-

- PCB TYPE

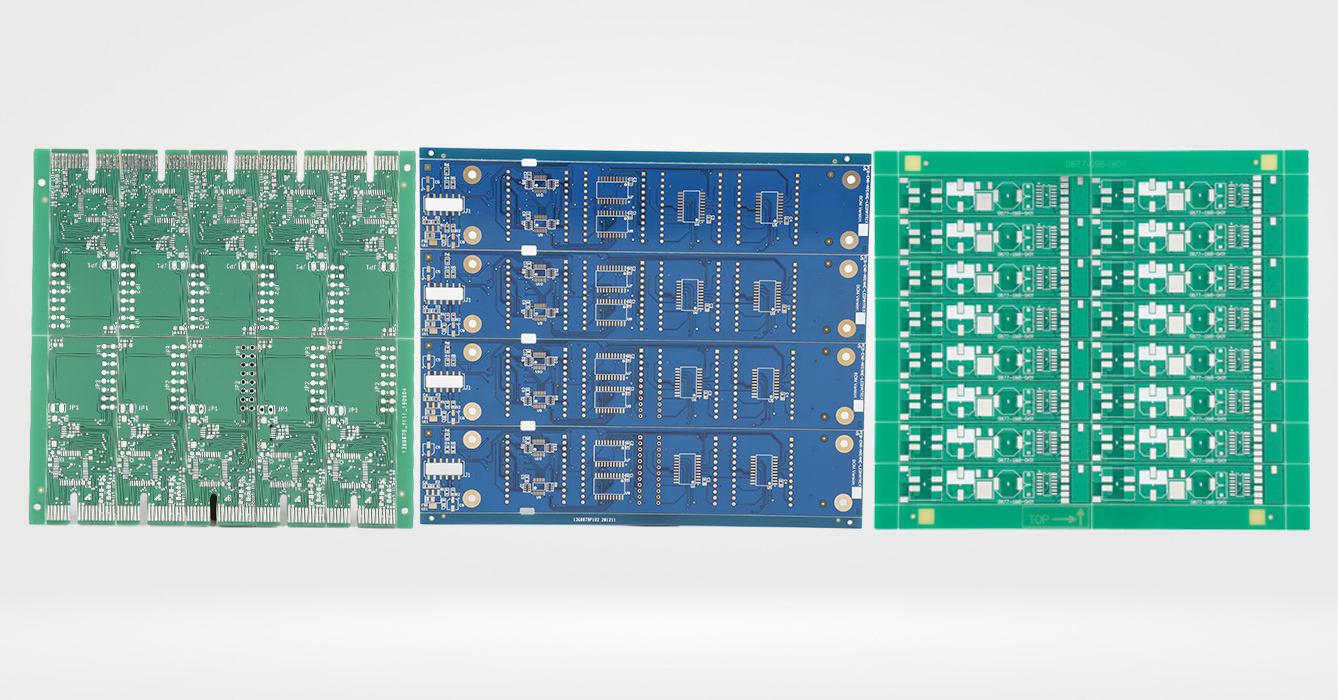

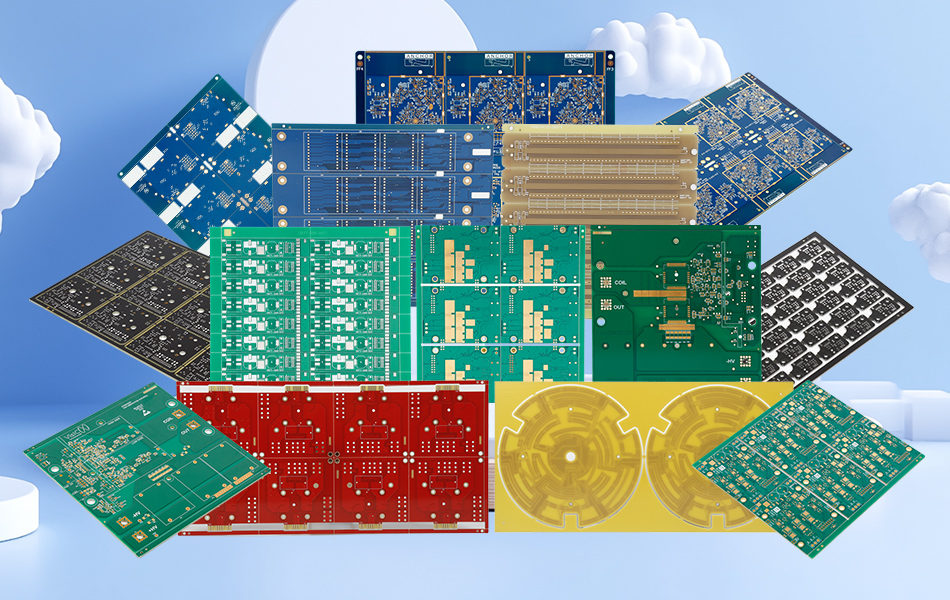

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 11. 2025, 16:21:40

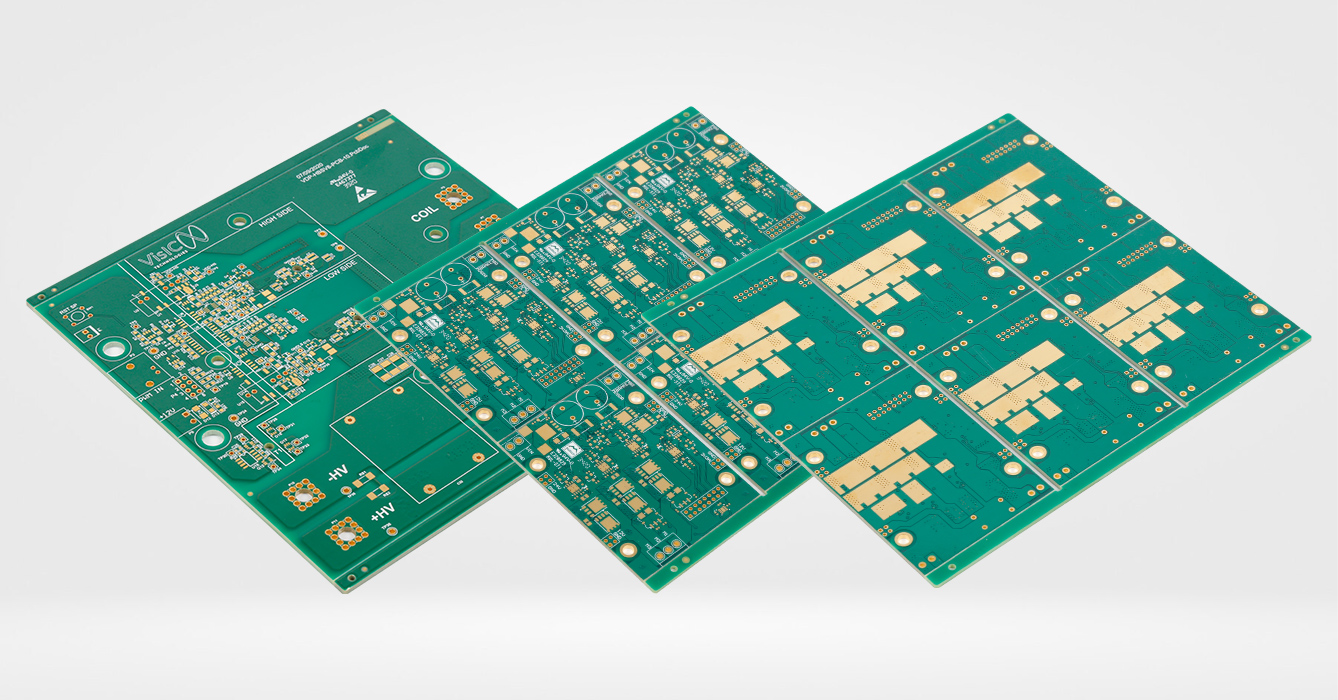

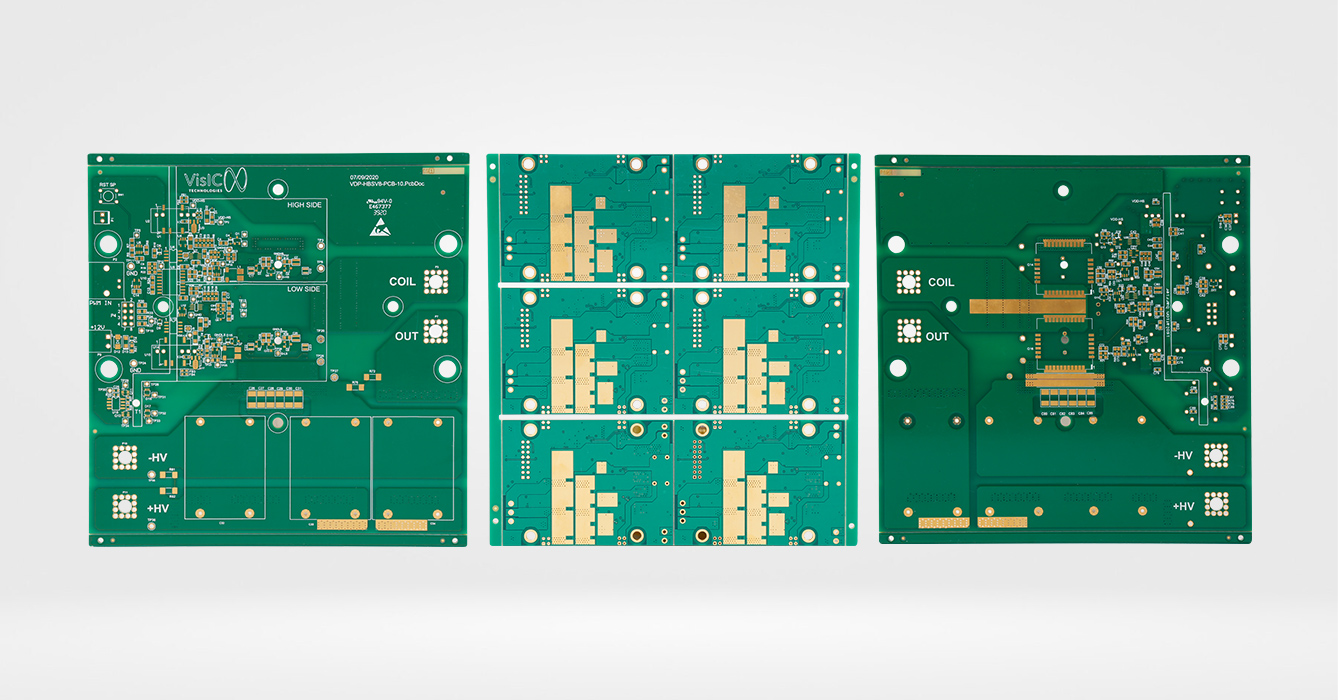

FR4 PCB is more than a material—it is the invisible backbone of the digital revolution, enabling the devices and systems that define modern life. From the smartphone in your pocket to the industrial robots in factories, FR4 PCBs form the structural and functional core of electronic technology. What makes FR4 exceptional is its ability to adapt to the ever-changing demands of innovation, balancing performance, cost, and practicality across decades of technological advancement. This article explores FR4 PCB’s role as a catalyst for progress, examining its cultural impact, its influence on design philosophy, and its future as a foundational material in emerging technologies. By looking beyond technical specifications, we uncover how FR4 has become integral to the way we live, work, and connect.

One of FR4’s most profound contributions is democratizing access to electronics by making advanced technology affordable.

Before FR4’s widespread adoption, PCBs relied on expensive materials like phenolic resins or ceramics, limiting electronic devices to niche markets and high-budget industries. FR4 changed this by offering a cost-effective alternative that maintained sufficient performance for most applications. Its simple manufacturing process—using readily available glass fibers and epoxy resin—allowed mass production, driving down the cost of consumer electronics, medical devices, and communication tools.

This affordability has had far-reaching societal impacts. It enabled the proliferation of personal computers in the 1980s, the rise of mobile phones in the 2000s, and the explosion of IoT devices today. In developing regions, low-cost FR4-based electronics have facilitated access to education (via tablets), healthcare (via portable diagnostic tools), and financial services (via mobile banking). FR4’s role in reducing technological barriers underscores its status as a material that not only enables innovation but also equitable access to its benefits.

FR4’s characteristics have shaped a design philosophy centered on practicality, adaptability, and efficiency.

Engineers and designers working with FR4 prioritize solutions that “fit for purpose”—avoiding over-engineering while ensuring reliability. This mindset stems from FR4’s own balance of properties: it is not the highest-performing material in any single category, but it excels at meeting the needs of most applications. For example, a smartwatch design using FR4 focuses on compactness and energy efficiency rather than extreme heat resistance, leveraging FR4’s thin-core variants to achieve a sleek form factor.

This philosophy extends to sustainability. FR4’s recyclability and compatibility with eco-friendly manufacturing processes align with modern design principles that prioritize reducing waste and carbon footprints. Designers increasingly choose FR4 for its ability to support circular economy models, where PCBs are disassembled, recycled, and reused at the end of their lifecycle.

FR4 also encourages modular design. Its compatibility with standard components and manufacturing processes allows engineers to create interchangeable parts, simplifying repairs and upgrades. This modularity not only reduces electronic waste but also extends the lifespan of devices, from home appliances to industrial equipment.

As new technologies emerge, FR4 continues to adapt, proving its relevance in cutting-edge fields:

Renewable Energy Systems: Solar inverters and wind turbine controllers rely on FR4 for its balance of thermal stability and cost-effectiveness. FR4 PCBs manage the power conversion process, ensuring efficient energy transfer while withstanding the outdoor conditions of renewable energy installations.

Smart Cities: Traffic management systems, environmental sensors, and smart grids use FR4-based electronics to collect and transmit data. FR4’s durability in outdoor environments and compatibility with wireless communication modules make it ideal for these distributed networks.

Wearable Technology: Flexible and thin-core FR4 variants enable the development of lightweight, body-worn devices. From fitness trackers to medical monitors, these devices leverage FR4’s flexibility and biocompatibility to integrate seamlessly with daily life.

Autonomous Systems: Drones and autonomous vehicles use FR4 PCBs in their navigation and control systems. While high-performance variants handle the heat of processing units, standard FR4 manages less critical functions, balancing performance with the cost constraints of mass production.

In each of these areas, FR4’s ability to adapt—whether through modified formulations or innovative manufacturing techniques—ensures it remains a key enabler of technological progress.

As sustainability becomes a global priority, FR4’s environmental footprint is undergoing reevaluation and improvement:

Recycling Innovations: Traditional PCB recycling focused on recovering valuable metals like copper, but new processes now extract and reuse glass fibers and epoxy resins from FR4. These advances reduce the need for virgin materials, lowering the environmental impact of PCB production.

Eco-Friendly Formulations: Manufacturers are developing FR4 using bio-based epoxy resins derived from plant oils and recycled glass fibers. These formulations maintain FR4’s performance while reducing reliance on petroleum-based materials and cutting carbon emissions.

Energy-Efficient Manufacturing: The production of FR4 PCBs is becoming more energy-efficient, with optimized lamination and etching processes reducing energy consumption. Some manufacturers now use renewable energy sources for production, further lowering the material’s carbon footprint.

Reduced Waste: FR4’s compatibility with additive manufacturing (3D printing) allows for precise material deposition, minimizing waste during prototyping and small-batch production. This shift from subtractive to additive processes aligns with circular economy principles.

These developments position FR4 as a sustainable choice for future electronics, addressing concerns about e-waste and resource depletion.

FR4’s global availability has made it a linchpin of international electronics supply chains, with production and distribution networks spanning continents:

Manufacturing Hubs: Major FR4 production centers in Asia, Europe, and North America ensure a stable supply, reducing the risk of shortages and supporting just-in-time manufacturing models. This global distribution allows electronics companies to source materials locally, lowering transportation costs and emissions.

Standardization and Compatibility: Universal standards for FR4—developed by organizations like IPC and UL—ensure that materials from different regions meet consistent quality requirements. This standardization simplifies cross-border trade and enables collaboration between international design and manufacturing teams.

Crisis Resilience: The distribute production of FR4 has proven resilient during global disruptions, such as natural disasters or pandemics. Manufacturers can shift production between regions, ensuring a continuous supply of critical materials for essential electronics like medical devices and communication equipment.

Localization Trends: While global supply chains dominate, there is a growing trend toward regional FR4 production to reduce transportation distances and support local manufacturing ecosystems. This localization balances efficiency with the need for supply chain resilience.

Despite its advantages, FR4 faces challenges that must be addressed to maintain its relevance:

Performance Limitations: In extreme applications—such as high-frequency radar or ultra-high-temperature industrial systems—FR4 is outperformed by specialized materials like PTFE or ceramic substrates. While advanced FR4 variants narrow this gap, they cannot match the performance of these niche materials.

E-Waste Concerns: Even with improved recycling, a significant portion of FR4 PCBs ends up in landfills, where epoxy resins can persist for decades. Addressing this requires better collection systems and consumer awareness of proper disposal methods.

Chemical Use in Manufacturing: Traditional FR4 production uses chemicals in etching and cleaning processes, which can harm the environment if not properly managed. While water-based alternatives are gaining ground, their adoption is not yet universal.

Competition from Alternatives: Emerging materials, such as biodegradable polymers and metal-core substrates, are challenging FR4 in specific applications. To remain competitive, FR4 must continue evolving to meet new performance and sustainability standards.

FR4’s future lies in its ability to combine innovation with its core strengths of versatility and cost-effectiveness:

Smart Materials Integration: Research is exploring FR4 embedded with sensors that monitor temperature, stress, or moisture, enabling predictive maintenance in industrial and infrastructure applications. These “smart” FR4 PCBs can alert users to potential failures before they occur.

Nano-Enhancements: Adding nanoparticles to FR4 formulations could improve thermal conductivity, mechanical strength, and electrical performance, expanding its use in high-demand applications without sacrificing cost-effectiveness.

Digital Twin Technology: Digital replicas of FR4 PCBs—“digital twins”—will allow engineers to simulate performance under different conditions, optimizing designs and reducing the need for physical prototyping. This technology will accelerate innovation while lowering development costs.

Customization at Scale: Advances in manufacturing will enable mass-produced FR4 PCBs with customized properties, allowing engineers to tailor materials to specific applications without the premium cost of small-batch production.

These innovations will ensure that FR4 remains a vital material in the electronics industry, adapting to meet the needs of a rapidly changing world.

FR4 PCB is more than a technical component; it is a symbol of technological progress and accessibility. Its ability to balance performance, cost, and adaptability has made it indispensable in everything from basic consumer devices to cutting-edge technologies. As we look to the future, FR4’s role will continue to evolve, driven by innovations in sustainability, design, and manufacturing. Whether enabling renewable energy systems, powering smart cities, or enhancing everyday devices, FR4 remains a foundational material that connects technological possibility with practical reality. Its story is intertwined with the story of the digital age—a testament to the power of a well-designed material to shape the world around us.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB