-

- PCB TYPE

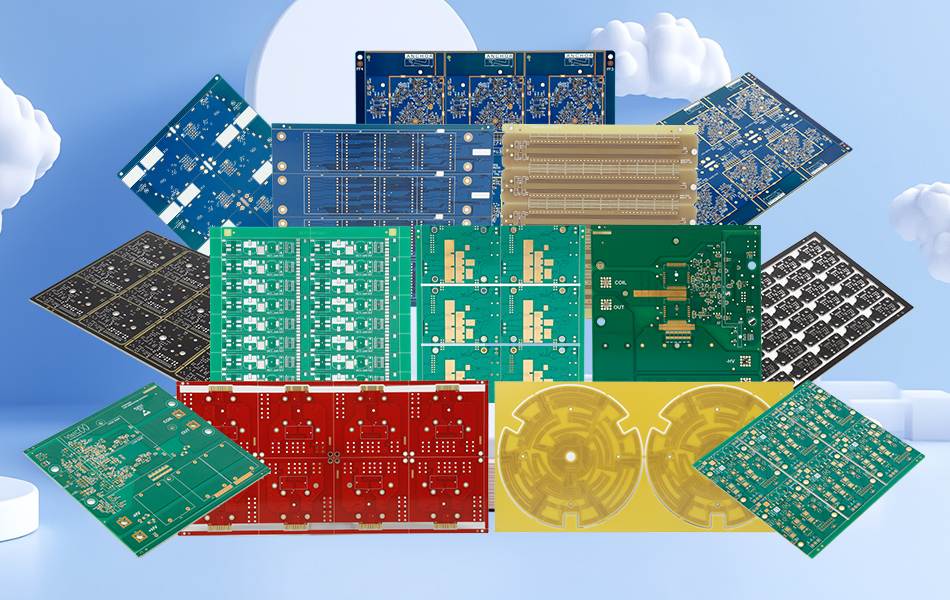

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 07. 2025, 18:34:18

Thermal conductivity is a defining characteristic of FR4 PCBs, dictating their ability to dissipate heat and maintain reliability in electronic devices. As power densities rise and form factors shrink, understanding FR4 PCB thermal conductivity becomes increasingly critical for engineers and manufacturers. FR4, the workhorse of printed circuit boards, typically exhibits a thermal conductivity range of 0.2–0.3W/mK, a value that balances cost, manufacturability, and performance for most low-to-moderate power applications. This article explores the science behind FR4 PCB thermal conductivity, its impact on device operation, factors influencing its efficiency, and strategies to optimize heat transfer within the constraints of this material. By demystifying this key parameter, we aim to equip designers with the knowledge to make informed decisions when selecting and utilizing FR4 PCBs in heat-sensitive applications.

Thermal conductivity (often denoted as k) measures a material’s ability to conduct heat through conduction, expressed in watts per meter-kelvin (W/mK). For FR4 PCBs, this property is determined by the material’s composite structure: a matrix of epoxy resin reinforced with glass fibers. Epoxy resin, with a low thermal conductivity of ~0.1–0.2W/mK, acts as an insulator, while glass fibers (typically E-glass) contribute ~1.0–1.2W/mK, creating a heterogeneous material with an effective thermal conductivity of 0.2–0.3W/mK.

This value—0.2–0.3W/mK—means that under steady-state conditions, 0.2 to 0.3 joules of heat will flow per second through a 1-square-meter cross-section of FR4 when there is a 1-kelvin temperature difference between two points. In practical terms, this limits FR4’s ability to dissipate heat over long distances, making it suitable for components generating up to 5W of power but requiring supplemental cooling for higher loads. Understanding this baseline is essential for designing PCBs that avoid overheating and ensure long-term reliability.

FR4 PCB thermal conductivity directly impacts three critical aspects of device operation:

Component Reliability: Electronic components (e.g., microprocessors, LEDs, transistors) have maximum operating temperatures (typically 85–125°C). Poor thermal conductivity in FR4 can lead to localized hotspots, accelerating component degradation and shortening lifespan. For example, a 3W LED on a low-conductivity FR4 PCB may exceed its safe temperature by 20–30°C without additional cooling.

Signal Integrity: Elevated temperatures alter the dielectric properties of FR4, increasing signal loss and impedance mismatch in high-speed designs. Thermal conductivity ensures heat is distributed evenly, maintaining stable dielectric constant (Dk) and dissipation factor (Df) across the PCB.

Mechanical Stability: Excessive heat can cause FR4 to approach its glass transition temperature (Tg), leading to dimensional changes and warpage. Effective thermal conductivity prevents temperature-induced stress on solder joints and vias, reducing the risk of cracks or delamination.

Several factors shape the thermal conductivity of FR4 PCBs, from material composition to manufacturing processes:

Resin Type: Epoxy resins form the matrix of FR4, and their chemical structure affects thermal performance. Standard bisphenol-A epoxies have lower conductivity (~0.15W/mK) compared to modified resins (e.g., bisphenol-F or novolac-based), which can reach ~0.2W/mK due to more ordered molecular structures that facilitate phonon (heat-carrying particle) propagation.

Glass Fiber Properties: E-glass, the most common reinforcement, has a thermal conductivity of ~1.1W/mK. Alternatives like S-glass (~1.4W/mK) or quartz (~1.3W/mK) offer modest improvements but increase cost. Fiber weave density also plays a role: tighter weaves (e.g., 1080) reduce gaps between fibers, creating more continuous thermal pathways.

Filler Additions: While standard FR4 contains minimal fillers, some variants include inorganic particles (e.g., silica, alumina) to reduce thermal expansion. These fillers, with higher conductivity than epoxy, can marginally boost overall thermal conductivity to 0.3–0.4W/mK when added at 10–20% by weight.

Lamination Quality: Voids or poor bonding between resin and fibers act as thermal barriers. High-pressure lamination (300–400 psi) during manufacturing minimizes voids, ensuring better heat transfer through the laminate.

Copper Cladding: While copper itself has high thermal conductivity (~401W/mK), its role in FR4 PCBs is indirect. Thick copper layers (2–4 oz) spread heat laterally across the PCB surface, complementing the laminate’s conductivity by distributing energy from hot components to cooler areas.

Accurate measurement of FR4 PCB thermal conductivity is essential for validating performance and comparing materials. Key methods include:

Laser Flash Analysis (LFA): The gold standard for composite materials, LFA measures the time it takes for heat to propagate through a sample after a laser pulse. It provides both in-plane and through-thickness conductivity, critical for understanding heat flow in multi-layer PCBs.

Hot Disk Method: A transient technique using a heated sensor sandwiched between two PCB samples. It calculates conductivity by monitoring temperature decay, offering a balance of accuracy and speed for quality control.

Guard Ring Method: Used for through-thickness measurements, this method applies heat to one side of the PCB and measures temperature rise on the opposite side, accounting for edge losses with a "guard ring" to ensure one-dimensional heat flow.

Thermal Imaging: While not a direct measurement, infrared (IR) cameras visualize temperature distributions on operating PCBs, helping identify hotspots and validate the effectiveness of thermal management strategies.

FR4 PCB thermal conductivity interacts with other material properties, creating tradeoffs that designers must navigate:

Thermal Conductivity vs. Tg: High glass transition temperature (Tg) FR4 variants (≥170°C) use cross-linked resins that enhance thermal stability but may slightly reduce conductivity (~0.25W/mK vs. 0.3W/mK for standard FR4). This tradeoff is acceptable for high-temperature applications where stability outweighs heat dissipation.

Thermal Conductivity vs. Electrical Insulation: FR4’s epoxy matrix provides excellent electrical insulation (volume resistivity ≥10¹⁴ Ω·cm), but additives to boost thermal conductivity (e.g., conductive fillers) can compromise insulation. Designers must ensure fillers remain non-conductive (e.g., alumina, BN) to avoid short circuits.

Thermal Conductivity vs. Mechanical Strength: Fiberglass reinforcement enhances FR4’s flexural strength (≥500MPa) but creates thermal resistance at the resin-fiber interface. Balancing fiber content (typically 50–60% by weight) ensures both strength and reasonable heat transfer.

FR4’s 0.2–0.3W/mK thermal conductivity is well-suited for applications with low-to-moderate heat generation:

Consumer Electronics: Smartphones, tablets, and wearables with low-power processors (1–3W) rely on FR4’s conductivity, augmented by device casings that act as passive heat sinks.

IoT Sensors: Low-power microcontrollers (≤1W) in environmental or industrial sensors operate within FR4’s thermal limits, with ambient airflow providing additional cooling.

Office Equipment: Printers, scanners, and routers use FR4 PCBs for their control electronics, where heat generation is dispersed across multiple low-power components.

LED Lighting (Low-Power): Residential LED bulbs (≤3W) dissipate heat effectively through FR4, eliminating the need for heat sinks in compact designs.

For high-power applications, FR4’s limited thermal conductivity becomes a constraint:

Power Electronics: Motor drives, inverters, and DC-DC converters with 10–50W components generate excessive heat, leading to hotspots that degrade performance.

High-Performance Computing: Servers and GPUs with 20–100W processors require active cooling (fans, liquid loops) to compensate for FR4’s inefficiency.

Automotive Underhood Systems: Engine control units (ECUs) and battery management systems (BMS) operate in high ambient temperatures, amplifying the need for enhanced heat dissipation.

In these cases, designers must combine FR4 with thermal management strategies or switch to materials with higher conductivity (e.g., thermally enhanced FR4, metal-core PCBs).

While FR4’s thermal conductivity is fixed, designers can implement strategies to maximize heat dissipation:

Thermal Vias: Plated through-holes filled with conductive epoxy create vertical pathways from hot components to internal or bottom-layer copper planes. A 3x3 array of 0.3mm vias can reduce thermal resistance by 40–50%, directing heat away from sensitive components.

Copper Pour Design: Large, continuous ground or power planes act as heat spreaders, distributing energy across the PCB. A 50mm x 50mm 1oz copper pour on FR4 can dissipate 2–3W with a temperature rise of <20°C above ambient.

Component Placement: Locating hot components near PCB edges or cutouts allows heat to escape via convection. Separating high-power devices by 10–15mm prevents cumulative heating, leveraging FR4’s conductivity to limit cross-talk.

Thermally Conductive Adhesives: Bonding heat sinks to copper pours using adhesives with 1–2W/mK conductivity bridges the gap between FR4 and the heat sink, reducing interface resistance.

Conformal Coating: Thin layers of thermally conductive silicone coating (0.8–1.2W/mK) protect the PCB while slightly enhancing heat transfer to the environment, useful in dusty or humid conditions.

For applications exceeding FR4’s capabilities, alternatives offer higher thermal conductivity but with tradeoffs:

Thermally Enhanced FR4: Modified with ceramic fillers (alumina, boron nitride), these variants achieve 0.5–1.0W/mK, costing 20–30% more than standard FR4. Ideal for 5–20W components in industrial sensors and LED drivers.

Metal-Core PCBs (MCPCBs): Aluminum or copper cores provide 1–2W/mK conductivity, excelling for high-power LEDs (10–50W). However, they are limited to 1–2 layers and cost 2–3x more than FR4.

Ceramic Substrates: Alumina (30W/mK) and aluminum nitride (200W/mK) offer superior conductivity for >50W applications but are brittle, expensive, and restricted to simple designs.

Copper-Clad Invar: Invar cores with copper cladding provide ~10W/mK conductivity and low thermal expansion, used in aerospace and precision electronics at 5–10x FR4’s cost.

Research is focused on enhancing FR4’s thermal conductivity while preserving its advantages:

Nano-Filler Integration: Graphene or carbon nanotubes (CNTs) dispersed in epoxy create conductive networks, targeting 0.4–0.5W/mK. Lab tests show 30–60% improvements, with commercialization expected by 2027.

Bio-Based Epoxies: Plant-derived resins combined with natural fillers (e.g., rice husk ash) aim to match standard FR4’s conductivity (~0.3W/mK) with lower environmental impact.

3D Woven Fibers: Advanced weaving techniques create continuous glass networks, reducing thermal barriers and boosting conductivity to 0.35–0.4W/mK without sacrificing strength.

FR4 PCB thermal conductivity—typically 0.2–0.3W/mK—strikes a critical balance between performance and practicality for most electronic applications. While it limits heat dissipation in high-power scenarios, its cost-effectiveness, processability, and compatibility with standard manufacturing make it indispensable. By understanding the factors influencing thermal conductivity and implementing optimization strategies (thermal vias, copper pours, strategic placement), designers can maximize FR4’s potential in low-to-moderate power devices. As material science advances, enhanced FR4 variants with higher conductivity will expand its capabilities, ensuring it remains a cornerstone of PCB design. For engineers, mastering FR4’s thermal properties is key to creating reliable, efficient electronics in an increasingly power-dense world.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB