-

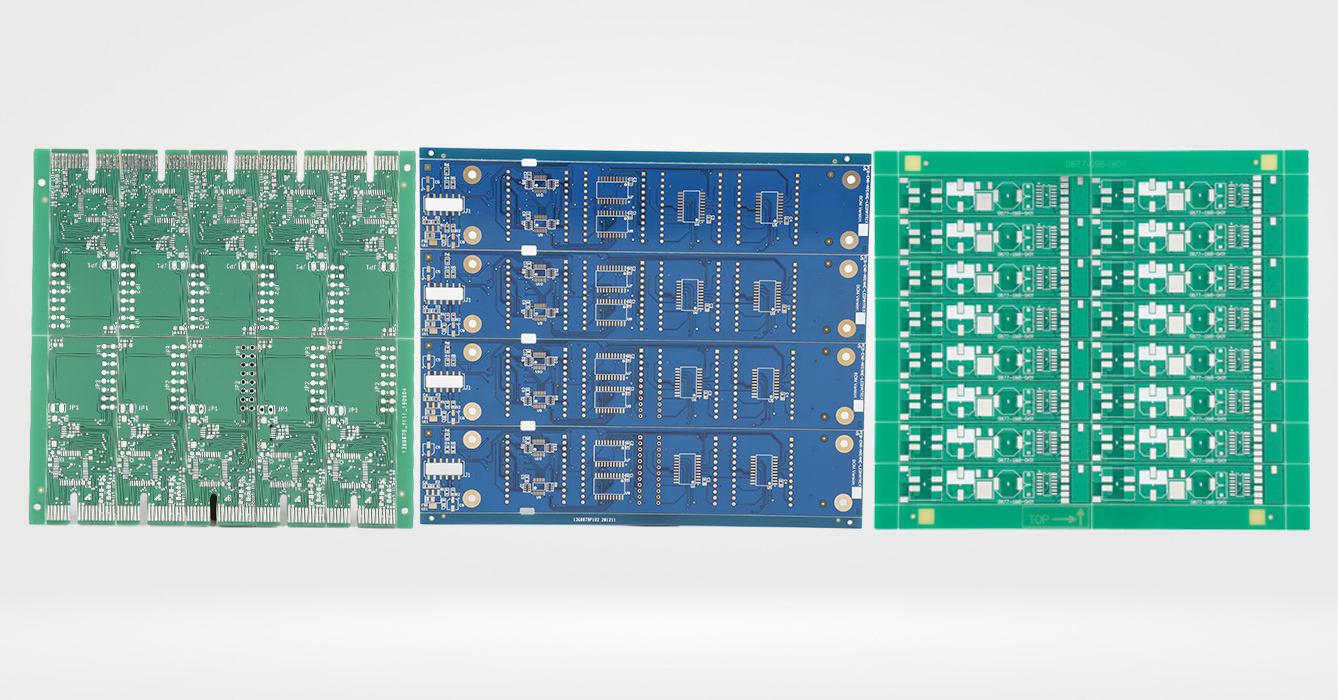

- PCB TYPE

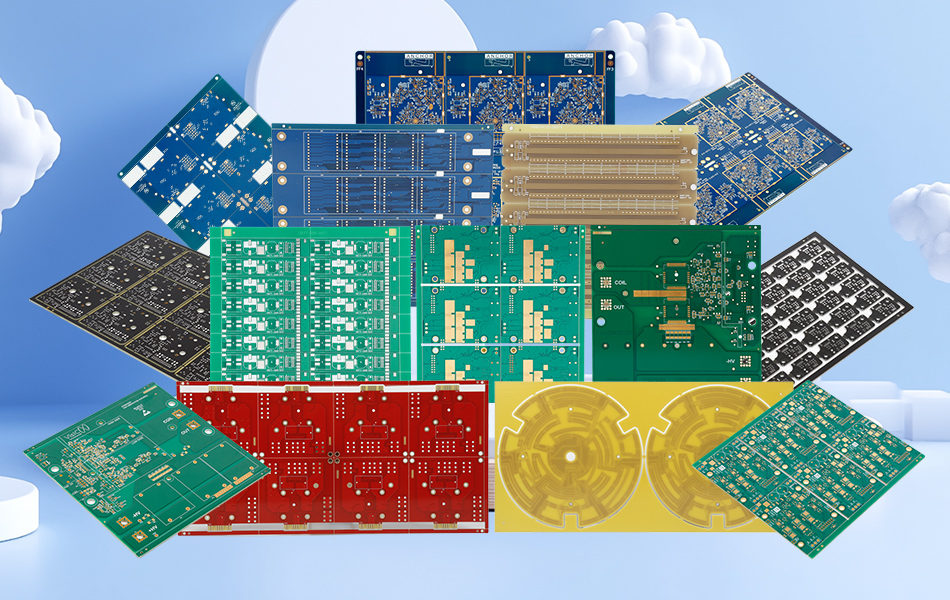

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 12. 2025, 11:50:54

In the realm of advanced printed circuit board (PCB) design, FR4-Aluminum Hybrid PCB Design has emerged as a innovative solution that combines the best properties of two distinct materials: the electrical insulation and processability of FR4 with the exceptional thermal conductivity and mechanical strength of aluminum. This hybrid approach addresses a critical challenge in modern electronics: managing increasing heat loads without sacrificing design flexibility or cost-effectiveness. Unlike traditional FR4 PCBs, which struggle with heat dissipation, or pure aluminum PCBs, which lack electrical insulation, FR4-Aluminum hybrids strike a balance that makes them ideal for power-dense applications. This article explores the intricacies of FR4-Aluminum hybrid PCB design, from its structural components and design considerations to manufacturing processes, applications, and the unique advantages it offers to engineers and manufacturers.

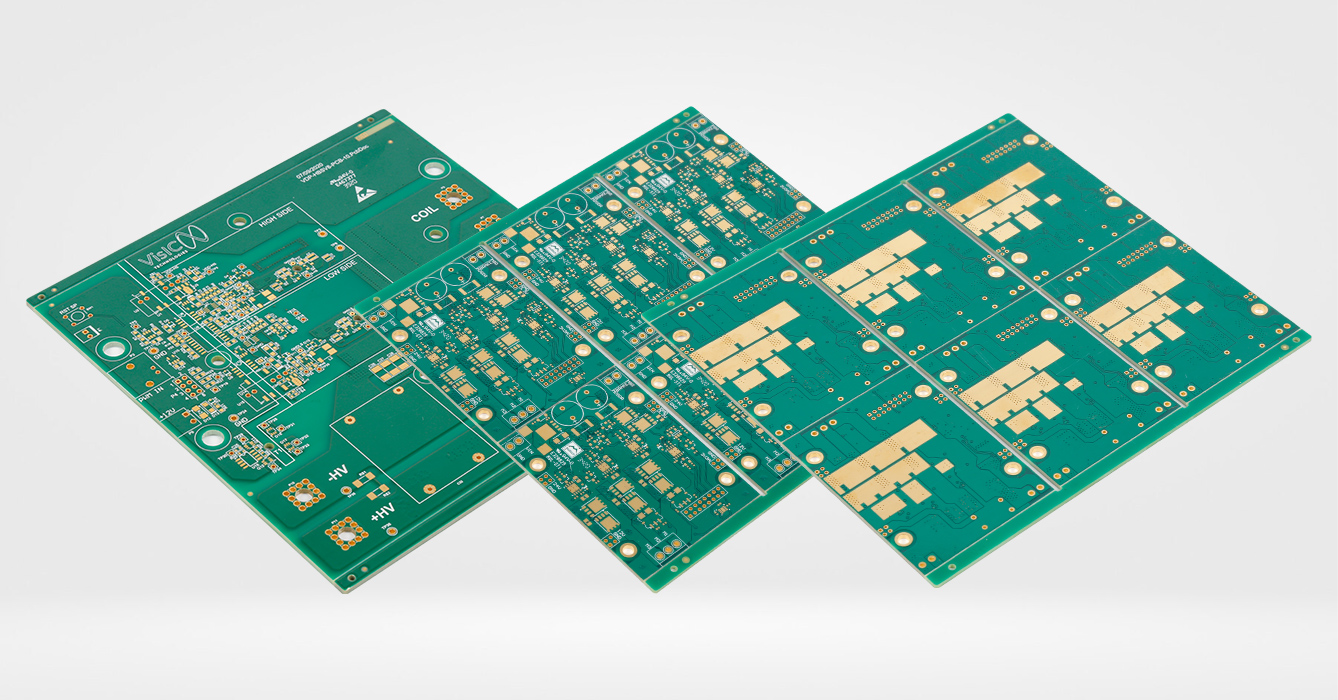

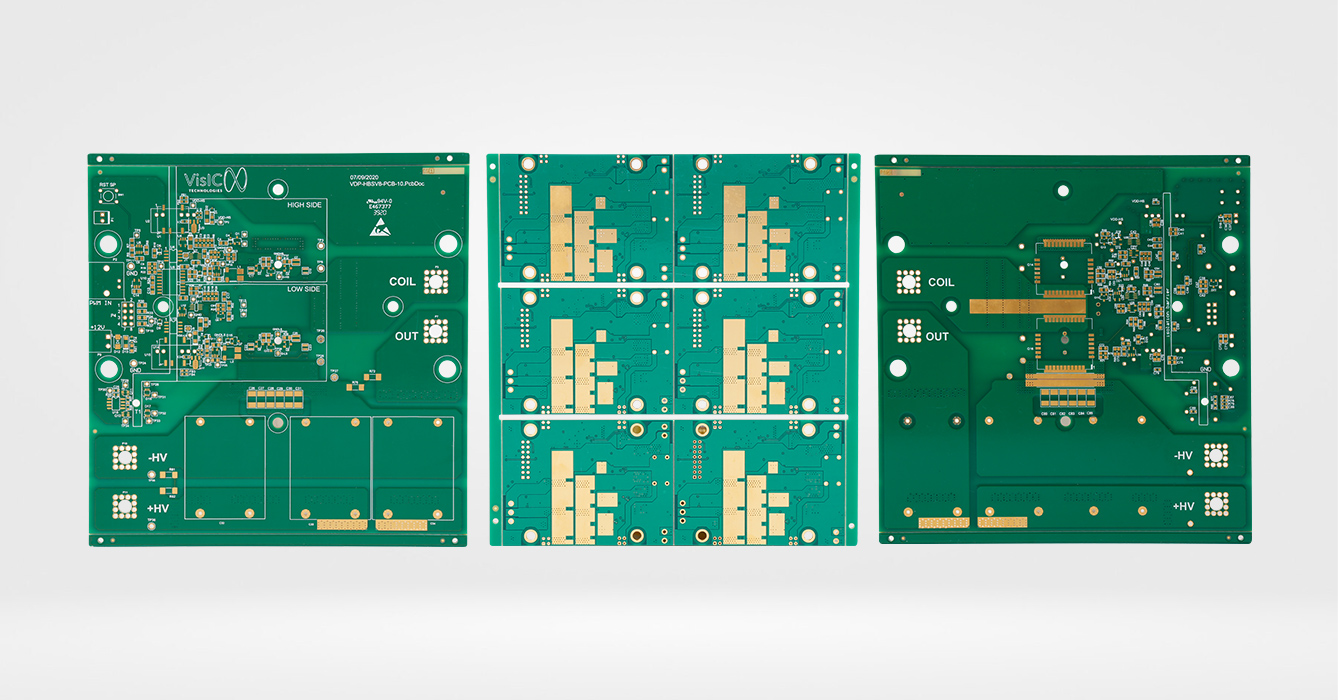

At its core, an FR4-Aluminum hybrid PCB is a layered structure that integrates FR4 and aluminum to leverage their complementary properties. The design typically consists of several key components working in tandem:

Aluminum Base Layer: Serving as the foundation, the aluminum layer acts as a heat sink, drawing thermal energy away from heat-generating components. Its high thermal conductivity ensures that heat is distributed evenly across the board, preventing hotspots that can degrade performance or shorten lifespan. The aluminum layer also adds mechanical rigidity, making the PCB more resistant to bending, vibration, and physical stress.

Insulating Layer: A thin, thermally conductive insulation layer sits between the aluminum base and the FR4, preventing electrical conduction between the metal and the circuit while allowing heat to pass through. This layer is often made from materials like epoxy resin reinforced with ceramic particles, which balance electrical insulation with thermal transfer.

FR4 Substrate: The top layer is a standard or modified FR4 laminate, which supports the copper traces, components, and solder mask. FR4 is chosen here for its excellent electrical insulation, compatibility with standard PCB manufacturing processes, and ability to support complex circuit designs. This layer may be a single sheet or multiple layers for more intricate circuits, enabling the integration of high-density components.

Copper Conductive Traces: Thin copper layers on the FR4 substrate form the electrical pathways that connect components. These traces are etched into precise patterns, with their design optimized to minimize electrical resistance while working in harmony with the thermal management capabilities of the aluminum layer.

This layered structure ensures that the PCB can handle both electrical performance and thermal management, making it suitable for applications where both factors are critical.

Designing an FR4-Aluminum hybrid PCB requires careful attention to how the two materials interact, as well as how the board will perform in its intended environment. Several critical factors guide the design process:

The primary goal of integrating aluminum is to enhance heat dissipation, so the design must prioritize thermal pathways. This includes positioning high-heat components (such as power transistors or LEDs) directly above areas of the aluminum layer to maximize heat transfer. Additionally, the thickness of the aluminum base and the thermal conductivity of the insulating layer must be matched to the expected heat load, ensuring that heat is efficiently drawn away from sensitive components.

While the aluminum layer excels at heat transfer, it is also a conductor, so the insulating layer must provide reliable electrical isolation between the aluminum and the FR4’s copper traces. The design must ensure that this layer is free from defects (such as pinholes or thin spots) that could lead to short circuits. The choice of insulating material is critical here, as it must balance thermal conductivity (to aid heat transfer) with electrical resistance (to prevent current leakage).

FR4 and aluminum have different coefficients of thermal expansion (CTE)—the rate at which they expand or contract when heated or cooled. This mismatch can cause stress at the interface between the layers during temperature cycles, leading to delamination or cracking over time. To mitigate this, designers often use intermediate layers or modified FR4 formulations with CTE values closer to aluminum, reducing stress and improving long-term reliability.

The presence of the aluminum layer influences component placement and trace routing. Heavy components (such as transformers or large capacitors) may require additional support to prevent warping, while high-speed signal traces must be routed to minimize interference, which can be more complex due to the metal base. Designers may also need to incorporate thermal vias—small holes filled with conductive material—that connect the FR4 layer to the aluminum base, further enhancing heat transfer from specific components.

FR4-Aluminum hybrid PCBs require adjustments to standard manufacturing processes, so the design must account for the capabilities of the chosen manufacturer. For example, drilling through the aluminum layer may require specialized tooling, and the lamination process must ensure strong bonding between the layers without damaging the insulating material. Designers should collaborate closely with manufacturers to ensure that the design is feasible and cost-effective to produce.

The production of FR4-Aluminum hybrid PCBs involves specialized steps that combine techniques used for traditional FR4 PCBs with processes tailored to aluminum:

The aluminum base is first cleaned and treated to remove oxides and contaminants, ensuring strong adhesion with the insulating layer. The FR4 substrate is prepared separately, with copper cladding applied to one or both sides depending on the circuit design. The insulating material—often a pre-preg or liquid epoxy with ceramic fillers—is cut to size and prepared for lamination.

The layers are stacked in order: aluminum base, insulating layer, and FR4 substrate. This assembly is then subjected to heat and pressure in a lamination press, causing the insulating material to cure and bond the layers together. The lamination parameters (temperature, pressure, and time) are carefully controlled to ensure complete curing without damaging the aluminum or FR4. This step is critical for achieving a strong, void-free bond that resists delamination.

After lamination, the board is drilled to create holes for components and vias. Drilling through aluminum requires carbide or diamond-coated tools to ensure clean cuts and prevent burring, which could interfere with electrical connections. The board is then routed to its final shape, with attention paid to maintaining the integrity of the aluminum layer, especially around edges where delamination is more likely.

The copper cladding on the FR4 layer is patterned using photolithography, where a photosensitive mask is applied and exposed to light to define the circuit traces. The unmasked copper is then etched away using chemical solutions, leaving the desired trace pattern. This process is similar to that used for standard FR4 PCBs but may require adjustments to account for the presence of the aluminum layer, which can affect etching chemical flow.

A solder mask is applied to the FR4 layer to protect copper traces from oxidation and prevent short circuits during assembly. The mask is cured using UV light, and openings are created for component pads and vias. A silkscreen layer is then printed to add component labels and identifiers, aiding in assembly and troubleshooting.

The finished PCBs undergo rigorous testing to verify electrical performance, thermal conductivity, and mechanical integrity. This includes continuity testing to ensure no short circuits between the aluminum layer and copper traces, thermal imaging to check heat distribution, and mechanical stress tests to evaluate resistance to bending and vibration. Only boards that meet all specifications proceed to assembly.

FR4-Aluminum hybrid PCBs are uniquely suited to applications where both thermal management and electrical performance are critical. Their ability to balance these factors makes them ideal for the following industries and devices:

Devices such as power supplies, inverters, and motor controllers generate significant heat due to high current flow. FR4-Aluminum hybrids efficiently dissipate this heat, ensuring stable operation and extending component life. The aluminum base acts as a built-in heat sink, reducing the need for external cooling solutions and simplifying design.

High-power LED fixtures—used in commercial lighting, automotive headlights, and outdoor floodlights—produce substantial heat that can degrade LED performance over time. FR4-Aluminum hybrid PCBs draw heat away from the LEDs, maintaining brightness and color consistency. Their compact design also allows for slimmer, more aesthetically pleasing lighting fixtures.

Vehicles contain numerous heat-generating components, from engine control units (ECUs) to infotainment systems. FR4-Aluminum hybrids are used in underhood applications where temperatures are high, as well as in cabin electronics where space is limited. Their mechanical strength also makes them resistant to the vibration and shock common in automotive environments.

Industrial equipment, such as robotics, factory automation controllers, and welding machines, operates in harsh conditions with high temperatures and mechanical stress. FR4-Aluminum hybrid PCBs withstand these environments, providing reliable performance in power-dense circuits that control motors, sensors, and actuators.

Solar inverters and wind turbine controllers convert and manage large amounts of electrical power, generating significant heat. FR4-Aluminum hybrids ensure these systems operate efficiently, even in outdoor environments with wide temperature fluctuations. Their durability also makes them suitable for remote installations where maintenance is challenging.

FR4-Aluminum hybrid PCBs offer several key benefits that make them a compelling choice for demanding applications:

By integrating aluminum’s high thermal conductivity with FR4’s electrical insulation, these PCBs provide superior heat dissipation compared to standard FR4. This reduces the risk of overheating, improving reliability and extending the lifespan of components—critical in applications like power electronics and LED lighting.

The built-in aluminum heat sink eliminates the need for separate cooling components (such as heat sinks or fans), reducing the overall size and weight of the device. This is particularly valuable in compact applications like automotive electronics and portable equipment, where space is at a premium.

The aluminum base adds rigidity, making the PCB more resistant to bending, vibration, and impact. This enhances durability in harsh environments, such as industrial settings or automotive underhood applications, where mechanical stress is common.

While FR4-Aluminum hybrids are more expensive than standard FR4 PCBs, they are often cheaper than pure aluminum PCBs or FR4 PCBs with external heat sinks. The integrated design reduces assembly costs by eliminating the need for additional cooling components, making them a cost-effective solution for medium to high-heat applications.

FR4-Aluminum hybrids retain FR4’s compatibility with standard PCB manufacturing processes, allowing for complex circuit designs with high-density components. This flexibility enables engineers to integrate both power and control circuits on a single board, simplifying system design and reducing assembly complexity.

Despite their advantages, FR4-Aluminum hybrid PCBs face several challenges that designers and manufacturers must address:

The materials and manufacturing processes for FR4-Aluminum hybrids are more expensive than those for standard FR4, making them less suitable for low-cost, low-heat applications. This cost premium can be justified in high-performance devices but may limit adoption in budget-sensitive markets.

Producing these hybrids requires specialized equipment and expertise, limiting the number of manufacturers capable of producing them at scale. This can lead to longer lead times and higher minimum order quantities, which may be prohibitive for small-scale projects.

As mentioned earlier, the CTE mismatch between FR4 and aluminum can cause reliability issues over time, especially in applications with frequent temperature cycles. While design strategies can mitigate this, they add complexity and may increase costs.

The aluminum layer is typically a solid sheet, limiting the ability to create complex shapes or cutouts without compromising structural integrity. This can restrict design flexibility in applications where space is extremely constrained or specific form factors are required.

As electronics continue to become smaller and more power-dense, FR4-Aluminum hybrid PCBs are evolving to meet new demands:

Research into next-generation insulating materials—such as nanocomposites with higher thermal conductivity and better electrical insulation—is improving heat transfer while maintaining reliability. These materials will allow for thinner insulating layers, reducing thermal resistance and enhancing performance.

3D printing techniques are being explored to produce custom aluminum bases with intricate structures (such as internal heat channels) that optimize heat dissipation. This could enable more precise thermal management tailored to specific component layouts.

Incorporating sensors into the aluminum layer to monitor temperature in real time could enable dynamic thermal management, where cooling systems (such as fans or heat pipes) are activated only when needed. This would improve efficiency in applications like server farms or electric vehicle controllers.

Manufacturers are exploring recycled aluminum and bio-based FR4 resins to reduce the environmental impact of hybrid PCBs. Additionally, processes to recycle the aluminum and FR4 layers separately at the end of the PCB’s lifecycle are being developed, supporting circular economy goals.

FR4-Aluminum Hybrid PCB Design represents a sophisticated fusion of materials, combining FR4’s electrical versatility with aluminum’s thermal and mechanical strengths. This hybrid approach addresses the growing need for efficient heat management in power-dense electronics, enabling smaller, more reliable devices across industries from automotive to renewable energy. While challenges such as manufacturing complexity and thermal expansion mismatch exist, ongoing advancements in materials and design techniques are overcoming these barriers. As electronics continue to evolve, FR4-Aluminum hybrid PCBs will play an increasingly vital role, offering a balance of performance, cost, and flexibility that is difficult to achieve with traditional materials alone. For engineers and manufacturers, understanding and leveraging this technology is key to developing the next generation of high-performance electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB