-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 18. 2025, 10:06:36

When it comes to creating electronic devices, the printed circuit board (PCB) is one of the most crucial components. A well-designed PCB ensures that your device functions correctly and efficiently. But how do you choose the right PCB manufacturer for your needs? In this article, we'll guide you through the critical factors to consider, helping you make an informed decision.

Before diving into how to choose a manufacturer, it's essential to understand what PCB manufacturing entails. A PCB is a flat board that connects electronic components using conductive pathways, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

PCB assembly is the process of mounting electronic components onto the board. This stage is crucial because it ensures that all parts are correctly placed and connected, enabling the device to function as intended.

Selecting the right PCB manufacturer requires careful thought. Here are some key considerations to keep in mind:

The quality of your PCB will significantly impact your product's performance and reliability. Therefore, it's vital to choose a manufacturer that adheres to high-quality standards. Look for certifications such as ISO 9001, IPC-A-610, and UL. These certifications indicate that the manufacturer follows industry best practices and maintains rigorous quality control measures.

If your project requires a custom PCB, you need a manufacturer with the expertise to design and produce boards tailored to your specifications. Custom PCBs often require unique materials, layouts, and features that standard boards do not offer. Ensure that the manufacturer has experience with custom designs and can accommodate your specific needs.

Consider the manufacturer's capacity and ability to handle your order volume. If you have a large-scale project, you'll need a manufacturer that can produce the required quantity within your timeline. Additionally, inquire about their turnaround time. A manufacturer with a fast turnaround can help you meet tight deadlines and get your product to market quickly.

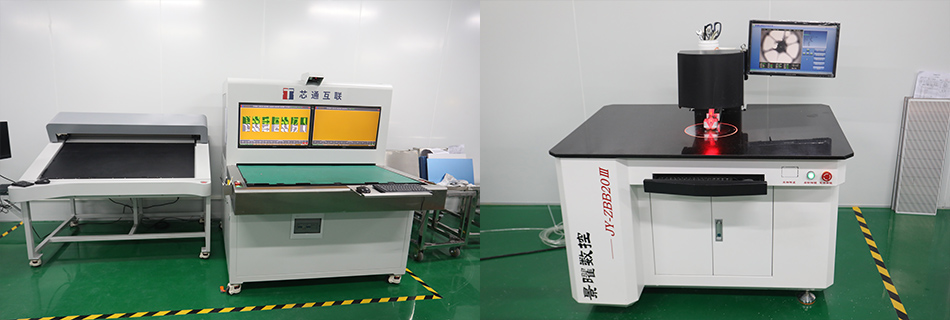

The complexity of modern electronic devices demands advanced technological capabilities. Make sure the manufacturer is equipped with the latest technology and machinery to produce high-quality PCBs. This includes capabilities for surface-mount technology (SMT), through-hole technology, and mixed technology assemblies.

While cost should not be the only factor in your decision, it's undoubtedly an important one. Compare quotes from different manufacturers, but be cautious of prices that seem too good to be true. Low costs may indicate compromises in quality or service. Aim for a balance between affordability and quality.

Once you have a list of potential manufacturers, it's time to evaluate them based on the criteria above.

If possible, visit the manufacturer's facility. A site visit allows you to see their operations firsthand, assess their equipment, and meet the team. This can provide valuable insights into their capabilities and commitment to quality.

Ask for samples of their previous work. Examining samples will help you gauge the quality of their products and determine if they meet your standards. Pay attention to the board's finish, solder mask, and silkscreen quality.

Research customer reviews and testimonials to learn about other clients' experiences with the manufacturer. Positive feedback can indicate reliability and high-quality service, while negative reviews may highlight potential issues.

Effective communication is essential when working with a PCB manufacturer. Ensure that they are responsive and easy to communicate with. A manufacturer that provides excellent customer support can help resolve issues quickly and ensure a smooth production process.

Choosing the right PCB manufacturer is critical to the success of your project. A reliable manufacturer can provide high-quality PCBs that meet your specifications, ensuring your device functions optimally. They can also offer valuable advice and support throughout the design and production process.

Building a long-term partnership with a trustworthy manufacturer can lead to cost savings and improved product quality over time. As they become familiar with your needs and expectations, they can offer tailored solutions and potentially reduce production times.

By selecting a reputable manufacturer, you can avoid common pitfalls such as production delays, subpar quality, and poor communication. This helps ensure a smooth production process and a successful end product.

Choosing the right PCB manufacturer requires careful consideration of several factors, including quality standards, custom design capabilities, and technological advancements. By evaluating potential manufacturers based on these criteria, you can find a partner that meets your needs and supports your project's success.

Remember, a reliable PCB manufacturer can be a valuable asset, providing high-quality products and exceptional service. Take the time to research and choose wisely, and you'll be well on your way to producing top-notch electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB