-

- PCB TYPE

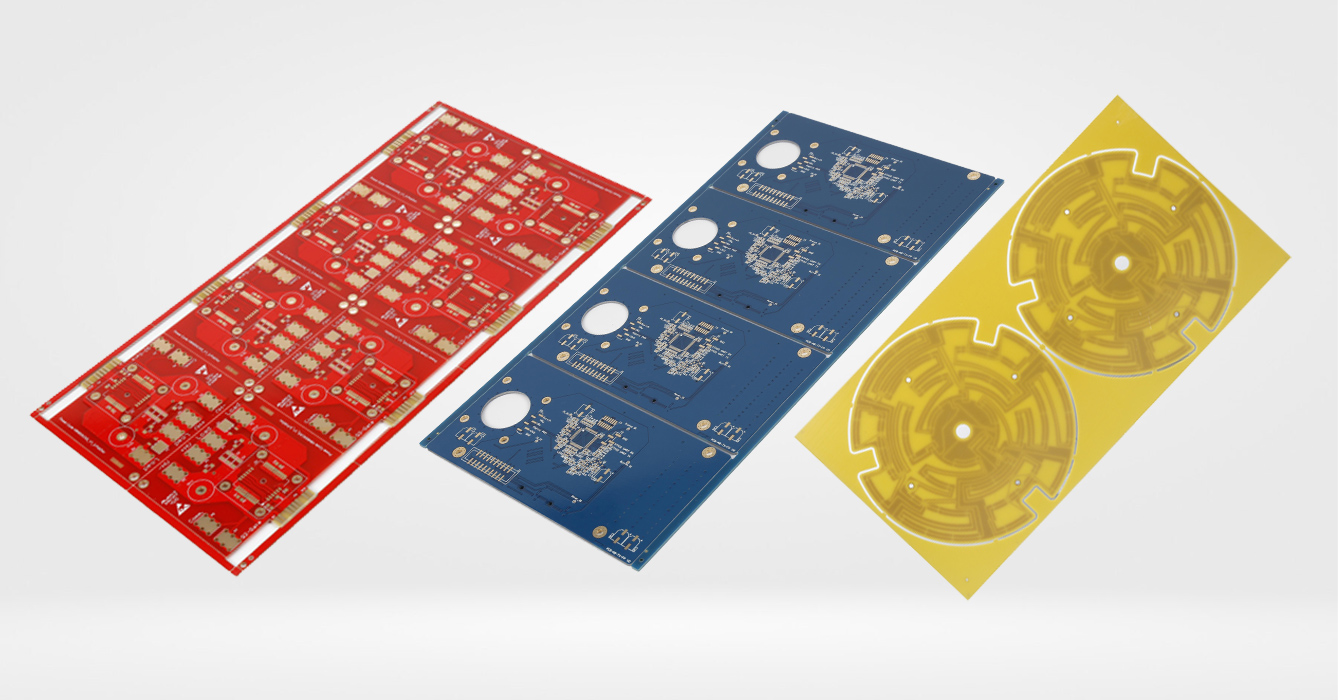

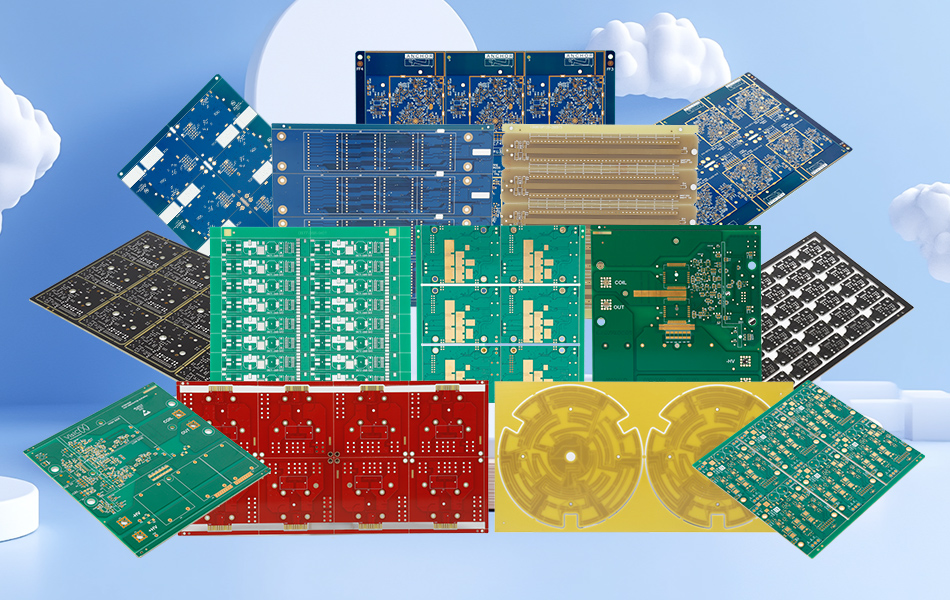

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 28. 2025, 10:16:59

As the backbone of modern electronics, FR4 PCB (Flame Retardant 4 Printed Circuit Board) remains the most widely used substrate in electronic manufacturing, valued for its balance of electrical performance, mechanical stability, and cost-effectiveness. Derived from glass-reinforced epoxy resin, FR4 PCB provides a reliable platform for mounting and interconnecting electronic components across industries, from consumer devices to industrial machinery. This article explores the material composition, core performance attributes, application versatility, manufacturing essentials, and evolving trends of FR4 PCB, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Material Composition: The Foundation of FR4 PCB

FR4 PCB’s performance is rooted in its composite material structure, engineered to meet the dual demands of electrical insulation and mechanical support:

Core Material Components

Glass Fiber Reinforcement: FR4 substrates are built around woven glass fiber cloth, which imparts mechanical rigidity, dimensional stability, and resistance to thermal expansion. The glass fiber network ensures the PCB maintains shape under temperature fluctuations, a critical trait for preventing solder joint fatigue and component misalignment.

Epoxy Resin Matrix: The glass fiber cloth is impregnated with flame-retardant epoxy resin, which binds the fibers together and forms the insulating matrix. This resin is formulated to meet UL94 V-0 flame resistance standards, reducing fire risk in electronic devices. Its chemical stability ensures resistance to moisture, solvents, and aging over time.

Copper Cladding: High-purity copper foil is bonded to one or both sides of the FR4 core (or between layers in multi-layer designs) to create conductive pathways. The copper’s thickness and purity are tailored to application needs, balancing electrical conductivity with weight and cost considerations.

This composite structure—glass fiber for strength, epoxy for insulation, and copper for conductivity—establishes FR4 as a versatile substrate for diverse electronic applications.

Core Performance Traits of FR4 PCB

FR4 PCB’s enduring popularity stems from a suite of performance characteristics that align with the needs of most electronic systems:

Electrical Performance

Stable Dielectric Properties: FR4 exhibits a consistent dielectric constant (Dk) and low dissipation factor (Df) across typical operating frequencies, ensuring minimal signal loss and reliable signal propagation. This stability makes it suitable for both low-speed analog circuits and moderate-frequency digital applications.

Excellent Insulation Resistance: The epoxy resin matrix provides high volume resistivity and dielectric strength, preventing electrical leakage between conductive traces and ensuring safe operation in high-voltage scenarios, such as power supply boards.

EMI Shielding Potential: In multi-layer configurations, FR4 PCBs can integrate ground planes and shielding layers to mitigate electromagnetic interference (EMI), enhancing signal integrity in noise-sensitive applications like medical monitors and communication devices.

Mechanical and Thermal Attributes

Rigidity and Durability: The glass fiber reinforcement gives FR4 PCB high tensile strength and flexural modulus, resisting physical stress from component mounting, vibration, and thermal cycling. This durability makes it ideal for rigid electronic enclosures in industrial and automotive systems.

Thermal Resistance: While not as thermally conductive as metal-core PCBs, FR4 maintains stable performance across a broad temperature range, withstanding soldering temperatures and operational heat from components in most consumer and industrial environments.

Dimensional Stability: Low coefficient of thermal expansion (CTE) minimizes warping under temperature changes, ensuring long-term reliability in applications where precise component alignment is critical, such as sensor modules and optical equipment.

Cost-Effectiveness and Accessibility

Mass Production Compatibility: FR4’s mature manufacturing processes enable high-volume production at lower costs compared to specialized substrates like ceramic or polyimide. This affordability makes it the default choice for cost-sensitive applications, from smartphones to home appliances.

Broad Availability: As the industry standard, FR4 materials and manufacturing capabilities are widely accessible globally, ensuring consistent supply chains and shorter lead times for prototyping and production.

Application Versatility of FR4 PCB

FR4 PCB’s balanced performance makes it indispensable across virtually every electronics sector:

Consumer Electronics

Smart Devices: Smartphones, tablets, laptops, and wearables rely on FR4 PCBs for their compact, high-density designs. FR4’s electrical stability supports the complex signal routing required for processors, memory modules, and wireless communication chips.

Home Appliances: Refrigerators, TVs, and kitchen appliances use FR4 PCBs in control panels and power management circuits, benefiting from its durability and cost-effectiveness in mass-produced goods.

Industrial and Commercial Systems

Industrial Automation: Programmable Logic Controllers (PLCs), motor drives, and sensor interfaces utilize FR4 PCBs for their resistance to vibration and temperature fluctuations, ensuring reliable operation in factory environments.

Power Electronics: Power supplies, inverters, and battery management systems leverage FR4’s insulation strength and thermal stability to handle voltage conversion and distribution in commercial and industrial settings.

Medical and Communication Equipment

Medical Devices: Diagnostic tools, patient monitors, and portable medical equipment use FR4 PCBs for their electrical stability and compliance with biocompatibility standards, ensuring accurate performance and patient safety.

Communication Infrastructure: Routers, modems, and low-frequency communication modules depend on FR4’s signal integrity to support data transmission, with multi-layer designs enabling complex routing for connectivity features.

Manufacturing Essentials for FR4 PCB

The production of FR4 PCB involves standardized processes optimized for consistency and quality:

Core Manufacturing Steps

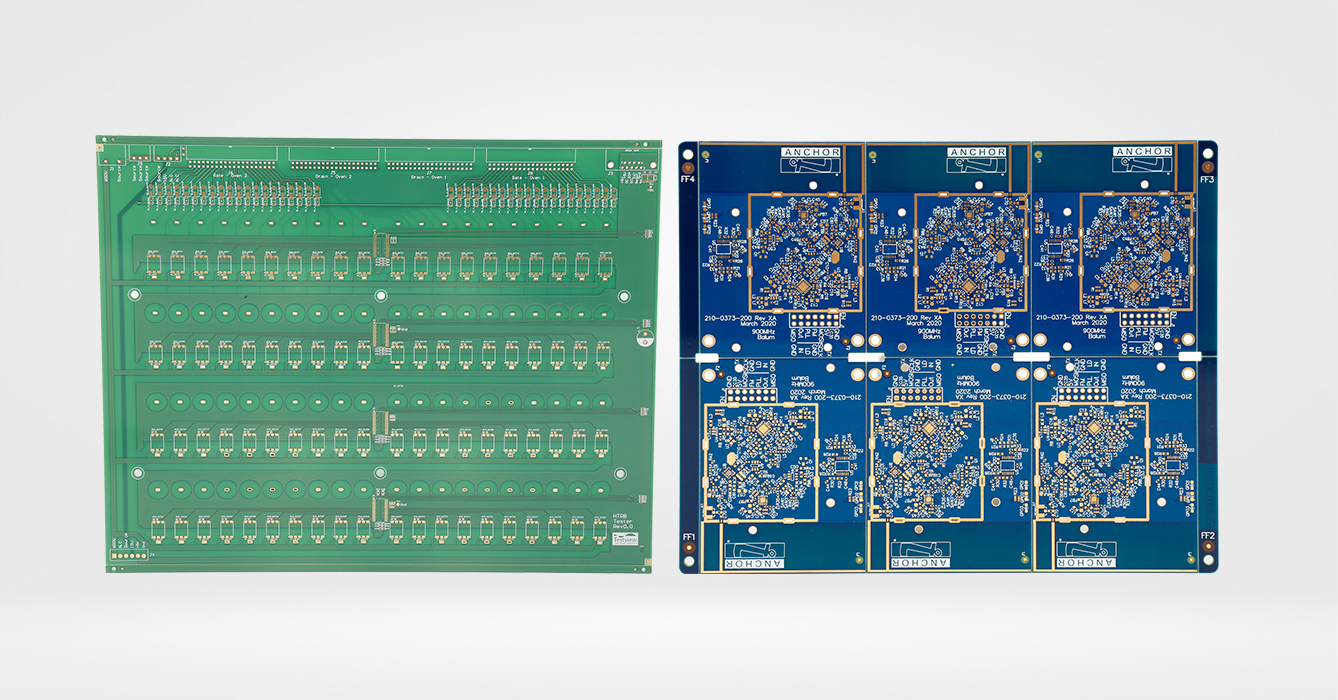

Layer Preparation: FR4 cores (pre-cured substrate sheets) are cut to size, and copper foil is bonded to surfaces via lamination. For multi-layer PCBs, inner layers are etched with circuit patterns before stacking.

Lamination: Multi-layer boards are assembled by stacking inner layers with prepreg (uncured resin-impregnated glass fiber) and outer copper layers, then cured under heat and pressure to fuse the structure into a single rigid board.

Drilling and Plating: Holes (vias) are drilled to connect layers, followed by copper plating to establish electrical continuity between inner and outer circuits.

Etching and Surface Finishing: Outer copper layers are etched to form traces, and surface finishes (e.g., ENIG, HASL, OSP) are applied to enhance solderability, corrosion resistance, and component adhesion.

Quality Control Measures

Automated Optical Inspection (AOI): Used to detect defects in copper patterns, such as short circuits, open traces, or misalignment, ensuring dimensional accuracy.

Electrical Testing: Flying probe or bed-of-nails testing verifies continuity, insulation, and impedance, ensuring the PCB meets design specifications.

Environmental Testing: Samples undergo thermal cycling, humidity exposure, and mechanical stress tests to validate durability in real-world operating conditions.

Evolving Trends in FR4 PCB Technology

While FR4 is a mature technology, ongoing innovations enhance its performance and sustainability:

Eco-Friendly Formulations

Halogen-Free FR4: Manufacturers are developing halogen-free epoxy resins to meet global environmental regulations, reducing toxic emissions during manufacturing and end-of-life disposal without compromising flame resistance or electrical performance.

Recyclable Materials: Research into bio-based resins and recycled glass fiber content aims to reduce FR4’s environmental footprint, aligning with circular economy initiatives in electronics manufacturing.

Advanced Design Adaptations

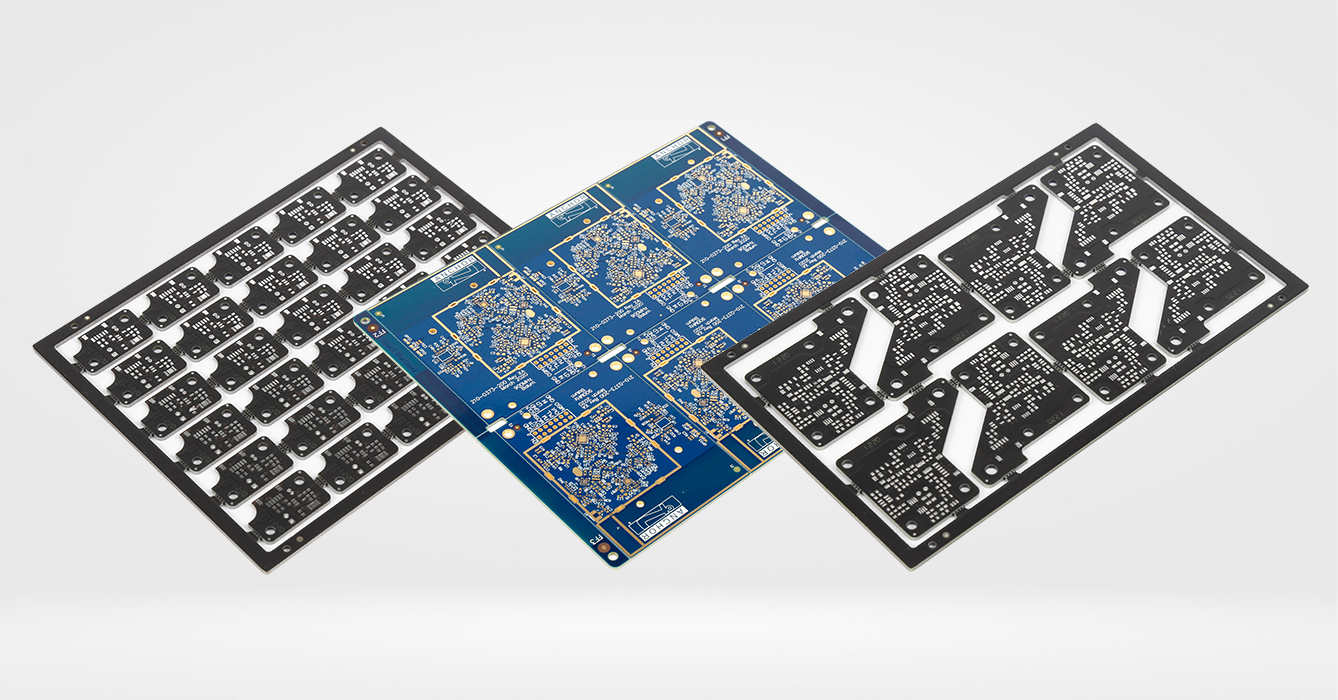

High-Density Interconnect (HDI): FR4 PCBs are increasingly integrated with HDI features, such as microvias and fine-pitch traces, enabling higher component density for compact devices like IoT sensors and wearables.

Hybrid Substrates: Combining FR4 with specialized layers (e.g., high-frequency dielectrics for 5G components) creates hybrid PCBs that balance cost with enhanced performance in specific applications.

Compatibility with Emerging Technologies

5G and IoT Integration: FR4 PCBs are being optimized for low-loss performance at higher frequencies, supporting 5G connectivity modules and IoT devices that require reliable signal transmission in crowded RF environments.

Automotive Grade FR4: Enhanced formulations with improved thermal resistance and vibration tolerance are expanding FR4’s use in automotive electronics, from infotainment systems to advanced driver-assistance systems (ADAS).

Conclusion

FR4 PCB remains the cornerstone of electronic manufacturing, offering an unrivaled balance of electrical performance, mechanical stability, cost-effectiveness, and versatility. Its glass fiber-epoxy composite structure delivers the reliability required across consumer, industrial, medical, and communication applications, while ongoing innovations in materials and manufacturing ensure it adapts to emerging technologies. As electronics continue to evolve toward higher density, connectivity, and sustainability, FR4 PCB will remain a critical enabler, providing engineers with a proven platform to build the next generation of electronic systems.

Keywords: FR4 PCB, printed circuit board, glass fiber epoxy, electronic substrate, electrical performance, multi-layer PCB, sustainable electronics, HDI PCB.

This article provides a focused, technically rigorous overview of FR4 PCB, emphasizing material fundamentals, performance traits, and evolving applications while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB