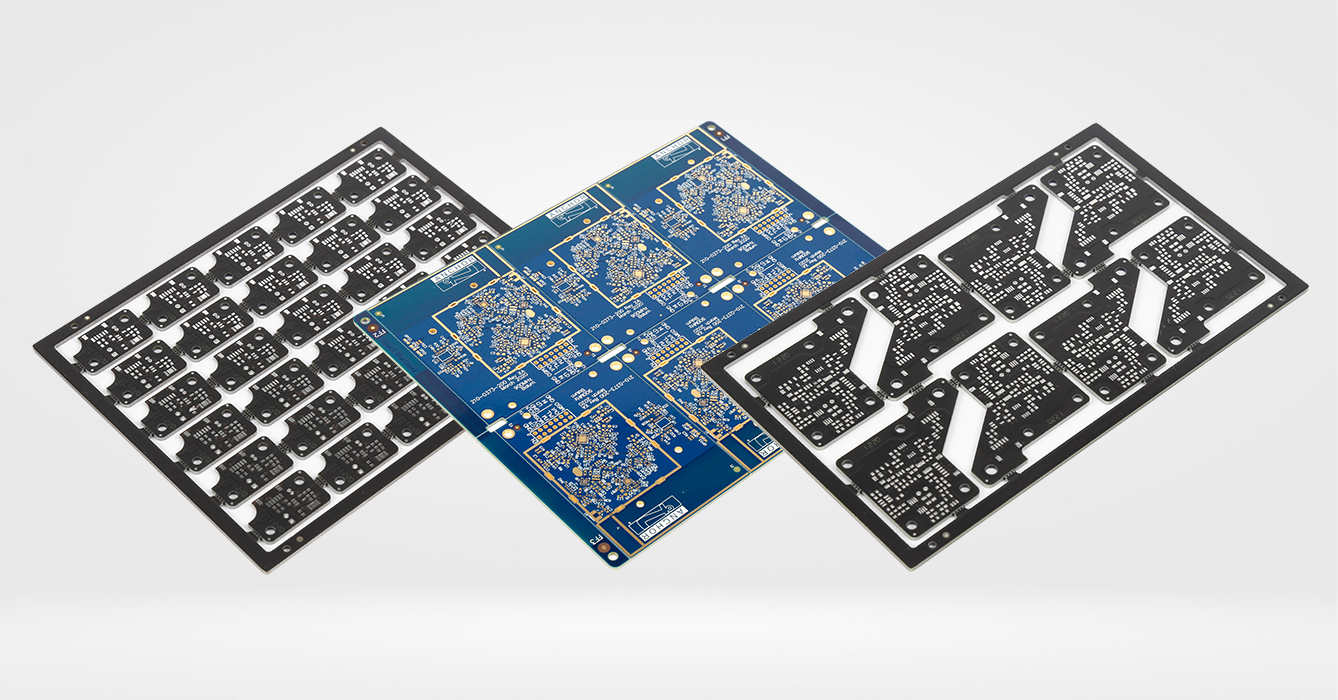

Rapid Prototyping and Scalable Production

Manufacturers offer quick-turn prototyping services, using advanced fabrication techniques to deliver small-batch samples for testing. Once validated, they scale to high-volume production with consistent quality, supporting product launches and market expansion.

Specialized Solutions

From flexible FR4 variants for wearable devices to high-temperature boards for automotive underhood systems, manufacturers develop specialized solutions by adjusting material formulations, layer counts, and surface treatments to meet niche requirements.

Sustainability: Eco-Friendly Practices in FR4 Manufacturing

Modern FR4 PCB manufacturers integrate sustainability into operations, aligning with global environmental goals:

Green Materials

Adoption of halogen-free FR4 substrates, recycled glass fibers, and lead-free solder masks reduces environmental impact, meeting RoHS and REACH regulations while minimizing toxic waste.

Energy and Waste Reduction

Manufacturing processes are optimized for energy efficiency, with renewable energy sources (solar, wind) powering facilities where possible. Waste streams from etching and lamination are recycled or treated to minimize landfill impact, supporting circular economy principles.

Lifecycle Considerations

Designs prioritize durability and recyclability, extending product lifespans and enabling end-of-life PCB recycling to recover valuable materials like copper and glass fiber.

Future Trends Shaping FR4 PCB Manufacturers

Innovation drives the evolution of FR4 PCB manufacturing, with key trends including:

Advanced Material Integration

Research into nanocomposite FR4 substrates aims to enhance thermal conductivity and mechanical flexibility, expanding applications in high-power electronics and flexible devices.

Smart Manufacturing

Industry 4.0 technologies—AI-driven quality inspection, IoT-enabled production monitoring, and digital twins—optimize efficiency, reduce defects, and enable predictive maintenance in manufacturing facilities.

High-Frequency Optimization

As 5G and 6G networks expand, manufacturers focus on low-loss FR4 formulations and precise impedance control to support higher data rates and millimeter-wave applications.

Conclusion

FR4 PCB manufacturers play a pivotal role in the global electronics supply chain, combining technical expertise, quality focus, and adaptability to deliver boards that power modern innovation. Through precision manufacturing, rigorous quality control, and customer collaboration, they meet the diverse needs of consumer, industrial, medical, and communication sectors. As sustainability and advanced technologies shape the industry, FR4 PCB manufacturers continue to evolve, ensuring they remain vital partners in the development of next-generation electronic devices.

Keywords: FR4 PCB manufacturer, FR4 substrate, PCB manufacturing, electronics production, quality control, industrial PCB, sustainable manufacturing, PCB design.

This article provides a comprehensive overview of FR4 PCB manufacturers, emphasizing their capabilities, industry impact, and commitment to excellence while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB