-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 19. 2025, 08:33:24

In the world of modern electronics, the design and fabrication of printed circuit boards (PCBs) are crucial. Among the various types of PCBs, IC substrate PCBs stand out for their role in supporting integrated circuits. Let's delve into the principles of IC substrate PCB design, understand the choice of substrate materials, and explore the PCB fabrication process.

An IC substrate PCB, or Integrated Circuit substrate printed circuit board, serves as a foundational platform for mounting integrated circuits and facilitating connections between the chips and the rest of the electronic system. These substrates are essential for miniaturizing electronics, enhancing performance, and ensuring reliability.

IC substrate PCBs are vital because they enable high-density connections. This is particularly important in applications like smartphones, computers, and other advanced electronic devices where space is limited, but performance requirements are high.

Choosing the right substrate material is key to achieving desired electrical, thermal, and mechanical properties in IC substrate PCBs.

FR-4: A widely used material due to its excellent balance of cost, performance, and reliability. It consists of woven fiberglass cloth with an epoxy resin binder that is flame resistant.

BT Epoxy: Known for better thermal stability and lower moisture absorption compared to FR-4. This makes it suitable for high-performance applications.

Polyimide: Offers superior thermal performance and is ideal for flexible circuits. It withstands higher temperatures but is more expensive than other materials.

Ceramic: Used in high-frequency and high-power applications due to its excellent thermal conductivity and electrical insulation properties.

When selecting substrate materials, consider factors like:

Thermal Conductivity: Higher thermal conductivity materials dissipate heat more effectively.

Dielectric Constant: Affects signal integrity, especially in high-frequency applications.

Cost: Balancing performance and budget is crucial for most projects.

The fabrication process of IC substrate PCBs involves several meticulous steps to ensure precision and reliability.

Design and Layout: Using computer-aided design (CAD) software, engineers create the schematic and layout of the PCB, specifying the exact placement of components and connections.

Material Preparation: The selected substrate material is cut into panels, and a thin layer of copper is applied to both sides.

Printing the Circuit Pattern: A photoresist layer is applied, and ultraviolet light is used to transfer the circuit pattern from the design onto the substrate.

Etching: The unprotected copper is etched away, leaving only the desired circuit pattern on the substrate.

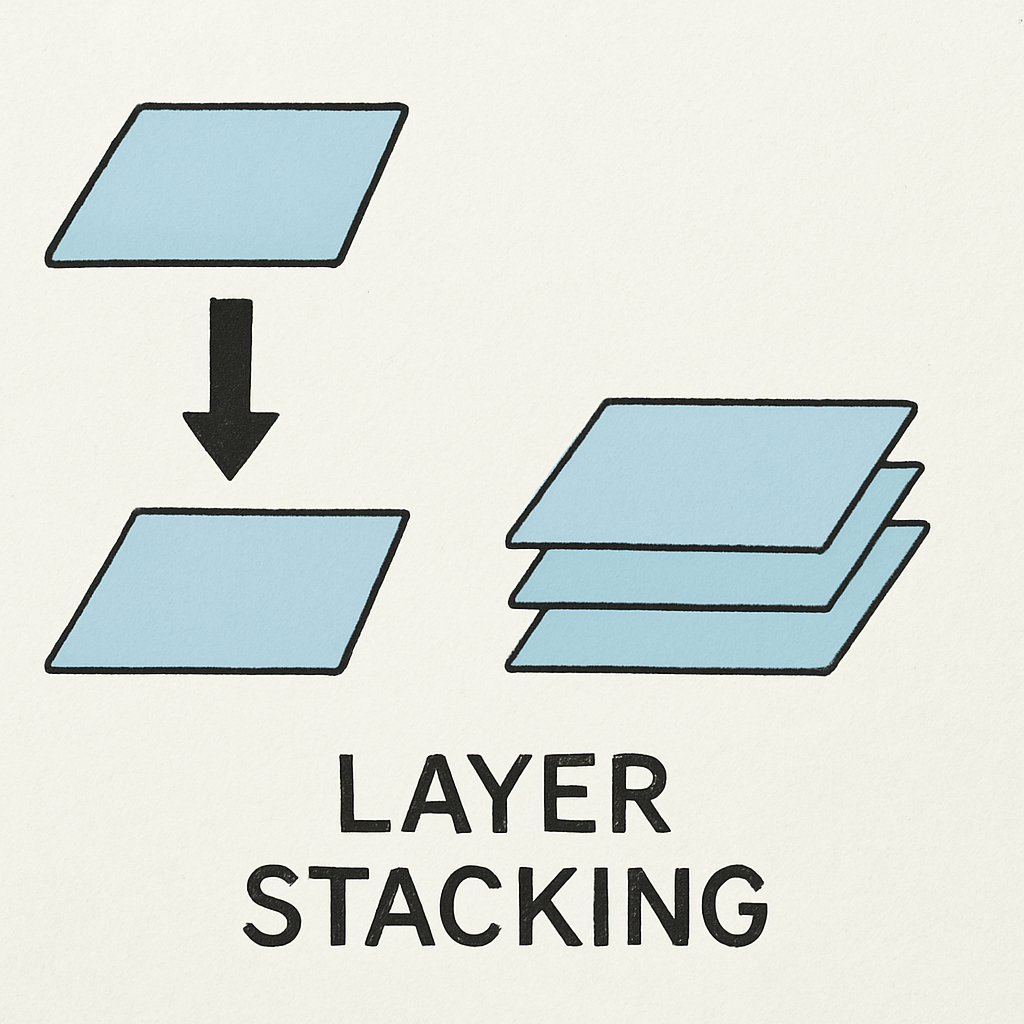

Drilling: Precise holes are drilled into the board for component leads and vias, which are the paths that connect different layers of the PCB.

Plating and Solder Mask Application: The drilled holes are plated with copper, and a solder mask is applied to protect the circuit and prevent short circuits.

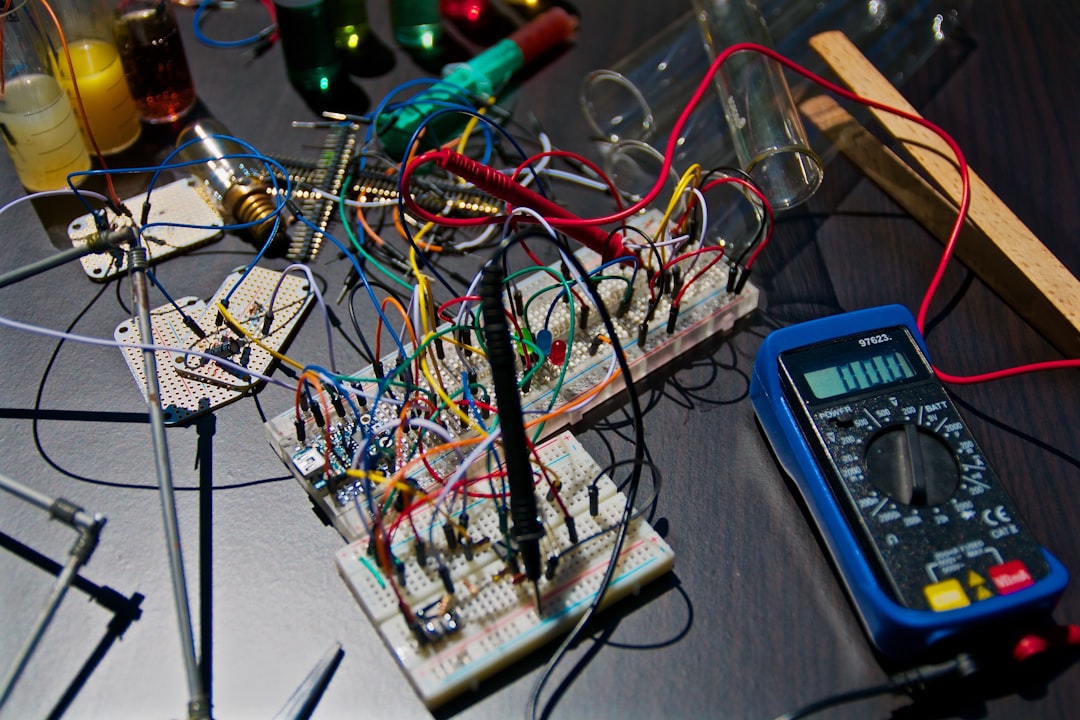

Component Mounting and Soldering: Components are placed on the board, and soldering ensures they are securely attached.

Testing and Quality Control: The completed PCB undergoes rigorous testing to ensure it functions correctly and meets all specifications.

Fabricating IC substrate PCBs presents unique challenges, including:

Miniaturization: As devices become smaller, the need for precise fabrication increases.

Thermal Management: Effective heat dissipation is crucial to prevent overheating and ensure reliability.

Signal Integrity: High-frequency applications require careful design to prevent signal loss and interference.

The field of IC substrate PCB design is continually evolving, with new technologies and materials being developed to meet the demands of modern electronics.

Researchers are exploring advanced materials like liquid crystal polymers (LCPs) and metal-based substrates to improve performance and reliability.

Techniques such as laser drilling and advanced plating processes are being adopted to enhance precision and reduce manufacturing time.

Understanding IC substrate PCB design principles is essential for anyone involved in electronics design and manufacturing. By selecting the right substrate materials, following a meticulous fabrication process, and embracing advancements in technology, engineers can create high-performance, reliable electronic systems. As technology continues to advance, the importance of IC substrate PCBs in enabling smaller, faster, and more efficient devices will only grow.

Whether you're a seasoned professional or a curious learner, grasping these concepts will provide a solid foundation in the ever-evolving world of PCB design.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB