-

- PCB TYPE

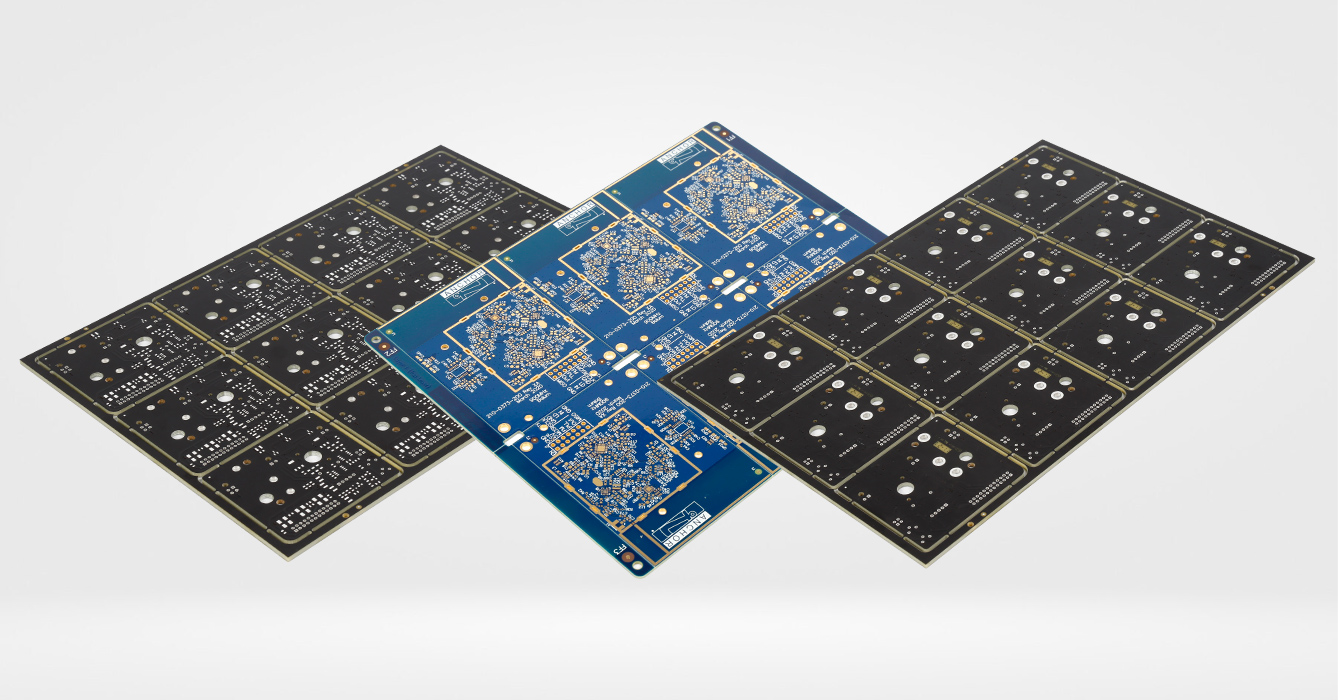

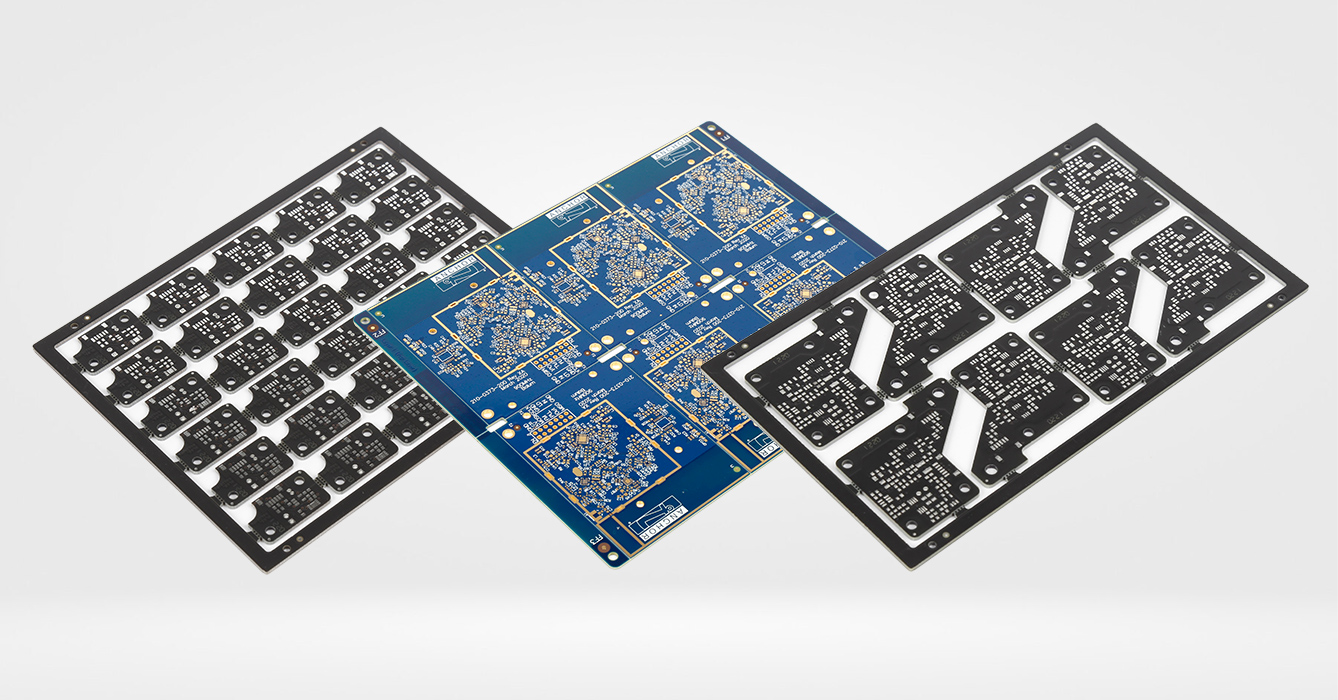

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 07. 2025, 18:37:39

FR4 PCB stands as the most widely used printed circuit board material in the electronics industry, prized for its unique blend of affordability, mechanical strength, and electrical insulation. Derived from glass-reinforced epoxy laminate, FR4 has become the backbone of devices ranging from simple consumer gadgets to complex industrial systems. Its name, "FR4," refers to its flame-retardant (FR) properties and classification under NEMA standards, where "4" denotes a woven glass reinforcement with an epoxy resin binder. This article explores the composition, manufacturing processes, performance characteristics, and diverse applications of FR4 PCB, highlighting why it remains the material of choice for engineers and manufacturers worldwide. By examining its evolution, key properties, and future trends, we uncover the enduring relevance of FR4 in an era of rapidly advancing electronics.

At its core, FR4 PCB is a composite material engineered to balance structural integrity and electrical performance. Its composition consists of three primary components:

Epoxy Resin Matrix: The binding agent in FR4, epoxy resin is a thermosetting polymer that cures into a rigid, insulating structure. Standard FR4 uses bisphenol-A epoxy, known for its excellent adhesion, chemical resistance, and electrical insulation properties (volume resistivity ≥10¹⁴ Ω·cm). Modified resins, such as bisphenol-F or novolac epoxies, are used in high-performance variants to enhance thermal stability or reduce water absorption.

Glass Fiber Reinforcement: Woven glass fibers (typically E-glass) provide mechanical strength to the laminate. These fibers are woven into fabrics with varying densities (e.g., 1080, 2116, 7628) to suit different thickness and strength requirements. E-glass offers high tensile strength (~3,400 MPa) and low thermal expansion, making it ideal for maintaining dimensional stability in PCBs.

Flame Retardants: To meet safety standards (e.g., UL94 V-0), FR4 incorporates flame-retardant additives. Traditional formulations use brominated compounds, while modern eco-friendly variants employ phosphorus-based additives to comply with RoHS and REACH regulations.

This combination creates a material that is lightweight, rigid, and resistant to heat, chemicals, and moisture—qualities that make it indispensable for PCB manufacturing.

The production of FR4 PCB involves several precise steps, each critical to ensuring the final product meets performance specifications:

Laminate Preparation: Glass fiber fabric is impregnated with epoxy resin to create "prepreg" sheets. These sheets are partially cured (B-staged) to a tacky state, allowing them to bond during lamination. Multiple prepreg layers are stacked with copper foil (0.5–10 oz thickness) to achieve the desired PCB thickness (0.2–6.4 mm).

Lamination: The stacked layers are subjected to high temperature (170–190°C) and pressure (300–500 psi) in a press. This fully cures the epoxy resin, bonding the layers into a solid laminate with copper cladding on one or both sides. Strict control of temperature and pressure prevents voids and ensures uniform thickness.

Drilling: Computer numerical control (CNC) drills create holes for vias and component leads. Drill sizes range from 0.1 mm (microvias) to several millimeters, with carbide bits used to maintain precision in the hard FR4 material.

Plating: Through-hole plating (PTH) coats the inside of drilled holes with copper, creating electrical connections between layers. Electroless copper plating first deposits a thin copper layer, followed by electrolytic plating to build up thickness (typically 20–35 μm).

Etching: A photolithographic process transfers the circuit pattern onto the copper cladding. Unwanted copper is removed using chemical etchants (e.g., ferric chloride), leaving the desired traces and pads.

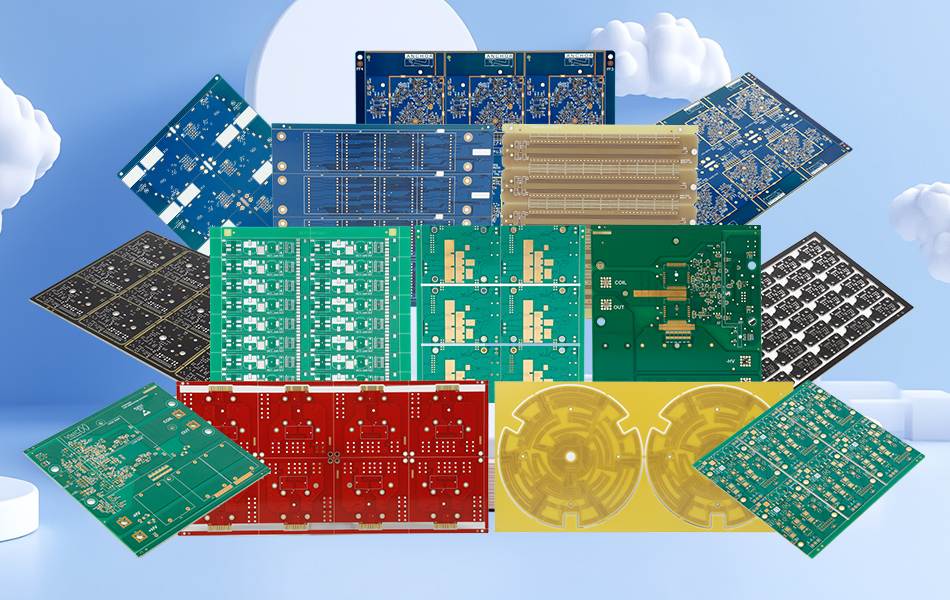

Solder Mask and Silkscreen: A protective solder mask (typically green, but available in other colors) is applied to insulate copper traces and prevent solder bridges. A silkscreen layer adds component labels and identifiers for assembly.

FR4 PCB’s popularity stems from its well-rounded set of properties, tailored to meet the needs of most electronic applications:

Mechanical Strength: FR4 exhibits high flexural strength (≥500 MPa) and modulus (≥20 GPa), allowing it to withstand handling, assembly, and operational stresses. Its rigidity minimizes warpage, critical for maintaining component alignment.

Electrical Insulation: With a dielectric constant (Dk) of 4.2–4.8 at 1 MHz and low dissipation factor (Df ≤0.02), FR4 provides excellent insulation and signal integrity for frequencies up to 1 GHz. This makes it suitable for analog and digital circuits alike.

Thermal Properties: The glass transition temperature (Tg) of standard FR4 ranges from 130–140°C, above which the material softens. High-Tg variants (150–200°C) are available for high-temperature applications. Thermal conductivity is moderate (0.2–0.3 W/mK), sufficient for low-to-moderate power dissipation.

Chemical Resistance: FR4 resists most solvents, oils, and moisture, with water absorption ≤0.15% (after 24-hour immersion). This ensures reliability in harsh environments, such as industrial or outdoor settings.

Flame Retardancy: As the "FR" in its name indicates, FR4 is self-extinguishing, meeting UL94 V-0 and IPC-4101 standards. This reduces fire risk in electronic devices.

While standard FR4 suits most needs, specialized variants address unique requirements:

High-Tg FR4: Formulated with cross-linked resins, these laminates have a Tg of 150°C or higher, maintaining stability in high-temperature environments (e.g., automotive underhood systems, industrial ovens).

Low-Dk FR4: Modified resins reduce the dielectric constant (Dk 3.8–4.2) for improved signal integrity in high-speed designs (5–10 GHz), such as 5G base stations and data center equipment.

Halogen-Free FR4: Uses phosphorus-based flame retardants instead of bromine, complying with environmental regulations for medical, automotive, and consumer electronics.

High-Strength FR4: Reinforced with S-glass or carbon fiber, these variants offer enhanced mechanical properties for aerospace and military applications, where durability is critical.

Thin-Core FR4: Laminates as thin as 0.1 mm enable flexible PCBs (flex-rigid designs) for wearable devices and compact electronics.

FR4 PCB’s versatility makes it suitable for a vast range of applications across industries:

Consumer Electronics: Smartphones, laptops, TVs, and home appliances rely on FR4 for their main PCBs, leveraging its cost-effectiveness and reliable performance.

Industrial Automation: Programmable logic controllers (PLCs), motor drives, and sensors use FR4 PCBs for their resistance to vibration and temperature fluctuations.

Automotive Electronics: Infotainment systems, navigation units, and body control modules utilize standard FR4, while underhood components often opt for high-Tg variants to withstand elevated temperatures.

Medical Devices: Diagnostic equipment, patient monitors, and wearable health trackers use FR4 for its biocompatibility (when paired with appropriate coatings) and reliability.

Telecommunications: Routers, switches, and base stations depend on FR4 (and low-Dk variants) for stable signal transmission in network infrastructure.

Aerospace and Defense: Non-critical avionics and military electronics use FR4 for its balance of performance and cost, with high-strength variants employed in harsh environments.

Engineers must account for FR4’s properties when designing PCBs to maximize performance and reliability:

Trace Width and Spacing: To handle current and prevent crosstalk, trace widths are calculated based on current capacity (e.g., 1 oz copper requires 0.2 mm width for 1 A). Spacing between traces is determined by voltage and signal frequency, with minimum distances often specified by IPC standards.

Via Design: Vias (through-hole, blind, or buried) must be sized to accommodate component leads and ensure reliable plating. High-Tg FR4 allows for smaller vias due to improved thermal stability during soldering.

Thermal Management: For components generating >5W, thermal vias, copper pours, and heat sinks complement FR4’s moderate thermal conductivity to prevent overheating.

Impedance Control: In high-speed designs, trace dimensions and dielectric thickness are optimized to achieve target impedance (e.g., 50 Ω for RF signals), leveraging FR4’s stable Dk.

Mechanical Constraints: FR4’s rigidity requires careful placement of mounting holes and consideration of thermal expansion to avoid stress on solder joints during temperature cycling.

Rigorous testing ensures FR4 PCBs meet industry standards and application requirements:

Electrical Testing: Continuity, insulation resistance, and hipot tests verify proper conductivity and insulation between traces.

Mechanical Testing: Flexural strength, peel strength (copper adhesion), and thermal shock tests validate structural integrity.

Environmental Testing: Moisture resistance (IPC-TM-650 2.6.2), temperature cycling (-40°C to +125°C), and vibration testing ensure reliability in harsh conditions.

Microsection Analysis: Cross-sectional examination of vias and layers checks for voids, delamination, and proper plating.

Signal Integrity Testing: Time-domain reflectometry (TDR) and network analyzers evaluate impedance and signal loss in high-speed designs.

While highly versatile, FR4 has limitations that may require alternative materials in specific scenarios:

High-Temperature Applications: Above 150°C, standard FR4 softens, making high-Tg variants or ceramics more suitable for extreme heat environments (e.g., downhole oil tools).

Ultra-High-Speed Signals: Frequencies >10 GHz suffer from increased loss in FR4, necessitating PTFE or ceramic laminates for mmWave applications (e.g., 5G mmWave antennas).

Flexibility Requirements: Rigid FR4 is unsuitable for bendable electronics, where flexible materials like polyimide are preferred.

Ultra-High Power: Components generating >50W require metal-core PCBs or ceramics to dissipate heat, as FR4’s thermal conductivity is insufficient.

Innovation continues to enhance FR4’s capabilities, expanding its applicability:

Sustainable Materials: Bio-based epoxies derived from plant oils and recycled glass fibers are being integrated into FR4 formulations to reduce environmental impact.

Enhanced Thermal Conductivity: Nano-fillers (graphene, boron nitride) are being added to epoxy resins to boost thermal conductivity (0.4–0.6 W/mK) without sacrificing electrical insulation.

Additive Manufacturing: 3D printing of FR4-like materials (epoxy resins with glass fillers) enables rapid prototyping of complex PCB geometries, reducing development time.

Smart FR4 PCBs: Integration of sensors (e.g., temperature, strain) directly into the laminate allows for real-time monitoring of PCB health in critical applications.

FR4 PCB’s enduring dominance in the electronics industry is a testament to its exceptional balance of cost, performance, and versatility. From consumer gadgets to industrial systems, it provides a reliable foundation for electronic circuits, adapting to evolving needs through specialized variants and manufacturing innovations. While alternatives exist for extreme applications, FR4 remains the material of choice for the majority of PCB designs, offering a pragmatic solution that meets the demands of modern electronics. As material science advances, FR4 is poised to evolve further, incorporating sustainable materials and enhanced properties to maintain its role as the workhorse of the industry. For engineers and manufacturers, understanding FR4’s capabilities and limitations is key to designing robust, cost-effective electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB