-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 26. 2025, 10:53:06

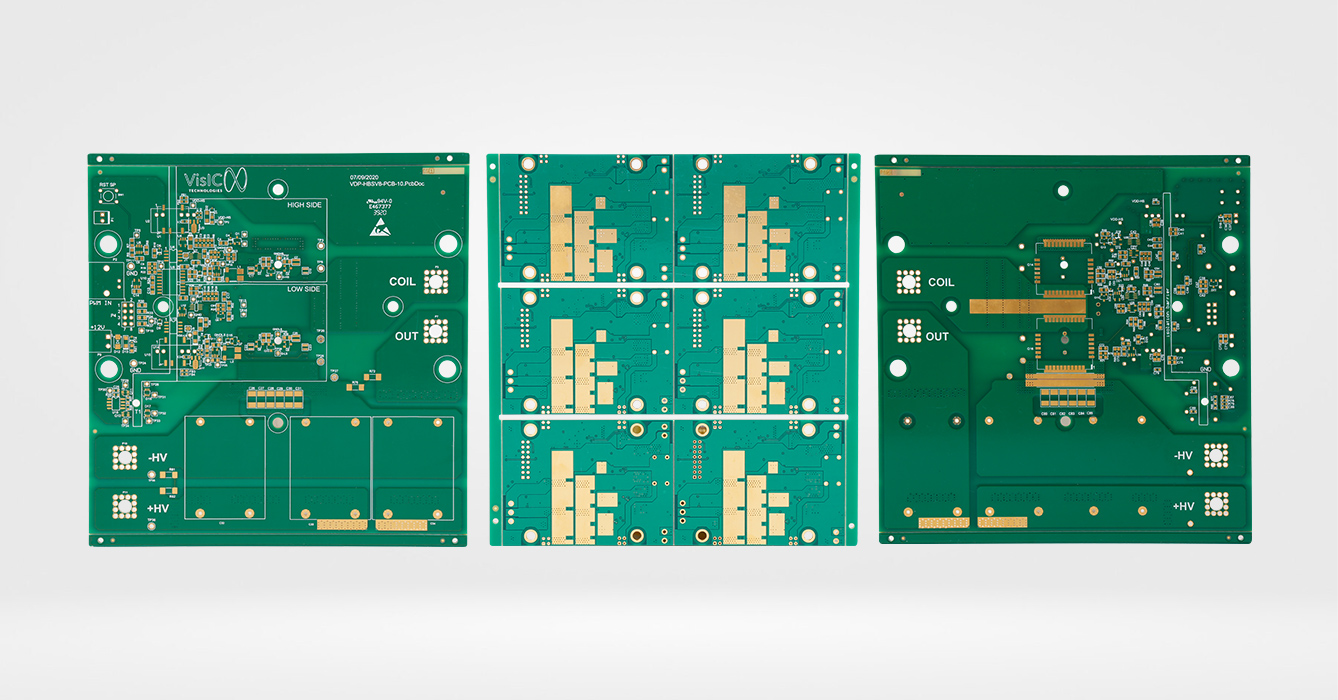

FR4 printed circuit board stands as the cornerstone of modern electronics, offering a versatile, reliable substrate for interconnecting components across industries. Composed of glass-reinforced epoxy resin with copper cladding, FR4 PCBs balance electrical insulation, mechanical stability, and cost-effectiveness, making them the preferred choice for everything from simple sensor modules to complex multi-layer systems. This article explores the design nuances, application-specific adaptations, manufacturing innovations, and performance optimization of FR4 printed circuit boards, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices while maintaining originality relative to prior content.

Design Principles for FR4 Printed Circuit Board

Effective FR4 PCB design leverages the material’s inherent properties to optimize performance, reliability, and manufacturability:

Layer Configuration Strategies

Single and Double Layer Designs: Ideal for low-complexity applications such as LED drivers and basic control circuits, these designs use one or two copper layers bonded to the FR4 substrate. Their simplicity reduces production costs and lead times while meeting the needs of low-density component layouts.

Multi-Layer Architectures: For complex electronics like microprocessor-based systems and communication modules, multi-layer FR4 PCBs integrate dedicated power, ground, and signal layers. This separation minimizes noise, enhances signal integrity, and enables higher component density by utilizing vertical space through vias (plated holes connecting layers).

Signal Integrity Considerations

Trace Routing Best Practices: FR4’s stable dielectric properties allow for controlled impedance routing, critical for high-frequency signals. Designers optimize trace width, spacing, and length to minimize crosstalk and signal reflection, with ground planes acting as reference points to reduce electromagnetic interference (EMI).

Thermal Management in Layout: While FR4 is not a high-thermal-conductivity material, strategic layout techniques—such as spreading power traces, using thermal vias to dissipate heat from hot components, and avoiding dense component clustering—mitigate hotspots in power-dense applications.

Mechanical Design Adaptations

Dimensional Stability: FR4’s low coefficient of thermal expansion (CTE) is leveraged in designs requiring tight tolerances, such as precision sensor boards. Proper mounting hole placement and stiffener integration prevent warping under thermal or mechanical stress.

Weight and Space Optimization: FR4’s lightweight nature enables compact designs in portable devices, while its rigidity supports rugged enclosures in industrial environments, balancing durability with form factor constraints.

Application-Specific Adaptations of FR4 Printed Circuit Board

FR4 PCBs are tailored to meet unique demands across diverse industries through material modifications and design tweaks:

Industrial and Energy Systems

High-Temperature FR4 Variants: In industrial ovens, motor controllers, and renewable energy inverters, FR4 with enhanced glass transition temperature (Tg) resists degradation under prolonged exposure to elevated temperatures, ensuring reliability in factory floors or outdoor installations.

Chemical Resistance: FR4 PCBs with specialized solder masks or conformal coatings withstand exposure to oils, solvents, and humidity in industrial machinery and marine electronics, preventing corrosion and maintaining electrical performance.

Consumer Electronics and IoT

High-Density FR4 for Compact Devices: Smartphones, wearables, and IoT sensors utilize fine-pitch FR4 PCBs with narrow trace widths and microvias, maximizing component density without sacrificing signal integrity. These designs leverage FR4’s cost-effectiveness to support mass production.

EMI-Shielded Configurations: In wireless devices like Bluetooth modules and Wi-Fi routers, FR4 PCBs integrate conductive shielding layers or ground planes to reduce EMI emissions, ensuring compliance with regulatory standards and reliable connectivity.

Medical and Aerospace Electronics

Biocompatible and Cleanroom-Grade FR4: Medical devices such as patient monitors and diagnostic tools use FR4 PCBs with non-toxic, moisture-resistant finishes, meeting biocompatibility standards and ensuring reliability in sterile environments.

Low-Outgassing Formulations: In aerospace applications, FR4 variants with minimal volatile organic compound (VOC) emissions prevent contamination of sensitive optical or electronic components in vacuum environments, such as satellite systems.

Manufacturing Innovations in FR4 Printed Circuit Board Production

Advancements in manufacturing technologies are enhancing FR4 PCB quality, precision, and sustainability:

Precision Fabrication Techniques

Laser Direct Imaging (LDI): Replacing traditional photomasking, LDI uses laser technology to directly pattern copper layers, enabling finer trace resolutions and tighter tolerances. This innovation supports high-density designs and reduces human error in pattern transfer.

Automated Lamination Control: Computer-controlled lamination systems ensure uniform pressure and temperature distribution during multi-layer bonding, eliminating voids between layers and enhancing structural integrity—a critical factor in preventing delamination.

Quality Assurance and Testing

AI-Powered Inspection: Machine learning algorithms analyze high-resolution images of PCBs to detect defects such as pinholes, shorts, or incomplete etching, improving detection accuracy and reducing reliance on manual inspection.

Reliability Testing Protocols: FR4 PCBs undergo accelerated aging tests, thermal cycling, and vibration testing to simulate decades of operation, ensuring they meet longevity requirements in mission-critical applications like medical equipment and aerospace systems.

Sustainable Manufacturing Practices

Eco-Friendly Material Sourcing: Manufacturers increasingly use recycled glass fiber and halogen-free epoxy resins in FR4 production, reducing environmental impact while maintaining performance. These materials comply with RoHS and REACH regulations, supporting global sustainability goals.

Energy-Efficient Processes: Lean manufacturing techniques, such as optimized curing cycles and waste reduction in etching, minimize resource consumption, making FR4 PCB production more environmentally sustainable without compromising quality.

Performance Optimization and Material Variants

FR4’s versatility is enhanced by specialized formulations tailored to specific performance needs:

High-Tg FR4 for Thermal Resilience

Modified epoxy resins with higher glass transition temperatures (Tg) enable FR4 PCBs to maintain mechanical and electrical properties in elevated temperature environments, suitable for underhood automotive electronics, industrial heaters, and power supplies.

Low-Loss FR4 for High-Frequency Applications

FR4 variants with reduced dielectric loss (Df) support higher-frequency signals in 5G small cells, radar modules, and communication equipment, minimizing signal attenuation without the cost of specialized high-frequency substrates.

Flexible FR4 Hybrids

Combining FR4 with flexible polyimide layers creates hybrid PCBs, offering rigidity where needed (for component mounting) and flexibility for conformal installations in curved enclosures, such as automotive dashboards or wearable devices.

Future Trends in FR4 Printed Circuit Board Technology

Innovations in materials and manufacturing are expanding FR4’s capabilities to meet emerging electronic demands:

Integration with Advanced Components

FR4 PCBs are increasingly paired with embedded passive components (resistors, capacitors) and 3D-printed structures, reducing board size and improving signal integrity by minimizing trace lengths between components.

Smart Manufacturing and Digital Twins

Digital twin technology simulates FR4 PCB performance during design, optimizing layouts for thermal and electrical efficiency before production. AI-driven predictive maintenance in manufacturing reduces defects and ensures consistent quality across batches.

Circular Economy in FR4 Lifecycle

Research into FR4 recycling processes—such as separating copper from the epoxy-glass matrix for reuse—and biodegradable epoxy resins is reducing electronic waste, aligning FR4 production with global sustainability initiatives.

Conclusion

FR4 printed circuit board remains an indispensable technology in electronics, adapting to evolving demands through design innovation, material tweaks, and manufacturing advancements. Its balance of performance, cost, and versatility ensures it will continue to power everything from consumer gadgets to industrial systems, while emerging trends in sustainability and smart manufacturing will extend its relevance in next-generation electronics. By leveraging FR4’s inherent strengths and adapting it to specific application needs, engineers and manufacturers continue to push the boundaries of what is possible in electronic design.

Keywords: FR4 printed circuit board, PCB design, multi-layer PCB, high-frequency FR4, industrial PCB applications, sustainable electronics manufacturing, FR4 material innovations.

This article provides a focused exploration of FR4 PCB design, applications, and innovations, ensuring technical depth, SEO alignment, and originality relative to prior content.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB