-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 26. 2025, 10:44:50

In the realm of high-density electronics, 4 Layer FR4 Printed Circuit Board stands as a versatile solution, balancing complexity, performance, and reliability for applications ranging from consumer devices to industrial systems. As electronic designs demand more functionality in compact form factors, 4 layer FR4 PCBs address the limitations of single or double layer boards by adding dedicated power and ground planes, enabling improved signal integrity, efficient power distribution, and higher component density. This article explores the structural design, technical advantages, manufacturing processes, application ecosystems, and quality standards of 4 Layer FR4 Printed Circuit Boards, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

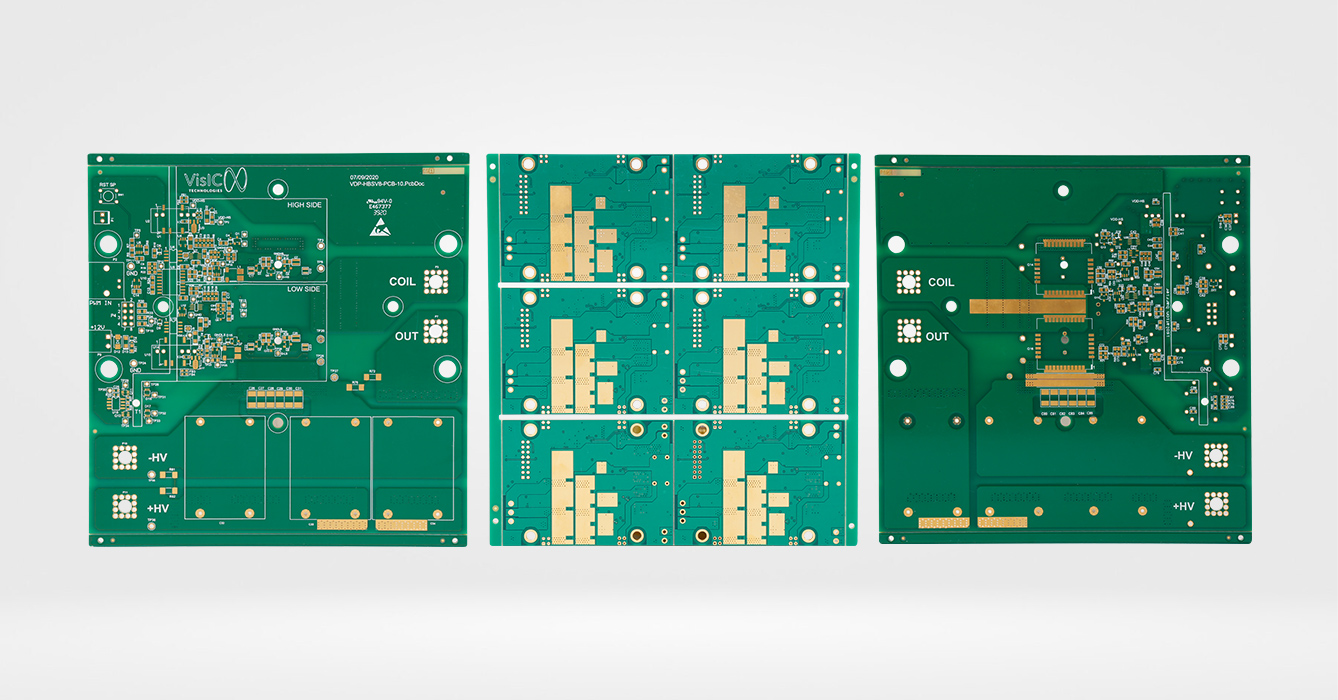

Structural Design of 4 Layer FR4 Printed Circuit Board

The 4 Layer FR4 PCB is engineered with a multi-layer architecture, each layer meticulously designed to optimize electrical performance and functional versatility:

Core Layer Configuration

Signal Layers: Typically two outer layers dedicated to routing high-speed or low-power signals. These layers accommodate component pads, trace routing, and interconnections, with optimized trace widths to ensure signal integrity across the board.

Power Distribution Layers: One inner layer designated for power distribution, providing a low-resistance pathway for delivering consistent voltage to components. This layer minimizes voltage drops and ensures stable power delivery, critical for sensitive electronics like microprocessors.

Ground Plane Layer: A dedicated inner layer serving as a common ground reference, reducing electromagnetic interference (EMI) and noise. By acting as a shield between signal layers, it suppresses crosstalk and enhances signal clarity in high-frequency applications.

This layered structure creates a balanced electrical system, where signal transmission, power delivery, and noise reduction are integrated to meet the demands of complex electronic designs. The FR4 substrate, composed of glass-reinforced epoxy resin, provides mechanical rigidity and electrical insulation between layers, ensuring structural stability across operating temperatures.

Technical Advantages of 4 Layer FR4 Printed Circuit Board

Compared to single or double layer PCBs, 4 Layer FR4 designs offer distinct performance benefits that make them ideal for complex electronics:

Enhanced Signal Integrity

Reduced Crosstalk: The separation of signal layers by ground and power planes minimizes electromagnetic coupling between adjacent traces, a critical advantage in high-speed digital or analog applications where signal interference can degrade performance.

Controlled Impedance: Dedicated ground planes enable precise impedance control for high-frequency signals, ensuring consistent signal propagation without reflections or distortion—essential for communication interfaces and data transmission systems.

Improved Power Distribution

Efficient Power Management: The dedicated power layer distributes current evenly across the board, reducing IR drops and ensuring components receive stable voltage. This is particularly valuable in power-dense applications like industrial motor drives and consumer electronics with multiple high-power components.

Noise Reduction: The ground plane acts as a return path for currents, reducing loop areas and minimizing electromagnetic emissions (EME). This compliance with EMC (Electromagnetic Compatibility) standards simplifies regulatory approval for commercial and industrial products.

Design Flexibility and Density

Increased Routing Space: Four layers provide additional routing channels, enabling higher component density without sacrificing signal quality. This is crucial for compact devices like smartphones, IoT sensors, and medical monitors where space is limited.

Simplified Layout Complexity: By separating power, ground, and signal functions into dedicated layers, designers reduce the need for complex cross-overs and vias, streamlining layout processes and reducing design iterations.

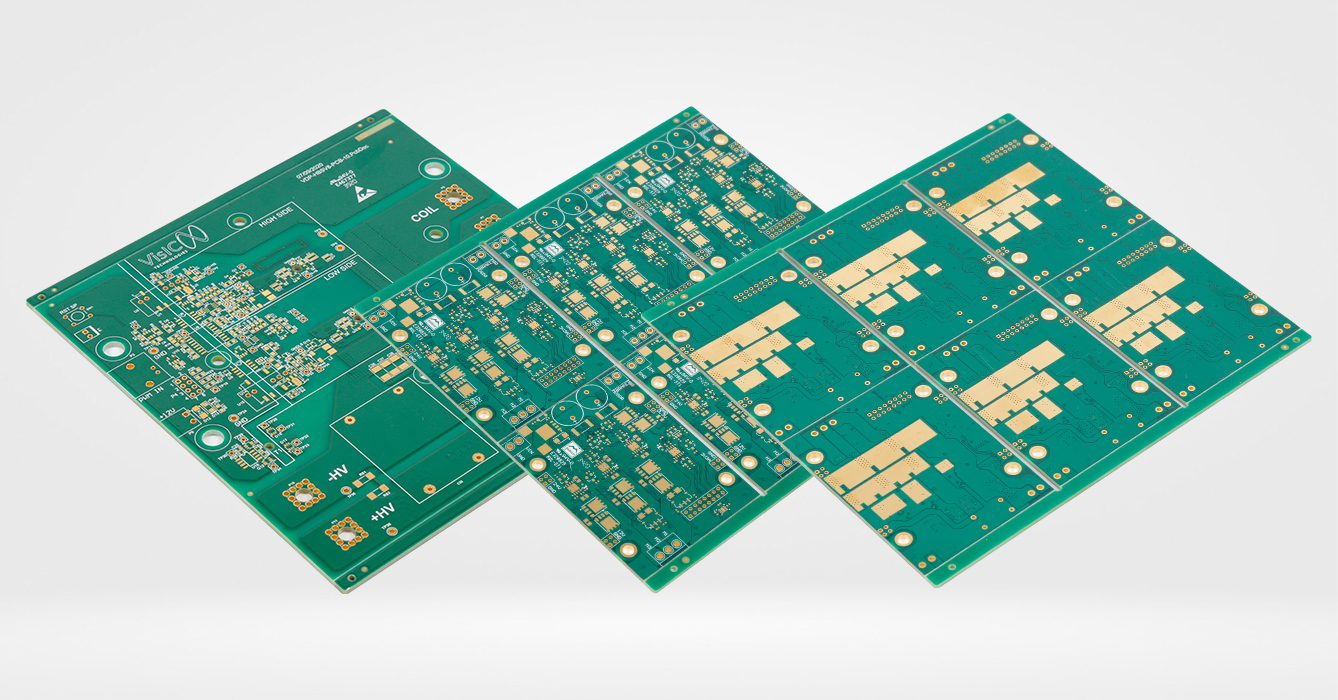

Manufacturing Processes for 4 Layer FR4 Printed Circuit Board

The production of 4 Layer FR4 PCBs requires precision engineering to ensure layer alignment, electrical connectivity, and structural integrity:

Layer Preparation and Lamination

Inner Layer Fabrication: Each inner layer (power and ground) is etched with copper patterns using photolithography, ensuring precise alignment with outer layers. These layers undergo inspection to verify pattern accuracy and copper integrity.

Layer Stackup and Lamination: Inner layers are bonded to outer signal layers using FR4 prepreg (fiberglass impregnated with epoxy resin) under controlled temperature and pressure. This process ensures uniform adhesion between layers, eliminating voids that could compromise insulation or thermal conductivity.

Drilling and Plating

Via Formation: Holes (vias) are drilled through the stacked layers to connect inner and outer circuits. These vias are plated with copper to establish electrical continuity between layers, with processes like electroless copper deposition ensuring reliable conductivity.

Outer Layer Processing: Outer signal layers are etched to form traces and component pads, with alignment referenced to the inner layers to ensure via connections are accurate. Surface finishes such as ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling) are applied to enhance solderability and corrosion resistance.

Quality Control in Manufacturing

Layer Alignment Verification: Automated optical inspection (AOI) checks layer registration to ensure inner and outer patterns align within tolerance, preventing short circuits or open connections.

Electrical Testing: Flying probe or bed-of-nails testing verifies continuity, isolation, and impedance across all layers, ensuring no electrical faults in the final product.

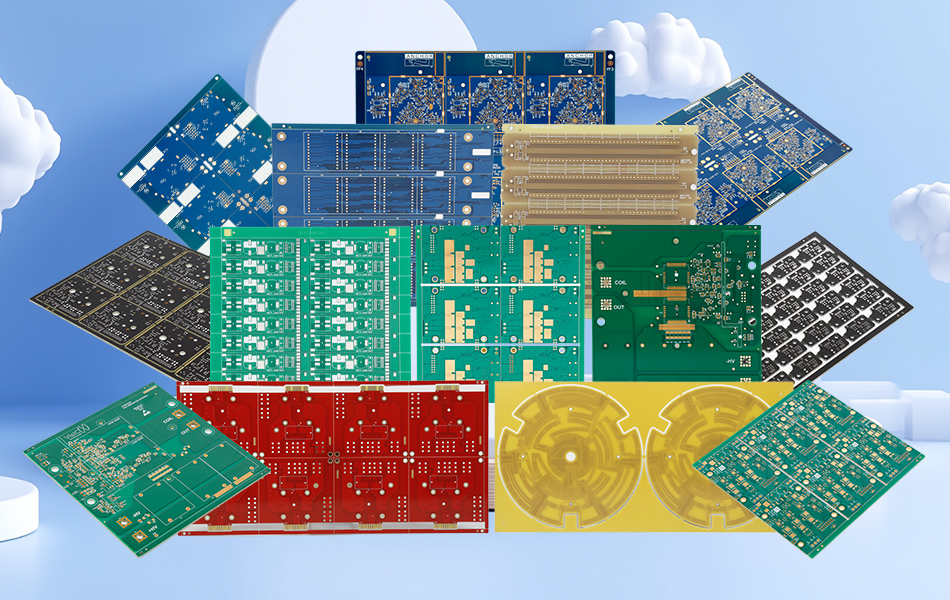

Application Ecosystems for 4 Layer FR4 Printed Circuit Board

4 Layer FR4 PCBs are widely adopted across industries where complexity, density, and reliability are critical:

Consumer Electronics

Smart Devices: Smartphones, tablets, and wearables use 4 Layer FR4 PCBs to accommodate high-density components (processors, memory, sensors) while managing power distribution and signal integrity for wireless communication and touch interfaces.

Home Appliances: Smart TVs, refrigerators, and audio equipment leverage four layers to integrate control circuits, power management, and connectivity modules in compact enclosures.

Industrial and Automation

Industrial Controllers: Programmable Logic Controllers (PLCs) and motor drives rely on 4 Layer FR4 PCBs for robust power distribution and noise immunity, ensuring reliable operation in factory environments with electrical interference.

Sensor Networks: Industrial IoT (IIoT) sensors and data acquisition systems use four layers to separate analog sensor signals from digital processing circuits, enhancing measurement accuracy and noise resistance.

Communication and Networking

Networking Hardware: Routers, switches, and 5G modems utilize 4 Layer FR4 designs to manage high-speed data transmission, with dedicated layers for power, ground, and signal routing to minimize latency and packet loss.

Telecom Infrastructure: Base station components and optical transceivers benefit from controlled impedance and EMC compliance, ensuring reliable communication in high-frequency environments.

Medical Electronics

Diagnostic Equipment: Medical monitors, imaging devices, and portable diagnostic tools use 4 Layer FR4 PCBs to integrate sensitive sensors, processing units, and power management systems, ensuring accuracy and patient safety.

Quality Assurance and Reliability Standards

4 Layer FR4 PCBs undergo rigorous testing to ensure performance and durability across operating conditions:

Electrical and Mechanical Testing

Continuity and Isolation Testing: Verifies all connections are intact and no unintended shorts exist between layers, critical for preventing system failures.

Thermal Cycling and Humidity Testing: Samples are exposed to temperature extremes and high humidity to simulate long-term environmental stress, ensuring layers remain bonded and insulation properties are maintained.

Compliance with Industry Standards

IPC Standards: Adherence to IPC-A-600 (Acceptability of Printed Boards) and IPC-2221 (Generic Standard on Printed Board Design) ensures consistency in manufacturing quality and design practices.

EMC Compliance: Testing to standards like CISPR (International Special Committee on Radio Interference) validates that 4 Layer FR4 PCBs meet electromagnetic emission and immunity requirements for global markets.

Future Trends in 4 Layer FR4 Printed Circuit Board Design

As electronics continue to evolve, 4 Layer FR4 PCB technology is adapting to meet emerging demands:

High-Density Interconnect (HDI) Integration

Manufacturers are developing 4 Layer FR4 PCBs with finer line widths and smaller vias to support even higher component density, enabling miniaturization in next-generation devices like foldable smartphones and compact industrial sensors.

Sustainable Manufacturing Practices

Innovations in eco-friendly FR4 materials (halogen-free resins, recycled glass fibers) and energy-efficient production processes are reducing the environmental impact of 4 Layer PCB manufacturing, aligning with global sustainability goals.

Advanced Material Combinations

Research into hybrid FR4 substrates, combining glass-reinforced epoxy with high-performance polymers, aims to enhance thermal conductivity and mechanical flexibility, expanding 4 Layer PCB applications in high-temperature or flexible electronics.

Conclusion

4 Layer FR4 Printed Circuit Board represents a critical advancement in electronic design, offering a balance of signal integrity, power efficiency, and design flexibility for complex systems. By leveraging dedicated layers for power, ground, and signals, these PCBs address the challenges of high-density electronics, enabling innovation in consumer devices, industrial automation, and communication systems. As manufacturing processes evolve and material technologies advance, 4 Layer FR4 PCBs will remain a cornerstone of modern electronics, providing engineers with a reliable platform to build the next generation of high-performance devices.

Keywords: 4 Layer FR4 PCB, printed circuit board, signal integrity, power distribution, high-density electronics, industrial automation, consumer devices, EMC compliance.

This article provides a comprehensive, technically rigorous overview of 4 Layer FR4 Printed Circuit Boards, emphasizing their unique design advantages and industry applications while ensuring originality and alignment with search engine optimization best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB